Journal of Water Resource and Protection

Vol.06 No.14(2014), Article ID:50581,8 pages

10.4236/jwarp.2014.614115

A Grey Water Dam Design for the Treatment and Reuse of Grey Water from Single and Multiple Households

Ababu Teklemariam Tiruneh

Department of Environmental Health Science, University of Swaziland, Kwaluseni, Swaziland

Email: atiruneh@uniswa.sz

Copyright © 2014 by author and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 25 August 2014; revised 21 September 2014; accepted 6 October 2014

ABSTRACT

An innovative design for the treatment and reuse of grey water is presented in the form of a grey water dam which is an outgrowth of the vertical grey water tower. A hydraulic equation has been formulated and is presented in this paper which is used to determine the seepage path within the grey water dam, and determine the dimensions of the dam components. The hydraulic equation model also helps in avoiding soil piping problems by keeping the phreatic line within the grey water dam. Vegetables are planted around the surface of the dam as a reuse option while helping recycling of water in the form of evapotranspiration. A successful pilot trial of this dam was run in Mnyamatsini area in Swaziland which can accept grey water from multiple households.

Keywords:

Grey Water, Water Reuse, Water Recycling, Wastewater Treatment, Pollution, Environmental Protection

1. Introduction

Water scarcity is a pressing problem being faced all over the world that prompted the need for conservation of water including the use of grey water [1] . Grey water is part of the wastewater generated from household water using activities including bathing, hand basins, washing machines, dish washing, laundry and kitchen [2] . Grey water does not include water from toilets. Grey water volume is often high (accounts for 50% - 80% of the water volume) and is less polluted. It is, therefore, considered as a potential source for water reuse option [3] -[6] . Reuse of grey water is being practiced in many countries because of the need for water saving and as a way of management to reduce transport of pollution to other areas. Water savings ranging from 10% - 80% have been reported as result of grey water reuse [6] -[8] . Public acceptance of grey water is more for uses such as gardening and toilet flushing [6] . The advantage of irrigation/agricultural reuse of grey water besides public acceptance is that there is less need for advanced treatment such as for the removal of nitrogen and phosphorus which are in fact needed for plant growth [9] .

However, despite the potential for reuse, the actual reuse practice of grey water is restricted by a number of factors. In many countries, including Swaziland, there are no standards for grey water reuse except for the water quality standards which are established for potable water supply and which may be too stringent standards for some grey water reuse demands such as toilet flushing and gardening. Treatment technologies for grey water treatment are not standardized and it is difficult to validate the efficiencies of treatment of some these technologies advocated due to the dispersed, proprietary and private nature of these technologies [10] . Regulations on grey water reuse are mostly available in developed countries and where plenty of water exists such as rain water, people often prefer to use such alternative water sources because of the high quality of water from these sources. There are also expressed objections or fear about the reuse of grey water.

Grey water studies tend to concentrate on reuse aspects. Information about grey water quality in terms of broad range of pollutants is often inadequate [11] . However, grey water apparently contains significant amounts pollutants in terms suspended solids, organic and inorganic chemicals originating from soap, shampoo, hair dyes, toothpaste, nutrients and from other cleaning products, BOD/COD, nutrients and microorganisms. Grey water as such poses a threat to health and the environment [6] [12] [13] . Grey water microbial pollution is detected in practically all streams of grey water including kitchen, bathing and laundry [14] . According to Katukiza et al. [12] , fecal coliform and total coliform concentrations of 7 and 8 logs respectively have been reported for grey water containing bathing water.

There are many types of technologies available for grey water treatment. Technologies that have been cited for grey water treatment include filtration, disinfection, membrane bio reactors, electro-coagulation, constructed wet lands, planted filter, soil filters, soil bio-technology, etc. [2] . Constructed wet land systems and soil filters employ natural processes for treatment and produce effluent of good quality with lower maintenance costs and energy savings.

According to Ushijima et al. [9] , pathogen removal by soil filter system is highly dependent on soil texture. Fine soils are able to remove pathogens to a greater degree while in coarse soils pathogens can survive and pass through the filter. For pathogen removal through soil systems, 2 - 5 log10 reduction of E. coli has been reported in fine soils whereas there was little removal of E. coli in coarse soil [9] . According to Kadam et al. [15] , Coliform removals ranging from 2 - 4 logs were achieved in soil filters with limited detention time in the filters ranging between 1 and 2 hours. Nelson [16] stated that constructed wetlands employing any of the range of media in use including soil, sand and gravel can be designed for at least 2 log removal of coliforms bacteria (99% removal). The pathogen reduction requirement of wastewater reuse for agriculture, according to WHO guideline [17] is pathogen reduction achieving 3 - 4 log reduction of E. coli (99.9% and 99.99% removal) within the soil in addition to <1 helminthes/egg per 100 gm of soil with an infection risk of 1 in 1000 [9] .

Removal of particulate COD in slanted soil treatment system has been reported to be high (94% - 97%) while removal of dissolved COD was comparatively lower (58% - 68%) [9] . COD removal rates constants through slanted soil filters are linearly related with flow rates [9] . The COD removal kinetics follows first order kinetics which can be used for determining the detention time required for a design removal rate of COD. Earlier studies by Etayamal et al. [18] of a soil filter for the treatment of high strength kitchen waste reported removal rates of 67% for the BOD and 78% for suspended solids with residual concentrations existing over and above published standard values for the reuse of grey water. Kadam et al. [15] reported BOD and COD removal efficiencies of soil filters of 90% and 80% respectively. Ammonia was removed 80% while suspended solids removal was 93%. Constructed wet lands may be designed with expected removal of COD up to 75% and BOD removal up to 95% [16] . Because of the high ratio of COD/BOD for grey water compared to wastewater, evaluation of grey water treatment efficiencies shall also account for COD removal [19] .

Regarding soil texture, a combination of fine and soil texture is being suggested for soil filters [9] . Too fine soil results in clogging even though pathogen and suspended solids removal may be the highest. In addition, suspended solids in grey water after preliminary treatment tend to be fine and require fine solids media texture for their removal. Too coarse soil texture minimizes clogging while on the downside flow through coarse soil texture enhances pathogen survival. Kadam et al. [15] reported hydraulic conductivity of soil filters ranging between 2 × 10−6 and 3 × 10−6 m/sec whereas the percentages of clay, silt, sand and gravel in the soil filter used for the study were 23%, 25%, 40% and 12% respectively. According to EPA [20] , the media used for constructed wetlands range between sand (2 mm) and gravel up to a size of 128 mm. A standard size media for constructed wetland system in Ohio [21] is a pea size grave ranging in size between 1.9 - 2.5 cm overlain by a top soil which is peat or mulch. Design aspects of grey water reuse must take account of the fact that the volume of grey water disposed may well exceed the reuse requirements [2] . A feature of grey water dam design described in this paper includes a provision for partial seepage of water underground in order to allow more water to be disposed into the dam.

2. The Study Area

The grey water dam designed and presented in this paper was undertaken as a pilot research project in the Mnyamatsini area in Swaziland whereas the research project is part of the Mbabane dry Sanitation and Waste Management Project which is funded by the Government of Finland. Mnyamatsini is a peri-urban settlement area existing near the capital city of Swaziland and has an estimated population of 10,000. A centralized system of wastewater disposal is not extended to the area which was one factor in the inclusion of grey water disposal as a project priority. Most of the households in the community have large space that can be used for urban agriculture while some members of the community do practice gardening. A perennial source of water exists from mountain streams that are diverted by gravity to satisfy the water supply needs of the community. Water is available abundantly except during the rainy season when occasional quality problems may be experienced. However, the abundance of water and the very low to non-existent fee for its abstraction has meant water is used in plentiful quantities and the grey water production is high.

Most of the households have yard tap connections with very few households having house connections. This implies that the grey water generated is segregated from other wastewater such as toilet water and is disposed separately. This aspect is convenient for grey water treatment which calls for segregation of grey water from other types of wastewaters. In addition the different grey water components are also disposed separately. Most of the households dispose the grey water produced inside the compound by splashing away the water. There is hardly any constructed system for grey water disposal except for a septic tank system available in few households with housing connections. The level of education and awareness about the health and environmental impact of grey water is low according to the baseline assessment study conducted. Except for few households that use grey water for gardening, grey water is disposed with no intention for reuse. The availability of water in plentiful quantities coupled with the very low fee for its abstraction means people have little incentive for reusing water. Any reuse attempt, therefore, should be combined with other benefits such as growing plants. The area can be considered as a low income area compared to the households in the main city. Grey water disposal systems should therefore, take into account the low ability of people to pay for such technologies.

This research work was undertaken with the objective of developing a grey water disposal system that is appropriate and affordable to the community while combining grey water disposal with reuse such as growing plants. A grey water dam was designed as an extension of the well-known grey water tower with the objective of handling greater volume of grey water, achieving better treatment and producing greater yield of plants using the grey water. The grey water dam consists of a central gravel distribution column surrounded by a partially compacted soil which is a mixture of ash, manure and fine/coarse soil mixture. A toe drain is provided in the bottom section of the conically shaped dam in order to keep the seepage line (phreatic line) below the surface. The sectional sketch of the grey water dam is given in Figure 2. Grey water after pretreatment enters the gravel column and is distributed outwards through the soil and is eventually used by plants that grow on the surface of the dam. The description of the grey water dam and its design is given below.

3. Materials and Methods

3.1. Development of Hydraulic Equation of Seepage in Grey Water Dam

A section through a grey water dam is shown in Figure 1 and consists of the central gravel cylindrical column AEFG, the soil section ACBE and the gravel toe drain CBD. The central gravel column has a diameter of

while the dam height is

while the dam height is . The radius of the dam is

. The radius of the dam is

and the angle of inclination of the grey water dam is

and the angle of inclination of the grey water dam is . The length of the toe drain measured along the dam surface is

. The length of the toe drain measured along the dam surface is .

.

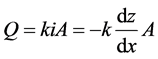

Assuming that the seepage line is along CD in the toe drain BCD, the hydraulic gradient for this seepage path can be written as:

Figure 1. Grey water dam section with the dimensional symbols and sketch of the phreatic line.

Figure 2. Vertical section of the grey water dam design.

The discharge through the toe drain face CB can be written using Darcy’s Law:

where

is the permeability of the soil and

is the permeability of the soil and

is the cross sectional area of flow at the face CB.

is the cross sectional area of flow at the face CB.

The Area,

is given by:

is given by:

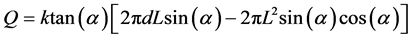

The discharge now becomes:

(1)

(1)

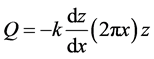

The discharge through upstream section within AEBC at a distance

from the center is given by:

from the center is given by:

(2)

(2)

Equating the discharges in Equations (1) and (2) using the principle of flow continuity:

Integrating the expressions in Equation (3) above between the boundaries of the upstream flow section AEBC:

The above expression after integration and elimination of the common term

Equation (4) above is solved for the drain length

After substituting the above dimensions, Equation (4) takes the form:

The above equation was solved for the unknown

Since

The discharge through the grey water dam is given by:

For the given dimension of the pilot grey water dam, this discharge will be:

For the measured maximum seepage rate of 2 m3/day, the corresponding permeability will be:

This corresponds to the permeability of a medium texture, sandy loam soil.

The volume of the saturated portion of the dam can be calculated from

Expressing the horizontal distance

The expression for the volume then becomes:

The integral expression in Equation (5) above does not have analytical solution. Therefore, the five point Gaussian Quadrature formula is used to evaluate the integral as shown in Table 1.

The volume then becomes:

Table 1. Calculation of volume integral using five point gaussian quadrature formula [23] .

The detention time for flow rate 2 m3/day will be

Therefore, at peak grey water discharge rate, the detention time of water in the grey water dam is approximately 2.4 days.

3.2. Construction of the Pilot grey Water Dam

The constructed grey water dam shown in Figure 2 has a central gravel column of 30 cm diameter and runs throughout the depth of the dam which is about 1.10 meters. The size of the grave is about 2 cm (#19 crashed gravel) and is course enough to allow the grey water to easily flow in the column space while providing some solid storage capacity. The gravel column is preceded by a pretreatment. In this pilot setup a limited pretreatment in the form of crashed gravel of 1 cm size of 50 cm depth is provided at the distribution tank in addition to a coarse screen made of cloth provided at the top of the tank. The detail of possible pretreatment modification will be discussed later.

The top width of the dam provided is about 1.3 meters. Preliminary evaluation with lesser width at the given height and slope were associated with piping problems and were later corrected after hydraulic equation was used to verify the proper dimensions. The outer surface slope of the dam provided is 2 H:1 V (2 horizontal to 1 vertical). It was also observed from the preliminary trials that surface slopes steeper than 2:1 resulted in piping problems particularly at the top section of the dam. Hydraulic equation was used to determine the positions and dimensions of the gravel toe drain and the associated seepage path. In addition an extra top width was provided for safety (see Figure 2).

The grey water dam was constructed with a conical wooden framework having the height, top and bottom width dimensions the same as the dam but which is extended to a depth of 0.5 m below the ground surface. An impermeable polyethylene plastic layer was provided at the bottom of the cone to prevent seepage. Alternatively a semi-permeable geo-textile can also be placed if seepage (recharge to ground water) may be allowed to pass excess and treated grey water to the ground.

The gravel is placed at the center inside a 30 cm diameter bucket with an open bottom and on the outside of the bucket a suitable soil, manure and ash mixture is placed and mildly compacted while some moisture was being sprinkled. In the pilot setup used, the soil used in the dam had a mixture of 1 part of ash to 2 part of manure to 3 part of soil in a manner similar to the vertical grey water dam. At the bottom section, a gravel toe drain was provided with dimension of 60 cm into the dam and having a height of 50 cm above the ground for the purpose of keeping the seepage line below the surface of the dam. Once the soil and grave were filled, the bucket was lifted up and the process of placing the gravel and soil and mild compaction continued within the conical wooden framework towards completion of the dam. Figure 2 shows the sectional drawing of the grey water dam design used for the construction of the pilot setup.

The soil mixture used must be uniform in order to have uniform seepage of grey water around the dam, for the uniform deposition of pollutants and uniform treatment conditions within the dam section. Otherwise flow may be end up being restricted to a limited section of the dam which will restrict the flow and in some cases might result in piping problem. Once the dam was completed, sprinkling of the dam from the top helped in opening up the pores and facilitating grey water flow. The outside bottom of the dam was surrounded with stones to prevent bottom erosion. In addition layers of grass were placed on the dam surface to stabilize the slope.

The water has to be fed to the dam slowly because movement of water in soil is rather slow. In flowing through the soil, the grey water undergoes treatment (physical, chemical and biological). The water gradually and eventually wets the inside and surface of the dam without actually flowing out (an undesirable phenomenon called piping out of soil). The original design that had a steeper slope had to be changed after hydraulic equation model given above was used because the slope was found to be too steep and resulted in piping out of the soil at the top and middle sections because the flowing water surface line within the dam could not be contained completely inside the dam and appeared to intersect the dam outer surface slope before it actually reaches the dam bottom.

4. Results and Discussion

The pilot grey water dam was constructed inside a homestead shared by five households and is located within Mnyamtsini area. Grey water generated within the households is brought by the members of the homestead and is discharged onto the common tank provided. The water supply to the homestead is in the form of a yard tap connection and earlier grey water generated used to be splashed within the compound. As part of the Mbabane Dry sanitation and waste Management project education campaign, members of the household have been given education on the importance of health, hygiene and sanitation as well as proper disposal of grey water involving grey water treatment and reuse.

A photograph of the constructed grey water dam with plantation after about a month of operation is shown in Figure 3. The concrete tank on the background is the grey water tank that also contains the pretreatment black screen cloth shown on top and the crashed gravel of 1 cm size provided inside the tank. A surface pipe extending from the bottom of the tank and downwards to the center of the gravel column in the grey water dam feeds the grey water to the dam. However, the storage tank is not uniquely provided for the grey water dam alone. It was initially constructed for another grey water treatment model, a multi-step filter followed by planted filter shown on the left of the photo. A more suitable arrangement would be a drum containing the pretreatment unit and connected to the grey water dam through a bottom pipe rather than the top surface pipe.

A seepage test was conducted from time to time and it was found out that for the configuration used in the pilot set up about 2000 liters of water can be accepted by the grey water dam on a daily basis. With a daily per capita use of 100 liters per day and with an average family size of 4, this rate corresponds to grey water generated from 5 households with the conservative assumption that all the water used ends up as grey water.

The intermittent nature of the grey water generation from the yard tap water connection suits the grey water dam as air is drawn during part of the time when grey water is not supplied to the dam and facilitates aerobic breakdown of organic matter within the grey water dam. It is essential that water is fed slowly into the grey water dam. Supplying grey water at a high rate results in overflow, over saturation (soaking) of the grey water dam

Figure 3. Photograph of the grey water dam with vegetables grown on the surface.

which is not suitable for plant growth. In addition piping problem may arise with too much water supplied to the grey water dam in a short time. In the pilot set up used, a valve has been provided along the pipe supplying the grey water from the tank to regulate the flow.

5. Conclusions

The grey water dam design as presented above was successful in terms of providing the necessary moisture for plantation, accepting greater quantities of grey water than is normally handled by the vertical grey water tower. The added advantage of the grey water dam is its low cost as it can be built from existing soils mostly available in the community and the minimum operational attention that is needed. Treatment of grey water with soil is reported to produce a treated grey water quality that is suitable for several reuse purposes.

The development of the hydraulic equations for determining the seepage path has helped in determining the right dimensions of the grey water dam and in preventing piping problems which can happen when the seepage path intersects the surface of the dam. In order to lower the seepage path and prevent piping problems, the provision of toe drain is critical and the hydraulic equation developed helps in determining the positions and dimensions of the toe drain. Keeping the seepage path within the grey water dam also means the height of the dam can be increased which can save the horizontal space requirement for the dam.

Partial compaction of the soil used is necessary for added stability and prevention of soil piping. This shall be done during the filling of the soil by spraying moisture and compacting in layers. In addition after the dam has been completed an initial period of wetting is essential in order to open up the pores. This wetting of the surface can be done by sprinkling water on the surface of the dam taking care not to erode the soil top.

The grey water dam design can be flexibly adapted to handle greater quantities of grey water by allowing partial seepage of water through the bottom. Such a provision may be necessary often because of the fact that the grey water production may be more than the reuse demand of the household. This means that instead of putting an impermeable layer the bottom section may be treated with semi-permeable material such a mixture of clay and soil compacted in place.

Although this papers focuses more on the hydraulic design aspects and that water quality and treatability profiles of soil filters has been studied by a number of researchers mentioned in the introduction, it is nonetheless necessary to ensure that adequate treatment takes place within the grey water dam. The grey water dam can be considered as a form of restricted irrigation and the WHO guideline of achieving 3 - 4 log reduction of E. coli (99.9% and 99.99% removal)within the soil in addition to <1 helminthes/egg per 100 gm of soil with an infection risk of 1 in 1000 might be the appropriate guideline to apply. The most probable risk in the case of the grey water dam might be direct ingestion of the soil containing pathogens in the course of dealing with harvesting plants and maintenance or contamination of plants by the soil and here proper hygiene also plays a role. In addition, the effect of long term use of the dam such as clogging of the soil and soil quality deterioration shall be studied as part of the investigation of sustainable use of the dam and determining the operation and maintenance requirements. This will be the next part of the study that shall be undertaken within the pilot project setups.

References

- International Water Management Institute, IWMI (2003) International Water Management Institute Water Policy Briefing-8.

- Golda, A.E., Poyyamoli, G. and Nandhivarman, M. (2014) Characterization of Domestic Gray Water from Point Source to Determine the Potential for Urban Residential Reuse: A Short Review.

- Jamrah, A., Al-Futaisi, A., Prathapar, S. and Harrasi, A.A. (2008) Evaluating Grey Water Reuse Potential for Sustainable Water Resources Management in Oman. Environmental Monitoring and Assessment, 137, 315-327. http://dx.doi.org/10.1007/s10661-007-9767-2

- Christova-Boal, D., Evans, R.E. and McFarlane, S. (1996) An Investigation into Gray Water Reuse for Urban Residential Properties. Desalination, 106, 391-397. http://dx.doi.org/10.1016/S0011-9164(96)00134-8

- Eriksson, E., Auffarth, K., Henze, M. and Ledin, A. (2002) Characteristics of Grey Wastewater. Urban Water, 4, 85- 104. http://dx.doi.org/10.1016/S1462-0758(01)00064-4

- Jamrah, A., Al-Omari, A., Al-Qasem, L. and Abdel Ghani, N. (2006) Assessment Availability and Characteristics of Gray Water in Amman. Water International, 31, 210-220. http://dx.doi.org/10.1080/02508060.2006.9709671

- Sheikh, B. (1993) The City of Los Angeles Grey Water Pilot Project Shows Safe Use of Grey Water Is Possible. In: Hon, K., Ed., Water Management in the 90s: A Time for Innovation, American Society of Civil Engineers, New York, 681.

- Dixon, A., Butler, D. and Fewkes, A. (1999) Water Saving Potential of Domestic Water Reuses Systems Using Grey Water and Rainwater in Combination. Water Science Technology, 39, 25-32. http://dx.doi.org/10.1016/S0273-1223(99)00083-9

- Ushijima, K., Ito, K., Ito, R. and Funamizu, N. (2013) Grey Water Treatment by Slanted Soil Filter System. Hokkaido University, Sapporo Hokkaido.

- Allen, L., Smith, J.C. and Palaniappan, M. (2010) Overview of Gray Water Reuse: The Potential of Gray Water Systems to Aid Sustainable Water Management. Oakland.

- Carden, K., Armitage, N., Winter, K., Sichone, O., Rivett, U. and Kahonde, J. (2007) The Use and Disposal of Grey Water in the Non-Sewered Areas of South Africa: Part 1—Quantifying the Grey Water Generated and Assessing Its Quality. Water SA, 33, 425-432.

- Katukiza, A.Y., Ronteltap, M., Niwagaba, C.B., Kansimme, F. and Lens, P.N.L. (2013) Grey Water Characterization and Pollutant Loads in Urban Slum. International Journal of Environmental Science and Technology, 10, 1-14.

- New South Wales Government, NSW (2007) Guidelines for Gray Water Reuse in Sewered, Single Household Residential Premises. Department of Energy Utilities and Sustainability, Sydney.

- Jamrah, A., Futaisi, A., Harrasi, A. and Al-Qasem, L. (2004) Assessment of Grey Water Characteristics and Potential for Reuse in Agriculture. Proceedings of the International Conference on Water Management, Dead Sea, 30 May-3 June 2004.

- Kadam, A., Oza, G., Nemade, P., Dutta, S. and Shankar, H. (2008) Municipal Wastewater Treatment Using Novel Constructed Soil Filter System. Chemosphere, 71, 975-981. http://dx.doi.org/10.1016/j.chemosphere.2007.11.048

- Nelson, M. (2014) Wastewater Garden Information Sheet. IS20120105. www.wastewatergardens.com/pdf/WWG_AboutConstructedWetlands.pdf

- World Health Organization, WHO (2006) Guidelines for the Safe Use of Wastewater, Excreta and Grey Water. Volume 2: Waste Water Use in Agriculture. WHO Publication, Geneva.

- Itayam, T., Kiji, M., Suetsugu, A., Tankan, N., Iwami, M. and Inamori, Y. (2004) On Site Experiments of the Slanted Soil Treatment Systems for Domestic Gray Water. Water Science and Technology, 53, 193-201. http://dx.doi.org/10.2166/wst.2006.290

- Jefferson, B., Palmer, A., Jeffrey, P., Stuetz, R. and Judd, S. (2004) Gray Water Characterization and Its Impact on the Selection and Operation of Technologies for Urban Reuse. Water Science and Technology, 50, 157-164.

- United States Environmental Protection Agency, EPA (2000) Wastewater Technology Fact Sheet Wetlands: Subsurface Flow, EPA 832-F-00-023.

- Ohio EPA (2007) Division of Surface Water Revision. Small Subsurface Flow Constructed Wetlands with Soil Dispersal System Rule Reference: OAC 3745-42.

- Tiruneh, A.T., Nkambule, S.J. and Ndlela, W.N. (2012) A Three Point Formula for Finding Roots of Equations by the Method of Least Squares. Journal of Applied Mathematics and Bioinformatics, 2, 213-233.

- Gerald, C.F. and Wheatley, P.O. (1994) Applied Numerical Analysis. 5th Edition, Addison-Wesley Publishing Company, New York.