Natural Resources

Vol.3 No.3(2012), Article ID:23280,6 pages DOI:10.4236/nr.2012.33021

Cost Optimal Selection of Storage Tanks in LPG Vaporization Station

![]()

Energy and Power Engineering Department, North China Electric Power University, Baoding, China.

Email: lucksgh@126.com

Received May 4th, 2010; revised June 3rd, 2011; accepted June 17th, 2011

Keywords: Liquefied Petroleum Gas; Storage Tank; Cost Optimization; Mixed Integer Nonlinear Programming

ABSTRACT

Liquefied petroleum gas (LPG) is an important urban gas source in China. Before supplied to customers by pipeline supply systems, LPG is stored in tanks in LPG vaporization stations. Designers usually decide the number and the size of storage tanks by their experience during constructions of vaporization stations. These decisions are usually not best and most economical. To solve the problem, a compact mixed integer nonlinear programming model has been developed in this paper. The objective is to minimize annual storage cost of the vaporization station. The model has been transformed into a general nonlinear programming model by transforming integer variables and 0 - 1 variables into continuous variables. One LPG vaporization station was taken as an example to illustrate the usage of the model. The results show that the optimal storage scheme can be determined accurately and quickly by the model and about 15% of storage cost can be saved every year after optimization.

1. Introduction

There were several hundred millions of people using solid fuels (biomass and coal) partially or exclusively for cooking and heating in China, most of these in rural areas, in 2007 [1]. The long-term and mass combustion of solid fuels makes the country suffer serious air pollution. Cooking with liquid or gas fuels is a strategic choice to reduce the level of atmospheric pollution, as well as to improve people’s living standard. Therefore, the Chinese government has been taking firm steps to develop its urban gas industry [2-4].

With some advantages, such as convenient transportation, easy operation, high energy density, and low pollution, liquefied petroleum gas (LPG) is a principal residential fuel for a lot of Chinese people not served by natural gas infrastructure [5]. In 2007, LPG was available in more than 90% of total cities and 7.3 million tons of LPG was consumed for households in China [6].

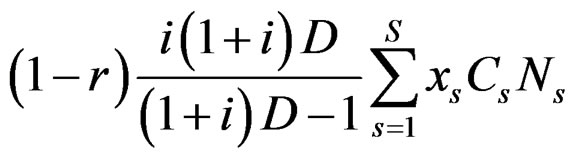

In China, a considerable portion of LPG is supplied to customers by a LPG pipeline supply mode (see Figure 1). LPG is firstly delivered from LPG import terminals or LPG plants to a vaporization station by tank trucks, and then unloaded and stored in cylindrical shaped LPG storage tanks. LPG in storage tanks is pumped into heated vaporizers and converted into gaseous LPG. After gas-liquid separation, the gas is regulated to a required pressure, and then transported to customers via a local gas distribution network.

Obviously, storage tanks ensuring reliable gas supply are key equipments of an LPG vaporization station. During constructions of LPG vaporization stations, designers usually decide the number and the size of storage tanks by their experience. Due to various sizes of LPG storage tanks, however, there are several selection schemes with different costs to meet the same storage requirement. The cost-optimal selection scheme is very important to increase the profitability of the LPG pipeline supply mode. At present, lack of a tool to evaluate the decision on the selection of storage tanks is a big barrier to build LPG vaporization stations in China.

In this paper, a mixed integer nonlinear programming (MINLP) model is developed. The model minimizes the annual storage cost of a LPG vaporization station in consideration of guaranteeing its normal and safe operation. To solute this model conveniently, integer variables and 0-1 variables are transformed to some continuous variables. In order to illustrate the mathematical model, the economically optimal selection of storage tanks is done for a LPG vaporization station in Guangdong, using a mathematical software package LINGO [7], and results are analyzed.

2. Methods

The objective of the model is to improve the aforementioned supply mode’s profitability by minimizing the annual storage cost of the vaporization station. The storage cost minimization is accomplished by determining a combination scheme of storage tanks. For solving this problem, the following steps are required [8,9]:

• defining the appropriate objective function• determining the related constraints.

Section 2.1 and Section 2.2 show parameters and decision variables that are used in the MINLP model, respectively.

| 2.1. Parameters S | The number of sizes of LPG storage tanks which can be used in the vaporization station, where s is the index for sizes, such that s = 1, ···, S. | ||

| Cs | Initial cost of a sth LPG storage tank. | ||

| Vs | Volume of a sth LPG storage tank. | ||

| i | Market discount rate. | ||

| r | Residual value rate of LPG storage tanks. | ||

| D | Depreciable life of LPG storage tanks. | ||

| Kmi | Ratio of annual management cost of storage tanks to initial cost of storage tanks. | ||

| Kmd | Ratio of annual maintenance cost of storage tanks to annual depreciation charge of storage tanks. | ||

| Gd | Average daily gas consumption in the design month (i.e. month of maximum average daily gas consumption). | ||

| ηs | Maximum filling ratio of a sth storage tank at its maximum operating temperature. | ||

| 2.2. Decision Variables Ns | The number of sth LPG storage tanks in the vaporization station. | ||

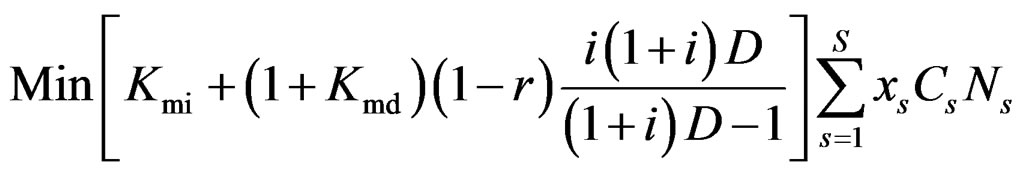

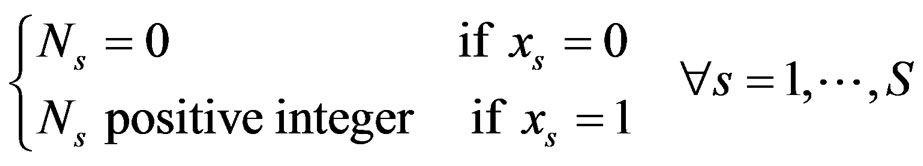

The following notation shows that a sth storage tank is used or not in the LPG vaporization station:

2.3. Objective Function

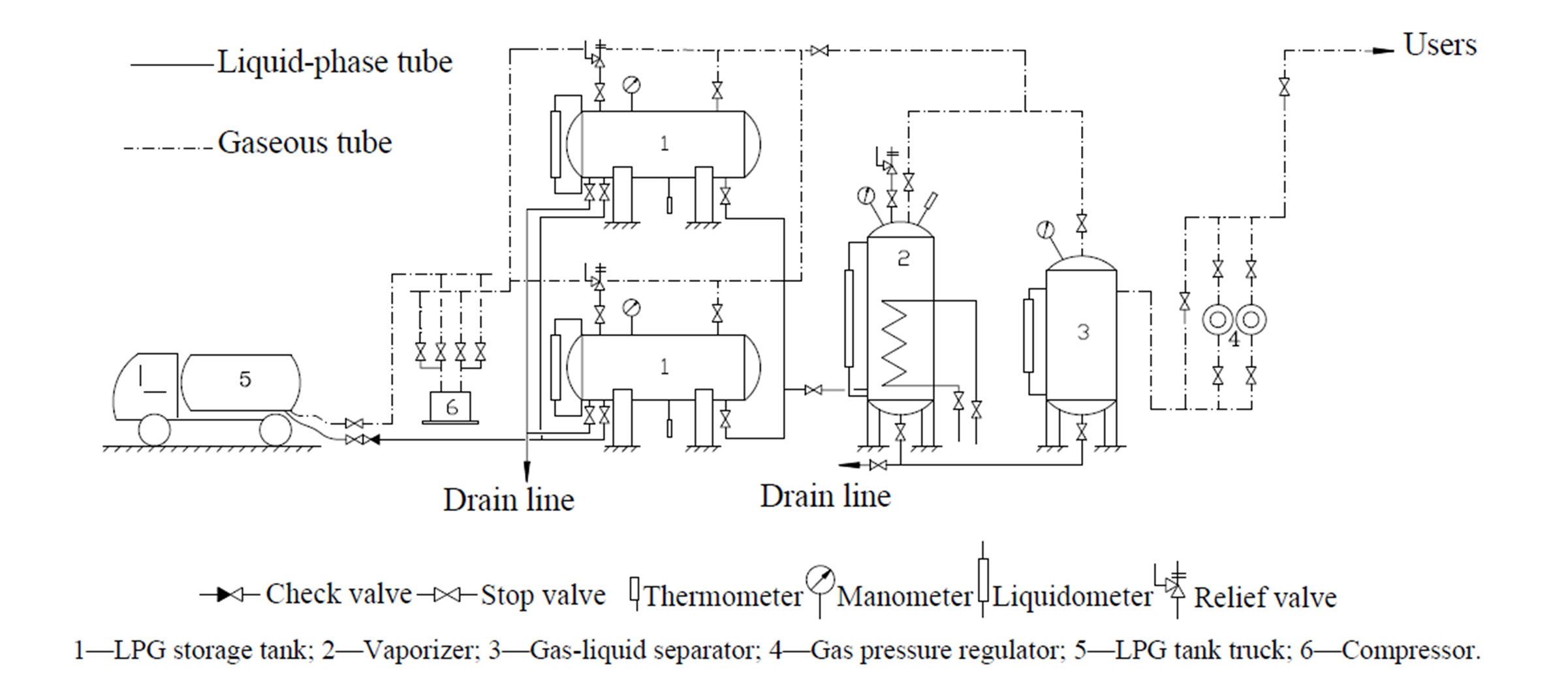

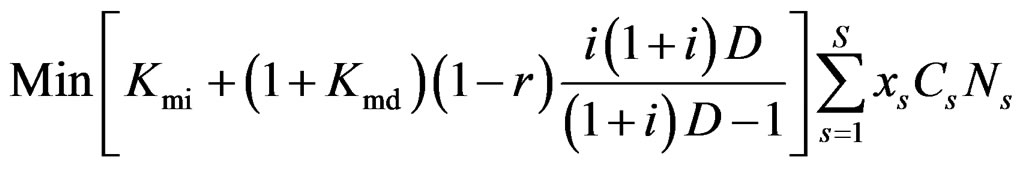

The objective function minimizes the annual storage cost of the LPG vaporization station.

In this paper, it is supposed that no funds are borrowed to buy and install LPG storage tanks. Therefore, for each LPG vaporization station, its annual storage cost consists of fixed costs (i.e. annual depreciation charge of storage tanks) and variable costs which include annual maintenance cost of tanks and annual management cost of tanks. For convenience, annual maintenance cost of storage tanks is calculated by multiplying their annual depreciation charge by a ratio, while their annual management cost is expressed by a proportion of their initial cost.

We assume that there are S possible sizes of LPG storage tanks and the residual value rate and the depreciable life are same for each tank.

Considering the time value of money, the annual depreciation charge of storage tanks is given by the following equation:

(1)

(1)

The objective function is then formulated as follows:

(2)

(2)

2.4. Constraints

Bad weather, such as flood, rain, fog and snow, may prevent LPG tank trucks from transporting LPG to vaporization stations timely. In consideration of adverse

Figure 1. Schematic diagram of the LPG pipeline supply mode.

weather factors, therefore, keeping a safety reserve in each vaporization station should be considered sufficient to guarantee the station’s ability to supply stable and enough LPG to consumers. In addition, the safety reserve is also used for meeting peak loads.

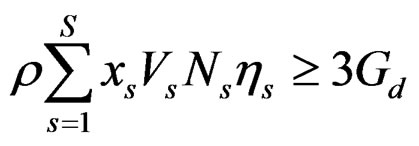

Reference [10] specifies the LPG storage capacity in one vaporization station, which is described as follows:

• If the LPG is supplied by LPG plants, the storage volume of LPG should be determined based on some factors, such as the gas supply scale of the vaporization station, the production situation of plants, the distance from plants to the station, etc.

• If the LPG is supplied by LPG import terminals, the storage volume of LPG should be triple of average daily gas consumption in the design month.

It is clear that the storage capacity of storage tanks in the station must be no less than the required safety reserve.

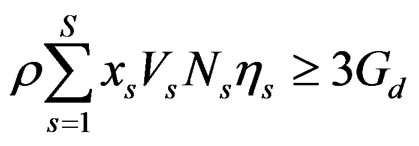

According to the investigation, a storage volume of fifteen times average daily LPG consumption is regarded as reasonable for a vaporization station which LPG is supplied by LPG plants [11]. Therefore, if LPG plants are suppliers, the storage capacity restriction is shown in (3):

(3)

(3)

If LPG import terminals are suppliers, the storage capacity restriction is as follows:

(4)

(4)

where ρ is the density of liquid LPG at the maximum operation temperature of storage tanks. In China, LPG storage tanks are generally equipped with fixed spray cooling devices, so that their maximum operation temperature is 40˚C.

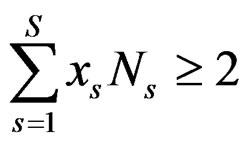

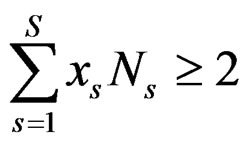

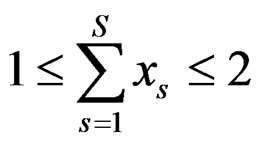

Reference [10] also requires that the number of storage tanks should not be less than two in each station. Installing two or more tanks in a station has two reasons. The first is that gas supply will not be interrupted when one tank is maintained. The other is that the LPG in a storage tank can be transported to other tanks when it has a dangerous fire and explosion risk. The constraint of the number of tanks is shown in (5):

(5)

(5)

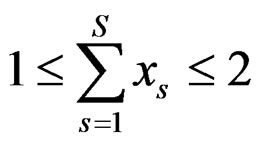

The corresponding management cost will rise with the sizes of storage tanks applied in the station. Additionally, using more sizes of tanks will make the management more difficult. Thus, we assume that one station has no more than two sizes of storage tanks at best. The constraint can be described in the following equation:

(6)

(6)

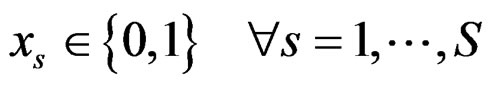

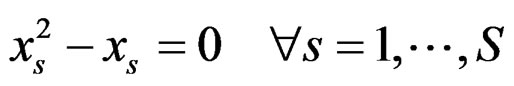

Equations (7) and (8) are the non-negativity and integer requirements for decision variables (xs, Ns). Note that the model can set Ns = 0 if the size sth LPG storage tank is not used in the vaporization station.

(7)

(7)

(8)

(8)

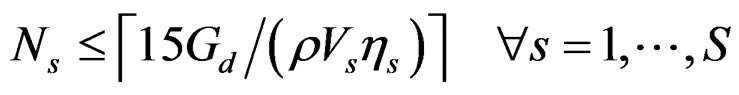

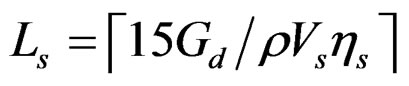

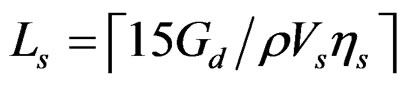

Furthermore, the following equation holds according to (3) and (4):

(9)

(9)

Here  denotes up-rounding (the next higher integer). Equation (9) can limit the value range of Ns, which contributes to cutting the solution time of the model.

denotes up-rounding (the next higher integer). Equation (9) can limit the value range of Ns, which contributes to cutting the solution time of the model.

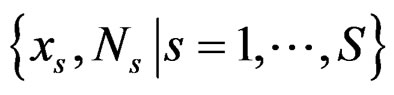

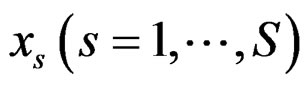

The optimization problem is to select the values of decision variables  that minimize the annual storage cost subject to (3)-(9).

that minimize the annual storage cost subject to (3)-(9).  are pure 0-1 variables, while

are pure 0-1 variables, while  are bounded integer variables.

are bounded integer variables.

2.5. Conversion of the Model

The developed model is a mixed integer nonlinear programming model. Because the value areas of variables are finite sets of discrete points, the solutions of MINLP problems are complicated and time-consuming [12,13]. However, there are many fast solution algorithms for general nonlinear programming (NLP) problems, such as variable metric algorithm, penalty function algorithm, trust-region algorithm, etc. [14]. For more convenience, we transform integer variables and binary variables to continuous variables using approaches suggested in [15] and [16]. Then, the proposed model is converted into a general nonlinear programming form.

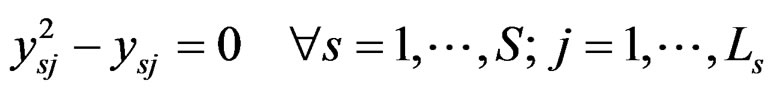

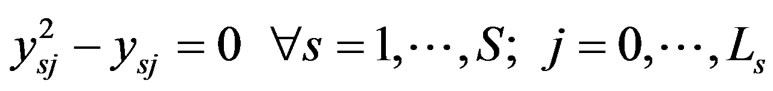

Every binary variable with values in {0,1}, xs, can be rewritten equivalently as the following quadratic equality:

(10)

(10)

Therefore, (7) can be substituted by (10).

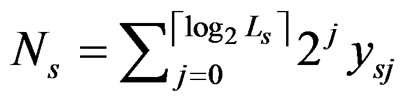

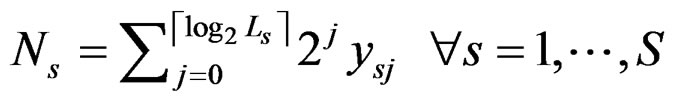

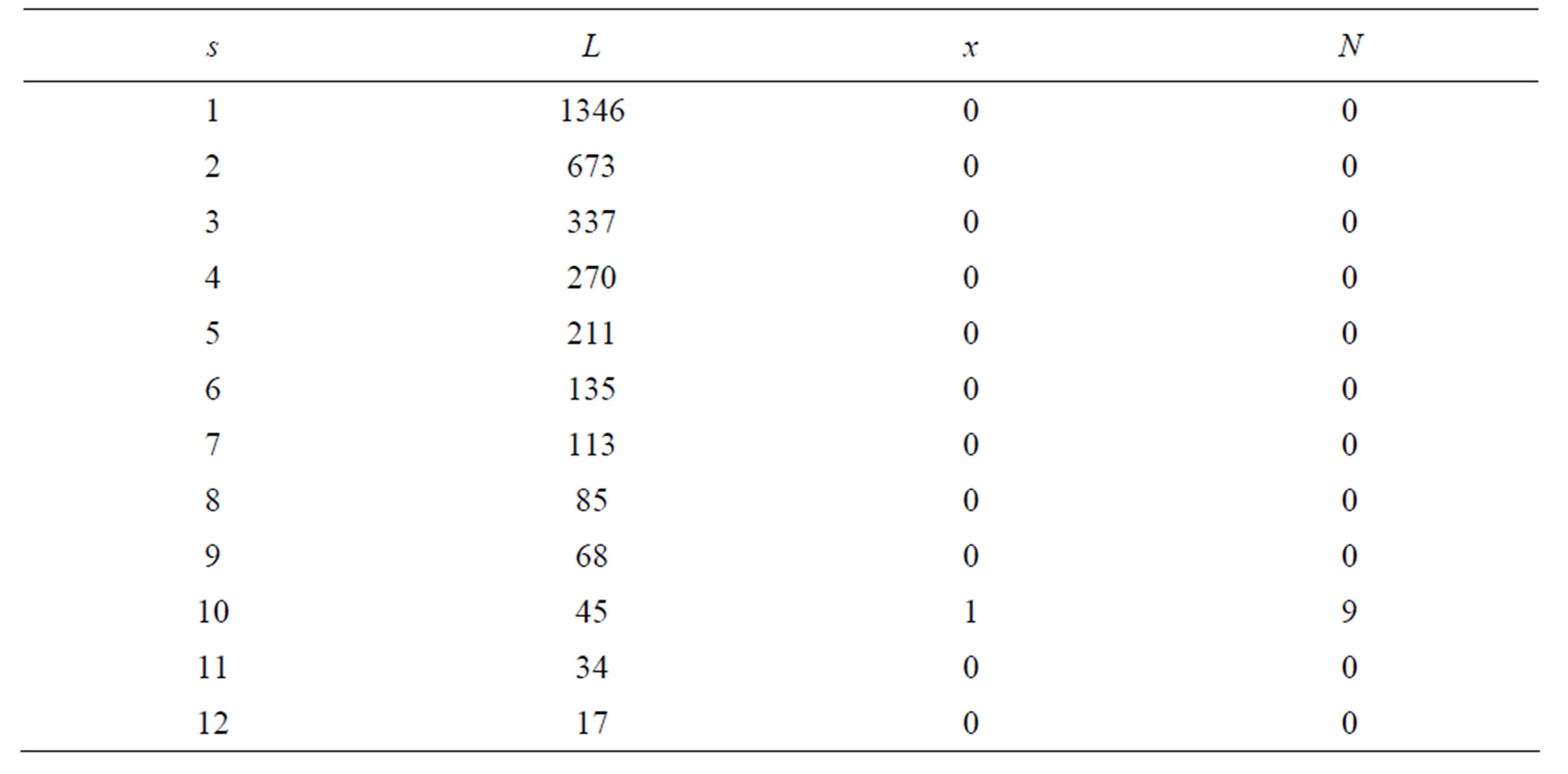

It is clear that each Ns in the model is a bounded integer variable. Without loss of generality, we write Ns in binary form, introducing new 0-1 variables ysj.

(11)

(11)

where Ls is the upper bound of Ns.

(12)

(12)

Each new 0-1 variable, ysj, can also be rewritten equivalently as follows:

(13)

(13)

Then, we can substitute (9) by (11)-(13).

After the above transformations, all integer variables and binary variables in the model are transformed to continuous variables.

2.6. Model

Considering the above sections, the whole mathematical model is as follows:

Subject to

or

or

The above model is in the general nonlinear programming form.

3. Results and Discussion

An illustrative example of the model usage is conducted as follows. It is a LPG vaporization station in Guangdong province of southern China, vaporizing the LPG from an import terminal and supplying gas at 0.14 MPa to ten thousands of households and hundreds of ceramic enterprises via local gas distribution pipelines.

3.1. Values of Parameters

The station supplies 179,320 kg LPG daily and the local maximum uneven factor of monthly gas consumption is 1.2. The product of the two data is the average daily gas consumption in the design month [17], i.e. Gd is 215,184 kg/d.

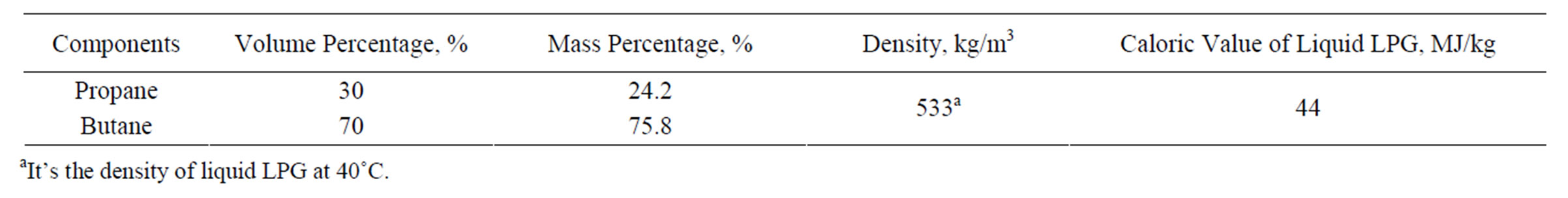

The physical parameters of the LPG are summarized in Table 1.

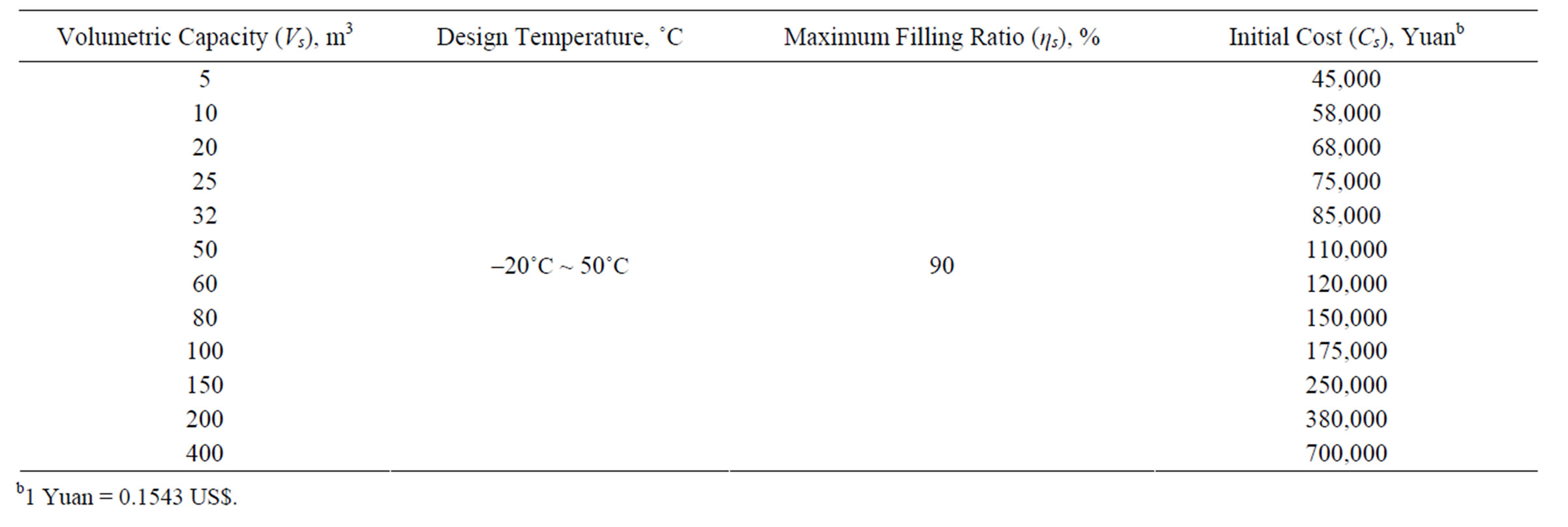

In China, the design pressure of tanks for LPG is 1.8 MPa and horizontal cylindrical storage tanks are generally used in LPG vaporization stations. Hence, LPG storage tanks just fall into several sizes by volumetric capacity in the example. All sizes of horizontal cylindrical storage tanks for LPG and their parameters are shown in Table 2.

From Tables 1 and 2, the values of some parameters used in the model can be obtained, such as ρ, S, Vs, ηs and Cs (s = 1, ··· , S). Based on some researches on cylindrical LPG storage tanks on the market, the depreciable life of storage tanks is taken as 20 years and the residual value rate is 4%. In this paper, market discount rate, i, is expected to be 3.87%.

According to experience gained from the construction and operation of domestic LPG vaporization stations, Kmi and Kmd are 5% and 30%, respectively.

Table 1. Physical parameters of LPG.

Table 2. Summary of LPG storage tanks in China.

Table 3. Values of some variables.

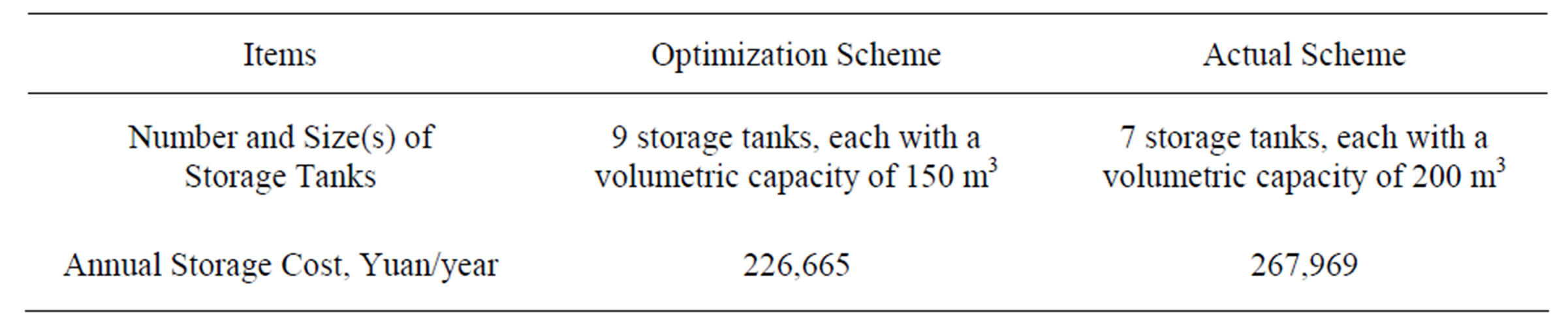

Table 4. Optimization results and comparison.

3.2. Solution and Results

To solve the optimal selection problem of storage tanks, the mathematical model were coded using LINGO 8.0. After importing the above values of parameters to LINGO, the values of variables were output by running the coded model (Table 3). The minimum annual storage cost and the optimal selection scheme of storage tanks for the vaporization station are presented in Table 4. The actual storage scheme of the station and its corresponding storage cost are also listed in the table.

From Table 4, it can be noted that using nine storage tanks with a total volumetric capacity of 1,350 m3 is the economic optimal storage scheme for the LPG vaporization station. After optimization, the annual storage cost is 226,665 Yuan/year which is about 85% of that of the actual storage scheme. It is also concluded that the optimization scheme can make more full use of storage tanks than the actual scheme, because the latter has a higher total volumetric capacity of tanks.

4. Conclusions

In this study, a mathematical model has been developed to help LPG vaporization stations select optimal mix of storage tanks. It minimizes the annual storage cost, guaranteeing the normal and safe operation of stations. For convenience in solving the MINLP model, it is transformed to be in the general nonlinear programming form. According to the analysis in this study, the following conclusions can be obtained:

• Each LPG vaporization station has its optimal selection scheme of storage tanks considering of the minimum annual storage cost.

• Using the mathematical model, the optimal storage scheme can be determined accurately and quickly.

Furthermore, minimizing annual storage cost can cut the LPG price for users under other same conditions. This will reduce the subsidy on residential LPG from the central government and contribute to extending the market for household LPG use in poorer areas in China.

5. Acknowledgements

This research was supported by the Fundamental Research Funds for the Central Universities (No. 11MG45).

REFERENCES

- National Bureau of Statistics, “China Statistical Yearbook (2008),” China Statistics Press, Beijing, 2008.

- L. W. Jiang and B. C. O’Neill, “The Energy Transition in Rural China,” International Journal of Global Energy Issues, Vol. 21, No. 1-2, 2004, pp. 2-26.

- Q. Y. Zhang, “Residential Energy Consumption in China and Its Comparison with Japan, Canada, and USA,” Energy and Buildings, Vol. 36, No. 12, 2004, pp. 1217-1225. doi:10.1016/j.enbuild.2003.08.002

- J. W. K. Wong, “City-Gas Development in China—An NG Perspective,” Energy Policy, Vol. 38, No. 5, 2009, pp. 2107-2109. doi:10.1016/j.enpol.2009.06.001

- J. F. Zhu and C. G. Duan, “Application of Solar Energy to LPG Vaporizer,” Gas and Heat, Vol. 25, No. 10, 2005, pp. 13-15.

- Ministry of Housing and Urban-Rural Development of the PRC, “China’s Urban Construction Statistical Bulletin (2007),” China Architecture & Building Press, Beijing, 2008.

- LINGO Systems Inc., “Lingo User’s Guide,” Chicago, 2000.

- S. S. Rao, “Optimization: Theory and Applications,” 2nd Edition, John Wiley, New York, 1984.

- G. Y. Shi and J. L. Dong, “Optimization Methods,” High Education Press, Beijing, 1999.

- Ministry of Housing and Urban-Rural Development of the PRC, “Code for Design of City Gas Engineering,” China Architecture & Building Press, Beijing, 2006.

- G. H. Shi, “Study on Non-Pipeline Gas Supply for Middle-Small Town,” M.S. Thesis, North China Electric Power University, Baoding, 2005.

- K. Aardal, R. Weismantel and L. A. Wolsey, “NonStandard Approaches to Integer Programming,” Discrete Applied Mathematics, Vol. 123, No. 1-3, 2002, pp. 5-74. doi:10.1016/S0166-218X(01)00337-7

- Q. L. Wu and N. R. Xie, “A New Method for Solving a Class of Nonlinear Integer Programming Problems,” Control and Decision, Vol. 12, No. 2, 1997, pp. 97-108.

- G. H. Xu and Y. Liu, “Handbook of Operations Research Fundamentals,” Science Press, Beijing, 1999.

- D. Bertsimas, G. Perakis and S. Tayur, “A New Algebraic Geometry Algorithm for Integer Programming,” Management Science, Vol. 46, No. 7, 2000, pp. 999-1008. doi:10.1287/mnsc.46.7.999.12033

- Z. Q. Meng, Q. Y. Hu and X. Q. Yang, “A Method of Non-Linear Penalty Function for Solving Integer Programming and Mixed Integer Programming,” Control and Decision, Vol. 17, No. 3, 2002, pp. 310-314.

- C. G. Duan, “Transportation and Distribution of Gas,” China Architecture & Building Press, Beijing, 2001.