Advances in Chemical Engineering and Science

Vol.4 No.2(2014), Article ID:44774,8 pages DOI:10.4236/aces.2014.42022

Rheological Characterization of Yam and Potato Paste (Dioscorea rotundata) and (Ipomea batata) for Adhesive Purpose

Rhoda H. Gumus*, Iweikumo Wauton

Department of Chemical/Petroleum Engineering, Niger Delta University, Yenagoa, Nigeria

Email: *rhodagumus@yahoo.com

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 27 February 2014; revised 27 March 2014; accepted 4 April 2014

Abstract

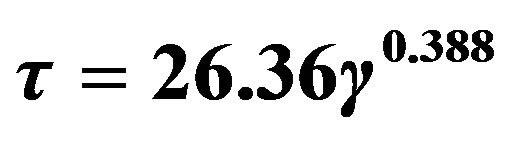

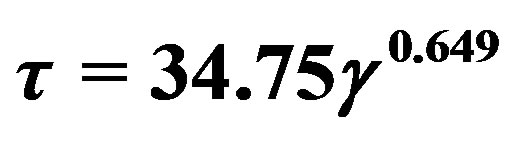

An experimental study has been carried out to determine the flow behavoir (rheological characterization) of potential adhesive of starch derived from sweet potato (Ipoemoa batatas) and yam (Dioscorea rotundata) at varying temperatures ranging from 40˚C to 85˚C with borax blend of 0.83%. The results obtained showed decreasing viscosity with an increasing temperature; potatoes had higher viscosity and density (27 × 103 cP), (0.813 g/m3) than yam (23 × 103 cP), (0.415 g/m3). The rheological data were evaluated by the power law and Casson models to describe the rheological behavoir. The Casson model gave a relatively poor fit to the experimental data with R values ranging from 0.899 to 0.967 from yam while a better fit was obtained for potato with r values ranging from 0.957 to 0.976. The predicted k and n values fit into experimental data (K = 26.36 and 0.388) and (K = 34.75 and 0.649) for yam and potato respectively; n < 1 showing Non-Newtonian behavoir. The relation between the temperature and K was described by an Arrhenius equation. Activation energies of 2.69 KJ/mol and 5.87 KJ/mol for yam and potato blends were obtained, indicating more sensitivity of yam blend to temperature compared to potato blend. With the experimental values obtained, a mathematical expression to relate shear stress and shear rate were proposed as:  and

and , for both the yam and potato blends respectively.

, for both the yam and potato blends respectively.

Keywords

Rheological Properties, Characterization, Yam, Potato, Blends

1. Introduction

Adhesives are recognized as essential to society just as enzymes; hormones and vitamins are required for individual well being [1] . Adhesives are polymer materials that are capable of joining two bodies together by surface attachment with the ability to sustain the designed load requirement without deformation [2] [3] . Processing of adhesive depends mainly on the rheological parameters and the quality of the final product which is determined by the interaction between adhesive and the adherend [4] .

In the world today, the industries of adhesives have grown and demand for starch adhesives has increased drastically, which has led developing countries like Nigeria to depend on locally sourced starchy materials for adhesive production [5] . Investigations reveal that components of starch adhesives are useful in the construction industry, packaging industry, textile, pharmaceutical industry, etc. [6] -[9] . Adhesives can be produced from various sources such as fish, natural rubber, animals, starch, milk protein (Casein) and cellulose wood etc. [5] [10] . The use of starch material for the formulation of adhesive has increased in recent times; because starch is one of the most abundant substances in nature, renewable and unlimited source [11] . It can be obtained by wet maize milling, fresh rice and starch bearing tropical roots such as cassava, sweet potato, cocoyam, yam, etc. However, in the production of adhesives, starch obtained from sweet potatoes (Ipoemoa batatas) and yams (Dioscorea rotundata) is scarcely given attention; compared to cassava derived starch.

The rheological properties such as viscosity, density, shear stress and shear rate are very important to be considered [11] in selecting potential adhesive material. Reliable rheological data are essential for design, quality control, sensory assessment, stability and consumer acceptance of a particular product [12] -[14] . It is also required for process engineering analysis (pumping, mixing, agitation, heating, shelf-life estimation, texture evaluation, product development and the development constitutive equation for rheological characterization [15] ). The knowledge of rheological properties of starch paste, with shear rate and shear stress relationship, is important for the evaluation spread ability and firmness paste production. Two variables that affect rheological properties of adhesive are the temperature and concentration of borax. The rheological properties of various materials such as labneh from barine milk, soups, cooked cassava and cassava starch with borax blends have been extensively studied by research groups [7] [11] [12] . However, literature does not provide adequate information for the rheological characterization of yam and potato borax blends for adhesive purposes. Thus, the objective of this study is to determine the flow behavoir (rheological characterization) of potential adhesive of starch derived from sweet potato (Ipoemoa batatas) and yam (Dioscorea rotundata).

2. Materials and Method

2.1. Sample Preparation

The fresh yam (Dioscorea rotundata) and potato (Ipoemoa batatas) used for this study were obtained from Opolo-Epie Market, Yenagoa, Bayelsa State, Nigeria.

Processing of the fresh potato roots (peeling, washing, grinding and filtering to obtain the starch) commenced that same day. The other materials are hydrochloric acid, sodium tetra borate (Borax), and weighing balance, and water-bath, Brookfield viscometer Model DV-E version 1.0 with cylindrical spindle #7HA, thermometer and Hot plate.

2.2. Preparation of Adhesive Materials

30 g of dry starch from potato (Ipoemoa batatas) was dissolved in 250 ml of 0.01 M of HCL (gelatinization Modifier) until there was complete dissolution. The solution was heated up with continuous stirring to obtain a uniform gel. This was allowed to cool at room temperature. 60 ml of the gel was poured into different beakers and 0.2 g to 0.5 g of borax (stabilizer) was added and stirred at 40˚C, with the aid of a water-bath to control the temperature. The viscosities were measured using Brookfield viscometer model version 1.0 with cylindrical spindle #7HA at constant 60 rpm. This was repeated at temperatures 45˚C, 50˚C, 55˚C, 60˚C, 65˚C, 70˚C, 75˚C, 80˚C, and 85˚C. The same procedure was repeated for starch derived from yam (Dioscorea rotundata). The density of each sample was determined using the method reported in literature [11] .

2.3. Rheological Analysis

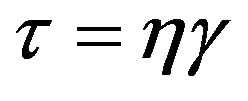

The rheological measurements were conducted at temperatures 40˚C, 45˚C, 50˚C, 55˚C, 60˚C, 65˚C, 70˚C, 75˚C, 80 and 85˚C. Samples were preheated in a water bath for about 10 minutes at the set temperature. The sample loaded to the sample cup, was placed into the water bath and allowed to rest for 5 minutes to maintain the system temperature. Samples were sheared using ten different rotational speeds at an increasing order (5 - 90 rpm) with 0.4 g of borax concentration. For all experiments, two replicates were made and the average reproducibility was ±8%. The spindle #7HA, with a factor of 0.209 was used for the viscosity measurement. Shear stress values were determined using the relationship . where τ = shear stress, η = viscosity, and

. where τ = shear stress, η = viscosity, and  = shear rate The flow curves of yam and potato paste were modeled by using the following model; the most frequently used for engineering applications.

= shear rate The flow curves of yam and potato paste were modeled by using the following model; the most frequently used for engineering applications.

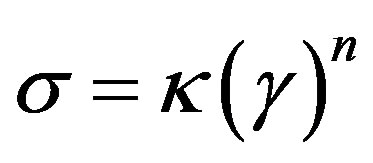

Power law model

(1)

(1)

Here  is the shear stress (Pa),

is the shear stress (Pa),  shear rate (s‒1),

shear rate (s‒1),  is consistency index (Pa×sn), n is the flow behavoir index (dimensionless).

is consistency index (Pa×sn), n is the flow behavoir index (dimensionless).

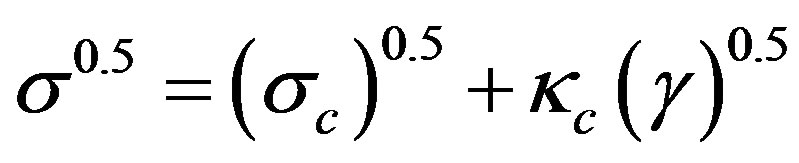

Casson model

(2)

(2)

Here  and

and  are Casson yield stress (pa) and Casson viscosity (Pa0.5×s0.5), respectively.

are Casson yield stress (pa) and Casson viscosity (Pa0.5×s0.5), respectively.

The flow behavoir index (n) and consistency index  were calculated by employing regression analysis of shear stress/shear rate data.

were calculated by employing regression analysis of shear stress/shear rate data.

3. Results and Discussion

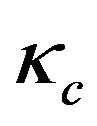

Figure 1 shows the pH curves of yam and potato paste at different temperatures. All materials exhibit alkaline solution ranging from 6 - 7 where the pH increased linearly with increasing temperature. The pH values for yam were little higher than that of potatoes at all temperatures studied, indicating that yam paste was more alkaline than that of potato (6.62 and 6.22) respectively.

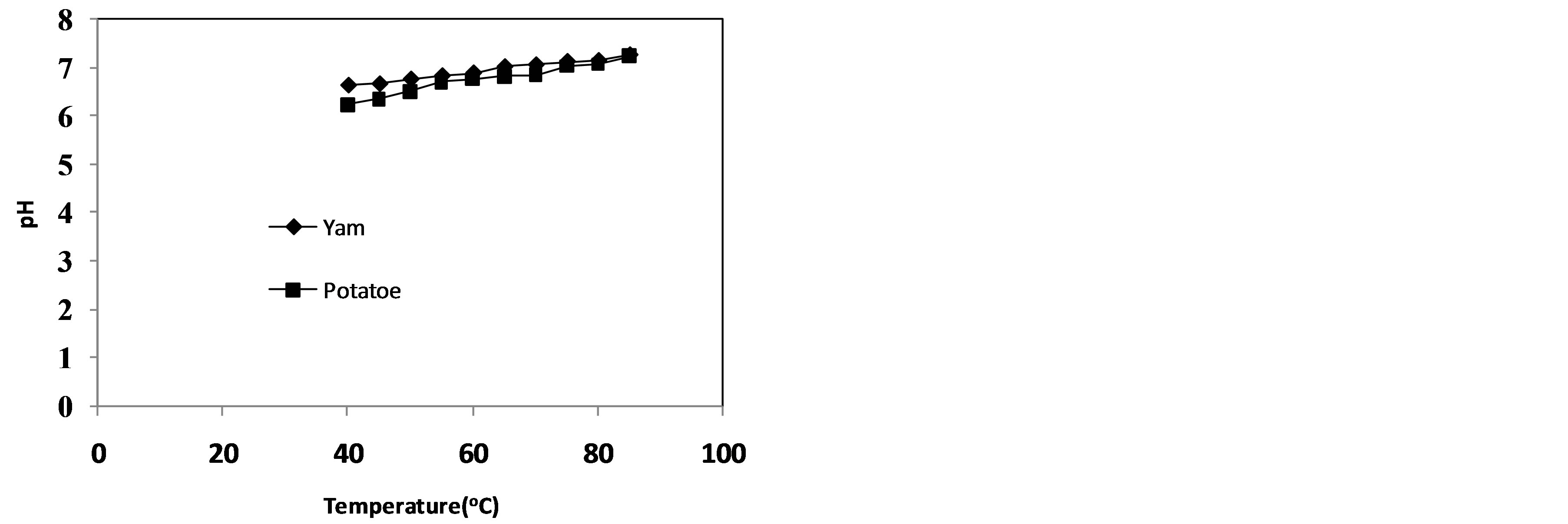

Densities of all paste decreased with increase in temperature. This can be explained by the increase in volume when temperature increases. Density is mass per unit volume; therefore an increase in volume would results to a decrease in density. For the blends, density of potato was higher than that of yam at all temperatures (1.406 - 1.286 g/m3) while the range of 1.017 - 0.751 g/m3) was observed for yam (see Figure 2).

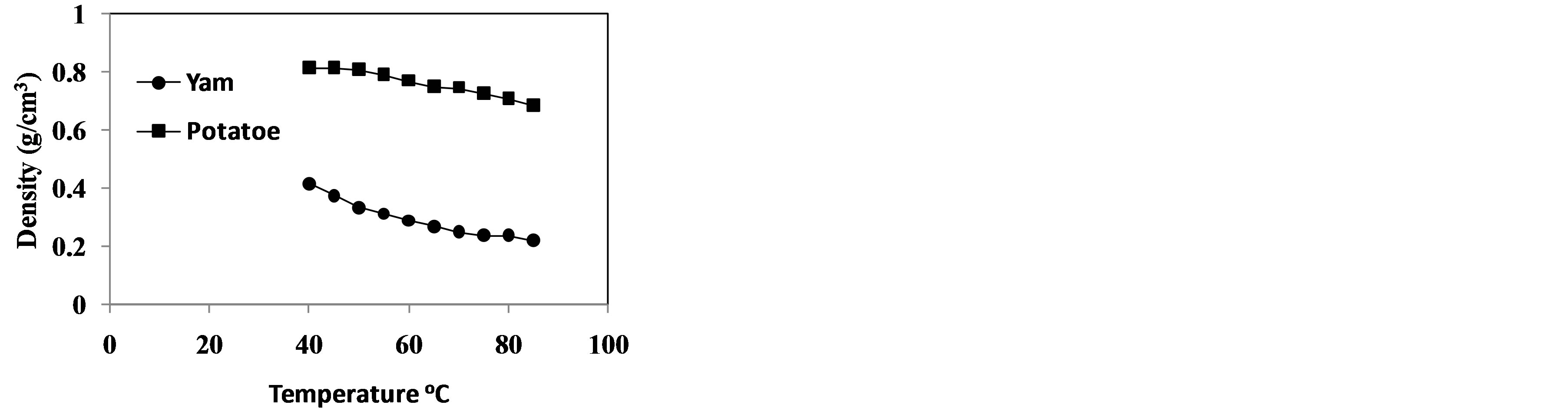

The experimental results of apparent viscosity versus shear rate were found to exhibit a non-Newtonian behavior. The apparent viscosity of the blends (0.83% borax) decreased with increasing shear rate (See Figure 3), with yam paste decreasing more rapidly than the potato paste; from 23 × 103 cP to 3 × 103 cP and 27 × 103 cP to 6 × 103 cP for yam and potato respectively, with potatoe having higher viscosity. Our results for yam and potato were consistent with the findings [11] (11 × 103 cP) for TME 419 cassava cultivar). Similar values were obtained for the remaining concentrations. The temperature increase also increases the thermal energy of the molecules, which in turn develop molecular distances due to reduction of intermolecular forces hence viscosity of the fluid decreases [13] .

Figure 1. Effect of temperature on pH of paste containing 0.83% borax at constant speed of 60 rpm.

Figure 2. Effect of temperature on density of paste containing 0.83% borax at constant speed of 60 rpm.

Figure 3. Apparent viscosity –shear rate relationship for the pastes containing 0.83% borax at constant temperature (40˚C).

Characteristics of Flow Properties

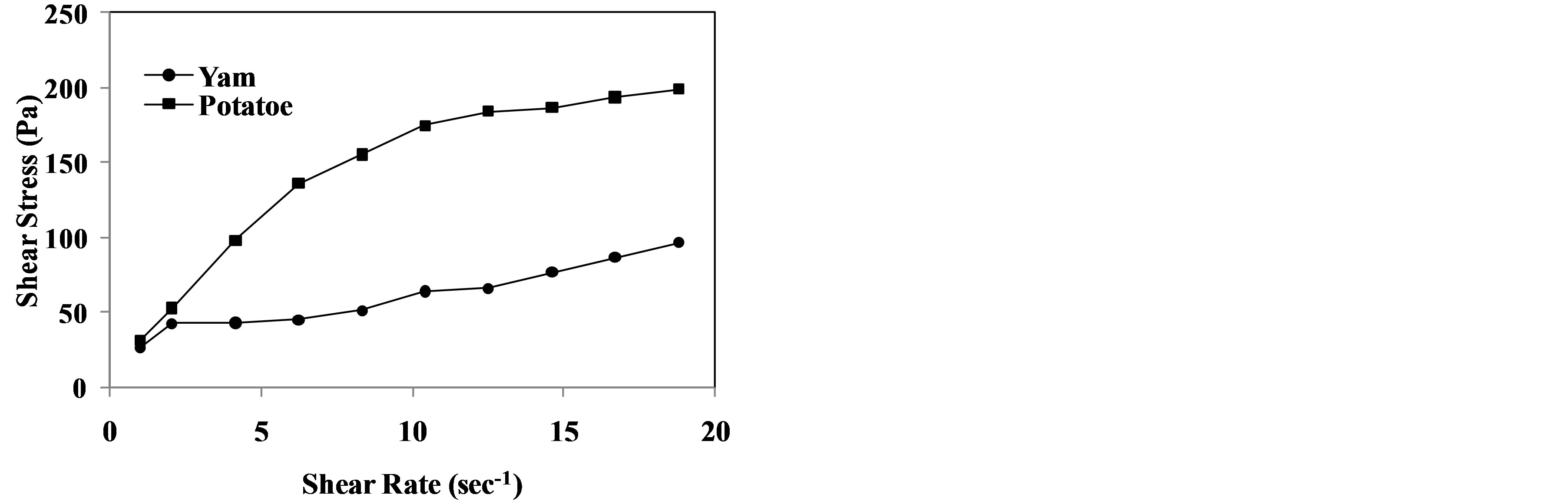

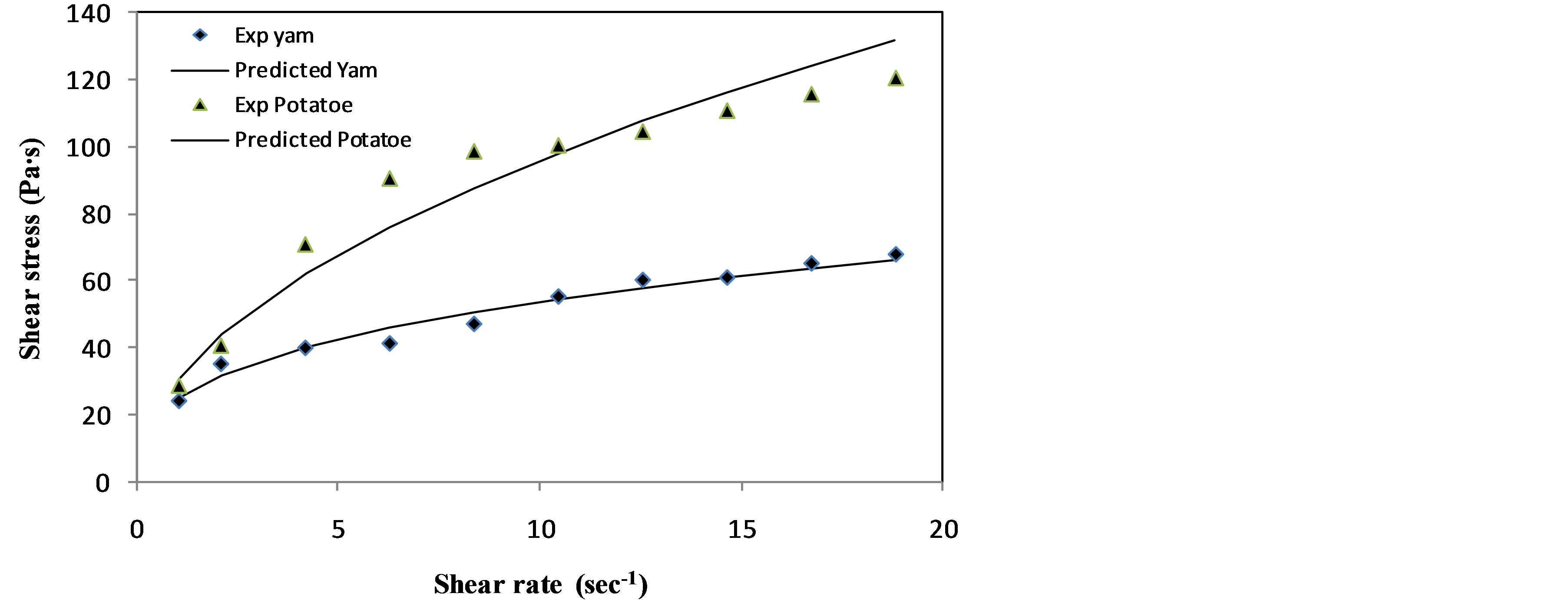

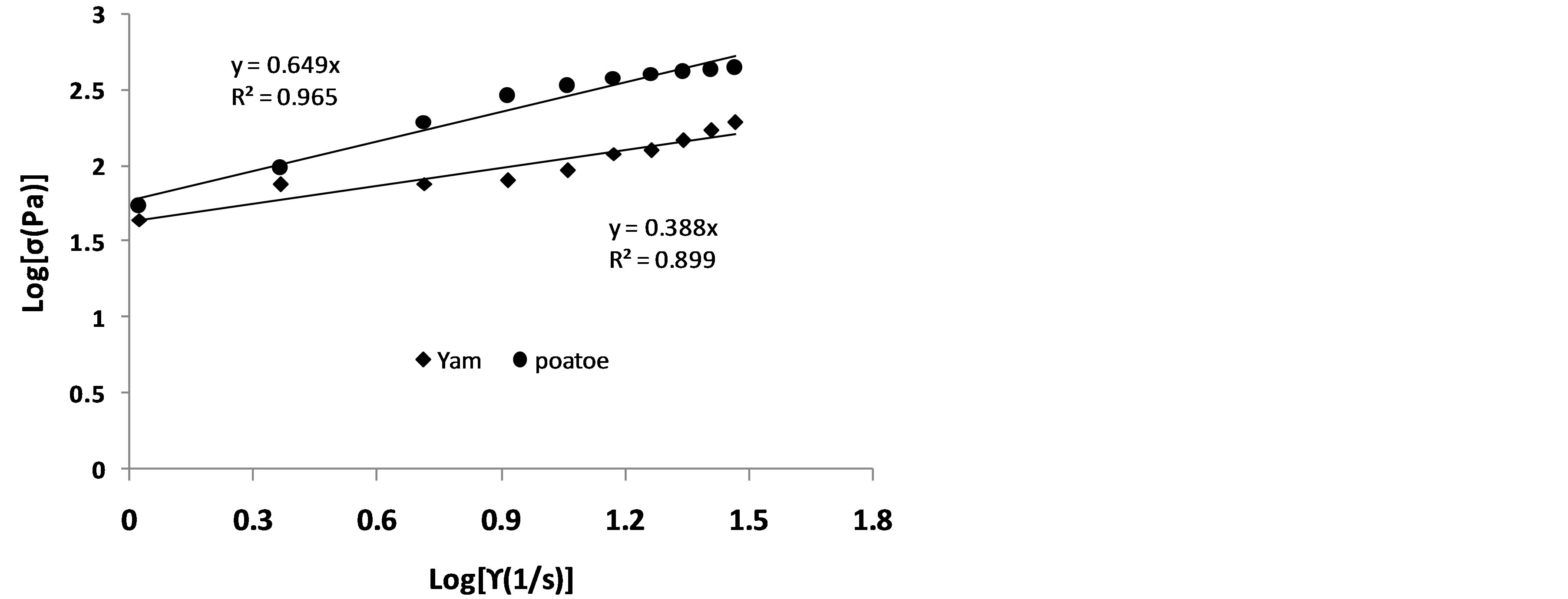

Figure 4 shows the flow curves (shear stress) of yam and potato blends of 0.83% borax at constant temperature of 40˚C with increasing shear rate. The shear stress increased with increasing shear rate. The shear stress flow curve for potato blend is higher than that of yam corresponding with low viscosity exhibited. The experimental values of shear stress gave good fit with modeled values for yam compared to potato (see Figure 5).

The rheological data were evaluated by the power law and Casson models which are commonly used to describe the rheological behaviour of fluids exhibiting no plastic behaviour [14] . From the power law model, apparent viscosity is represented in Equation (1)

The logarithmic form of Equation (1) was used to determine the values of the model parameters for the two blends of yam and potato (See Tables 1-3).

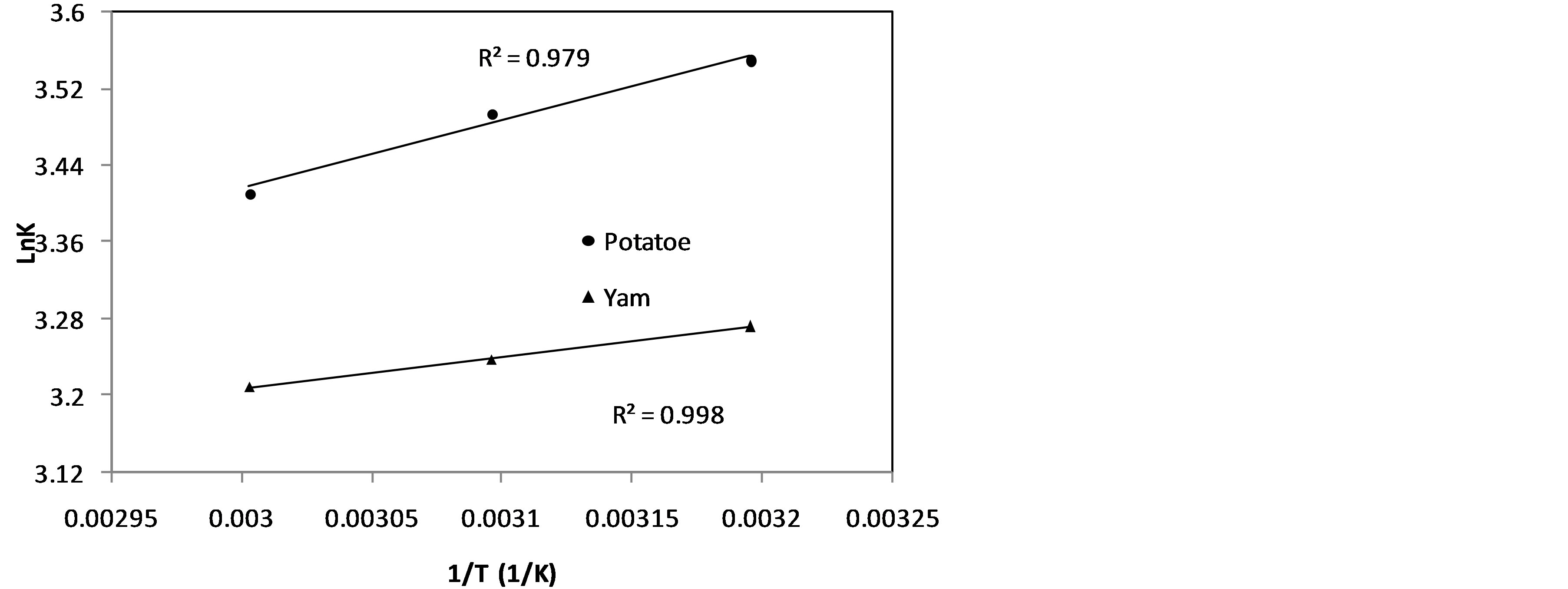

The Casson model gave a relatively poor fit to the experimental data, with R values ranging from 0.899 to 0.967 for yam while a better fit was obtained for potatoes with R values ranging from 0.957 to 0.976. The consistency coefficient, K and flow index behavior, n were both significantly influenced by the change in temperature. The values of both parameters decreased with increasing temperature, except for the flow behavior of yam at the temperatures of 40˚C and 50˚C respectively, agrees in literature that temperature has no effect on the flow index [6] . The decrease in n can be attributed to higher departure from Newtonian behavior [13] . The n values for both yam and potato (0.388, 0.336) and 0.649, 0.631, 0.50) at 40, 50 and 60 respectively: were considerably lower compared to report in literature (0.717) for TME 419 Cassava cultivar. The K values for yam and potato were (26.36, 25.47, 24.77) and (34.75, 32.96, 30.34) respectively at 40˚C, 50˚C and 60˚C, comparable to values in literature [11] (see Figure 6). The temperature dependency of the consistency coefficient was described by an Arrhenius type equation

(3)

(3)

Figure 4. The flow curves of pastes containing 0.83% borax at constant temperature (40˚C).

Figure 5. Shear stress versus shear rate, 0.83% borax, 40˚C.

Figure 6. Shear stress-shear rate relationships for yam and potato paste (forward measurement), Casson model. 0.83 % borax, 40˚C.

where, Ko is the proportionality constant, Ea is the activation energy (KJ/mol), R is the universal gas law constant (KJ/mol×K) and T is the absolute temperature (K). The linear regression analysis was applied to the logarithmic form of Equation (3) (See Figure 7). The activation energy, which measures the sensitivity of the blend viscosity to temperature, was higher for potato (5.87 KJ/mol) than that of yam (2.69 KJ/mol). This indicates that the consistency coefficient of aqueous suspension of yam is more sensitive to the temperature changes. The

Table 1. Experimental and predicted values of power law model of consistency coefficient.

Table 2. Experimental and power law model values of flow behaviour index.

Table 3. Casson model parameters blends constant concentration (0.83%) at different temperatures.

Figure 7. Influence of temperature on apparent viscosity.

activation energy values were also consistent with findings [11] [16] [17] .

4. Conclusion

The results for yam and potato of borax blends exhibited non Newtonian shear thinning fluid. The apparent viscosity of both blends decreased with increasing temperature. The viscosity-shear rate relationship of the yam and potato blends could be successfully represented by the power-law and Casson models. The flow behavior index, n was less than unity but showed no significant effect with increasing temperature for both yam and potato paste while consistency coefficient decreased with increasing temperature. The consistency coefficienttemperature relationship could be described successfully by an Arrhenius-type equation. The consistency coefficient of potato was higher compared to that of yam, indicating less sensitivity to temperature.

Acknowledgements

This work was supported by the Niger Delta University, Bayelsa State, Nigeria.

References

- Ukpaka, C.P., Amadi, S.A. and Gumus, R.H. (2009) Experimental Analysis of the Effect of Preservative Methods of Cassava Starch for Adhesives. Global Journal of Engineering and Technology, 2, 623-634.

- Perry, R.H. and Green, D.W. (1998) Chemical Engineering Handbook. International Edition Section 6, McGraw-Hill, Boston.

- Kerr, R.W. (1950) Chemistry and Industry of Starch. Academics Press Inc., New York.

- Peter, O., Emmanuel, S.A. and Peter, A.I. (2007) Production of Adhesive from Cassava Starch. Leonardo Electronic Journal of Practices and Technologies, 6, 93-98.

- Barnes, H.A. (2000) A Hand Book on Elementary Theology. Institute of Non Newtonian Fluids, Mechanics, Aberystwyth.

- Abu-Jdayil, B. (2003) Modelling the Time Dependent Rheological Behavior of Semi Solid Foodstuffs. Journal of Food Engineering, 57, 97-102.

- Azeez, O.S. (1994) Preparation of Adhesive from Starch. Thesis Obafemi Awolowo University, Ile Ife.

- Grace, M. (1970) Processing of Cassava Food and Agriculture. Organization of the United Nations, Rome.

- Shields, J. (1970) Adhesive Handbook Compiled by SIRA for Ministry of Technology. Butterwogth Group, Krishna Nagar.

- Tonukari, N.J. (2007) Cassava and the Future of Starch. Electronic. Journal of Biotechnology, 7, 37-46.

- Gumus, R.H. and Udezue, D.N. (2011) Investigation of Rheological Properties of Cultivar TME 419 for Potential Adhesive Material. Journal of the Nigeria Society of Chemical Engineering, 26, 78-86.

- Abu-jdayil, B., Shaker, R.R. and Sumah, R.Y. (1994) Rheological Behavior of Concentrated Yogurt (Labneh). International Journal of Food Properties, 3, 207-213. http://dx.doi.org/10.1080/10942910009524628

- Arslan, E., Yener, M.E. and Esin, A. (2005) Rheolgical Characterization of Tahin/Pekmez (Sesame Paste/Concentrated Grape Juice) Blends. Journal of Food Engineering, 69, 167-172. http://dx.doi.org/10.1016/j.jfoodeng.2004.08.010

- Isikli, N.D. and Karababa, E. (2004) Rheological Characterization of Fenugreek Paste (Cemen). Journal of Food Engineering, 69, 185-199. http://dx.doi.org/10.1016/j.jfoodeng.2004.08.013

- Ofoli (1990) Interrelationships of Rheology Kinetics and Transport Phenomena in Food Processing. In: faridi, H. and Faubion, J.M., Eds., Dough Rheology and Baked Products Texture, AVI, New York.

- Heikel, Y. and Chnnam, A. (1990) Rheological Characterization of Tomatoe Puree at Different Temperatures. Journal of Engineering and Food, 1, 151-158.

- Nyghowo, I.V. (2004) Cassava and Future of Starch. Electronic Journal of Biotechnology, 1, 6-8.

Nomenclature

K = Consistency coefficient Kc = Casson viscosity (Pas)

Ea = Activation energy (KJ/mol)

Ko = proportionality constant R = Universal gas constant (KJ/mol·K)

T = Temperature (K)

γ = Shear rate (s)

τ = Shear stress (Pa)

n = Flow behavior index

σ = Shear stress (Pa)

= Casson yield stress

= Casson yield stress

NOTES

*Corresponding author.