World Journal of Mechanics

Vol.04 No.09(2014), Article ID:50194,15 pages

10.4236/wjm.2014.49028

Effective Yield Strength for Material Powder Consolidated at Stage II Compaction

Larbi Siad, Sophie Gangloff

BIOS EA 4691, Université de Reims, Reims, France

Email: larbi.siad@univ-reims.fr, sophie.gangloff@univ-reims.fr

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 19 June 2014; revised 15 July 2014; accepted 9 August 2014

ABSTRACT

This work is concerned with the estimation from the outside of effective yield strength for the stage II consolidated material package of axisymmetric solid particles. Once an appropriate simple representative axisymmetric unit cell is chosen, the kinematical approach of the yield design homogenization method is used in order to obtain external estimates which has been found depending on the loading history (isostatic and closed die compactions) as well as on the relative density of the material powder. For comparison purpose, finite element simulations that describe the behavior of spherical elastic plastic particles uniformly distributed inside the material powder are carried out.

Keywords:

Stage II Compaction, Kinematic Approach, Relevant Failure Mechanism, Unit Cell Model, Effective Yield Strength, Finite Element Analysis

1. Introduction

Isostatic and closed-die compaction are useful methods to manufacture complex shape engineering components such as, for example, gears, and cams for automotive applications. The ability to control accurately the size, composition and morphology of the microstructure, as well as the ease of processing are major advantages of the process. Consolidation in powder compaction occurs simply by the motion of particle centers toward each others by mechanisms of rearrangement and deformation. Nowadays the process of compaction is a successful and well-established process for metals, alloys, polymers and ceramics. It is usually divided into two stages according to packing state change and relative density. For the first stage, referred to as “stage I”, relative density is low

and consolidation of the powder is attributed to both changes in particles packing and particle deformation by growth of localized necks between particles. In the second stage, referred to as “stage II”, at higher compacted relative densities

and consolidation of the powder is attributed to both changes in particles packing and particle deformation by growth of localized necks between particles. In the second stage, referred to as “stage II”, at higher compacted relative densities , consolidation occurs purely by plastic deformation. The change in component dimension is much greater during stage I than in stage II compaction. It should be mentioned that a stage II powder is different from a porous solid (or sintered powder) of equal relative density in that the former has zero or low cohesive strength, while the later usually has tensile strength equal to the compressive one. Densification of the compact is achieved at elevated temperature with or without the simultaneous application of pressure [1] [2] . The present paper is concerned with the theoretical estimation “from the outside” of macroscopic yield surfaces for cold pressed powder in stage II at fixed relative density.

, consolidation occurs purely by plastic deformation. The change in component dimension is much greater during stage I than in stage II compaction. It should be mentioned that a stage II powder is different from a porous solid (or sintered powder) of equal relative density in that the former has zero or low cohesive strength, while the later usually has tensile strength equal to the compressive one. Densification of the compact is achieved at elevated temperature with or without the simultaneous application of pressure [1] [2] . The present paper is concerned with the theoretical estimation “from the outside” of macroscopic yield surfaces for cold pressed powder in stage II at fixed relative density.

In modeling the compaction process, the powder medium is considered as a solid with isolated voids that undergoes large elastic-plastic deformation. Numerous theoretical, numerical and also experimental studies have been published on the subject. A review as well as further details dealing with powder compaction modeling can be found for example in [3] [4] . The used phenomenological models provide information on the macroscopic behavior of the powder assembly such as density distribution, stress state and the shape of the compact during and after compaction. For describing the plastic flow of metal powders at low homologous temperature, Gu et al. [5] have developed a “two-mechanism” rate-independent constitutive model representable as a combination of a distortion mechanism and a consolidation mechanism which are dominated at the microstructural level by inter-particles sliding and the deformation of particles, respectively. Research work based on micromechanical approach has been initiated and developed by Ashby and co-workers (see for example the reference mentioned above) and Fleck et al. [6] [7] . Basically, the essential physics are the relationship between the macroscopic strain and the micro-mechanics of grain contact deformation, and the relationship between local contact loads and the resulting macroscopic stress. Fleck et al. [6] used the Bishop and Hill [8] method to estimate the macroscopic yield surface for a random aggregate made from rigid-perfectly plastic spheres. The roles of inter-particles friction, cohesive strength of the contacts and anisotropy resulting from grain periodicity upon the macroscopic yield surface was examined by these authors and also by Xin et al. [9] . The later used explicit Finite Element Analysis (FEA) to simulate monolithic and composite powders consisting of periodic unit cells. They concluded that the size and the shape of the macroscopic yield surface is sensitive to the magnitude of the cohesive strength between particles but the effect of friction is relatively minor.

In this study, in the framework of the kinematic approach of the Yield Design Homogenization Method (YDHM) [10] - [13] , external estimates of the effective yield strength of an array of axisymmetric particles are determined for both modes of compaction. In this context, since the yield design theory stipulates that large geometry changes are precluded, an appropriate axisymmetric Representative Volume Element (RVE) for material powder in stage II at fixed relative density is proposed together with four axisymmetric relevant (virtual) velocity fields. Similar investigations have been carried in [14] for stage stage II compaction using another appropriate axisymmetric RVE. For comparison purpose, Finite Element (FE) simulations similar to those of Ogbanna and Fleck [15] for spherical elastic plastic particles uniformly distributed inside the consolidated material powder are carried out. They have been used to examine the evolution of contact size, contact pressure and macroscopic yield surface with the degree of consolidation.

2. Representative Volume Element

The first step in micromechanical constitutive modeling is the suggestion of a RVE which adequately captures essential features of the underlying microstructural geometry and deformation modes of the heterogeneous material under consideration. On the other hand, a convenient way to numerically solve the homogenization problem is to use periodic boundary conditions applied on a periodic unit cell. The two other commonly used boundary conditions are the homogeneous boundary strain rate condition and the homogeneous boundary stress condition. Both homogeneous and periodic boundary conditions may introduce additional constraints resulting in “biased” numerical solutions including boundary effects and eventually unrealistic stiff response (See in [16] the discussion about the minimal boundary conditions applicable to a RVE of any shape). Periodic boundary conditions require periodic spatial distribution of the microstructure, and this enables the approximation of the heterogeneous material by an indefinite extension of a periodic elementary cell in the three dimensions of space. This assumption has been widely used in the literature as it requires the modeling of only the highlighted elementary cell, greatly saving computational cost. The arrangement of particles for this study is shown in Figure 1(a). The powder compact is considered as an assemblage of hexagonal cylinder unit cells filled with an axisymmetric cylindrical particle (Figure 1(b)). The assumption of regularly (instead of random) packed mono-

Figure 1. Model microstructure for a powder material. (a) 3D package of hexagonal cylinder unit cells; (b) RVE Ω for a consolidated material powder with 0.90 ≤ D ≤ 0.95 (stage II).

sized particles substantially simplifies the analysis as the entire densification process can be analyzed from relatively simple unit cell calculations. However, it should be mentioned that the stacked hexagonal array RVE assumes a rather unrealistic particle distribution, and as a result, desired modes of deformation such as interparticle shear are restricted.

The plastic deformation of particles during stage II compaction is confined in the vicinity of small traction- free voids since the interaction of plastic contact zones is such that the solid material is forced to be extruded towards the traction-free voids. For the sake of simplicity and having regard to the smallness of the traction-free void with respect to the particle dimension, the boundary of the void is assumed diamond shaped with edge

(Figure 1(b)). This claim is consistent with FE results presented in section 5 and dealing with the deformation mode of spherical particle for various initial relative densities. Let us consider an axisymmetric RVE Ω of a powder compact with a relative density

(Figure 1(b)). This claim is consistent with FE results presented in section 5 and dealing with the deformation mode of spherical particle for various initial relative densities. Let us consider an axisymmetric RVE Ω of a powder compact with a relative density

corresponding to stage II compaction, that is

corresponding to stage II compaction, that is .

.

is defined by the ratio , where

, where

and

and

denote the parts of Ω occupied by the solid particle and

denote the parts of Ω occupied by the solid particle and

the void, respectively and

stands for the volume of

stands for the volume of . In the undeformed configuration, Ω is a circular cylinder with diameter

. In the undeformed configuration, Ω is a circular cylinder with diameter

and height

and height

filled with an circumscribed axisymmetric cylindrical particle with chamfered edges (initial length

filled with an circumscribed axisymmetric cylindrical particle with chamfered edges (initial length ). Along the compaction process the current values of diameter, height and chamfer length fulfill the constraint

). Along the compaction process the current values of diameter, height and chamfer length fulfill the constraint

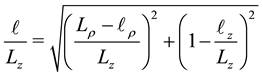

(1)

(1)

The macroscopic response of the unit cell model is given by the average state of strain and stress within it. Its overall deformation can be calculated from the normal displacements of both rigid plates. Apparently, the macroscopic total logarithmic strains tensor and Cauchy stresses tensor possess the same principal directions, which are the radial and axial directions. The logarithmic radial

The effective strain

is chosen as the overall plastic deformation of the unit cell model and the independent variable for presenting most results. We introduce

where

In the next two sections the unit cell model

3. Basics of the Yield Design Homogenization Method

The average of a field

with

where

microscopic stress field in equilibrium with

states that:

with

heterogeneous medium reduces to solving a yield design boundary value problem defined over a RVE [12] [13] . The static definition of

The convexity of

where

second order tensors

with

normal vector

Velocity fields complying with constraints of zero volume change (i.e.

The dual definition of

where

Using Hill’s lemma (7) together with the definition Equation (12), de Buhan [13] has noticed that, for any periodic perturbation

The domain

4. External Estimates of Effective Yield Strength

External estimates of effective yield surfaces of powder compacts at fixed densities

where

where

4.1. First Proposed Class of Virtual Velocity Fields

Using cylindrical reference coordinate system with radial coordinate

where

Figure 2. Boundary conditions and loading of the quarter of the unit cell Ω. The failure pattern depends upon geometrical parameter α which defines the shapes of the three zones.

The three zones , and are separated by two velocity jump axisymmetric surfaces, the cross sections of which by the figure plane are the lines

with

with

where

The general form of the virtual power performed by external loading for any velocity field

where the dot stands for the inner product of vectors. For the velocity field

The maximum resisting power

velocity is continuous.

with

Comparing (26)-(27) and (25), the fundamental inequality (16) results in:

which may be rearranged to provide upper bound solutions to the normalized macroscopic axial stress once the normalized macroscopic radial stress is given a particular value. Indeed, one has

where

Whenever the geometric parameter

The relationships contained in Expressions (30) are too involved to allow differentiation to derive directly the critical condition, and the procedure is cumbersome. Alternatively, the optimization of the proposed virtual failure mechanism in order to obtain the minimum upper bound for the ultimate loads supported unit cell

In the macroscopic stress plane reported to macroscopic normalized stresses axes

corresponding curve to the theoretical bound (32) is simply represented by a horizontal line which intercept with the coordinate axis

4.2. Second Proposed Class of Virtual Velocity Fields

Hereafter, one follows the same procedure as in the foregoing analysis but considering a second relevant class of virtual velocity field

Figure 3. Second proposed failure mechanism of Ω. The failure pattern depends upon geometrical parameter β which defines the shapes of the three zones.

where both

with

with

with

and

Inequality (36) combined with Equations (37) and (38) may be rearranged in order to provide the following upper bound solutions for

where, for the sake of conciseness, the expression of the function

Figures 4-5 show the third and forth proposed relevant virtual failure mechanisms. The failure mechanisms again exhibit three zones within Ω and contributions to the maximum resisting power are developed inside volumes of zones and , and along the displayed three velocity jump surfaces

5. Finite Element Analysis

Suitable FE simulations allow to highlight the deformation mode of the chosen unit cell model as well as to obtain the overall stress-strain curves that represent the behavior of the powder compact at the macroscopic scale. The analysis presented hereafter is similar to Ogbonna and Fleck’s studies [15] where, in particular, the nature of contact growth and material flow based on the deformation of a spherical particle subject to combined radial and axial constraints is discussed. The “probing method” is used to determine the size and shape of the macroscopic yield surface for a consolidated material powder with a prescribed relative density. To this goal, the unit cell model is first strained to a prescribed relative density and unloaded to zero macroscopic stress. The so-called precompact that results from this operation is then re-loaded along various prescribed straining path until the point of plastic collapse. Both proportional and nonproportional straining paths may used to generate data for the yield behavior of the unit cell model. The proportional straining paths include the special cases of closed die compaction and isostatic compaction. The nonproportional paths are for uniaxial compression and for radial compression. The locus of macroscopic stresses at the point of plastic yielding gives the shape of the

Figure 4. Relevant virtual failure mechanism

macroscopic yield surface. In the initial undeformed configuration the axisymmetric unit cell model

which initial value

where

Figure 6. FEA of quarter of the unit cell. Boundary conditions and loading system through vertical and horizontal rigid surfaces.

Figure 7. FEA of isostatic compaction. Characteristic dimensions of the contact areas between adjacent solid particles. The unit cell Ω is pressed to a relative density D equals to 0.95.

Figure 8. FEA of closed die compaction. Characteristic dimensions of the contact areas between adjacent solid particles. The unit cell Ω is pressed to a relative density D equals to 0.95.

6. Results and Discussion

The obtained external estimates of effective yield surfaces for stage II consolidated material powder, for both isostatic and closed die consolidated material powders, are shown in Figure 9 and Figure 10 respectively. The relative density has been fixed to

Figure 9. Yield surfaces for isostatic consolidated material powder at relative density taking values 0.90 and 0.95. Comparison of the kinematic approach results (solid blue lines) to those provided by FE simulations (dashed red lines). (a) Normalized plane stress

Figure 10. Yield surfaces for closed die consolidated material powder at relative density taking values 0.90 and 0.95. Comparison of the kinematic approach results (solid blue lines) to those provided by FE simulations (dashed red lines). (a) Normalized plane stress

・ The shape and the size of effective yield surfaces, for both isostatic and closed die consolidated material powder, change as the relative density

・ For both values of

・ For a given relative density, the yield stress in uniaxial yield compression is lower for isostatic consolidated material powder than for closed die one. The results are opposite for the yield stress in pure radial compression. This observation apparently confirms the fact that the yield behavior of a particle is not just a function of the relative density but also depends on the loading history.

・ The results provided by the kinematic approach is adequate with the finite element predictions that is taken as the reference solutions for the determination of macroscopic yield criteria. Differences can be attributed to the fact that the assumed geometries of unit cells are slightly different for both methods since the size contacts for both methods are in some degree different. It should be kept in mind among other from analysis developed in section 5 that under isostatic compaction, the contact radius

The corpus of the obtained results should necessarily be enriched by lower bound solutions or, even better, by experimental results, since these results are upper bound solutions and they are thus found on the unsafe side of the design. Pastor et al. [17] has provided very close lower and upper bounds of the famous Gurson model used in ductile failure of materials. The methodology employed by these authors comes just at the right moment to address the problem under consideration with however various complexities such as, for example, composite powders. Brown and Weber [18] has demonstrated that the yield behavior of compacted and then sintered powder is different from that of identical powder compacted without sintering, and the uniaxial tensile yield stress is lower for the compacted-only powder. In addition, the Brown and Abou-Chedid's experimental results [19] proved that relative density and particle hardening are not the only state variables to represent powder yield behavior. In this context, the kinematic approach of the yield design theory could turn out to be useful in accounting for the interparticle-cohesion.

7. Conclusion

Based on the kinematic approach of the yield design homogenization method, optimal external estimates of effective yield surfaces of stage II powder compact materials under isostatic and closed die compaction have been obtained. To this goal, an appropriate unit cell model and four relevant failure mechanisms are considered. For comparison purposes, numerical simulations based on FEA similar to those of Ogbana and Fleck [15] have also been carried out. Several interesting conclusions may be drawn.

・ First, the obtained external estimates of the effective strength criteria of the powder compacts at hand may be used either as a rigorous upper bound, or to assess the quality of existing models for yielding of powder compacts during stage compaction II.

・ Compared to the results provided by the FEA, the external estimates of the effective yield surfaces could be deemed to be acceptable from a practical point of view.

・ As expected, their shape and size are found to be dependent on the relative density and on the loading history as well.

・ The results has revealed the existence of a corner on the effective yield surfaces at the loading point.

・ The analysis presented herein may easily be extended to more complex situations than that selected in this paper for illustrative purposes (e.g., consideration of additional classes of failure mechanisms is required, composite powders compacts, accounting for the interparticle-cohesion).

Cite this paper

LarbiSiad,SophieGangloff, (2014) Effective Yield Strength for Material Powder Consolidated at Stage II Compaction. World Journal of Mechanics,04,273-288. doi: 10.4236/wjm.2014.49028

References

- 1. M.F. Ashby Back Ground Reading: Hot Isostatic Pressing and Sintering. Internal Report, Cambridge University Engineering Department, Cambridge, 1990.

- 2. McMeeking, R.M. and Kuhn, L.T. (1992) A Diffusional Creep Law for Powder Compacts. Acta Metallurgica et Materialia, 40, 961-969.

http://dx.doi.org/10.1016/0956-7151(92)90073-N - 3. Helle, H.S., Easterling, K.E. and Ashby, M.F. (1985) Hot-Isostatic Pressing Diagrams: New Developments. Acta Metallurgica, 33, 2163-2174.

http://dx.doi.org/10.1016/0001-6160(85)90177-4 - 4. Brewin, P.R., Coube, O., Doremus, P. and Tweed, J.H. (2008) Modelling of Powder Die Compaction. Springer-Verlag, London.

- 5. Gu, C., Kim, M. and Anand, L. (2001) Constitutive Equations for Metal Powder: Application to Powder Forming Process. International Journal of Plasticity, 17, 147-209.

http://dx.doi.org/10.1016/S0749-6419(00)00029-2 - 6. Fleck, N.A., Kuhn, L.T. and McMeeking, R.M. (1992) Yielding of Metal Powder Bonded by Isolated Contacts. Journal of the Mechanics and Physics of Solids, 40, 1139-1162.

http://dx.doi.org/10.1016/0022-5096(92)90064-9 - 7. Fleck, N.A. (1995) On the Cold Compaction of Powders. Journal of the Mechanics and Physics of Solids, 43, 1409-1431.

http://dx.doi.org/10.1016/0022-5096(95)00039-L - 8. Bishop, J.F.W. and Hill, R. (1951) A Theoretical Derivation of the Plastic Properties of a Polycrystalline Face-Centred Metal. Philosophical Magazine Series 6, 42, 1298-1307.

http://dx.doi.org/10.1080/14786444108561385 - 9. Xin, X.J., Jayaraman, P., Daehn, G.S. and Wagoner, R.H. (2003) Investigation of Yield Surface of Monolithic and Composite Powders by Explicit Finite Element Simulation. International Journal of Mechanical Sciences, 45, 707-723.

http://dx.doi.org/10.1016/S0020-7403(03)00107-3 - 10. Salencon, J. (2013) Yield Design. ISTE Ltd. and John Wiley & Sons, Inc., London, Hoboken.

http://dx.doi.org/10.1002/9781118648988 - 11. Salencon, J. (1993) Yield Design: A Survey of the Theory. CISM Lectures Series, No. 332, Springer, Wien, New York, 1-44.

- 12. Suquet, P. (1983) Analyse limite et homogeneisation. Comptes Rendus de l’Academie des Sciences, 1355-1358.

- 13. de Buhan, P. (1986) A Fundamental Approach to the Yield Design of Reinforced Soil Structures. Chap. 2, Yield Design Homogenization Theory for Periodic Media. Doctorat d’Etat, Universite Pierre et Marie Curie, Paris (In French).

- 14. Benabbes, A., Siad, L., Dormieux, L. and Liu, W.K. (2010) Yield Design Homogenization Method for Compaction of Monosized Spherical Powders. International Journal of Applied Mechanics, 2, 457-4883.

http://dx.doi.org/10.1142/S1758825110000615 - 15. Ogbonna, N. and Fleck, N.A. (1995) Compaction of an Array of Spherical Particles. Acta Metallurgica et Materialia, 43, 603-620.

http://dx.doi.org/10.1016/0956-7151(94)00286-Q - 16. Mesarovic, S.D. and Padbidri, J. (2005) Minimal Kinematic Boundary Conditions for Simulations of Disordered Microstructures. Philosophical Magazine, 85, 65-78.

http://dx.doi.org/10.1080/14786430412331313321 - 17. Trillat, M., Pastor, J. and Francescato, P. (2006) Yield Criterion for Porous Media with Spherical Voids. Mechanics Research Communications, 33, 320-328.

http://dx.doi.org/10.1016/j.mechrescom.2005.05.013 - 18. Brown, S.B. and Weber, G.G.A. (1988) A Constitutive Model for the Compaction of Metal Powders. Proceedings of International Powder Metallurgical Conference, 18, 465-476.

- 19. Brown, S. and Abou-Chedid, G. (1994) Yield Behaviour of Metal Powder Bonded Assemblages. Journal of the Mechanics and Physics of Solids, 42, 383-399.

http://dx.doi.org/10.1016/0022-5096(94)90024-8

.

.