Paper Menu >>

Journal Menu >>

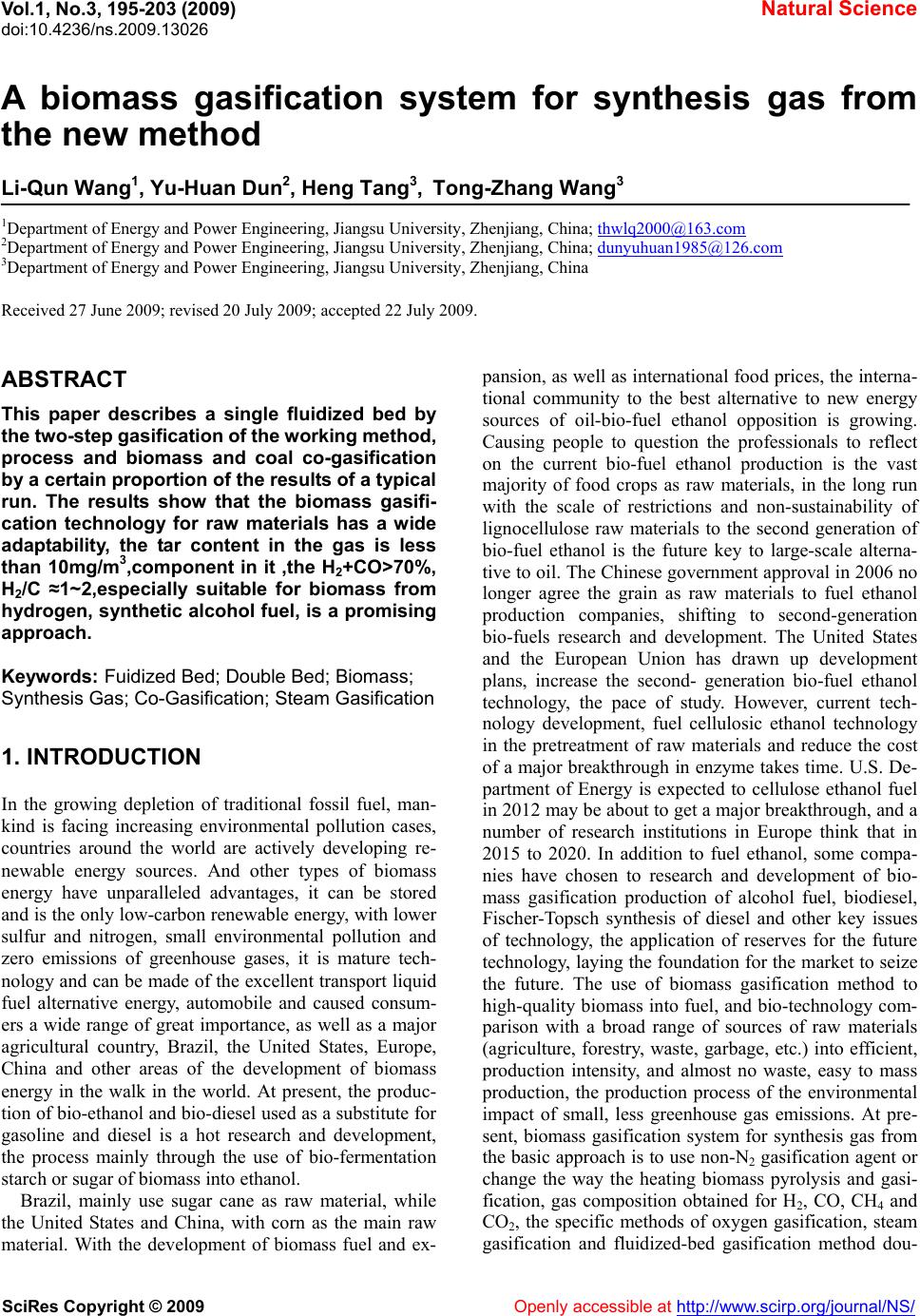

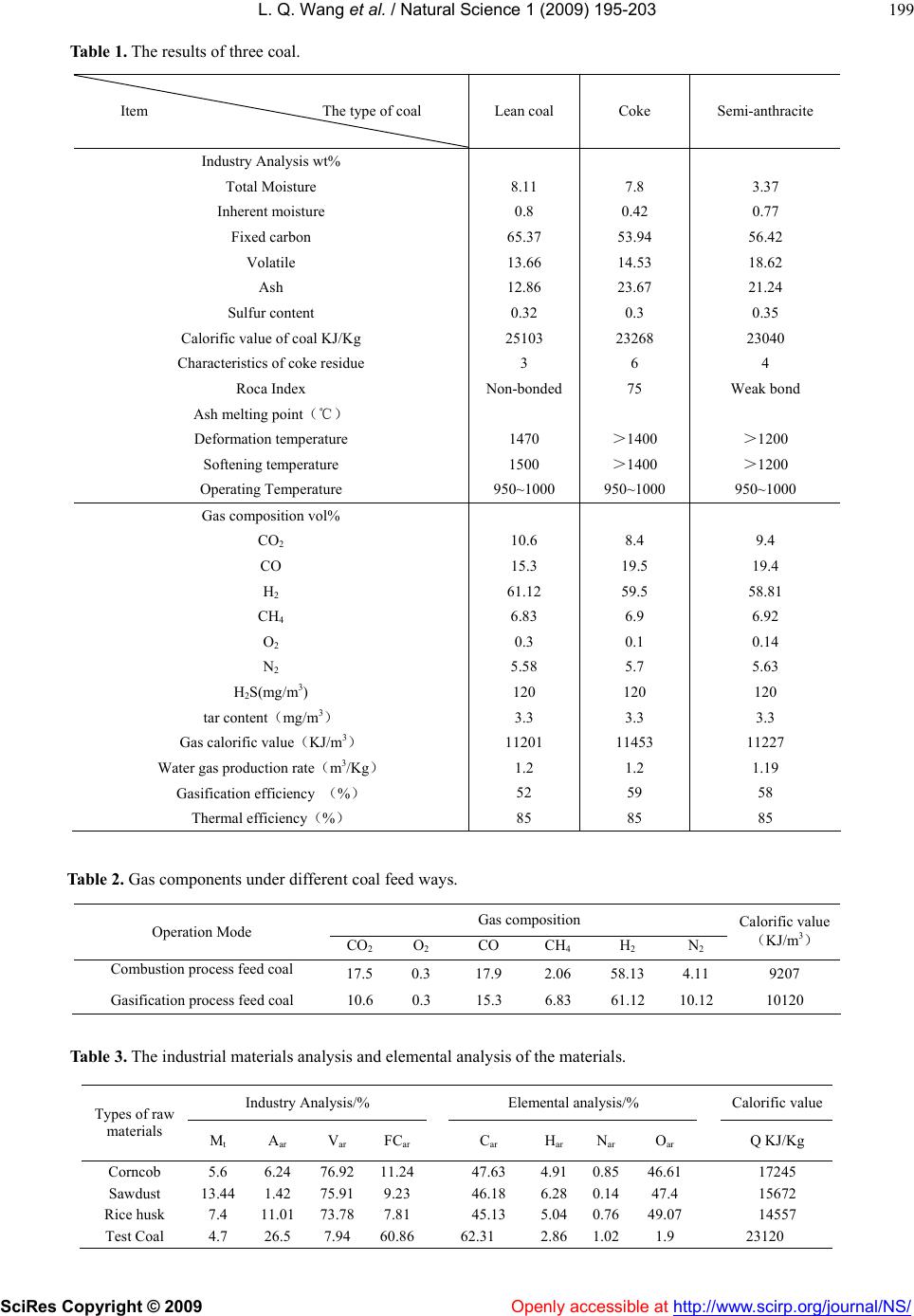

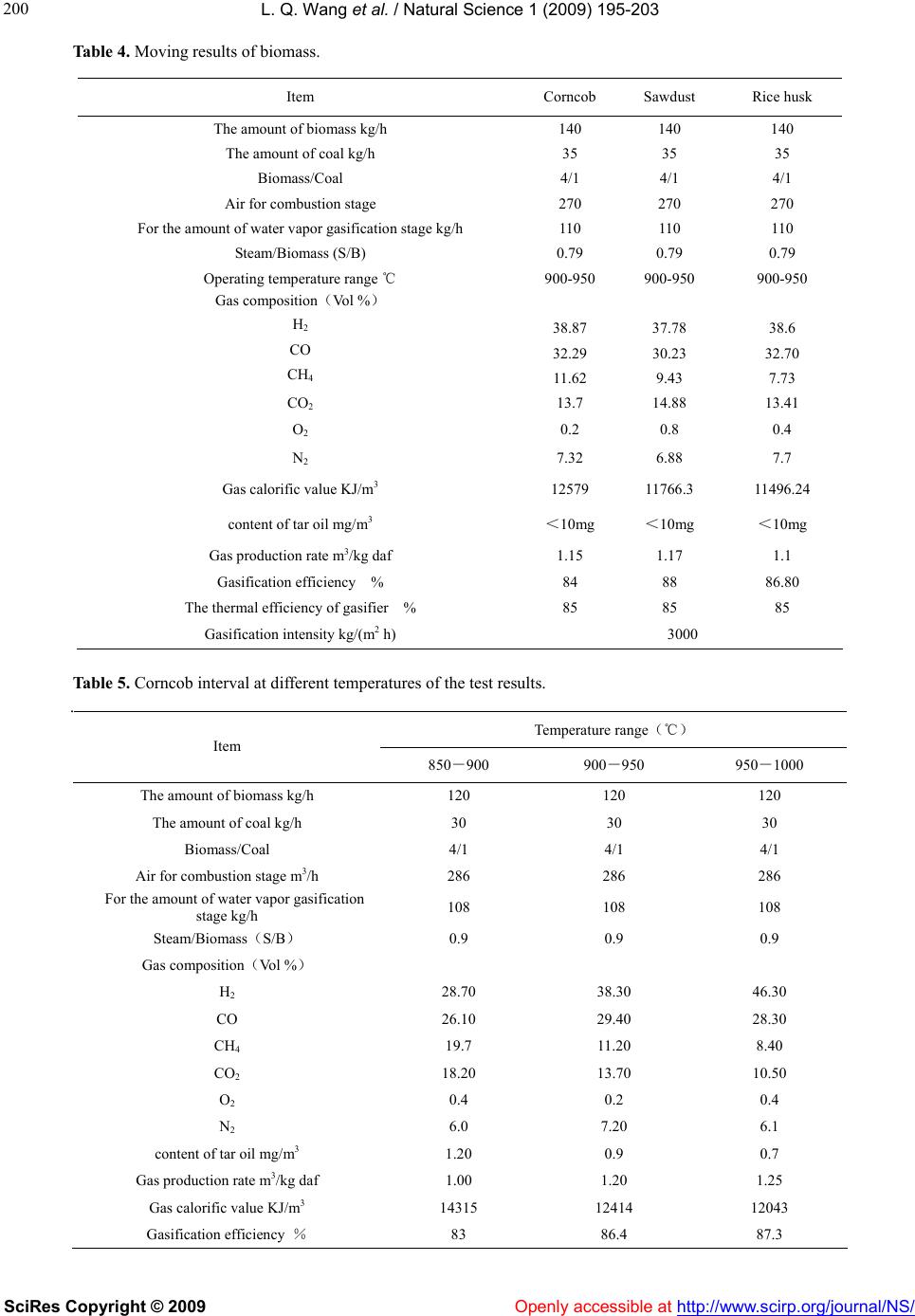

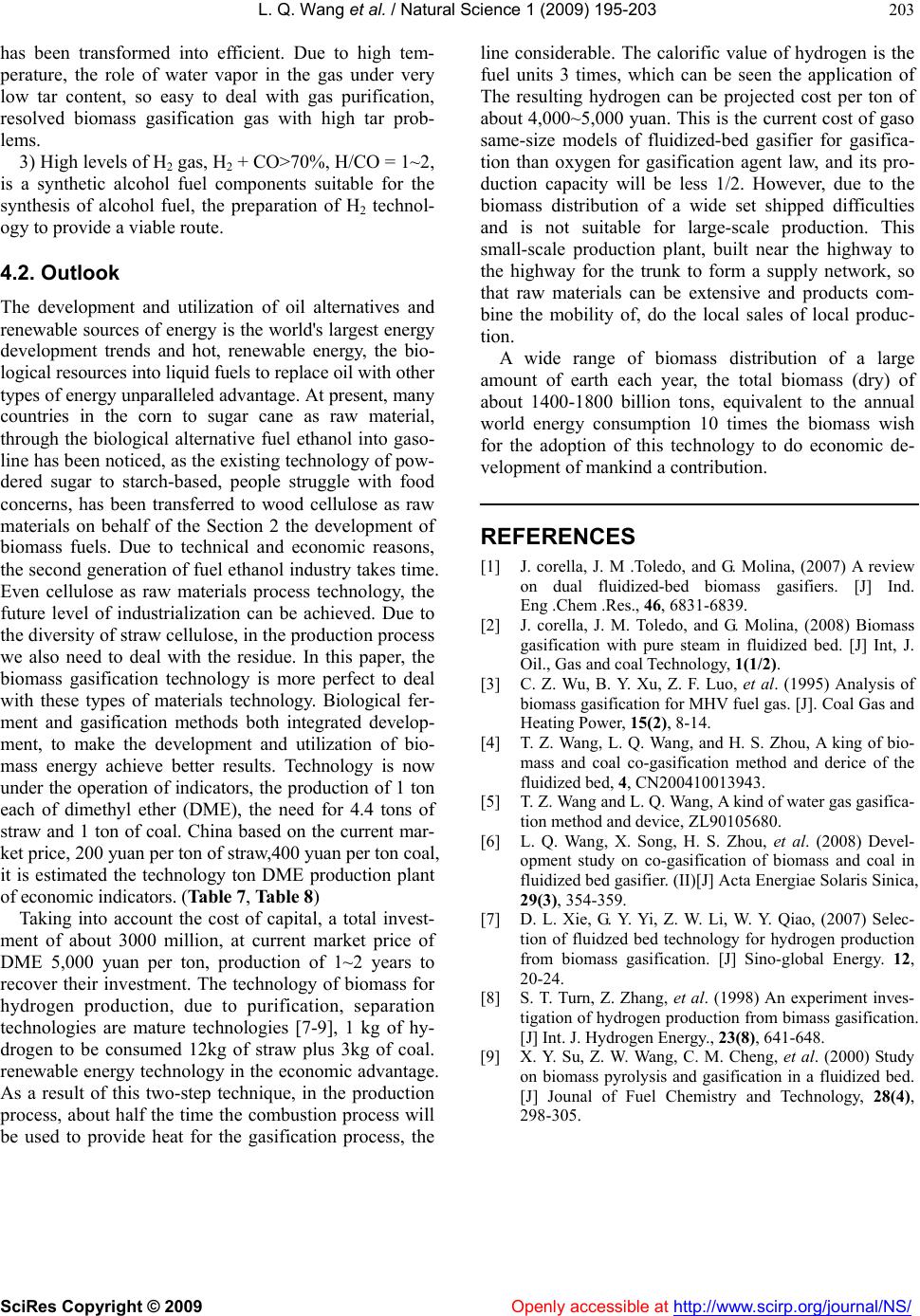

Vol.1, No.3, 195-203 (2009) doi:10.4236/ns.2009.13026 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ Natural Science A biomass gasification system for synthesis gas from the new method Li-Qun Wang1, Yu-Huan Dun2, Heng Tang3, Tong-Zhang Wang3 1Department of Energy and Power Engineering, Jiangsu University, Zhenjiang, China; thwlq2000@163.com 2Department of Energy and Power Engineering, Jiangsu University, Zhenjiang, China; dunyuhuan1985@126.com 3Department of Energy and Power Engineering, Jiangsu University, Zhenjiang, China Received 27 June 2009; revised 20 July 2009; accepted 22 July 2009. ABSTRACT This paper describes a single fluidized bed by the two-step gasification of the working method, process and biomass and coal co-gasification by a certain proportion of the results of a typical run. The results show that the biomass gasifi- cation technology for raw materials has a wide adaptability, the tar content in the gas is less than 10mg/m3,component in it ,the H2+CO>70%, H2/C ≈1~2,especially suitable for biomass from hydrogen, synthetic alcohol fuel, is a promising approach. Keywords: Fuidized Bed; Double Bed; Biomass; Synthesis Gas; Co-Gasification; Steam Gasification 1. INTRODUCTION In the growing depletion of traditional fossil fuel, man- kind is facing increasing environmental pollution cases, countries around the world are actively developing re- newable energy sources. And other types of biomass energy have unparalleled advantages, it can be stored and is the only low-carbon renewable energy, with lower sulfur and nitrogen, small environmental pollution and zero emissions of greenhouse gases, it is mature tech- nology and can be made of the excellent transport liquid fuel alternative energy, automobile and caused consum- ers a wide range of great importance, as well as a major agricultural country, Brazil, the United States, Europe, China and other areas of the development of biomass energy in the walk in the world. At present, the produc- tion of bio-ethanol and bio-diesel used as a substitute for gasoline and diesel is a hot research and development, the process mainly through the use of bio-fermentation starch or sugar of biomass into ethanol. Brazil, mainly use sugar cane as raw material, while the United States and China, with corn as the main raw material. With the development of biomass fuel and ex- pansion, as well as international food prices, the interna- tional community to the best alternative to new energy sources of oil-bio-fuel ethanol opposition is growing. Causing people to question the professionals to reflect on the current bio-fuel ethanol production is the vast majority of food crops as raw materials, in the long run with the scale of restrictions and non-sustainability of lignocellulose raw materials to the second generation of bio-fuel ethanol is the future key to large-scale alterna- tive to oil. The Chinese government approval in 2006 no longer agree the grain as raw materials to fuel ethanol production companies, shifting to second-generation bio-fuels research and development. The United States and the European Union has drawn up development plans, increase the second- generation bio-fuel ethanol technology, the pace of study. However, current tech- nology development, fuel cellulosic ethanol technology in the pretreatment of raw materials and reduce the cost of a major breakthrough in enzyme takes time. U.S. De- partment of Energy is expected to cellulose ethanol fuel in 2012 may be about to get a major breakthrough, and a number of research institutions in Europe think that in 2015 to 2020. In addition to fuel ethanol, some compa- nies have chosen to research and development of bio- mass gasification production of alcohol fuel, biodiesel, Fischer-Topsch synthesis of diesel and other key issues of technology, the application of reserves for the future technology, laying the foundation for the market to seize the future. The use of biomass gasification method to high-quality biomass into fuel, and bio-technology com- parison with a broad range of sources of raw materials (agriculture, forestry, waste, garbage, etc.) into efficient, production intensity, and almost no waste, easy to mass production, the production process of the environmental impact of small, less greenhouse gas emissions. At pre- sent, biomass gasification system for synthesis gas from the basic approach is to use non-N2 gasification agent or change the way the heating biomass pyrolysis and gasi- fication, gas composition obtained for H2, CO, CH4 and CO2, the specific methods of oxygen gasification, steam gasification and fluidized-bed gasification method dou-  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ 196 ble. Gasification as a result of oxygen-free N2 gas in the gas, a higher calorific value gas, the CO, H2 with a high level, CH4 low, due to oxygen gasification free to adjust the reaction temperature, the reaction completely and higher gas production, gasification higher efficiency, the technology is mature, simple, stable operation and suit- able for large- scale production, as a result of oxygen equipment, investment and operating costs are higher, it is difficult to adapt to storage and transportation of bio- mass resources, the high cost of dispersed and difficult to mass production characteristics. The water vapor is a strong endothermic reaction gasification, biomass pyro- lysis and gasification temperature above 800℃ need to have a higher reaction rate, it is generally difficult to achieve this temperature steam requirements, so less gas production, gasification and low efficiency. The advan- tage is to form H2, CH4 more, CO2,CO and other content in a relatively small amount of synthesis gas in favor of simplifying the follow-up process. The using of steam gasification process in the world is very few, mainly used in laboratory research. The last century 80's, Pro- fessor Kunii, D. first dual fluidized bed gasification technology methods [1-3]. Packages are equipped with a Figure 1. The gasifier of two fluidized beds of biomass. Figure 2. Single fluidized bed gasification two-step working principle, 1-1 Air control valve, 1-2 Flue control valve, 2-1 Steam Control Valve, 2-2 Gas Control Valve. fluidized bed gasifier and the composition of fluidized bed combustion furnace (Figure 1). Burner for heating air combustion of coke particles in the gasifier heating inert particles, while for the steam gasifier and high temperature so that biomass particles in the flow of inert state pyrolysis reaction occurs to produce hydrogen-rich synthesis gas. This method does not require external heat source, and therefore do not require oxygen equipment and low cost operation. However, due to the volume and temperature of heat carrier restrictions, not more than gasifier temperature of 800℃, resulted in lower gasifica- tion efficiency, on the other hand, un-time as a result of coke and the heat carrier are at a high temperature cycle, it is difficult to quantitatively control, temperature easy to change, it is difficult to stable operation, restrictions on use of the fact that, at present there is no practical case of industrialization. Professor Wang Tongzhang, Jiangsu University, at the conclusion of the research team based on previous experience, in 1990 put forward a single fluidized bed by two-step gasification method. Synthesis gas was prepared with steam gasification agent. And obtained a patent in China [4,5]. Principle of the work of this process known as fluidized-bed water gas gasifier (FWG). The equipment with coal as raw materials has industrialized. With biomass as raw material the equipment being promoted in this paper technological processes of the gasification process, the scope of appli- cation and the moving results are introduced. 2. A SINGLE FLUIDIZED BED TWO-STEP GASIFICATION PROCESS AND DEVICE [6] Water vapor and carbon for the gasification agent of raw materials to form H2, CO, CH4 and CO2, the main reac- tion is: C + H2O → CO + H2 -162.3 MJ (1) C + 2H2O → CO2 + 2H2 -75.2 MJ (2) CO + H2O → CO2 + H2 -43.56 MJ (3) C + 2H2 → CH4 +87.36 MJ (4) C + O2 → CO2 +408.86 MJ (5) Endothermic reaction is basically, in order to enable the reaction can be carried out, it is necessary to provide the necessary reaction heat. To this end will be in the same fluidized bed biomass gasification process is di- vided into two processes: First, the combustion process (the heating process); First, the process of pyrolysis and gasification. To the gasifier for combustion into the air and raw materials, so that flow of raw materials in a state of combustion heat release style (5), so that the material layer gasifier rapid increase in temperature is expected when the temperature rise to the scheduled (scheduled for 1000℃), to stop for air, the end of the combustion process; gasifier turn to pyrolysis and gasification proc-  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ 197 1 Fluidized bed biomass gasifier, 2 High-temperature cyclone, 3 Superheater, 4 Waste heat boile, 5 Scrubber, 6 Bell type gasholder, 7 Air preheater, 8 Precipitator(dust collector ), 9 Chimney, 10 Setting pond, 11 Roots blower, 12 Reserve gray box, 13 Feed back, 14 Air, steam nozzle, 15 Spiral feeding machine with biomass bunker, 16 Wind Room, 17 Spiral feeding machine with coal bunker. Figure 3. The process flow of the water gas gasifier of fluidized bed of biomass. ess, into the steam for the gasifier and biomass to bio- mass and the original high-temperature materials in the water vapor layer of the under the conditions in the flow of pyrolysis and gasification reaction occurred, resulting in the synthesis of H2-rich gas, because the process is endothermic reaction, the rapid temperature decline in bed when the bed temperature dropped to predetermined temperature (scheduled for the 900℃), gasification proc- ess is over. The gasifier gets into the combustion process. The two processes repeated conversion to achieve the production of synthesis gas purpose. Two processes in the fluidized bed gasifier through imports and exports of two pairs of control valves: air control valve 1-1, vapor control valves 2-1 and Flue control valves 1-2, gas con- trol valves 2-2 to achieve (see Figure 2) flue and gas, respectively, into the flue system and gas system, the gate valve by the furnace temperature control. Figure 3 Biomass fluidized bed water gas gasifier (BFWG) process. Fluidized bed biomass gasifier (1) with two feeders, screw feeder biomass (15) and coal screw feeder (17) for the conduct of the total biomass and coal gasification, gasifier start when run-time, water vapor control valve 2-1 and gas control valve 2-2 to close,air control valve 1-1 and flue control valve 1-2 open when the combustion channels in working condi- tion, when Roots blower (11 ) through the air control valve 1-1 at the bottom of the wind from the gasifier chamber (16) for the first time into the air, at the same time coal screw machine (17) adding coal to the furnace (0~6mm), to enable complete combustion of fuel in the heater do, in the furnace equipped with a secondary air nozzle (14), secondary air jet from the nozzle to increase, so that paragraph into the suspension of particles of in- complete combustion of carbon and the gas composition to continue to burn, so that the furnace temperature the rapid increase in high-temperature combustion gas from the gasifier cyclone export to high temperatures, (2) after the beginning of dust into the superheater (3) and waste heat boiler (4) heat exchanger, the flue gas temperature to about 400℃ below the flue control valve 1-2 to enter the air preheater (7), flue gas temperature to 200℃ the following into the dust collector (8), purified by the chimney (9) into the atmosphere. Under the high tem- perature cyclone separation carbon dust by the return feeder (13) returns to re-combustion gasification gasifier. When the furnace temperature up to set temperature (1000℃), the end of the combustion process, when the air control valves, flue control valves 1-1 and 1-2 fol- lowed by self-closing, steam control valve2-1 and gas control valve 2-2 automatically open one after another, from the waste heat boiler (4) water vapor generated by the steam superheater (3), the steam control valve 2-1 by the wind Room (16) into the gasifier, while biomass feeder (15) to adding biomass furnace (0~10mm), then high-temperature material layer and adding biomass state in the flow of pyrolysis and gasification reaction occurred, resulting in hydrogen-rich gas. Since the reac- tion is endothermic reaction, the furnace temperature dropped quickly when the high temperature gas gener- ated by cyclone (2) after the separation of carbon dust by  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ 198 the return under the feeder (13) into the re-gasification furnace, after the separation of crude gas into the waste heat boiler (4) for heat exchange cooling to below 400 ℃,the gas control valves, 2-2 to enter the scrubber tower (5),by the washing water after the cooling device into the gas cabinet (6),for users. When the furnace temperature down to set temperature(900℃),the gasification process, steam control valves 2-1 and gas control valve 2-2 auto- matically shut down one after another, the air control valves1-1andflue control valves 1-2 followed by open, into the gasifier and the combustion process, alternating back and forth these two processes to work, production of the H2-rich syngas. Since the fluidized bed gasifier with a uniform temperature characteristic, temperature control in bed for two processes is not only conducive to the stability of production quality, and temperature can be arbitrary in order to obtain the synthesis gas compo- nents of satisfaction. General low-temperature limit de- termined by the reaction rate of raw materials, high temperature limit determined by the ash melting point of raw materials. Two waste heat recovery processes can be generated by steam gasification to meet their own needs. 3. BIOMASS FLUIDIZED BED WATER GASIFIER IS RUNNING RESULTS AND ANALYSIS Biomass feedstock to 0~10mm smash into the furnace, due to the shape of biomass particles of diversity, so that net flow of biomass is more difficult biomass powder usually include a certain amount of inert particles such as sand, to improve the Health the flow of material per- formance, as a result of China's coal-dominated energy structure, the authors selected coal (0~6mm) in place of the inert particles, such coal to improve the flow of not only played the role of performance, because coal is a hot body, together with the biomass total gasification, coal and biomass in the physical and chemical properties of many complementary aspects, such as the coal density high, fixed carbon content high, ash melting point high, chemical activity low; and biomass density low, fixed carbon contentlow, ash melting point low, high volatile, highchemical activity and easy to gasification, gasifica- tion of the two were complementary to each other will receive such good results. Therefore this section will be a comprehensive discussion of this technology to coal, biomass gasification and the two kinds of co-gasication were the result of the operation [6]. 3.1. The Operation of Coal as Raw Materials Results Table 1 shows the results of the operation in the type FWG 1.6 gasifier. The three kinds of coal in the long-term continuous operation, results showed that regardless of coal for the weak or strong adhesive bonding of all long-term stable operation and good results. The strong bond not only of coal coking phenomenon did not happen, and gas indi- cators are generally better than the weak bonding of coal, mainly air and water vapor at 950℃ and above the turn of coal particles for combustion and gasification reac- tions, so that caking coal rapid destruction of the gluey layer, the strong bond of coal can be a smooth operation. Fluidized bed water gas gasifier is automatically adjust- able, the results in Table 1 is a coal gasification process of running the results can be seen from the gas composi- tion, gas composition in the H2 high,CH4 content is gen- erally 5~7%. The CO content of less than 20%,which is due to the process of coal gasification, when there are complex reaction mechanism, when the water vapor and carbon bed water-gas reaction to produce high gas mix- tures containing H2, has just joined the Fan coal in such a high temperature pyrolysis atmosphere makes reaction CH4 and H2 gas in a marked increase in the content, and some scholars believe that the main CH4 from the hy- drogenation reaction (4). Table 2. Different ways of coal feeding have an effect on gas composition. Coal feeding in different ways, from changing in gas composition obviously. In the process of coal gasification, coal is fed, the component of the H2 and CH4 in the gas increased obviously, while reducing CO, for high volatile coal, the greater difference. This factor is a gasifier to provide a more convenient, that is, through different ways to increase coal output is suitable for the requirements of different gas components. 3.2. Biomass as Raw Materials Moving Results Water fluidized bed biomass gasifier (BFWG) set up two feeders: biomass and coal screw feeders. Generally the gasifier was fed with biomass powder(0-10mm) in the gasification process(0~10mm), coal combustion process by adding(0~6mm), this study used corncob, rice husk, wood chips as raw material, high in the inner diameter 300×4000mm bed water-gas gasifier in operation results (Table 3). 3.3. Discussion and Analysis of the Results From the corn cob, sawdust, rice husk three experiments show that the agricultural and forestry waste (Table 4), The diversity of the types of biomass does not affect the performance of their gasification, the gas composition, calorific value, the efficiency of gasification, tar and other parameters in the same operating conditions, the results were similar. The results from Table 5 show that the impact of gasification temperature gasification gas production rate and efficiency of key parameters, (the technology can easily adjust the parameters), with the in- crease in transition temperature, gas production rate and a corresponding increase in efficiency gasification,  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 http://www.scirp.org/journal/NS/ 199 Table 1. The results of three coal. Openly accessible at Table 2. Gas components under different coal feed ways. Table 3. The industrial materials analysis and elemental analysis of the materials. Industry Analysis/% Elemental analysis/% Calorific value Types of raw materials Mt A ar V ar FCar C ar H ar N ar O ar Q KJ/Kg Corncob 5.6 6.24 76.92 11.2447.63 4.910.8546.61 17245 Sawdust 13.441.42 75.91 9.23 46.18 6.280.1447.4 15672 Rice husk 7.4 11.01 73.78 7.81 45.13 5.040.7649.07 14557 Test Coal 4.7 26.5 7.94 60.8662.31 2.861.021.9 23120 Item The type of coal Lean coal Coke Semi-anthracite Industry Analysis wt% Total Moisture 8.11 7.8 3.37 Inherent moisture 0.8 0.42 0.77 Fixed carbon 65.37 53.94 56.42 Volatile 13.66 14.53 18.62 Ash 12.86 23.67 21.24 Sulfur content 0.32 0.3 0.35 Calorific value of coal KJ/Kg 25103 23268 23040 Characteristics of coke residue 3 6 4 Roca Index Non-bonded 75 Weak bond Ash melting point(℃) Deformation temperature 1470 >1400 >1200 Softening temperature 1500 >1400 >1200 Operating Temperature 950~1000 950~1000 950~1000 Gas composition vol% CO2 10.6 8.4 9.4 CO 15.3 19.5 19.4 H2 61.12 59.5 58.81 CH4 6.83 6.9 6.92 O2 0.3 0.1 0.14 N2 5.58 5.7 5.63 H2S(mg/m3) 120 120 120 tar content(mg/m3) 3.3 3.3 3.3 Gas calorific value(KJ/m3) 11201 11453 11227 Water gas production rate(m3/Kg) 1.2 1.2 1.19 Gasification efficiency (%) 52 59 58 Thermal efficiency(%) 85 85 85 Gas composition Operation Mode CO2 O2 CO CH4 H2 N2 Calorific value (KJ/m3) Combustion process feed coal 17.5 0.3 17.9 2.06 58.13 4.11 9207 Gasification process feed coal 10.6 0.3 15.3 6.83 61.12 10.12 10120  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ 200 Table 4. Moving results of biomass. Item Corncob Sawdust Rice husk The amount of biomass kg/h 140 140 140 The amount of coal kg/h 35 35 35 Biomass/Coal 4/1 4/1 4/1 Air for combustion stage 270 270 270 For the amount of water vapor gasification stage kg/h 110 110 110 Steam/Biomass (S/B) 0.79 0.79 0.79 Operating temperature range ℃ 900-950 900-950 900-950 Gas composition(Vol %) H2 38.87 37.78 38.6 CO 32.29 30.23 32.70 CH4 11.62 9.43 7.73 CO2 13.7 14.88 13.41 O2 0.2 0.8 0.4 N2 7.32 6.88 7.7 Gas calorific value KJ/m3 12579 11766.3 11496.24 content of tar oil mg/m3 <10mg <10mg <10mg Gas production rate m3/kg daf 1.15 1.17 1.1 Gasification efficiency % 84 88 86.80 The thermal efficiency of gasifier % 85 85 85 Gasification intensity kg/(m2 h) 3000 Table 5. Corncob interval at different temperatures of the test results. . Temperature range(℃) Item 850-900 900-950 950-1000 The amount of biomass kg/h 120 120 120 The amount of coal kg/h 30 30 30 Biomass/Coal 4/1 4/1 4/1 Air for combustion stage m3/h 286 286 286 For the amount of water vapor gasification stage kg/h 108 108 108 Steam/Biomass(S/B) 0.9 0.9 0.9 Gas composition(Vol %) H2 28.70 38.30 46.30 CO 26.10 29.40 28.30 CH4 19.7 11.20 8.40 CO2 18.20 13.70 10.50 O2 0.4 0.2 0.4 N2 6.0 7.20 6.1 content of tar oil mg/m3 1.20 0.9 0.7 Gas production rate m3/kg daf 1.00 1.20 1.25 Gas calorific value KJ/m3 14315 12414 12043 Gasification efficiency % 83 86.4 87.3  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 http://www.scirp.org/journal/NS/Openly accessible at 201 Table 6. The current production methods of medium-heating value compared with the technique. Item Methods Steam gasification Oxygen gasification Dual fluidized bed gasification Two-step gasification method Gasification conditions Gasification medium Gasification temperature /℃ The main auxiliary equipment Gasifier type Gasification efficiency /% Gasification yield /m³/kg Gasification calorific value /MJ/m³ Gasification intensity /kg/(m³·h) Steam 550~750 Steam generator Fluidized bed ~55 ~0.46 20 1000 O2 850~950 Oxygen generator Fluidized bed 80 1.0 13.0 3000 Steam 600~800 Waste heat recovery unit Fluidized bed 65 ~0.55 16 1500 Steam 900~1000 Waste heat recovery unit Fluidized bed 85 ~1.1 14 3000 Gas composition CO2 CO CH4 CnHm H2 N2 O2 24.0 27.0 20.0 8.0 20.0 1.0 0.3 28.0 30.0 13.0 4.0 25.0 2.0 0.5 15.0 44.0 16.0 5.5 18.0 1.0 0.5 15.0 30.0 10.0 40 5.0 0.4 Technical and economic evaluation Technical difficulty Stability One-time investment Running costs Content of tar oil Application of General General General General More Little General Better Higher Higher Less More Higher Poor Higher Lower More Less General Better General Low Trace Application Table 7. 10,000 tons / year to estimate the scale of investment in manufacturing plant (equipment). Serial number Item Total(Million) 1 Part of biomass gasification(prepare feed、Gasifier、Purification Storage cabinets,Counter to the gas purification) 1000 2 Fine desulfurization 、Dechlorination 95 3 Compression Section 130 4 Synthesis of dimethyl ether 210 5 Distillation of dimethyl ether 50 6 Electrical instrumentation 130 7 Other 100 Total 1715 and gas heat values increase with the transition tem- perature decreased. H2 is mainly expressed in the incr- ease as the temperature increases, and decreases due to CH4. S/B is the impact of gas composition, gas yield and gas calorific value of the important parameters in Figure 4 that the gas temperature of 900-950℃, corn cob/coal ratio of 4/1,gas H2,CH4,CO content and S/B relationship. As well as gas production rate and the S/B relationship (Figure 5), gas heat value and the S/B relationship. (Fig- ure 6).  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ 202 Table 8. Estimates of consumption of fixed costs (per ton of DME). Serial number Name Units Amount Units(yuan) Amount(yuan) 1 Straw t 4.4 200 880 2 Coal t 1 400 400 3 Electricity Kwh 600 0.5 300 4 Water t 300 0.2 60 5 Steam t 1.5 60 90 6 Catalyst Kg 2.5 40 100 7 Subtotal 1830 8 Other 500 9 Cost of sales t 2330 As can be seen from the chart, in the experimental conditions, the gas content in H2 increases with the S/B increasing, and CH4, CO content both reduces with the S/B increasing. 4. CONCLUSION AND OUTLOOK 4.1. Conclusion Fluidized bed biomass gasifier water and put into service, after a long-term operation test, indicating that the sta- bility of the furnace is running, convenient operation, stable performance. In this paper, biomass and coal ratio under different experimental results show the feasibility of gasification technology and economic advantages (Table 6). The results from the pilot to see in biomass synthesis gas preparation methods, this technology has the following characteristics. 1) Applies to a wide range of raw materials: agricul- tural and forestry waste and organic solid waste can be used effectively. Biomass as a result of agriculture, for- estry, raw material suppliers subject to seasonal changes, Figure 4. The influence to the H2, CH4 and CO per- cents of the product gas by the value of S/B. can be adjusted to ensure that the coal to security of en- ergy supplies. 2) This technology is particularly applicable to a total of coal and biomass gasification. A result of coal in the combustion process can be quickly obtained by adding the necessary high-temperature gasification process and heat conditions. So the process of biomass gasification Figure 5. The influence to the yield of the product gas by the value of S/B. Figure 6. The influence to the heat value of the product gas by the value of S/B.  L. Q. Wang et al. / Natural Science 1 (2009) 195-203 SciRes Copyright © 2009 Openly accessible at http://www.scirp.org/journal/NS/ 203 has been transformed into efficient. Due to high tem- perature, the role of water vapor in the gas under very low tar content, so easy to deal with gas purification, resolved biomass gasification gas with high tar prob- lems. 3) High levels of H2 gas, H2 + CO>70%, H/CO = 1~2, is a synthetic alcohol fuel components suitable for the synthesis of alcohol fuel, the preparation of H2 technol- ogy to provide a viable route. 4.2. Outlook The development and utilization of oil alternatives and renewable sources of energy is the world's largest energy development trends and hot, renewable energy, the bio- logical resources into liquid fuels to replace oil with other types of energy unparalleled advantage. At present, many countries in the corn to sugar cane as raw material, through the biological alternative fuel ethanol into gaso- line has been noticed, as the existing technology of pow- dered sugar to starch-based, people struggle with food concerns, has been transferred to wood cellulose as raw materials on behalf of the Section 2 the development of biomass fuels. Due to technical and economic reasons, the second generation of fuel ethanol industry takes time. Even cellulose as raw materials process technology, the future level of industrialization can be achieved. Due to the diversity of straw cellulose, in the production process we also need to deal with the residue. In this paper, the biomass gasification technology is more perfect to deal with these types of materials technology. Biological fer- ment and gasification methods both integrated develop- ment, to make the development and utilization of bio- mass energy achieve better results. Technology is now under the operation of indicators, the production of 1 ton each of dimethyl ether (DME), the need for 4.4 tons of straw and 1 ton of coal. China based on the current mar- ket price, 200 yuan per ton of straw,400 yuan per ton coal, it is estimated the technology ton DME production plant of economic indicators. (Table 7, Table 8) Taking into account the cost of capital, a total invest- ment of about 3000 million, at current market price of DME 5,000 yuan per ton, production of 1~2 years to recover their investment. The technology of biomass for hydrogen production, due to purification, separation technologies are mature technologies [7-9], 1 kg of hy- drogen to be consumed 12kg of straw plus 3kg of coal. renewable energy technology in the economic advantage. As a result of this two-step technique, in the production process, about half the time the combustion process will be used to provide heat for the gasification process, the line considerable. The calorific value of hydrogen is the fuel units 3 times, which can be seen the application of The resulting hydrogen can be projected cost per ton of about 4,000~5,000 yuan. This is the current cost of gaso same-size models of fluidized-bed gasifier for gasifica- tion than oxygen for gasification agent law, and its pro- duction capacity will be less 1/2. However, due to the biomass distribution of a wide set shipped difficulties and is not suitable for large-scale production. This small-scale production plant, built near the highway to the highway for the trunk to form a supply network, so that raw materials can be extensive and products com- bine the mobility of, do the local sales of local produc- tion. A wide range of biomass distribution of a large amount of earth each year, the total biomass (dry) of about 1400-1800 billion tons, equivalent to the annual world energy consumption 10 times the biomass wish for the adoption of this technology to do economic de- velopment of mankind a contribution. REFERENCES [1] J. corella, J. M .Toledo, and G. Molina, (2007) A review on dual fluidized-bed biomass gasifiers. [J] Ind. Eng .Chem .Res., 46, 6831-6839. [2] J. corella, J. M. Toledo, and G. Molina, (2008) Biomass gasification with pure steam in fluidized bed. [J] Int, J. Oil., Gas and coal Technology, 1(1/2). [3] C. Z. Wu, B. Y. Xu, Z. F. Luo, et al. (1995) Analysis of biomass gasification for MHV fuel gas. [J]. Coal Gas and Heating Power, 15(2), 8-14. [4] T. Z. Wang, L. Q. Wang, and H. S. Zhou, A king of bio- mass and coal co-gasification method and derice of the fluidized bed, 4, CN200410013943. [5] T. Z. Wang and L. Q. Wang, A kind of water gas gasifica- tion method and device, ZL90105680. [6] L. Q. Wang, X. Song, H. S. Zhou, et al. (2008) Devel- opment study on co-gasification of biomass and coal in fluidized bed gasifier. (II)[J] Acta Energiae Solaris Sinica, 29(3), 354-359. [7] D. L. Xie, G. Y. Yi, Z. W. Li, W. Y. Qiao, (2007) Selec- tion of fluidzed bed technology for hydrogen production from biomass gasification. [J] Sino-global Energy. 12, 20-24. [8] S. T. Turn, Z. Zhang, et al. (1998) An experiment inves- tigation of hydrogen production from bimass gasification. [J] Int. J. Hydrogen Energy., 23(8), 641-648. [9] X. Y. Su, Z. W. Wang, C. M. Cheng, et al. (2000) Study on biomass pyrolysis and gasification in a fluidized bed. [J] Jounal of Fuel Chemistry and Technology, 28(4), 298-305. |