Advances in Biological Chemistry

Vol.4 No.1(2014), Article ID:43305,7 pages DOI:10.4236/abc.2014.41011

Investigation and development on processing of Vietnamese lacquer

![]()

1Institute of Chemical Industry of Forestry Products, CAF; Nation Engineering Laboratory for Biomass Chemical Utilization; Key and Open Laboratory on Forest Chemical Engineering, SFA; Key Laboratory of Biomass Energy and Material, Nanjing, China

2Institute of New Technology of Forest, CAF, Beijing, China

3Hubei Academy of Forestry, Wuhan, China

4Hanoi University of Science and Technology, Hanoi, Vietnam

Email: wangczlhs@sina.com

Received 10 January 2014; revised 15 February 2014; accepted 22 February 2014

ABSTRACT

Vietnamese sap and lacquerware have a splendid history. In order to promote a sustainable Vietnamese lacquer value chain, this review was carried out for us to investigate at site Vietnamese lacquer cultivation and processing of lacquer sap, then introduce the chemical components, HPLC-MS characteristic, properity and polymerization mechanism, as well as processing techniques of Vietnamese lacquer sap. Combined with the experience of lacquer cultivation and processing of Chinese lacquer, key problems to restrict the development of lacquer value chain were analyzed in Vietnam, and some suggestions would also be proposed in this investigation.

Keywords:Vietnamese Lacquer; Lacquer Sap; Lacquerware; UV Modification; HPLC-MS

1. LACQUER DISTRIBUTION AND LACQUER SAP OUTPUT

Lacquer tree belongs to the family of Anacardiaceae. There are mainly three kinds of laquer tree distributed in Southeast Asia, Vietnamese lacquer belongs to Rhus succedanea, which is clearly distinguished from rhus vernicifera in china, Japan and Korea, also is different from Melanorrhoea usitata in Myanmar, Laos, and Thailand [1-4].

In Vietnam, lacquer trees are cultivated in many provinces in the upland areas of central, coastal and north mountainous regions, the main cultivation area is in Tam Nong, Thanh Son and Cam Khe districts in Phu Tho. According to morphology, lacquer trees are classified into three groups including “la tram”, “la is” and “mo ga” lacquers, however farmers do not pay attention about classification. All of them are cultivated in population and “mo ga” lacquers trees are predominating. According to Vietnamese actual experience, seedling for lacquer trees are mainly using sowing seedlings, this situation has reduced quality and productivity of lacquer in the area, while new way of seedling for lacquer trees is buried root seedlings with an advantage to keep the female parent excellent characters, buried root seedlings can increase the quality of lacquer tree. However, this new technology had not been used, which has been used popularly in China.

In recent years, lacquer tree cultivation area and lacquer sap output increase every year. In 2009, the total area of lacquer trees planted in Tam Nong district was 496 ha, in which 320 ha with mature trees under harvesting.and total output of lacquer sap in Tam Nong was 125.5 tons in 2009. According to the last statistics from Tem Nong district, Agriculture Division (Table 1), the sap output is about 300 t - 350 t in vietnam. Compared to 3500 t - 4000 t output of raw lacquer per year in china, Viet Nam just ranks number two with 10% - 15% of the global production.

2. THE COMPONENTS AND STRUCTURE OF LACQUER SAP

Lacquer sap collected from lacquer trees is composed of water, plant gum (polysaccharides), glycoproteins (nitrogen-containing substrance), laccase enzymes, and polyphenols (urushiol/thisiol/laccol). These compounds

have diverse physiological and pharmacological activities such as antitumor, antimicrobial, and anti-inflammatory effects. However, lacquer sap shows great difference in the constitution and structures from different species and regions (Table 2 and Figure 1).

Compared with Chinese lacquer sap and Japan sap, Vietnamese lacquer sap contains more impurities, in particularly 30% - 50% of water, 14% - 18% of plant gum and 3% - 7% of glycoproteins, that is why vietnamese lacquer sap takes more long time to dry, and shows poor gloss, it may be caused by lacquer varieties and growth environment.

Lacquer sap often contain 60% - 75% urushiols, in which contain 2% - 3% of saturated alkyl phenols, 14% - 15% of monoene alkyl phenols, 5% - 8% of diene alkyl phenols, and 65% - 70% of triene alkyl phenols. While Vietnamese laccols are orthodiphenol compounds made of 3-substituted catechols with saturated and unsaturated long hydrocarbon side Chains. Vietnamese lacquer contained 3% - 6% of saturated alkyl phenols, 25% - 50% of monoene alkyl phenols, 20% - 25% of diene alkyl phenols, and 25% - 45% of triene alkyl phenols. Particularly, red lacquer sap contained 45% - 50% of monoene alkyl phenols, which showed red lacquer sap has the best quality. In addition, due to oxidation, monomer laccol could be transferred into oligomers or polymers [1-6].

3. HPLC CHARACTERISTIC OF VIETNAMESE LACQURER SAP

Vietnamese often cultivate and harvest together both of white and red lacquer trees. Red lacquer has high quality sap but low production, whereas white lacquer has poor quality sap. We visited the household of Mr. Nguyen Van Khuong in Di Nau commune and took red and white sap samples respectively. The samples of red and white sap were analyzed by HPLC-MS, and are also compared with Ba lacquer from Hubei Province, China, and the results showed polyphenols of lacquer saps are clearly distinct from different regions. Figures 2 and 3 showed HPLC-MS characteristic of Vietnamese and Chinese lacquer sap, and Table 3 showed of Vietnamese lacquer, in which MS 682 may be the form of dimerization of MS 342 (C17 triene unsaturated urushiol), MS 685.5 may be the form of dimerization of MS 344 (C17 diene unsaturated urushiol), while MS 689.4 may be the form of dimerization of MS 346 (C17 monoene unsaturated urushiol) [6-14]. The result showed that the samples of red and white sap from Vietnam have been transferred into dimer by HPLC-MS after half year shorage.

4. PROPERITY AND POLYMERIZATION MECHANISM OF VIETNAMESE LACQUER SAP

As naturally eco-friendly occurring coating material, raw lacquer has strong durability when drying by enzymatic polymerization at the room temperature, it is possible to sculpture on the paint film. The lacquer is glossy and very beautiful. However, natural lacquer sap often causes strong allergic responses, particularly paint film drying is very slow, and color of paint film single. Therefore, some scientific questions had been the hot points to investigate anti-allergic mechanism, polymerization mechanism, light-colored and UV-curable lacquer, and anticorrosion coatings etc. [5-8].

Lacquer sap differs essentially from chemical paint in the way in which it dries. It is polymerized by laccase enzyme to produce a beautiful coating through a drying process but rather requires exposure to specific temperatures of 20˚C - 30˚C and humidity of 70% -90%. Once raw lacquer has hardened, it creates a lacquer sheath that can withstand acid, alkali, alcohol and high temperatures. With it adhesive strength, raw lacquer is completely different from any other kind of paint.

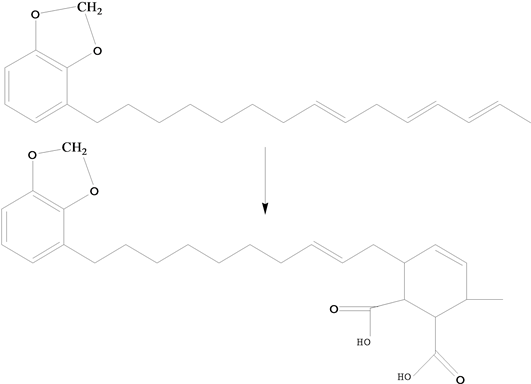

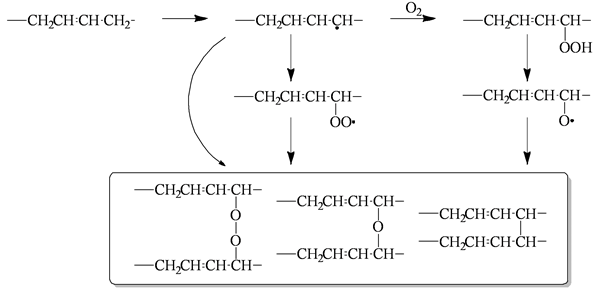

The polymerization mechanism of laccols has been thoroughly studied. The catechol ring of urushiol is first oxidized by laccase to form dimers, trimers, and oligomers, and after the laccols monomer concentration decreases to less than 305, a bridge-constraction reaction by oxidation of the unsaturated side chain occurs. Both enzymatic reaction and auto-oxidation are repeated to form a durable network polymer. Scheme of the reaction mechanism of drying of laccols catalyzed by laccase is as shown in Figures 4 and 5 [5,8].

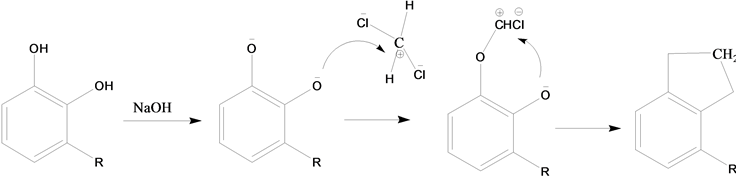

In order to prevent the urushiol auto-oxidation, we take chemical method to react with the two hydroxyl groups with catechol structure by aldolization or D-A

Figure 2. HPLC Chromatogram of Vietnamese and Chinese lacquer sap [13,14].

reaction was used for the conjudate double bond in the side chain of catechol. Urushiol was modified and carboxylic acetal was synthesized, 96.5% purity of acetal urushiol was made, the methylene ether was moved by boron tribromide, a lewis acid, under low temperature without oxygen, and high classical urushiol was obtain finally. The mechanism of aldolization polymerization and D-A reaction of lacquer sap was showed in Figure 6.

Figure 3. HPLC-MS TIC and HPLC of the puried Vietnamese lacquer sap [13,14].

Figure 4. Scheme of the reaction mechanism of enzyme oxidation [5,8].

Figure 5. Scheme of polymerization mechanism of urushiol auto-oxidation [5,8].

5. PROCESSING TECHNIQUES OF VIETNAMESE LACQUER SAP

Vietnamese lacquer sap refers to the freshly collected, untreated sap from trunks of tree belonging to Rhus succedanea. Once the lacquer is collected, first, the sap is filtered since it contains foreign bodies such as tree bark, insects and impurities. Because the fresh sap includes so much water (25% - 50% depending on the time of collection), therefore the collector take the freshly gathered sap home, put it in special round bottomed lacquered bamboo baskets, carefully topped with oil and lacquer impregnated paper cover and leave it in cool places under the floorboards to ferment. Every day they lift the paper lid off the bamboo baskets and remove the fermentation foam. Over one month, the mature product is called crude raw lacquer with a brownish color and amount 30% - 50% of water [5,8].

Usually raw lacquer is made by filtratation of crude raw lacquer to remove mud, clay and sawdust, then to grind and stir at room temperation or infrared drying heat to make refined lacquer sap, further to mix with pigment or iron or soot to produce colored lacquer for lacquerware. In the process of film-drying, Vietnam sap often take more time to curing, in general over 24 h, even last 10 - 15 days. It is clear that the natural lacquer sap dried very slowly due to the saturated and monoenyl laccols. By mixed Vietnam sap and Chinese sap in different rate (Table 4), the curing time can be short less 24 h at a drying condition of 25˚C - 28˚C, a relative humidity of 70% - 75% and 77 μm thich film. However, when vietnamese red and white sap could be shoraged over half year, the drying time just need 45 min. the reason may be monomer laccol wholly transferred into dimmer or polymer [1,5-8].

In the same time, in order to shorten drying time and raise the hard and glossy, we investigated the chemical

Table 4 . Drying time of mixed sap from Vietnam and china [1,5-8].

modification of Vietnamese sap by UV light curing and adding rosin, lignin, and tannin etc. We founded that UV curing just consumed 2 min, rosin-based sap material has good hardness and gloss for Vietnamese lacquer sap [12].

6. THE KEY QUESTIONS TO RESTRICT VIETNAMESE LACQUER VALUE CHAIN

By our investigation, we find one of the key questions is lack of scientific research in Vietnam. In the whole lacquer value chain, there are too little specialized research team and institution, so there are too many scientific questions have not been solved, such as the relation among cultivars, seedling styles, growth environment, and output of lacquer sap, as well as the effect on tree ages and tapping, as well tapping period etc. In particular, seedling ways and pest control techniques are lag. In Vietnam, so far the advanced buried root seedlings have not been adapted yet, so the degeneration of lacquer tree is serious, it directly cause heavily decrease of the quality and output of Vietnamese lacquer sap. In addition, the traditional scale method is consuming long time, low fidelity, unsafe, there is lack of quick method at site to scale laccols for sap quality. We suggest a new kind of Near-infrared chromatography (NIR) can be adapted to scale total phenols and moisture, which just cost 3 - 5 min to finish the analysis of lacquer samples. NIR is a quick score method to evaluate the quality of lacquer sap at site, however, it need large of samples over 100 to build the analyzed mode before it can be used at site.

The most problematic technology constraint is the lack of know-how on lacquer processing. Up to now, there are no factory to produce high quality refined lacquer sap and its modified products. Due to the low level of design innovation, producers lack the capacity to design new lacquerware products, which is why very few products of lacquer ware can meet the demand of high value markets in domestic or abroad.

Lacquer tree not only secretes lacquer sap, but also produce large of fruits, which can be used to extract wax or fatty oil. Lacquer wax has a yield of 25% - 35% of the berries, and the principal constituents of lacquer wax are glycerides of palmitic acid because it contains a special ingredient known as “Japan acid”, a high-grade fatty acid. Being 100% natural in origin and therefore non-toxic to the human body, lacquer wax is used not only in candles, but also in a wide range of cosmetics, foodstuffs and medicines. However, in Vietnam there are no processing and utilization of lacquer berries [15-17].

7. SUGGESTION

At first, the most important thing is to build an international innovative team in lacquer value chain by paying more investment and attention, and systematically carrying out scientific research. Thus further to promote the industrial development of lacquer value chain, i.e. the advanced technology may be impleted to produce refined lacqer sap and its modified products as well as series products of lacqer wax. Meanwhile, lacquer plantations of high-quality raw lacquer and high yield lacquerberry will be established to build the same standards, etc.

Due to traditions and customs, Vietnamese are used to breed seedling by seed and tap very young lacquer tree of 3 - 4 years old, thus it causes serious breeding degradation and pest. In order to raise the output of lacquer sap and the income of the mountainous and rural farmers to plant lacquer tree, it will be necessary to filter fine varieties and adopt advanced breeding methods (i.e., buried root method), to control pest. To extend the growth period of lacquer trees, the tree must has a diameter of over 8 cm or at least for more than 10 years, then they can be used to tap the sap.

Lacquer grower and processors are keen to improve addition by refining lacquer sap, so international standard and appropriate techniques and facilities to process lacquer sap will be provided by international cooperation.

ACKNOWLEDGEMENTS

The authors would like to thank UNIDO to provide the chance for us to investigate at site Vietnamese lacquer, thank Ms Hoang Mai Van Anh from UNIDO for her careful arrangement and accompany. The financial support of this work is also gratefully acknowledged by international cooperation programme “No.2014DFR31300, 0S2012GR0138” as well as 948 programme (2012-4-05).

REFERENCES

- Lu, R., Kanamori, D. and Miyakoshi, T. (2011) Characterization of thitsiol dimer structures from melanorrhoea usitata with laccase catalyst by NMR spectroscopy. International Journal of Polymer Analysis and Characterization, 16, 86-94. http://dx.doi.org/10.1080/1023666X.2011.541030

- Phai, L.T., Dieu, T.V., Kim, T.N. and Tho, P.Q. (1995) Structures of laccol. I. Chemical constituents of laccol. Journal of Chemistry (Vietnamese), 33, 16-20.

- Phai, L.T., Dieu, T.V., Kim, T.N. and Tho, P.Q. (1996) Structures of laccol. II. Long chain substituents. Journal of Chemistry (Vietnamese), 34, 56-62.

- Jefferson, A. and Wangchareontrakul, S. (1986) Long chain phenols: Urushiol, laccol, thitsiol and phenylalkyl catechol compounds in Burmese lac from Melanorrhoea usitata. Journal of Chromatography, 367, 145-154.

- Miyakoshi, T. ( 2010) Chemistry of traditional lacquering technology. Journal of Chinese Lacquer, 29, 27-31.

- Yamauchi, Y., Oshima, R., Kumanotani, J. (1982) Configuration of the olefinic bonds in the heteroolefinic side. Chains of japanese lacquer urushiol: Separation and identification of components of dimethylurushiol by means of reductive ozonolysis and high performance liquid chromatography. Journal of Chromatography A, 243, 71-84. http://dx.doi.org/10.1016/S0021-9673(00)88165-0

- Niimura, N. and Miyakoshi, T. (2003) Characterization of natural resin films and identification of ancient coating. The Mass Spectrometry Society of Japan, 51, 439-457. http://dx.doi.org/10.5702/massspec.51.439

- Kamiya, Y., Saito, W. and Miyakoshi, T. (2002) Synthesis and identification of laccol components from rhus succedanea lacquer sap. Journal of Oleo Science, 51, 473- 483. http://dx.doi.org/10.5650/jos.51.473

- Yamauchi, Y., Oshima, R., Kumanotani, J. (1980) Separation of japanese lac urushiol diacetate on silver nitratecoated silica gel columns by high performance liquid chromatography. Journal of Chromatography A, 198, 49- 56. http://dx.doi.org/10.1016/S0021-9673(00)81195-4

- Lu, R., Kamiya, Y., Wan, Y.-Y., Honda, T. and Miyakoshi, T. (2007) Synthesis of rhus succedanea lacquer film and analysis by pyrolysis-gas chromatography/mass spectrometry. Journal of Analytical and Applied Pyrolysis, 78, 117-124. http://dx.doi.org/10.1016/j.jaap.2006.05.002

- Kim, D.H. and Yang, J.S (2003) Analysis of urushiols by liquid chromatography/atmospheric pressure chemical ionizationion trap mass spectrometry. Journal of Liquid Chromatography & Related Technologies, 26, 17-28.

- Li, L., Wei, S.-N. and Hu, Z.-H. (2010) Analyzing the urushiols in extracts of oriental lacquer by liquid chromatography-electrospray ionization trap mass spectrometry, Journal of Northwest University (Natural Science Edition), 40, 1017-1018.

- He, Y.F. (2013) Chemical modification, purification and bioactivity of urushiol from lacquer. Dissertation for Master Degree, Chinese Academy of Forestry, Beijing.

- He, Y.F. and Wang, C.Z. (2012) Identification of chemical structure of urushiol from maoba lacquer by HPLCMS. Chemistry and Industry of Forest Products, 32, 47- 52.

- Dong, Y.H., Wang, C.Z. and Gong, K. (2009) Research progress on chemical constituents and comprehensive application of lacquer trees. Chemistry and Industry of Forest Products, 29, 225-232.

- Tsuji, S., Tonogai, Y., Ito, Y. and Harada, M. (1985) General analysis of various natural waxes in cosmetics. Journal of Society of Cosmetic Chemists of Japan, 192, 79-89. http://dx.doi.org/10.5107/sccj.19.79

- Wang, C.Z., Dong, Y.H., Cheng, H.X., He, Y.F., Ye, J.Z. and Zhou, H. (2013) Physicochemical properties of lacquer berries and decolorization of lacquer wax by physical adsorption and UV irradiation. Advances in Biological Chemistry, 3, 1-9. http://dx.doi.org/10.4236/abc.2013.33037