Energy and Power Engineering

Vol.5 No.8(2013), Article ID:37361,9 pages DOI:10.4236/epe.2013.58053

Effect of Shape of the Absorber Surface on the Performance of Stepped Type Solar Still

1Department of Mechanical Engineering, Rajarshi Shahu College of Engineering, Buldana, India

2SGB Amravati University, Amravati, India

3Department of Mechanical Engineering, PRM Institute of Technology & Research, Badnera, India

Email: jsg725@gmail.com, lbbhuyar@gmail.com

Copyright © 2013 Jagannath S. Gawande, Lalit B. Bhuyar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received August 1, 2013; revised September 1, 2013; accepted September 8, 2013

Keywords: Stepped Type Solar Still; Absorber Plate; Flat Surface; Concave Surface; Convex Surface; Distillate Yield

ABSTRACT

In this work, we have selected three number of stepped type solar stills of the same overall dimensions 620 mm (W) × 808 mm (L) but with different absorber surface areas due to the variation in the shape of the basin surface. The other design parameters like depth of water, thickness of glass cover, insulation thickness, type of condensing cover, absorbing material provided over the basin, and angle of inclination of the still were kept constant to study the effect of shape of the absorber surface over the distillate yield obtained. The shape of the absorber surface provided in the basins of solar stills A, E and F was flat, convex and concave respectively. When the convex and concave type stepped solar stills are used, the average daily water production has been found to be 56.60% and 29.24% higher than that of flat type stepped solar still respectively. Also an economic analysis was made. The payback period of flat type, convex type and concave type stepped solar still is 823 days, 525 days and 637 days respectively. Thus, the convex type solar still gives the returns within the least possible time as compared to other two types of stepped solar stills. The laboratory tests were conducted to test the quality of water after distillation. The tests indicate that the quality of water in terms of pH, electrical conductivity, total hardness, TDS, Alkalinity, Nitrates etc. is well within the desirable limits as prescribed by WHO for Indian specific conditions.

1. Introduction

Water is one of the prime elements responsible for life on earth. It covers three-fourths of the surface of the earth. However, most of the earth’s water is found in oceans as salt water, contains too much of salt, and cannot be used for drinking, growing crops or most industrial uses. The remaining earth’s water supply is fresh water. Most of this is locked up in glaciers and ice caps, mainly at the north and south poles. If the polar ice caps were to melt, the sea level would rise and would flood much of the present land surfaces in the world. The rest of the world’s supply of fresh water is found in water bodies such as rivers, streams, lakes, ponds and in the underground. Our drinking water today, far from being pure, contains some two hundred deadly commercial chemicals, toxins and impurities. So there is an important need for clean and pure drinking water. In many coastal areas where sea water is abundant but potable water is not available, solar water distillation is one of the many processes that can be used for purification as well as desalination. Solar still is the widely used solar desalination device. But the productivity of the solar still is very low. To augment the productivity of the single basin type solar still, several research works have been carried out. But its effect on a stepped type solar still is unidentified till date. The works carried on a single basin type solar still are summarized as follows.

The operating performance of a simple basin type passive still augmented with a passive concentrating reflector and double effect still arrangement was investigated by M. Smyth, A. Strong, W. Byers and B. Norton [1]. Three units were designed, fabricated and tested. System A was a simple basin type still. System B and System C utilized the basic still arrangement (System A) and augmented with an asymmetric inverted convection suppression circular reflector design with a Compound Parabolic Concentrator (CPC). System B collected both direct and indirect incident solar radiation, whilst System C collected indirect incident solar radiation only, coupled with a double effect still arrangement. System B attained the highest operating temperatures and produced the most water. System A had the best collection area to output yield performance. The use of the double effect still arrangement was shown not to improve output. All systems improved the quality of the input water.

A weir-type solar still was proposed by S. B. Sadineni, R. Hurt, C. K. Halford and R. F. Boehm [2] to recover rejected water from the water purifying systems for solar hydrogen production. This consists of an inclined absorber plate formed to make weirs, as well as a top basin and a bottom basin. Water is flowed from the top basin over the weirs to the bottom collection basin. A small pump is used to return the unevaporated water to the top tank. Hourly distillate productivity of the still with double and single pane glass covers was measured and the latter showed higher production rates. The average distillate productivities for double and single pane glass covers are approximately 2.2 and 5.5 l/m2/day in the months of August and September in Las Vegas, respectively. Mathematical models that can predict the hourly distillate productivity are developed. These compared well with the experimental results. Productivity of the weir-type still with a single pane glass was also compared with conventional basin types tested at the same location. The productivity of the weir-type still is approximately 20% higher. The quality of distillate from the still is analyzed to verify the ability of the still to meet the standards required by the electrolyzers.

Helmy E. Gad, Safya M. El-Gayar and Hisham E. Gad [3] investigated experimentally the performance of a simple solar still with clothes moving wick driven with a DC motor via a control circuit. The clothes wick is immersed in water when the motor is ON and the wet clothes are subjected to solar radiation when the motor is in OFF period. Results show that an ON period 30 seconds is suitable and an OFF period of 25 minutes yields maximum thermal efficiency. This research work proves that it is possible to operate such solar still with the computer to reduce the cost of production of distilled water.

Y. P. Yadav and G. N. Tiwari [4] studied monthly comparative performance of solar stills of various designs. His work presents design, fabrication details and long term performance of single slope basin type fibre reinforced plastic (FRP) solar still, double slope basin type FRP solar still, single slope FRP multiwick solar stilldouble slope FRP multiwick solar still, single slope FRP multiwick solar distillation plant and double slope FRP multiwick solar distillation plant. On the basis of performance under Delhi climatic conditions following conclusions were drawn: In winter, the single slope FRP basin type still gives better yield than the double slope FRP basin type solar still. In summer, the distillate output of the double slope FRP basin type solar still is greater than that of the single slope FRP basin-type solar still. The same idea holds good for single and double slope FRP multiwick solar stills and the solar distillation plants.

An experimental work has been conducted to predict the productivity of single slope solar still using different enhancement parameters by O. Badran [5]. The use of asphalt in the basin resulted in a significant improvement in still production for an increase of 29%. The sprinkler combination with the asphalt was more effective than the use of asphalt alone by another 22%, increasing the productivity by 51%. It has been concluded also that the ambient conditions i.e. wind and ambient temperature have a direct effect on the still productivity.

V. Velmurugan, S. Senthil Kumaran, V. NiranjanPrabhu and K. Srithar [6] have studied the performance characteristics of basin plate with two different depths of trays. Fin type, sponge type and combination of fin and sponge type stepped solar still are analyzed in terms of productivity. Production of water increases by 80% when fin and sponge type stepped solar still is used than flat type stepped solar still. Result shows that integration of fins in the basin plate gives more evaporation rate than adding sponges. Maximum productivity occurs when both these effects are combined. Experimental results show that productivity increased by 76%, 60.3% and 96% when fins, sponges, and combination of both the fins and sponges are used respectively.

The objective of this work is to optimize the shape of absorber plate in the basin. In this work, the author provided three different shapes to the absorber plate. The setup A was of plain type, setup E was given convex shape to the basin and setup F was given concave shape to the basin. The distillate yield of all three solar still was collected and measured in the beakers. Theoretical analysis is also made by solving energy balance equations and compared with experimental results.

2. Experimental Setup

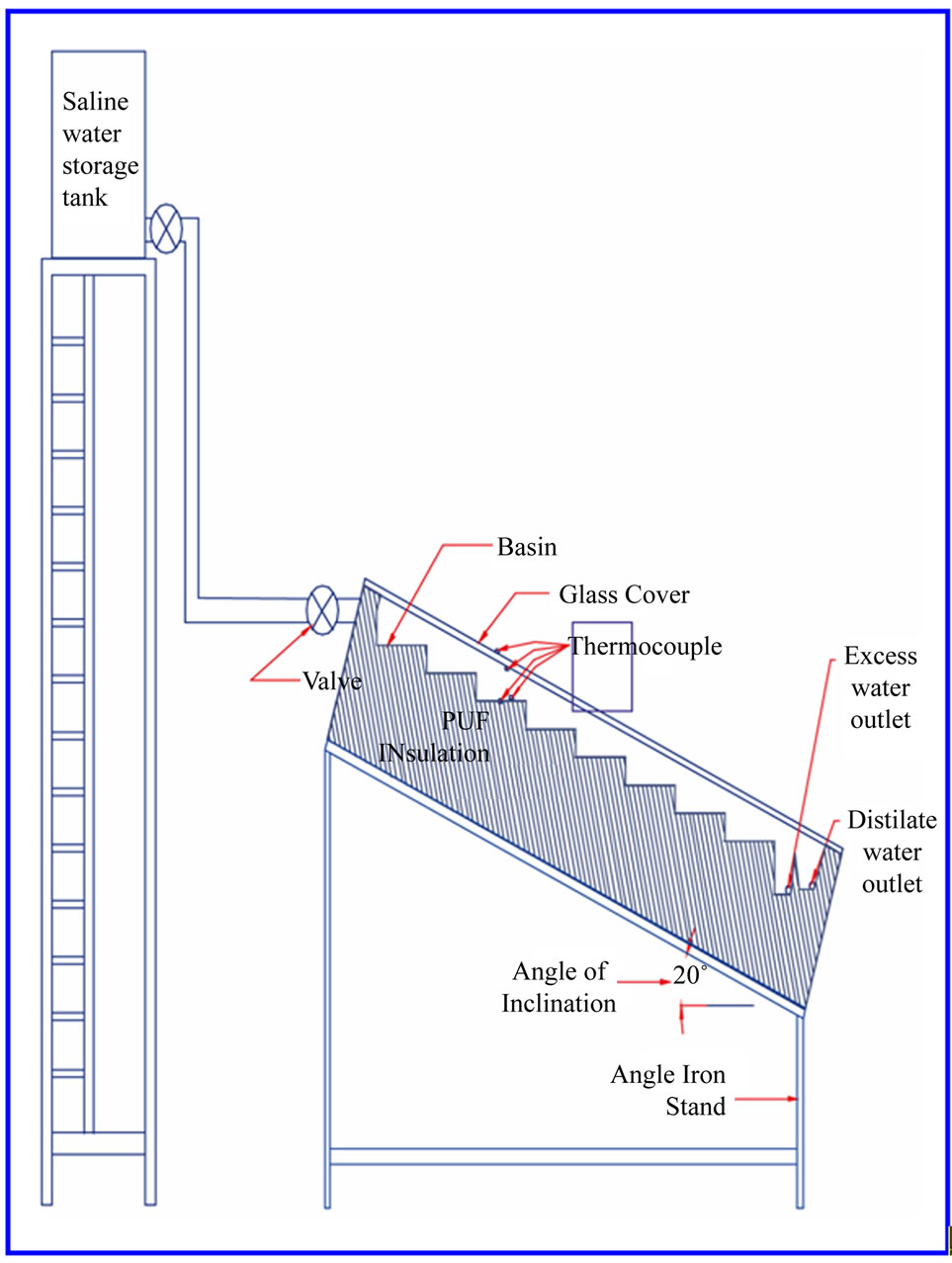

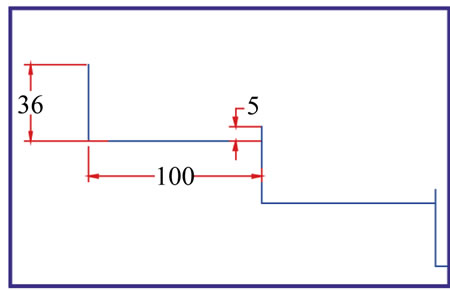

The experimental setup consists of a saline water storage tank and a stepped type solar still mounted on an iron stand as shown in Figure 1. The absorber plate is made up of galvanized iron sheet of 1 mm thickness i.e. 22 gauge. The size of the absorber plate is 620 mm (W) × 808 mm (L). There are totally 8 number of steps in the

Figure 1. Schematic diagram of the experimental setup.

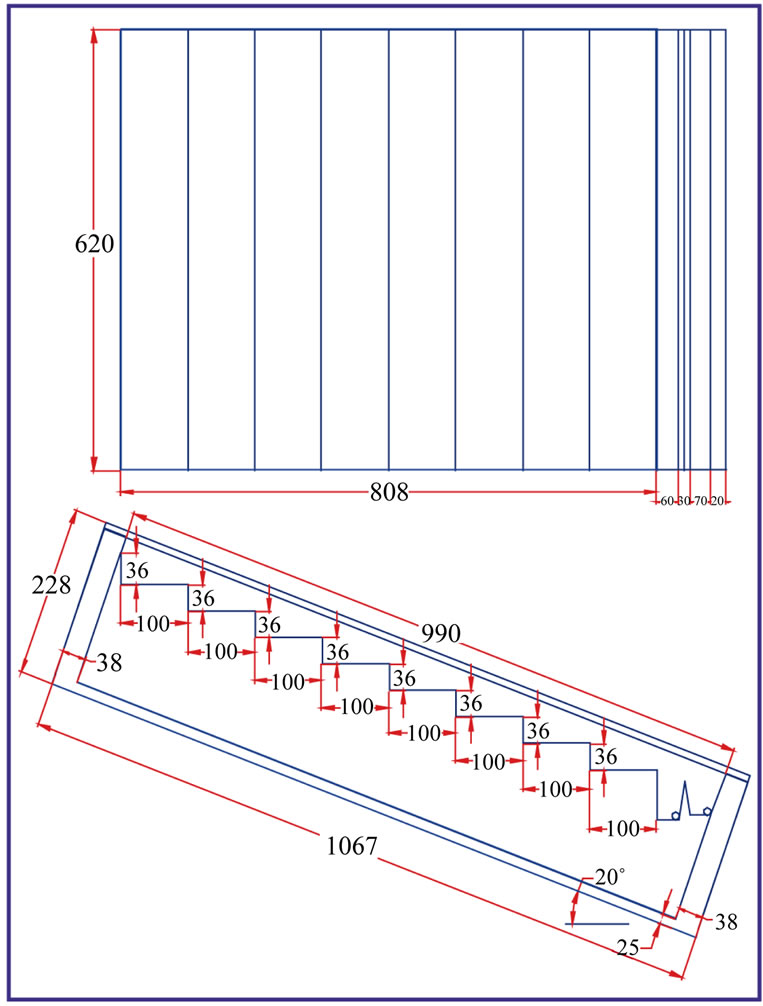

absorber plate. Each individual step is of 100 mm (W) × 620 mm (L) cross-section and 36 mm height. The stepped type structure of the absorber plate is coated with heat absorbent black dye because it is an established fact that black dye is the best solar radiation absorbing material. The plan and elevation of the stepped type absorber plate is shown in Figure 2.

The absorber plate is placed inside a sheet metal box of size 620 mm (W) × 990 mm (L). The space between the sheet metal box and stepped type absorber plate is filled with polyurethane foam (PUF) to avoid the heat loss from the bottom and sides of the solar still. The cover of the solar still is made up of 4 mm thick simple window glass. The saline water is supplied to the solar still from the saline water storage tank through poly vinyl chloride (PVC) hose pipe. The steps are filled with saline water one after another starting from the top and the excess water comes out from the excess water channel provided at the bottom. The excess water, if any is collected for reuse in the solar still. When solar radiations fall on the glass cover, it gets absorbed by the black absorber plate. Due to this, the water contained in the steps begins to heat up and the moisture content of the air trapped between the water surface and the glass cover increases. When the water absorbs maximum solar radiations equal to the specific heat capacity of its mass, it is saturated and evaporation of water takes place. The basin also radiates energy in the infrared region, which was reflected back into the solar still by the galas cover, trapping the solar energy inside the solar still. The water vapors formed due to the evaporation of water are condensed at the inside of glass cover, as its temperature is less. To ensure that vapors are not lost to the atmosphere, the glass cover is sealed with a rubber gasket using an adhesive of Araldite and Bond-Tite. The condensed water trickles down to the distillate collection trough provided at the bottom and is collected into a glass beaker by using a hose pipe which is mounted at the side of the solar still.

As evaporation of water in the steps takes place, the saline water level in the solar still decreases. To com-

Figure 2. Plan and elevation of the stepped type absorber plate.

pensate the loss of water, for every half an hour, the makeup water is added to the solar still from the storage tank. A separate hole is also drilled in the sidewall of the still to fix thermocouples to sense the temperatures of water in the basin, absorber plate temperature and inner glass cover temperature. The whole unit is placed on an angle iron stand inclined at an angle of 20˚ equal to the latitude of Buldana to the horizontal. The whole experimental set up was oriented due south as the location lies in the northern hemisphere to receive maximum solar radiation throughout the year.

This experimental setup was designed, installed and tested in the laboratory of Non-Conventional Energy Systems, Department of Mechanical Engineering, Rajarshi Shahu College of Engineering, Buldana, India. The experiments were performed during the months of January 2012 to April 2012 when the sky was clear, i.e. on sunny days. The average sunshine in Buldana was 5.83 kWh/m2/day during the above said period.

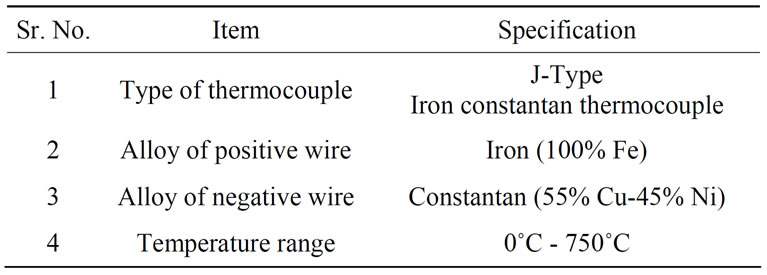

Hourly measurements were made for various temperatures from 9.00 am to 5.00 pm during the trial period. These temperatures were measured with the aid of J-type iron constantan thermocouples and noted from a digital temperature indicator. Five different thermocouples were installed on the soar still system at different locations. These locations were (i) bottom of the basin to measure the temperature of absorber plate, Tb (ii) inner surface of the glass cover, Ti (iii) outer surface of the glass cover, To (iv) water temperature in the basin, Tw and (v) ambient temperature, Ta. Thermocouples were integrated with a multi channel digital temperature indicator and a selector switch. The collecting vessel is used for measuring distillate yield and a vane type digital anemometer is used for measuring wind velocity. The alloy combination, polarity and measurement range for the thermocouples is as given in the Table 1.

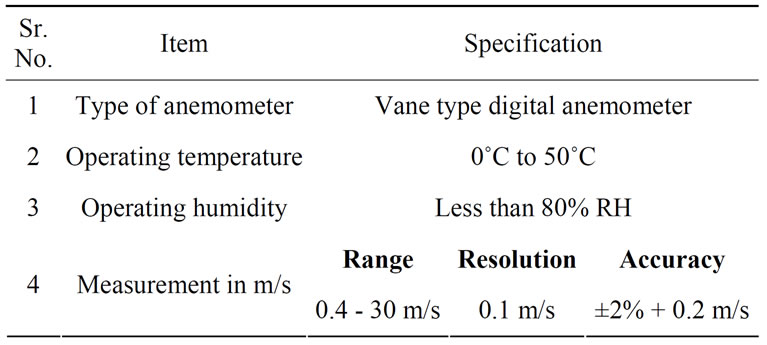

The hourly weather data, i.e., wind speed was measured with the help of Lutron anemometer. The operating parameters and electrical specifications of anemometer are as given in Table 2.

2.1. Stepped Type Solar Still with Varying Shape of Absorber Surface

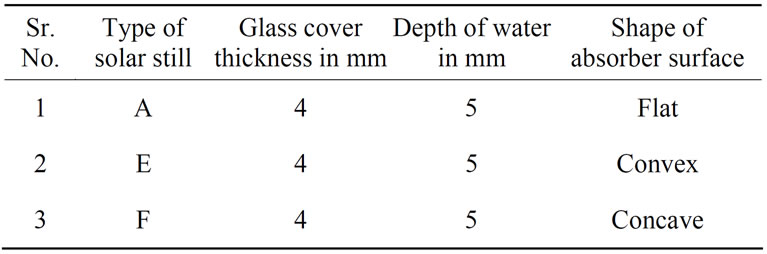

The configuration and design parameters of solar stills A, E and F are as given in Table 3.

2.2. Convex and Concave Type Stepped Solar Stills

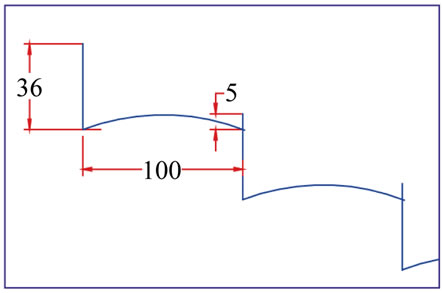

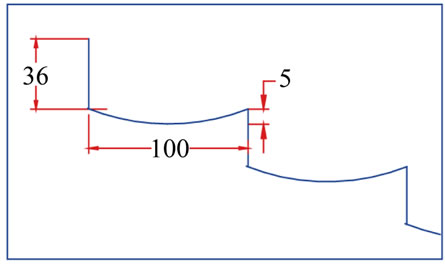

The shape of absorber surfaces provided to the basins of flat (A), concave (E) and convex (F) type solar stills are as shown in Figure 3.

Table 1. Thermocouples.

Table 2. Anemometer.

Table 3. Design parameters of solar stills A, E and F.

(a)

(a) (b)

(b) (c)

(c)

Figure 3. Absorber surface of flat, concave and convex type stepped solar still. (a) Absorber surface of flat type solar still A; (b) Absorber surface of convex type solar still E; (c) Absorber surface of concave type solar still F.

3. Thermal Model

A thermal model has been developed to determine the convective heat transfer for different Grashoff numbers in the solar distillation process. The model is based on simple regression analysis. Based on the experimental data obtained from the rigorous outdoor observations on various configurations of stepped type solar stills for summer climatic conditions, the values of C and n have been calculated. From these values, convective heat transfer coefficient is calculated based on the distillate yield obtained from the experimental observations. The percentage deviation between experimental and theoretical distillate yield is also obtained.

3.1. Thermo Physical Properties of Water

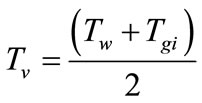

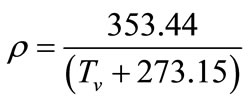

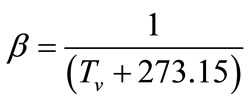

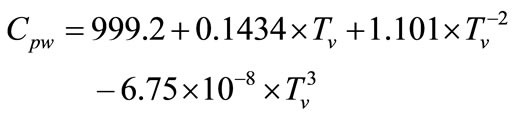

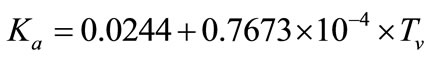

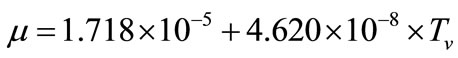

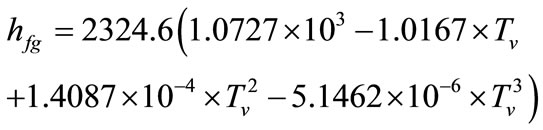

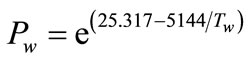

The thermo physical properties of water have been evaluated by using the following expressions wherein Tv represents the arithmetic mean of the temperatures of evaporation and condensing surfaces and can be expressed as follows:

3.2. Internal Heat Transfer Coefficients

Experiments were performed on three different configurations of stepped type solar still during the months of January 2012 to April 2012 for several days, but the measured parameters on a typical day namely, 5th March, 2012 are considered for computations of internal heat transfer coefficients.

The governing equations applied to a stepped type solar still are discussed. Heat transfer occurs across the humid air inside the enclosure of the distillation unit by free convection which is caused by the action of buoyancy force due to density variation in the humid air. Density variation is caused by a temperature gradient in the fluid.

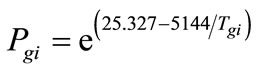

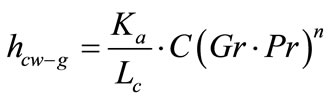

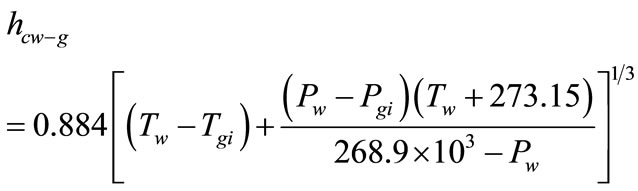

The convective heat transfer rate from water surface to condensing glass cover is given by:

(1)

(1)

where,  is convective heat transfer coefficient from water surface to condensing glass cover. The convective heat transfer coefficient

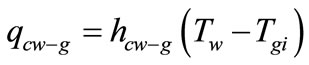

is convective heat transfer coefficient from water surface to condensing glass cover. The convective heat transfer coefficient  is calculated by using the non-dimensional Nusselt number as shown below:

is calculated by using the non-dimensional Nusselt number as shown below:

(2)

(2)

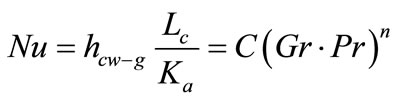

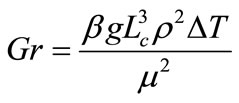

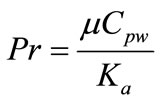

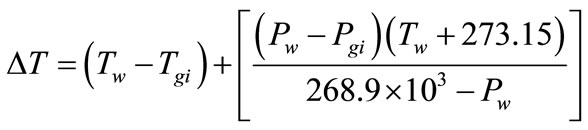

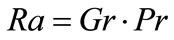

In Equation (2), non-dimensional numbers Gr and Pr are called Grashoff number and Prandtl numbers respectively. These numbers are expressed as:

(3)

(3)

(4)

(4)

where

Variables on right hand side of expressions are the temperature dependent physical properties and are determined as discussed in the previous section.

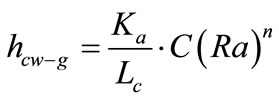

Equation (2) can be rewritten as,

(5)

(5)

where  is the Rayleigh number.

is the Rayleigh number.

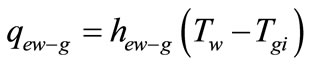

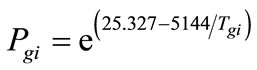

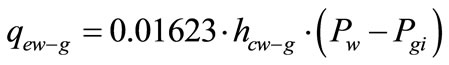

Malik et al., 1982 [2] have assumed that water vapour obeys the perfect gas equation and have given the expression for evaporative heat transfer rate as:

(6)

(6)

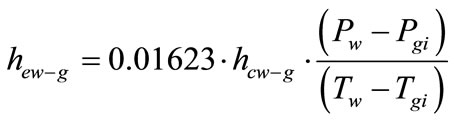

where,  is the evaporative heat transfer coefficient between water surface and condensing glass cover and expressed as

is the evaporative heat transfer coefficient between water surface and condensing glass cover and expressed as

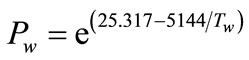

(7)

(7)

where

It is worth mentioning here that only evaporative heat transfer causes and contributes to water distillation.

Substituting the value of  in Equation (6) above, we get

in Equation (6) above, we get

(8)

(8)

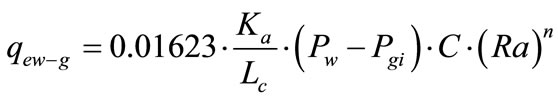

Substituting the value of  in the above equation, we get

in the above equation, we get

(9)

(9)

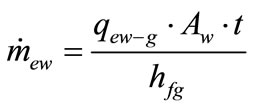

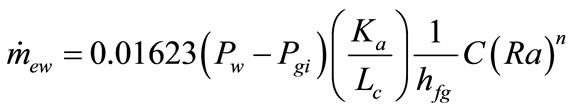

By knowing the evaporative heat transfer rate; mass of the water distilled can be derived by the following equation:

(10)

(10)

Substituting the value of  in the above equation, we get

in the above equation, we get

(11)

(11)

(12)

(12)

(13)

(13)

where,

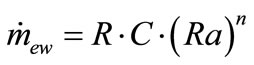

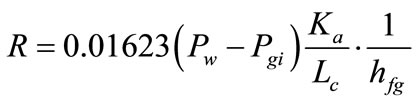

In Equation (13), there are two unknown parameters C and n. They are determined by regression analysis using experimental values of distillation yield (mew), saline water temperature in the basin (Tw), glass cover temperature at the inner surface (Tgi).

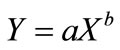

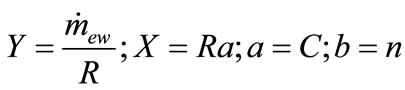

Equation (13) can be rewritten in the following form:

(14)

(14)

where,

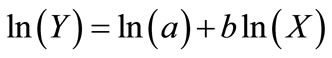

Equation (14) can be reduced to a linear equation by taking log on both the sides:

(15)

(15)

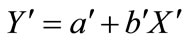

OR

(16)

(16)

where

(17)

(17)

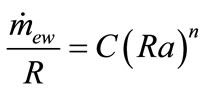

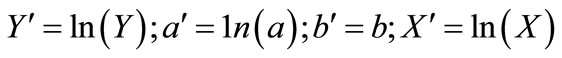

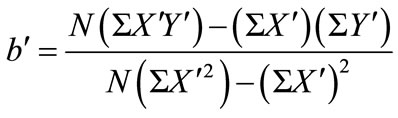

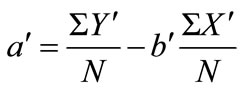

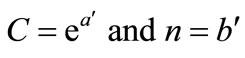

From Equation (17), the values of coefficients a' and b' are calculated using regression analysis. The expressions for a' and b' are given by:

(17a)

(17a)

(17b)

(17b)

where N is the number of experimental observations.

Knowing a' and b' from Equation (15), the value of C and n can be obtained by the following expressions:

Once the values of C and n are known, the experimental data are used to obtain the internal heat and mass transfer coefficients for the solar stills. Equation (3) can be used to obtain the convective heat transfer coefficient, . Dunkle [1], by using the values of C = 0.075 and n = 1/3, gave following expression for

. Dunkle [1], by using the values of C = 0.075 and n = 1/3, gave following expression for , valid for a mean operating temperature range of approximately 50˚C.

, valid for a mean operating temperature range of approximately 50˚C.

(18)

(18)

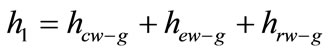

The internal heat transfer coefficient; heat transfer from water to glass cover inside the solar still is done by three possible ways called evaporation, convection and radiation, Hence total internal heat transfer coefficient of solar still is sum of all three possible ways heat transfer coefficients,

(19)

(19)

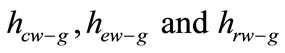

In Equation (19), h1 is total heat transfer coefficient and  are called convective, evaporative and radiative heat transfer coefficients.

are called convective, evaporative and radiative heat transfer coefficients.

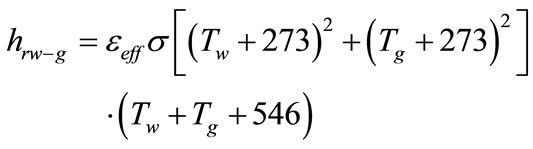

The radiative heat transfer coefficient between the water surface and condensing glass cover is given by is given by following equation:

(20)

(20)

where,

where, εg and εw are emissivities of basin water and glass cover and are given by

4. Results and Discussion

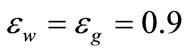

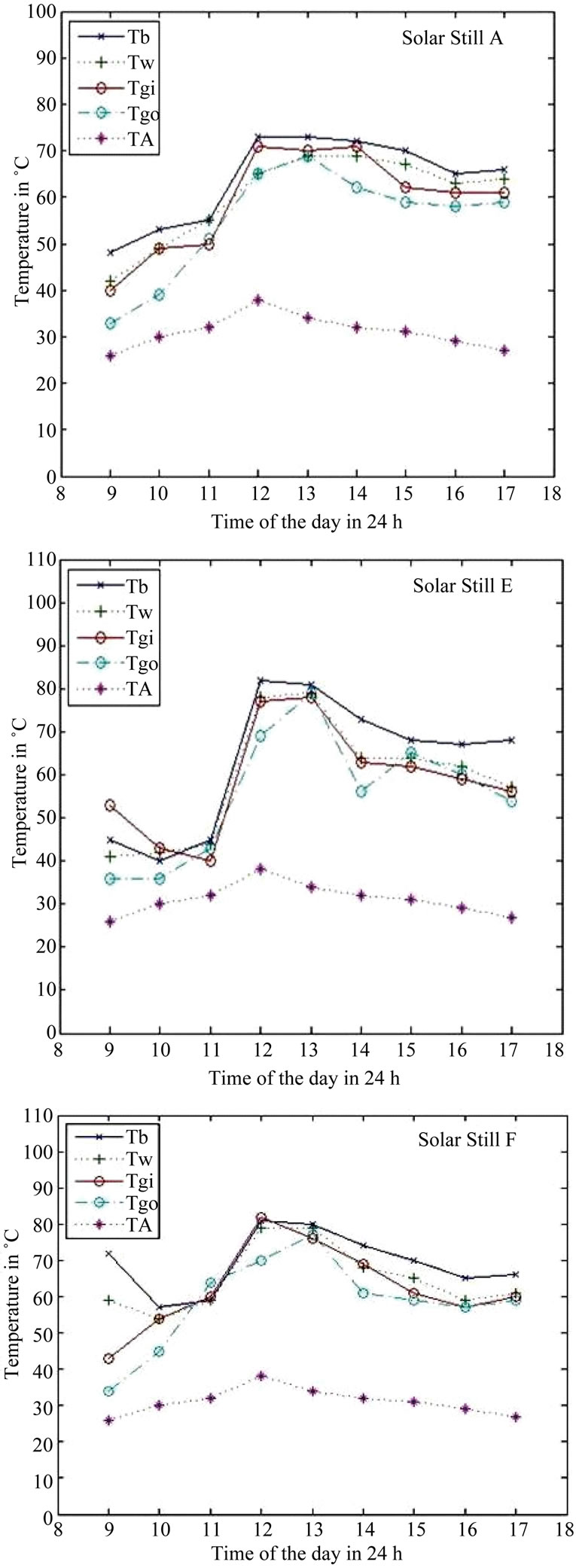

Variation of temperatures at different locations for solar stills A, E and F.

It is observed from the Figure 4 that the temperature changes during the experimental hours are narrower, which means that the maximum temperature was maintained for several hours between 11:00 am up to 3:00 pm due to the increase in the amount of energy absorbed by the stepped type solar still as to the single basin solar still. Thus it gives higher production rate in comparison to that of the single basin solar still.

4.1. Variation of Distillate Yield for Solar Stills A, E and F

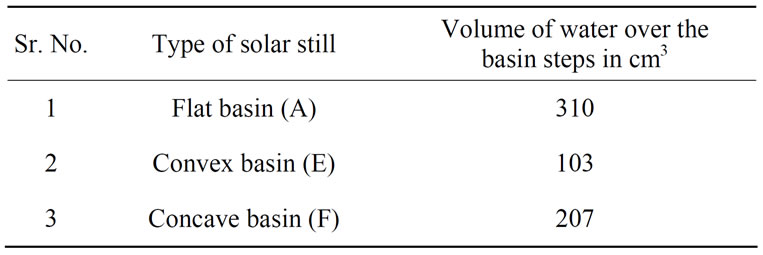

The volume of water contained in each step for the solar stills A, E and F is different as the shape of absorber surface is different for these solar stills. Table 4 shows the volume of water contained in each step for these solar stills.

Figure 4. Temperatures at different locations for solar stills A, E & F.

Table 4. Volume of water over the basin steps.

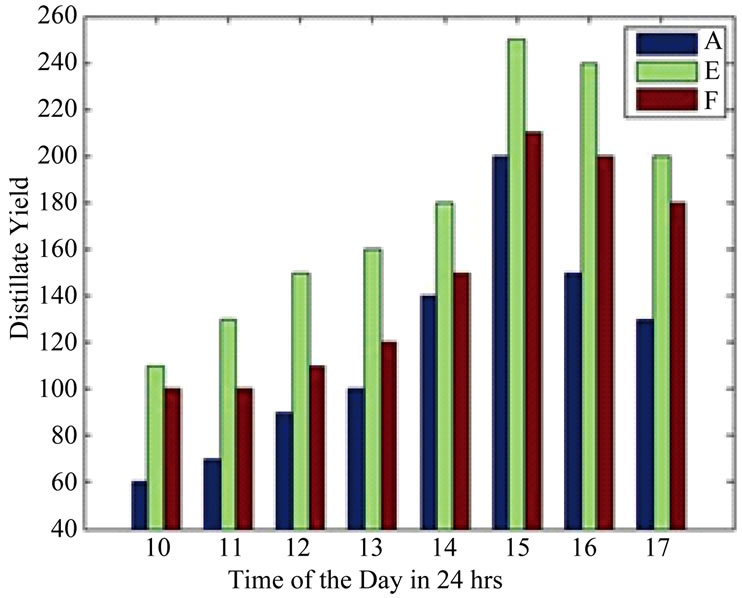

Figure 5 shows the hourly variation of distillate yield for solar stills A, E and F on 5th March, 2012. The distillate yield of solar still A with flat basin surface is observed to be 1060 ml during the period from 10 am to 5 pm.

The basin surface of solar still E is convex and the distillate yield obtained is 1660 ml during the period from 10 am to 5 pm on the same day. Due to the change in shape of the basin, the distillate yield increases by 600 ml and this is 56.6% higher than the stepped type solar still A provided with flat basin. Due to the convexity of the absorber surface, the depth of water is the least at the middle of the basin steps. Whereas the depth of water is the most at the outer edges of the basin steps; the water mass at the middle of basin steps being thinner; its specific heat capacity is less. This results in increase in the water temperature causing faster evaporation of at the middle of the basin steps. Hence more distillate yield is obtained than that of flat basin steps.

The basin surface of solar still F is concave and the distillate yield obtained is 1370 ml during the period from 10 am to 5 pm on the same day. Due to the change in shape of the basin, the distillate yield increases by 310 ml and this is 29.24% higher than the stepped type solar still A provided with flat basin. Due to the concavity of the absorber surface, the depth of water is the most at the middle of the basin steps. Whereas the depth of water is the least at the outer edges of the basin steps. The water mass at the outer edges of the basin steps being thinner; its specific heat capacity is less. This results in increase in the water temperature causing faster evaporation of water at the outer edges of the basin steps. Hence more distillate yield is obtained than that of flat basin steps.

As the mass of water is lesser in case of convex basin steps as compared to concave as well as flat basin steps; its specific heat capacity is less. Hence faster evaporation of water over the surface of convex basin takes place resulting in higher distillate yield as compared to concave and flat basin solar still.

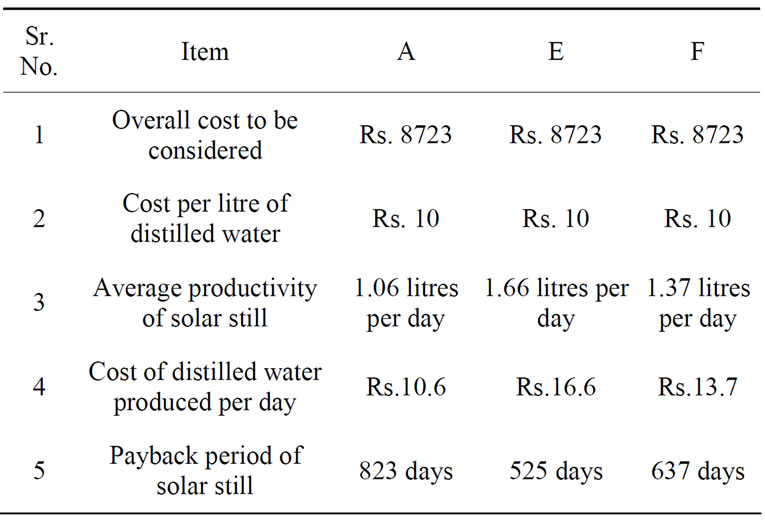

4.2. Economic Analysis

The payback period of the experimental setup depends on overall cost of fabrication, maintenance cost, operating cost and cost of feed water. The overall fabrication cost is Rs. 8723.

Figure 5. Distillate yield with time of the day for solar stills A, E & F.

It is not necessary to take into account the operation and maintenance cost and the cost of feed water, which is almost negligible. Thus, the payback period of the setup E with convex shape of the absorber surface is the least as shown in Table 5.

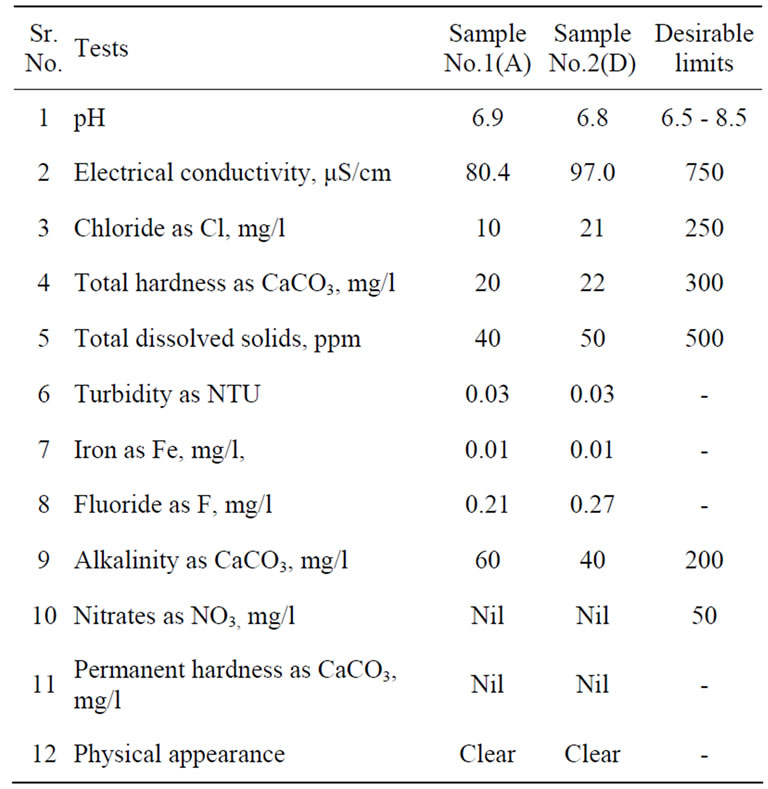

4.3. Distilled Water Quality

Two different water samples from solar stills A and D were tested in the District Public Health Laboratory, Buldana, Government of Maharashtra, India. The distilled water was tested with highly accurate digital instruments having an accuracy of ±l mg/l. The laboratory test results as shown in Table 6 indicate that the quality of water after distillation is well within the desirable limits as prescribed by WHO for Indian specific conditions.

5. Summary and Conclusions

Three numbers of solar stills with different shapes of the basin surface area are installed and tested. Solar still A is provided with plain surface area of the basin, Solar still E is provided with convex type surface area of the basin and solar still F is provided with concave type surface area of the basin. The readings were taken from 10 am to 5 pm. Hourly variations of solar radiation and distillate yield were recorded. It has been observed that the distillate yield of convex type solar still E is 56.6% higher than that of A and distillate yield of concave type solar still F is 29.24% higher than that of A. Thus, it can be concluded that the maximum distillate yield is obtained when the convex type of absorber surface is provided. In addition, the distillate yield of concave type absorber surface is greater than that of flat type absorber surface. Hence, the convex type surface area gives the maximum distillate yield for the given design and climatic conditions of the stepped type solar still.

Table 5. Calculation of payback period.

Table 6. Report on chemical examination of water for drinking purposes.

The laboratory tests indicate that the distillation process has eliminated total dissolved solids and total hardness. This shows that the distillation process is suitable for obtaining potable water as per the prescribed standards. Also, an economic analysis was made. The payback period of the convex type stepped solar still is the least as compared to other two types of solar stills and it is 525 days. The laboratory tests indicate that the pH, electrical conductivity, total hardness, TDS, Alkalinity, Nitrates etc. of water after distillation are well within the desirable limits as prescribed by WHO for Indian specific conditions.

REFERENCES

- M. Smyth, A. Strong, W. Byers and B. Norton, “Performance Evaluation of Several Passive Solar Stills,” Centre for Sustainable Technologies, School of the Built Environment, University of Ulster, Newtown Abbey, 2001.

- S. B. Sadineni, R. Hurt, C. K. Halford and R. F. Boehm, “Theory and Experimental Investigation of a Weir-Type Inclined Solar Still,” Energy, Vol. 33, No. 1, 2008, pp. 71-80. http://dx.doi.org/10.1016/j.energy.2007.08.003

- H. E. Gad, S. M. El-Gayar and H. E. Gad, “Performance of a Solar Still with Clothes Moving Wick,” 15th International Water Technology Conference, IWTC, 28-30 May 2011, Alexandria.

- Y. P. Yadav and G. N. Tiwari, “Monthly Comparative Performance of Solar Stills of Various Designs,” Desalination, Vol. 67, 1987, pp. 565-578.

- O. Badran, “Experimental Study of the Enhancement Parameters on a Single Stage Solar Still Productivity,” Desalination, Vol. 209, No. 1-3, 2007, pp. 136-143. http://dx.doi.org/10.1016/j.desal.2007.04.022

- V. Velmurugan, S. SenthilKumaran, V. Niranjan Prabhu and K. Srithar, “Productivity Enhancement of Stepped Solar Still—Performance Analysis,” Thermal Science, Vol. 12, No. 3, 2008, pp. 153-163.

Abbreviations

PUF: Polyurethenefoam;

TDS: Total dissolved solids.

NOTES

*Corresponding author.