Geomaterials

Vol.3 No.3(2013), Article ID:34583,4 pages DOI:10.4236/gm.2013.33009

Schedule Control of Coal Mine Construction Projects Based on Factor Analysis

1Department of Safety Engineering, Shijiazhuang Railway University, Shijiazhuang, China

2China Shenhua International Engineering Co., Ltd., Beijing, China

3School of Mechanics, Architecture and Civil Engineering, China University of Mine and Technology, Beijing, China

Email: fanlingling76@163.com, zkhuier@sohu.com

Copyright © 2013 Lingling Fan et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received March 1, 2013; revised April 1, 2013; accepted April 10, 2013

Keywords: Schedule Management; Factor; Factor Analysis; Validity Analysis

ABSTRACT

Schedule management is the crucial capability for large-scale coal mining investors to successful finish the construction project, which could get by the accumulation of the long-time institutional executive force and ability training. By using factor analysis and validation analysis, extracted control factors of schedule management from data have been made in large coal mine construction companies. Some control factors have a greater influence on the schedule management which are the system factor, measures factor, economic controlling factor, behavioral factor, process factor, organization factor, thus the enterprise schedule management system should include the terms of the above factors.

1. Introduction

Schedule control ability plays a vital part in enterprise ensure construction projects operation, which is the important measure to reasonable arrangement of resources supply and low cost. The project related partly and the whole process of project construction affect large-scale coal mine construction progress and make process of schedule construction complex and difficult. There are many influencing factors in the large-scale coal mine construction’s process, and the schedule control of the construction can be divided into the internal and the outer factor. The internal factor was mainly influenced by the project owner. Using the factorial analysis, we can find out the defect of the internal schedule management, and summed up the essential measure to average up management. Through the investigation and study, we seize the common factor that can impact the progress of the factor analysis, use SPSS17.0 to process the data.

The factor analysis is a multivariable statistical analysis method which could sum up the minority several comprehensive factors from the research most variable mutual dependency relationship of the internal variables. Factor analysis, regarding the studied question, attempts to describe each component of the original observation with the least number of unpredictable factor in the socalled public and special factor of the linear function. At present, the scholars have used the factor analytic method in every filed, such as technological innovation ability appraisement [1], urban economy development condition empirical analysis [2], profitability of listed companies [3], the biological pathology analysis, organization culture, the psychologically healthy analysis, the national minority characteristic, the meteorology, the geology, and so on, which make the factor analysis enrich the theory and practice.

2. Factor Data Reliability Examination

The mine project has a complicated environment, which construction time is longer and influenced by many factor. Only we could understand and estimate these factors fully, get over them, make the engineering construction progress as far as possible be in accord with the plan, so establish, execute and control the construction schedule as to fulfill the schedule goals. The variable selection of the factor analysis is critical to determine the factor which controls the construction projects progress. On these grounds, we work out the appropriate management measures. Based on the experts’ suggestion, we list the influential factor what are importance and selected by the investigators. The fundamental factor as follows: fulltime management personnel (V1), the regular inspection of the system (V2), experiences of project management (V3), the perfect management (V4), effective schedule control of information system (V5), clear responsibility list (V6), regular schedule of the inspection and acceptance system (V7), system of penalties and rewards(V8), continuous dynamic monitoring of the whole process of construction (V9), application of the new craft, new technical and new material (V10), determine the progress of the construction project objective (V11), improve the construction plan to adjust working logic relationship (V12), draws up the construction measure reasonably (V13), establishes the organization measure of the schedule control (V14), fund raising ability (V15), have ability to organize and coordinate with the project stakeholders (V16), signing the economy responsibility contracts of the schedule timetable (V17), the target funds implementation progress (V18), implementation of the progress management responsibilities (V19), the measures to improve the progress payment (V20).

2.1. Provide and Recycling of the Questionnaire

The research take the basic construction of coal mine items as the main object of study, the newly built coal mine of large-scale nationalized coal enterprise group as the questionnaire survey objective. The researchers have selected different professions as the respondent, such as, the management, the technical personnel and the design, the consultation, overseeing, the owner, the construction, who worked in the three coal mines under construction. They provided 75 questionnaire, recycled completely, and effective 71. Effective returns ratio was 94.67%.

2.2. Reliability Analysis

In order to examine the uniformity or the stability of the result of the investigation and study data, we needs to make the reliability analysis of the data, which namely the survey reliability, and test whether the internal questions between each line, or a different test point, the consistency of the test results before and after the degree.

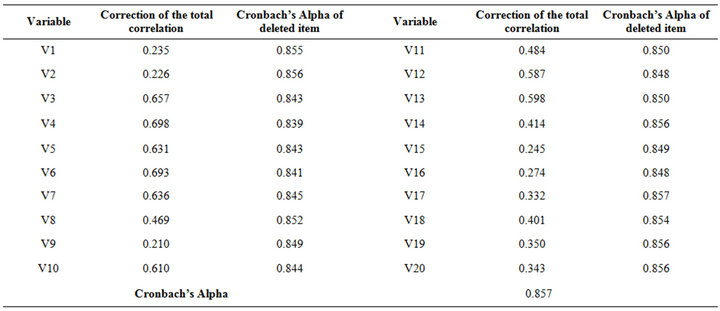

Reliability is an important indicator for the measure of data quality, American statistician Joseph F. Hair Jr., et al. (1998) believe that, if the Cronbach α bigger than 0.7, which indicated that the data has high reliability; when the measurement criterion’s number of entry is smaller than 6, and if Cronbach α value is bigger than 0.6, which indicated that the number may also be accepted according to what is believed. When we are make the internal consistency check, and if the value of Corrected Item Total Correlation is smaller than 0.2, the item will be deleted; If we delete some item which may obviously enhance Cronbach α value, we should do. Here, we use SPSS software to calculate the internal consistency of each variable coefficient, and according to the analysis of the test results to consider whether delete the items.

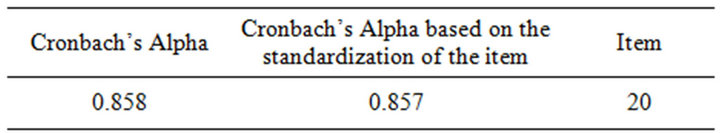

Calculation results have been shown in Tables 1 and 2. According to validity analysis of fact scales, the Cronbach α value of the total factor is 0.857, and the correlation of the 20 indicators with their respective total score between the 0.226 - 0.698, which have surpassed 0.2 of the standard. The Cronbach α value at the range of 0.839 - 0.857 after each question item is deleted, and deletes each item can not to be able to enhance the overall Cronbach α value, which show that the technical factor meter data has the high reliability.

Table 1. Reliability statistics.

Table 2. Validity analysis of fact scales.

3. Data Factorial Analysis

3.1. Inspection on KMO and Bartlett’s

Validity is the accuracy results of the measurement, is the measurement tool’ accuracy test. The higher of the survey validity is, which indicated that the more content to show of the measurement results that the true measure of its features is seeking According to Kaiser (1974), the KMO value above 0.9, is perfect; The KMO value between 0.8 - 0.9, is very suitable; KMO value between 0.7 - 0.8, suitable; The KMO value between 0.6 - 0.7, is not too suitable; The KMO value between 0.5 - 0.6, is very reluctant; The KMO value below 0.5, is unsuitable. According to Inspection on KMO and Bartlett, the date of KMO is 0.753, Bartlett’s value is 525.660, the degreeof-freedom (df) is 190, and the significance probability is 0.000, which is smaller than 1%, and achieves the remarkable level. The above result indicated that the KMO sample measure result is remarkable, and the data’s related is not the unit matrix, the sampled data suitable to make the factorial analysis.

3.2. Factorial Analysis

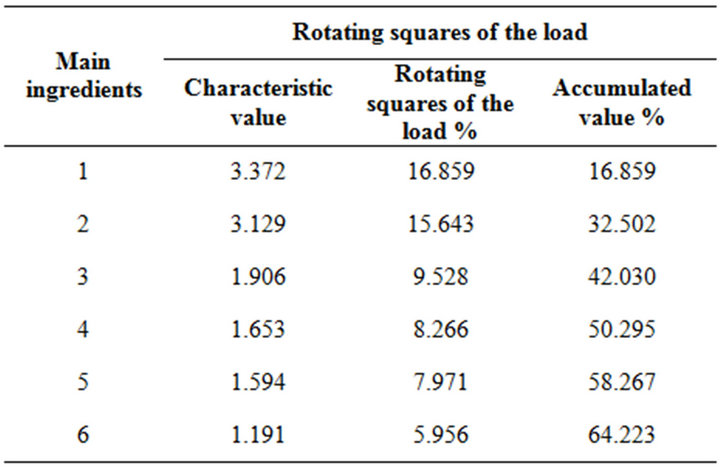

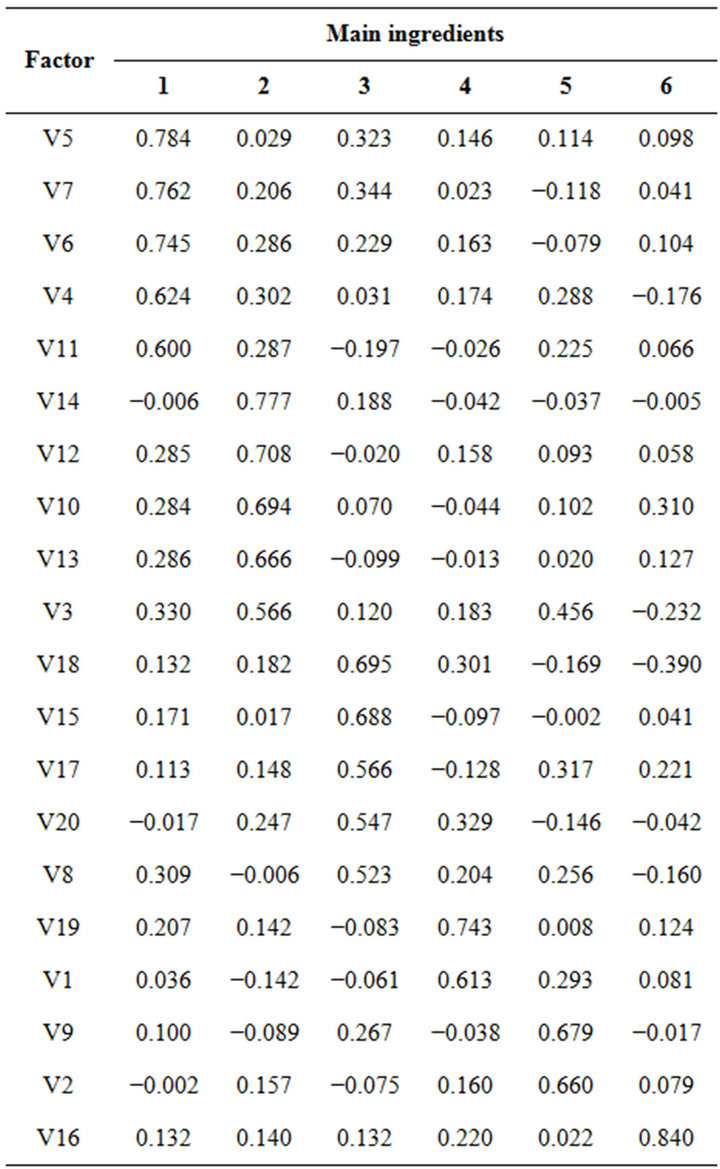

The basic step of factorial analysis [4]: choose a strong correlation of the variables, the relevant analysis, extract common factor, factor revolving and the computation of factor score. It has using SPSS soft ware for principal component analysis of the technical factor, and carries on oblique to revolve superiorly, in order to take withdraws from the common factor, and the extraction method is bigger than the characteristic value 1. After 23 revolving, we finally have withdrawn 6 factors, and can explain the population variance 64.223% (Table 3). The rotated factor loading matrix has shown in Table 4.

The data in Table 3 shows the factor loadings in each factor between 0.507 - 0.907, and each factor is smaller than 0.35 in other latitude’s load value, which explains the good degree of the differences factor and convergent validity. V4, V5, V6, V7, V11, these factor are mainly

Table 3. The total variance.

Table 4. Rotating component matrix.

influencing factor of the schedule control system, and the content of the system’s formulation should be the clearly responsibility, strong execution, take full advantage of information control system. The five dimensions of factor have larger proportion in the first principal components which can be called the system actor. V3, V10, V12, V13, and V14, the factor which influence the implementation schedule of project by the organization measure and the technical measure, which meet the schedule safeguard with the measure. Who can be called the measure factor, the five dimensions of factor have larger proportion in the second principal components. V8, V15, V17, V18, V20. These factors could be material incentive for controlling measure implementation, and would ensure continuity of progress controlling implement. The components which can be called the economic control, the five dimensions of factor have larger proportion in the third principal factor. V1, V19, mainly reflect the personnel of the project owner whether meet the engineering management needs.

The administrative personnel, as the active factor of the management, satisfactorily, dutifully, work, what is the key to carry out the management goal. The two factors have larger proportion in the third principal components which can be called the behavior factor. V9, V2, these factor that have larger proportion in the fifth principal components, called the process control factor, which would dynamic, continuous and timing to achieve the continuous of the progress monitoring management. V16 has larger proportion in the sixth principal components which can be called the organization factor, is mainly manifests the coordinated ability of the construction organization. Because we cannot forecast every factor of construction management process, as an important aspect of the development, should foster the management coordinated ability. We have extracted six main principal components from the survey data analysis of the largescale coal mine construction schedule for effective schedule management.

3.3. Schedule Management Measure

Corporation make up a project schedule system which should not only meet the total project schedule, but also adapt the funds, equipment, and obtain materials power, and arrange the annual construction project requirements reasonably according to the requirement of complete or partial delivery of adaptation. Improve the organizational system of the project management, increase the ability to communicate timely; and the project plan has the dynamic alignment. In the organizational structure of the project, we should have the special work department and the qualification person who in line with the progress control to be responsible for the progress control work, and it is also possible to strengthen the progress control department’s strength according to the needs; Regarding the technique and the administrative personnel, we should strengthen the education and training as far as possible, and use the incentive mechanism in their work. And the construction of the mine pit project, the civil engineering, and the installation work, we should use the time and the space fully of these three kind of projects, During the construction of the lane project, we should arrange the construction of the key project reasonably, such as construction, installation of the main auxiliary shaft hoisting system, the ventilation system and the raw coal production system, and so on, coordinated the parallel cross assignments and balanced the engineering construction.

4. Conclusions

Survey data reliability and validity have confirmed that the data distribution is very likely to actual status of schedule control, and factor analysis can be used for schedule controlling and seeking out controlling factor.

To the builders, the different extracted factor analysis show the control system should contain the progress of technical and organizational management, guarantee of the economic capital, the implementation of incentive measures, the conduct of due diligence, continuous and dynamic aspects of management control, to ensure the management goals implement.

When we build the schedule management based on the time and analysis for the mine construction, should achieve aim that restraint action with institution, measure against the external effects, consummate the internal manage system, promptly communicate, maximize organization coordinate of manager, fulfill management system implement continuity, we would attain to predictable goal.

REFERENCES

- Z. D. Liu, “Application of Factor Analysis to Evaluation of Business Technology Innovation Ability,” Journal of Chongqing Normal University (Natural Science Edition), Vol. 23, No. 2, 2006, pp. 75-79.

- L. J. Liu and L. J. Wu, “Demonstrative Analysis on the Economic Development Condition of 12 Western Cities in China Based on Factor Analysis,” Journal of Chongqing University of Technology (Natural Science), Vol. 24, No. 11, 2010, pp. 118-122.

- J. R. Zhang, Z. W. Jia and Y. M. Sun, “Factorial Analysis on a Listed Company’s Profitability,” Modern Economic Science, Vol. 26, No. 6, 2004, pp. 53-59.

- W. D. Li, “Applied Multivariate Statistical Analysis,” Peking University Press, Beijing, 2008.