Journal of Water Resource and Protection

Vol. 1 No. 2 (2009) , Article ID: 618 , 7 pages DOI:10.4236/jwarp.2009.12019

Screening and Domestication of High Effective Microorganism Used in Oil Containing Wastewater Remediation

School of Resources and Civil Engineering, Northeastern University, Shenyang, China

E-mail: chenxineu@mail.neu.edu.cn

Received March 31, 2009; revised May 22, 2009; accepted May 25, 2009

Keywords: Oil Containing Wastewater, Screening, Domestication, CODCr, Removal Ratio

ABSTRACT

According to the characteristics of oil containing wastewater, four strains of microorganism, named TA-11, TA-17, HA-9, HD-1, were picked out from the oil contaminated soil and activated sludge of biochemical treatment system of an asphalt plant wastewater in Panjin. They can degrade oil and CODCr in oil containing wastewater. The research result showed that each strain of microorganisms can remove oil and CODCr in oil containing wastewater effectively when the pH value was 7.0, the temperature was 30 degree Celsius, the rotation speed was 140r/min and the inoculation amount was 10%. Especially the highest removal ratio of CODCr was 68% after growth of 64 hours. The removal ratio of CODCr in oil containing wastewater of mixed bacilli was much higher than that of unitary bacilli, and mixing a certain amount of domestic sewage with the oil containing wastewater will also improve the removal rate of CODCr.

1. Introduction

The source of oily wastewater is very extensive, mainly including the oil industry, the oil processing, refining, storage and transportation, the emulsified oil waste water owing to the machinery manufacturing and processing, car washing in the transport industry, railway maintenance of the wash tank, and other oily waste water emissions of restaurants, food processing, textile industry and other manufacturing wastewater [1]. The main pollutant in oily wastewater is oil, as well as the sulfide, volatile phenol and so on.

According to the existing form of oil in the oily wastewater, it can be divided into floating oil, dispersed oil, emulsified oil, dissolved oil and so on. In the processing of oily wastewater, first of all, most of the floating oil, dispersed oil and emulsified oil are removed by physical or physical-chemical methods. And then biochemical method is used in further treatment. At last, the treated water was discharged after reaching standard [2-5]. However, the oily wastewater is poor biodegradability, and problems such as running instability and low efficiency commonly exist in the bio-chemical process. Consequently, it is academic and practical significance that we should develop screening and domestication of microorganism which is used in oil containing wastewater remediation.

2. Materrial and Methods

2.1. Experimental Strains

Strains of microorganism used in the experiment were isolated from the oil contaminated soil and activated sludge of biochemical treatment system of an asphalt plant wastewater in Panjin. Four strains of microorganism, which can degrade oil and CODCr of oil containing wastewater effectively, were obtained through screening and domestication [6-8]. In the laboratory they were named TA-11(short rod-like, yellow, gram positive bacteria), TA17 (globular, pink, gram positive bacteria) isolated and purified from the oil contaminated soil of Panjin

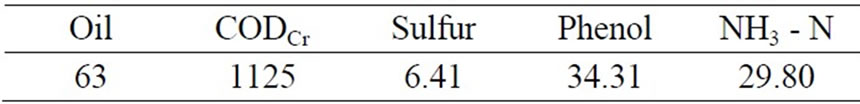

Table 1. Water quality of oil containing wastewater sample (mg/L).

asphalt plant and HA-9 (rod-like, yellow, gram positive bacteria), HD-1 (rod-like, pink, gram positive bacteria) from activated sludge of biochemical treatment system of an asphalt plant wastewater in Panjin.

2.2. Experimental Wastewater Sample

The oily wastewater is from biochemical treatment system of an asphalt plant wastewater in Panjin, of which the water quality is listed in Table 1.

2.3. Screening and Domestication of Strains

2.3.1. Preliminary Screening Method of the Strains

Through esterase decomposition test, strains which can highly degrade oil were screened out. Pick one purified strain, streak in prepared lipid culture medium, then put it into biochemical incubator with the temperature of 30℃, finally observe the color of medium after static culture for 64h. If it became red, it would suggest that the strain can degrade oil. The deeper the color showed, the stronger the ability of oil degradation was.

2.3.2. Secondary Screening Method of Strains

After obtaining strains in preliminary screening, secondary screening was based on ability of single strain degradation of COD in oil containing wastewater.

2.3.3. Domestication Methods of Strains

Domestication processes were divided into three phases. In the first phase, sterilized culture solution was filled into erlenmeyer flasks with 70 ml in each, and inoculation amount in each erlenmeyer flask was 5 ml. They were cultivated in shaking cultivation at the speed of 130~140r/min, in the temperature of 30oC and for 72h. At the same time, the OD550 was measured every 6 hours. In the second phase, the condition was the same as first phase except that culture medium formula was different. In the third phase, sterilized culture solution was filled into the erlenmeyer flasks with 30 ml in each, and Inoculation amount of each erlenmeyer flask was 2 ml. The culture condition was the same as the two phrases before.

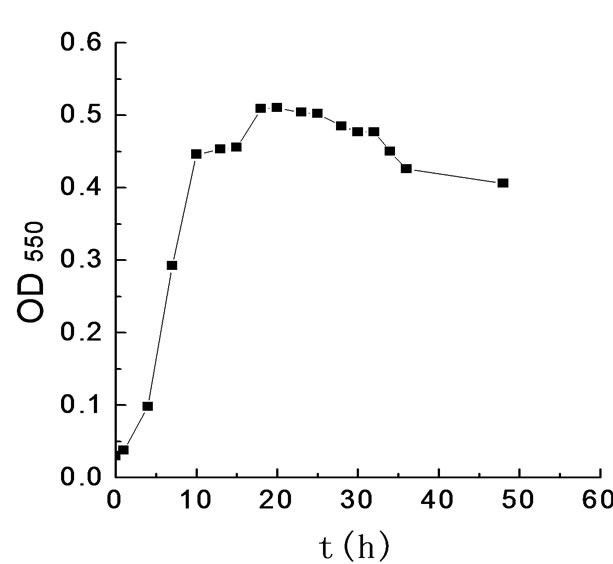

2.4. Determination of Growth Curve of Strains

Turbidimetry was applied to determine concentration of bacterial suspension in order to decide the growth curve. 2ml of bacterial suspension was inoculated in newly prepared and sterilized basic culture medium, and cultivated in 30℃. The OD550 was measured every 2h.

2.5. Medium-Related

Medium: beef extract 3g, peptone 10g, NaCl 5g, agar 15~20g, distilled water 1000 ml, pH value 7.0~7.2.

Oil medium: beef extract 3g, peptone 10g, NaCl 5g, agar 15 ~20g, 90# diesel 1ml, the concentration of 1.6% neutral red solution 1ml, distilled water 1000ml, pH value 7.0~7.2.

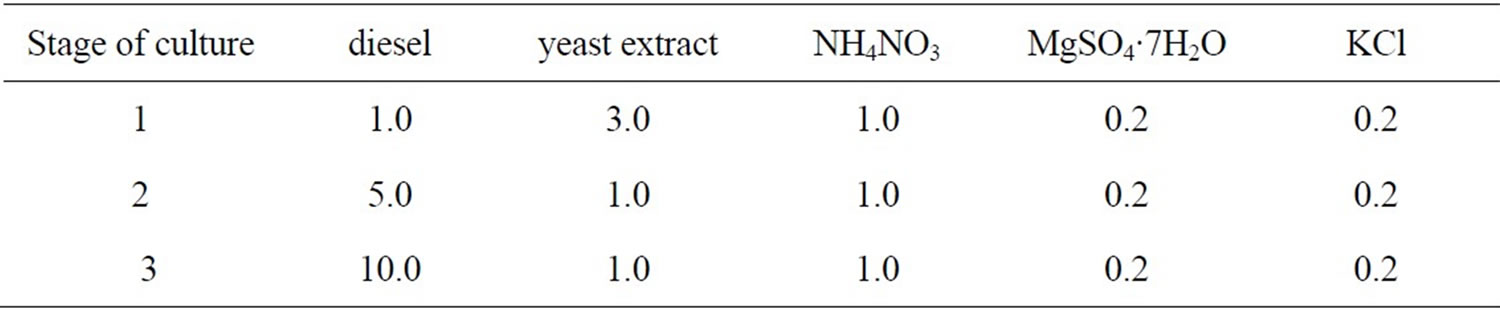

Domesticated medium:components of domesticated medium shown in Table 2.

Seed Media: glucose 12.5g, yeast extract 2.5g, NH4NO3 1g, MgSO4·7H2O 0.2g, KCl 0.2g, distilled water 1000ml, pH value 7.0~7.2.

Proliferated medium: glucose 30g, yeast extract 4g, beef extract 1g, NH4NO3 1g, MgSO4•7H2O 0.2g, KCl 0.2g, distilled water 1000ml, pH value 7.0~7.2.

2.6. Test Method of CODCr

CODCr in wastewater was determined by CODCr instrument with the principle of potassium dichromate method.

2.7. Test Method of OD550

OD550 was determined by 722E spectrophotometer at 550nm wavelength.

3. Results and Discussion

3.1. Screening of Strains

3.1.1. Primary Screening of Strains

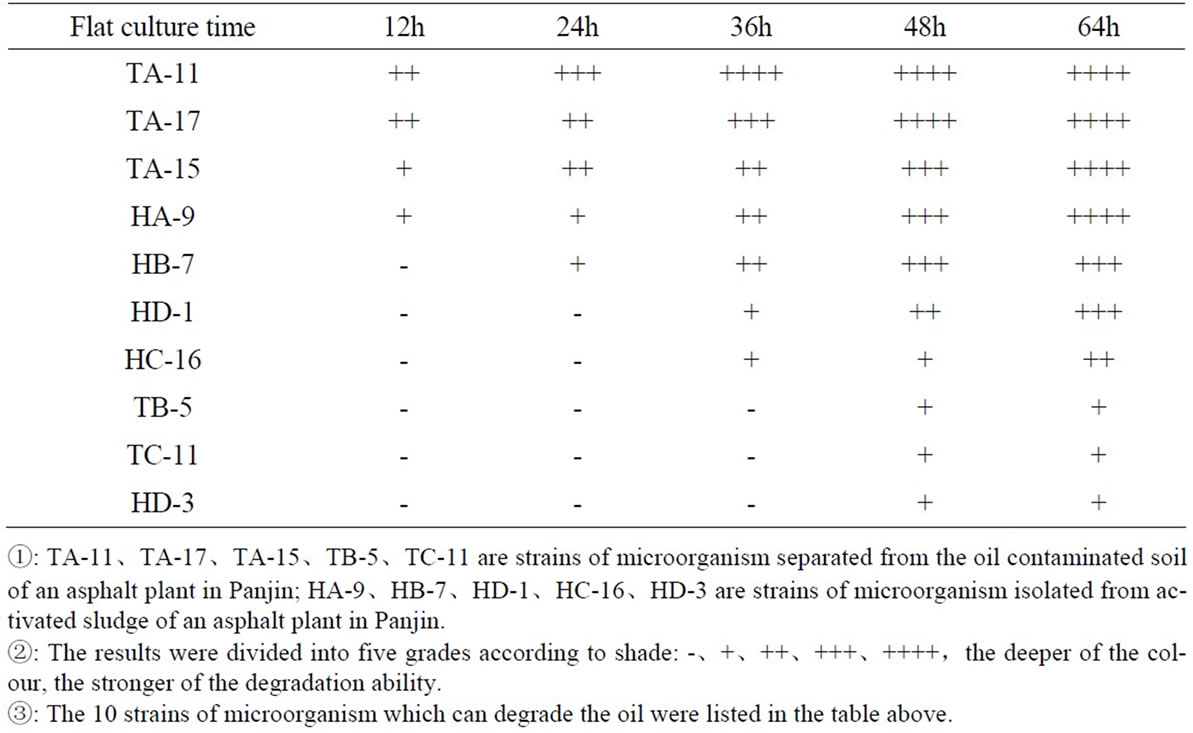

Screen out the strains which can degrade the oil containing wastewater according to the esterase decomposition experiment. The result is shown in Table 3.

Table 2. Culture medium component of high oil domesticating at different stages (g/L).

Table 3. Esterase decompound experiment.

3.1.2. Secondary Screening of Strains

The secondary screening standard of the strains is the removal ability of CODCr.

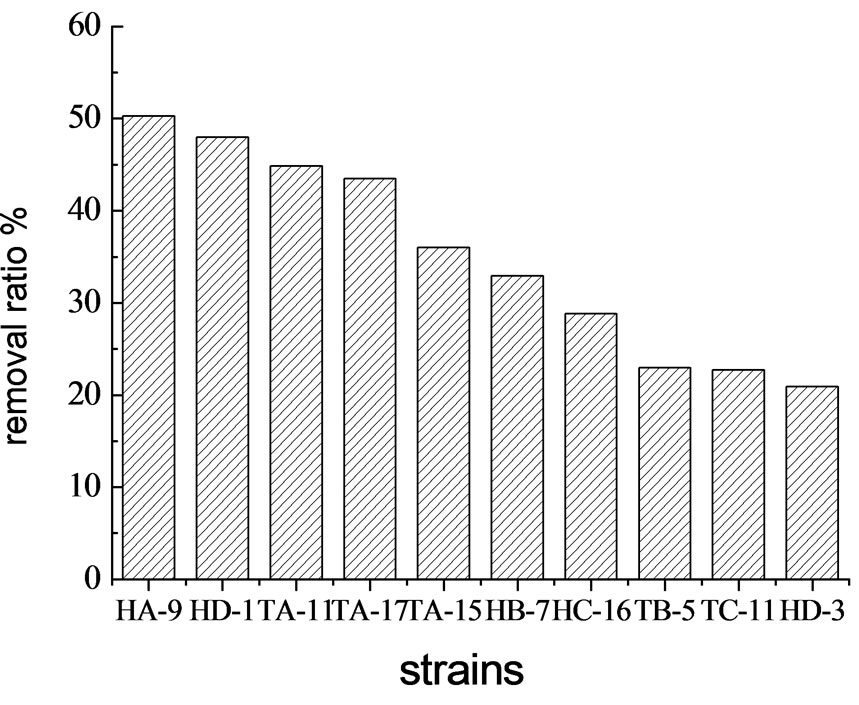

We inoculated the single strain to the oil containing wastewater with the pH value 7.0~7.2 and rotation speed 140r/min in 30oC. After 72 hours’ cultivation, CODCr was determined. We performed the same experiment 3 times and the average result was shown in Figure 1.

In Figure 1, HA-9 has the highest CODCr removal ratio of 50.3%, the next is the strain named HD-1 48%, and then TA-11, TA-17, with the removal ratio of 44.8%

Figure 1. Variation of degradation ratios of pure strain.

(a)

(a) (b)

(b) (c)

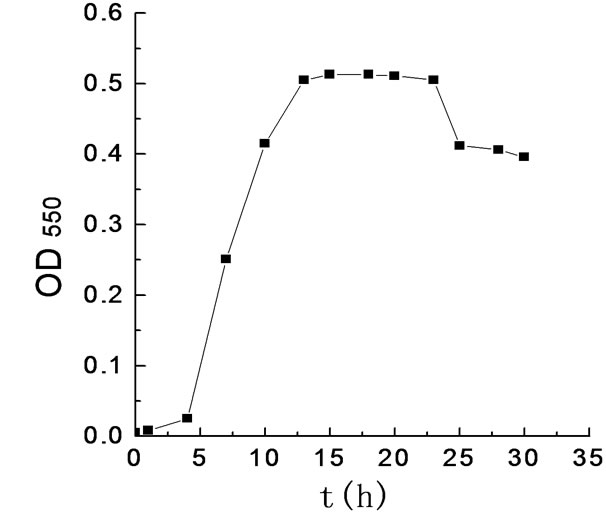

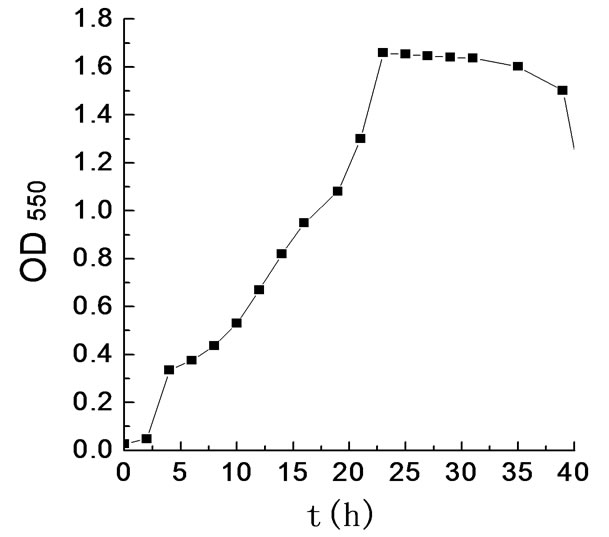

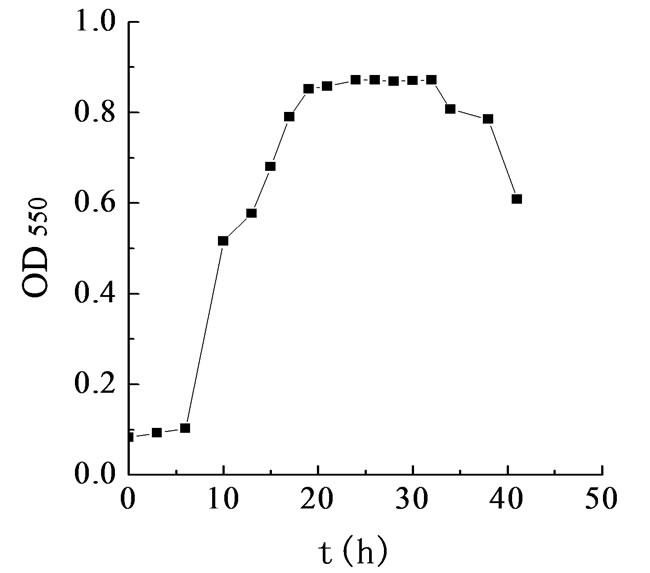

(c) (d)

(d)

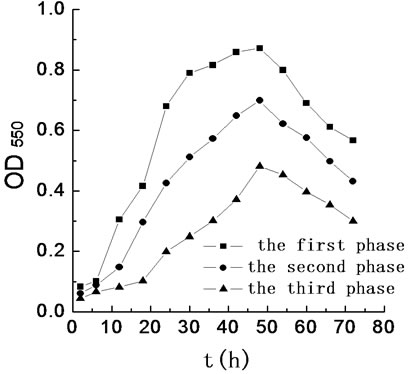

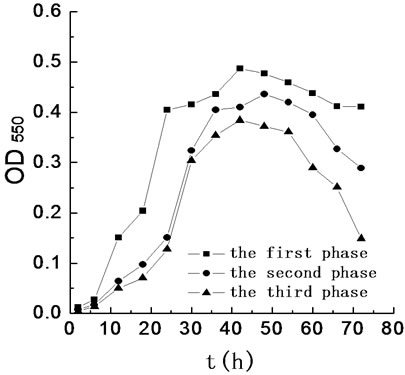

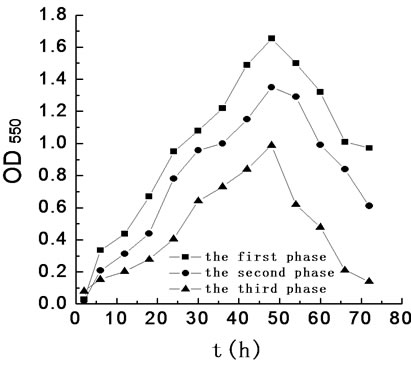

Figure 2. Result of high oil domesticating.

(a)—TA-11; (b)—TA-17; (c)—HD-1; (d)—HA-9 and 43.8% respectively. Consequently, the four strains named HA-9、HD-1、TA-17 and TA-11 are chosen to domesticate in the following experiment.

3.2. Taming of Stains

4 strains selected were domesticated, of which the result is shown in Figure 2.

In Figure 2,the value of the optical density OD550 reflects the number of bacteria in suspension, thereby reflecting the propagation of growth of microorganisms. According to the growth tendency, the number of bacteria reaches to the highest value within about 48h with the extension of time, while the trend becomes slow after 48h. It indicates that strains have a good capacity for diesel degradation within a certain period of time, and can survive in high oil concentration.

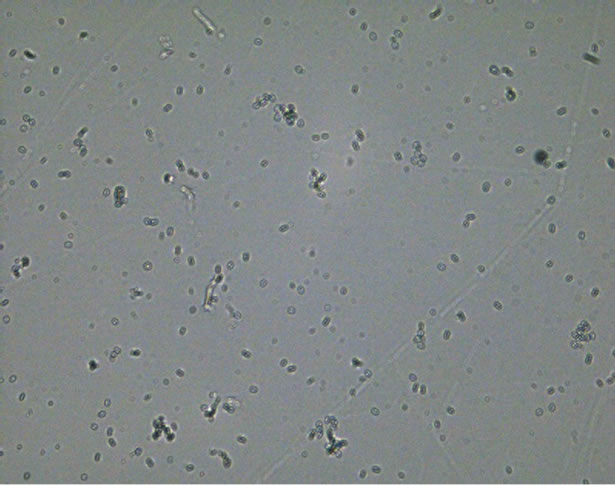

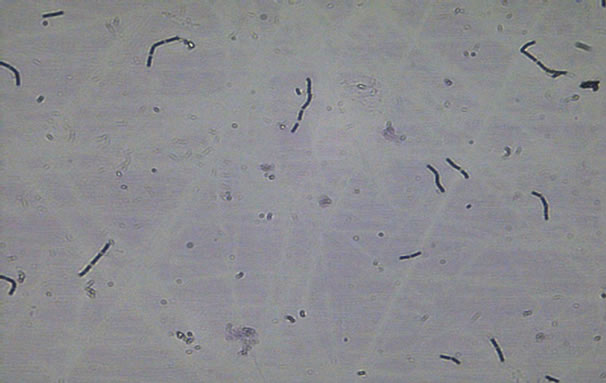

3.2.1. Morphological Characteristics and Growth Curve of Strains

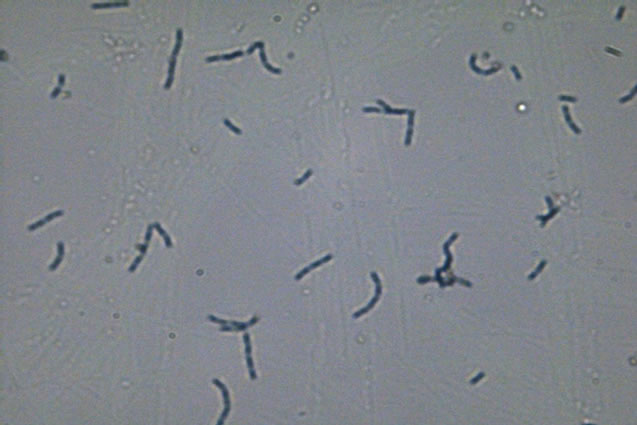

In beef extract peptone solid medium, TA-11 was yellow, transparent, smooth in surface, round uplift for the colony, and regular around. Cells were short rod-shaped, positive in gram stain when they were observed in the microscope.

In beef extract peptone solid medium, TA-17 was pink, opaque, smooth in surface, of round colonies, smaller, and regular around. Observed in the microscope, cells were spherical, positive in gram stain.

In beef extract peptone solid medium, HD-1 was pink, opaque, smooth in surface, of round colonies, regular of the edge. Observed in the microscope, cells were rodshaped, positive in gram stain.

In beef extract peptone solid medium, HA-9 yellow, deep color in center, opaque, of round colonies, regular around. Observed in the microscope, cells were rodshaped, positive in gram stain.

The morphology characteristics and growth curves of different strains are shown in Figure 3.

(a)

(a) (b)

(b) (c)

(c) (d)

(d)

(e)

(e) (f)

(f) (g)

(g) (h)

(h)

Figure 3. Micro photos and growth curves of microorganism. (a),(b)—TA-11; (c),(d)—TA-17; (e),(f)—HD-1; (g),(h)—HA-9

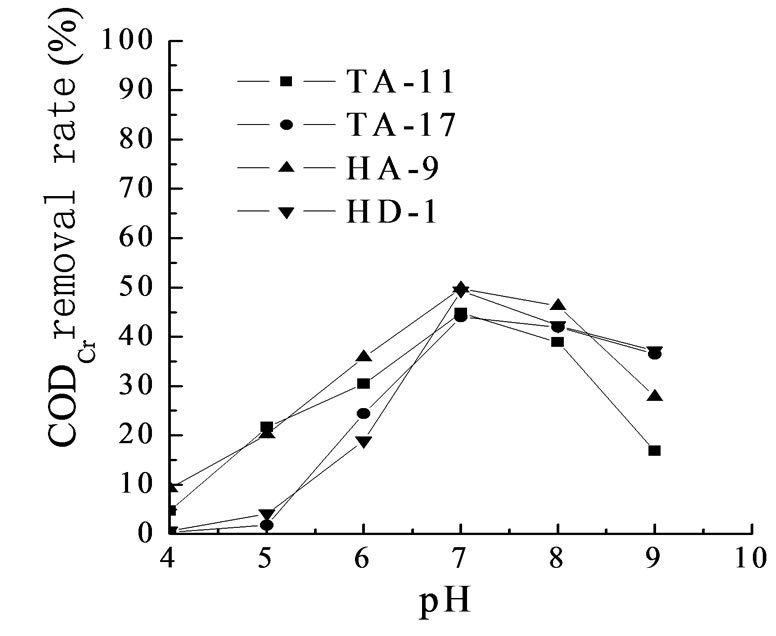

Figure 4. Influence of pH on CODCr removal.

3.3. The Influence of Environmental Factor on CODCr Removal Effect

3.3.1. The Influence of Original pH Value on CODCr Removal Effect

PH value has a great influence on living activity of microorganism. It mainly changes electric charge on the cell’s membrane, thereby affecting microorganism’s absorbability of nutriment; affects the enzyme’s acting; transforms the acquirable ability of nutriment and the toxicity of injuring in their living circumstance. All kinds of microorganism have their own and optimal pH value.

In order to investigate the influence of original pH value on CODCr removal effect, we took bacterium liquid 2ml from each single bacteria, put them into 50ml wastewater of different pH value respectively, cultivated them at 30℃ and rotate speed of shaking bed of 130r/min, and then measured the CODCr removal ratio after 64h. The result is shown in Figure 4.

The optimal pH value range of four bacteria is 7-8. In this scope, their removal rates are high. When pH<5, the removal efficiencies of CODCr in the wastewater are very limited. When pH> 8, the removal efficiencies of all kinds of microorganism are obvious declined. The result shows that it is suitable for the four stains of bacteria to survive in a neutral condition, while it is not conducive to microbial growth and the degradation of oil in the condition of too high or too low pH value.

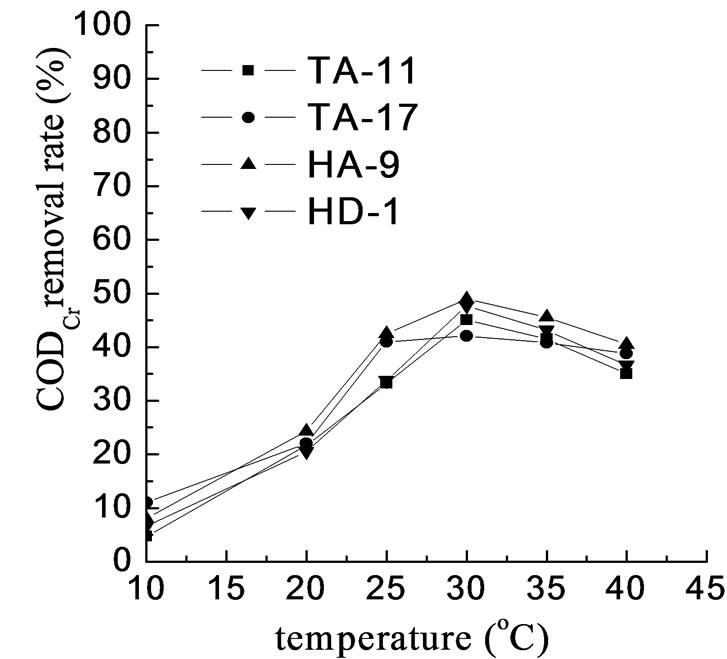

3.3.2. The Influence of Temperature on CODCr Removal Effect

The principal part of wastewater treatment is kinds of microorganism which have special function. And their growth and propagating have consanguineous connections with the temperature. Microorganisms’ growth is complicated biochemical reaction, which requires a certain range of temperature to perform in. The temperature range is wide (-10~95 degree Celsius), but each kind of microorganism can only growth in a definite range of temperature. In the range of the optimal temperature, microorganisms are vigorous physical activity, which conducts high treatment efficiency of the wastewater. And above or below this temperature range, it will injure microbial enzymatic systems, and affect the microorganisms’ metabolism and the degradation of organic pollutants.

In order to investigate the influence of temperature on CODCr removal effect, we took each single bacterium liquid, put them into 50ml wastewater with pH value about 7.0, cultivated them at different temperatures and rotate speed of shaking bed of 130r/min, and measured the CODCr removal ratio after 64h. The result is shown in Figure 5.

As shown in Figure 5, when the scope of temperature is between 25 to 35 degree Celsius, removal ratios of these four bacterium are high. In conclusion, the optimal degradation temperature is 30 degree Celsius.

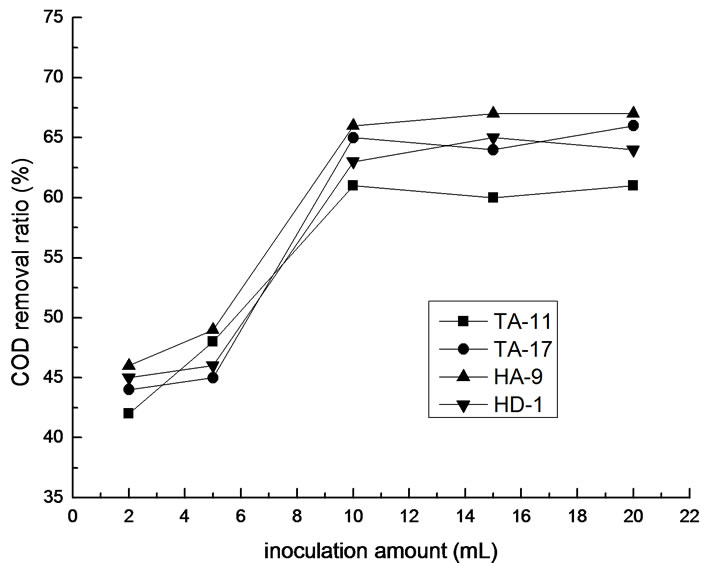

3.3.3. The Influence of Inoculation Amount on CODCr Removal Effect

In order to investigate the influence of inoculation amount on CODCr removal effect, we took each single bacterium liquid of 1ml, 2.5ml, 5ml, 7.5ml, 10ml, put them

Figure 5. Influence of temperature on CODCr removal.

Figure 6. Influence of inoculation amount on CODCr removal.

Figure 7. Influence of shaking rate on CODCr removal.

into 50ml wastewater with pH value at about 7.0, cultivated for 64h at 30℃ and rotate speed of shaking bed of 130r/min, and then measured the CODCr removal ratio. The result is shown in Figure 6.

It can be seen that the less of inoculation amount, the higher concentration of residual CODCr. When the inoculation amounts are 2% and 5% respectively, the removal ratios of the 4 strains are less than 50%. And when the amount is over 10%, the influence on removal ratio is not obvious. Considering the economic benefit, 10% inoculation amount is optimal.

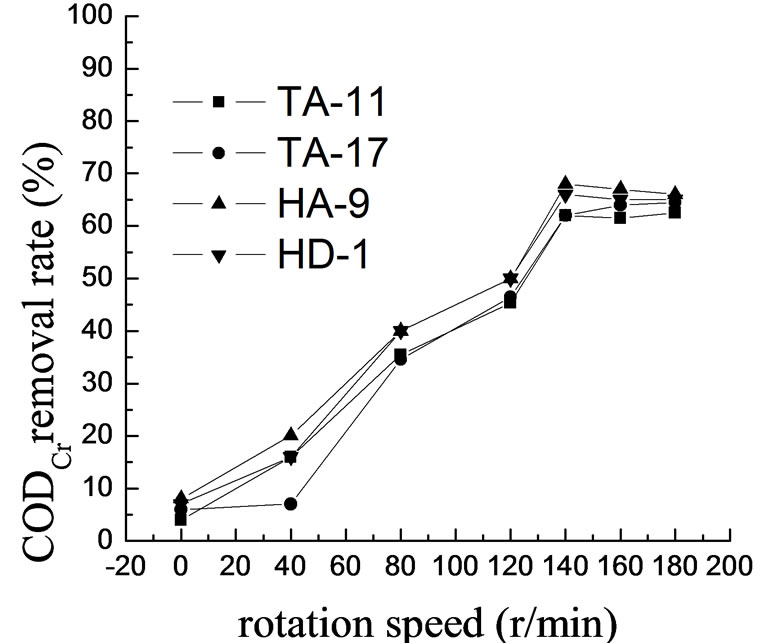

3.3.4. The Influence of Aeration Intensity on CODCr Removal Effect

The speed of shaking bed is used to represent aeration intensity in this experiment. We have investigate the influence of aeration intensity on CODCr removal effect at the range of 0~180 r/min.

We chose each single bacterium liquid, put them into 50ml wastewater with pH value about 7.0, in the 30 degree Celsius temperature conditions, cultivated them at the speed of 0, 40, 80, 120, 140, 160 and 180 r/min respectively for 64h. At last, we contrasted the CODCr removal ratios in the wastewater of different bacterium liquids at different speeds. The result is shown in Figure 7.

As the result shown in Figure 5, with the increase of speed, CODCr removal ratios in the oil containing wastewater are in upward trend. When the speed is at 140r/min, the CODCr removal ratios are the highest, especially the removal ratio of HA-9 can be 68%.

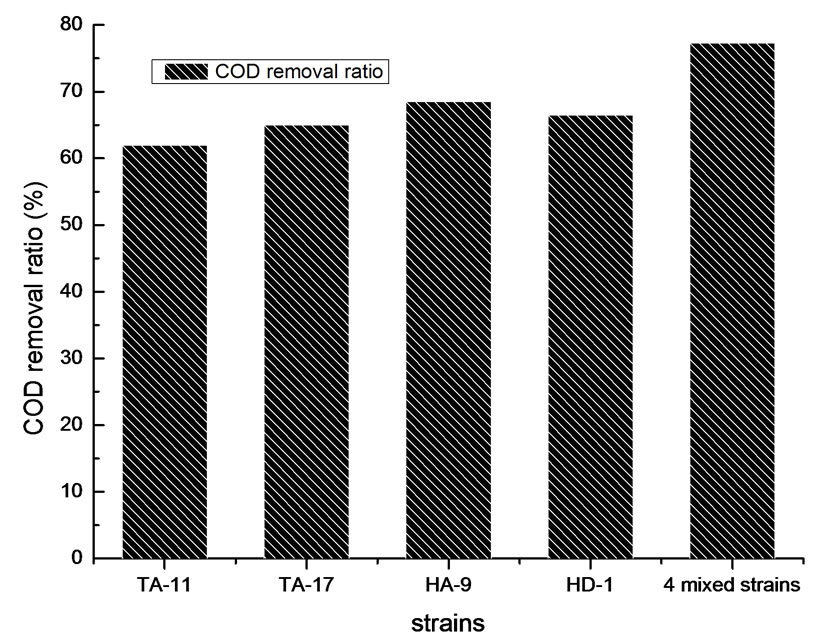

3.3.5. The Influence of Mix-Bacterium on CODCr Removal Effect

We took 5ml bacterium liquid of each bacterium, put all of them into 50mL wastewater with pH value about 7.0 in the 30 degree Celsius temperature conditions, cultivated them for 64h at the speed of 140r/min. At last, we measured CODCr removal ratios which changed with time, and compared with the equivalent single-strain vaccine. The result is shown in Figure 8. As shown, the removal ratio of the mix of efficiency is higher than that of each single stain.

Figure 8. Removal ratio of CODCr for mixed bacilli.

Table 4. Comparation of the removal ratios of CODCr.

3.3.6. The Influence of Nutriment on CODCr Removal Effect

It is not only enough organic matters, but also many kinds of well-proportioned nutriment that are required in the growth of microorganism, including C, N, P, S and many microelements such as K, Ca, Mg, Fe and vitamins. Domestic sewage can meet the requirement. As a result, domestic wastewater which was simulated with compounds of 0.4% NH4NO3, 0.8% K2HPO4, 0.8% KH2PO4, 0.1% MgSO4·H2O and distilled water with pH value around 7 is added to the oil containing water in this experiment. Their proportional is 1:1, and CODCr of the mixed wastewater is 850 mg/L. We added 10% of total inoculation amount, and 2.5% of inoculation amount of each single bacterium, into the mixed wastewater, and cultivated them in 30℃, at rotate speed of shaking bed of 140r/min for 64h. Compared with the wastewater which is diluted as twice of the original, we investigated the removal ratio of CODCr of immobilized bacterium. The result is shown in Table 4.

The result shows that the removal ratios of each strain have increased after 64h. So it is helpful to improve the removal effect if a certain amount of domestic sewage is added into the oil containing wastewater in practical treatment.

4. Conclusions

1) We have separated four objective stains of bacterium which have high efficiencies on removal of oil and CODCr in the oil containing wastewater from soil polluted by heavy oil and activated sludge biochemical treatment system of an asphalt plant wastewater in Panjin. And they are named in the laboratory: TA-11, TA-17, HA-9 and HD-1. It is observed in the microscope that the four stains of bacterium are gram-positive.

2) The biochemical degradation tests on the oil containing wastewater show that the treatment effects of each stain are best when the pH value is 7.0, the rotation speed 140r/min, the inoculation amount 10% and the temperature of circumstance 30 degree Celsius. And after 64h’s cultivation, the CODCr removal ratio can reach approximately 68% of single bacterium. The CODCr removal efficiency of the mix stains is higher than that of any single stain.

3) It is mixing a certain amount of domestic sewage with the oil containing wastewater that will also improve the removal efficiency of CODCr in practical treatment.

REFERENCES

- S. B. Hou, X. M. Xuan, “Status of research and application of the oily wastewater treatment technology [J],” Shanghai Chemical Industry, Vol. 9, pp. 11-14, 2003.

- T. Berrin, “Microscopic characterization of oil droplets removed by flocs after coagulation of oil-water emulsions [J],” Journal of Environmental Science and Health, Vol. 37, No. 2, pp. 127-138, 2002.

- A. M. A. Omar, “Recovery of residual emulsifiable oil from wastewater by flotation lubrication science [J],” Water Science Technology, Vol. 14, No. 2, pp. 275-284, 2002.

- D. D. Qian, L. J. Xu, and J. W. Shi, “Study on high-strengh oil-containing wastewater treatment attached yeasts [J],” Energy Environmental Protection, Vol. 23, No. 1, pp. 41-45, 2009.

- G. Q. Liu, J. W. Shen, and C. K. Gao, “Study on treatment oil wastewater by screening high efficicent degradation bacteria of crude oil [J],” Technology of Water Treatment, Vol. 34, No. 10, pp. 26-29, 2008.

- G. Yang, “A Course of microbiology experiment [M],” Science press, pp. 15-25, 2004.

- X. Y. Xu, Y. Zhang, and H. B. Li, “Immobilization process of flavobacterium sp. for bioremediation of contaminated surface water [J],” Journal of Northeastern University: Natural Science, Vol. 8, pp. 783-786, 2005.

- X. Y. Xu, Y. Zhang, and H. B. Li, “Chemical embedding immobilization technique of micrococcus sp. used in contaminated surface water remediation [J],” Journal of Northeastern University: Natural Science, Vol. 1, pp. 1146-1149, 2006.