Soft

Vol.04 No.03(2015), Article ID:61730,10 pages

10.4236/soft.2015.43003

Linear Algebra Provides a Basis for Elasticity without Stress or Strain

H. H. Hardy

Math/Physics Department, Piedmont College, Demorest, USA

Copyright © 2015 by author and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

Received 16 November 2015; accepted 4 December 2015; published 7 December 2015

ABSTRACT

Linear algebra provides insights into the description of elasticity without stress or strain. Classical descriptions of elasticity usually begin with defining stress and strain and the constitutive equations of the material that relate these to each other. Elasticity without stress or strain begins with the positions of the points and the energy of deformation. The energy of deformation as a function of the positions of the points within the material provides the material properties for the model. A discrete or continuous model of the deformation can be constructed by minimizing the total energy of deformation. As presented, this approach is limited to hyper-elastic materials, but is appropriate for infinitesimal and finite deformations, isotropic and anisotropic materials, as well as quasi-static and dynamic responses.

Keywords:

Elasticity, Stress, Strain, Finite Elasticity

1. Introduction

Soft materials like rubber, foam, and many biological materials can stretch far beyond the limits of infinitesimal elasticity and yet return to their original shape when forces are removed. It is useful to be able to model these deformations, but infinitesimal elasticity based on stress and strain tensors cannot be used for these large deformations. The classical equations of finite elasticity are quite difficult, requiring 30 or more tensors to explain the theory. The description of elasticity presented here presents the same equations for both infinitesimal and finite elasticity, and requires only two tensors to define the theory.

The description of elasticity presented here will be for hyper-elastic materials. A hyper-elastic material stores energy when it is deformed and returns this energy to its surroundings when it is returned to its original state. Rubber is the most common example. The energy stored in the material can be expressed as a function of the positions of the points within the material. By minimizing the stored energy, differential equations of elasticity and forces can be found. The idea of describing deformations in terms of points and forces was first used by Euler, Lagrange, and Poisson and predates Cauchy’s introduction of stress and strain [1] . The earlier researchers, however, did not complete the description of the general differential equations for finite elasticity. I will do that here. To do this, I will follow the notation of Spencer [2] to describe the positions of the points within the body before and after deformation.

2. Deformation as a Mapping

Define the initial location of each point within a material as the vector,  , with components

, with components ,

, . After the deformation, each point in the material will be at some new position,

. After the deformation, each point in the material will be at some new position,  , with components

, with components ,

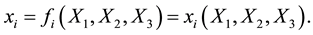

, . The components of each point after the deformation are functions of the components of the position of each point before deformation. That is

. The components of each point after the deformation are functions of the components of the position of each point before deformation. That is

(1)

(1)

To match the physical reality of the deformation of a material, neither inversions nor a change of dimension of the material will be allowed (i.e. a three-dimensional material cannot be turned inside out or pressed into a plane or a line). As a result of this restriction, every point in the material after the deformation will correspond to exactly one point in the material before deformation, so that the mapping from  to

to  is one-to-one.

is one-to-one.

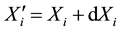

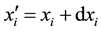

Consider now a point near the point , i.e.

, i.e. . The point

. The point  is mapped into the point

is mapped into the point . We can find the relationship between

. We can find the relationship between  and

and  by differentiating Equation (1) and using the chain rule to give

by differentiating Equation (1) and using the chain rule to give

here and throughout the rest of this paper, the Einstein summation notation is used so that repeated indices are summed over. In general

is called the deformation gradient tensor by Spencer [2] . The results found so far are appropriate for any coordinate system, but I will use two specific inertial coordinate systems (i.e. fixed coordinate systems where New-

Figure 1. In this figure,

ton’s laws apply). One I will call the observer coordinate system. This coordinate system is the one chosen to solve some problem in (e.g. a simulation or an engineering problem). The second inertial coordinate system I will call the experimental coordinate system. This coordinate system will be the one chosen by an experimentalist who wishes to measure the energy associate with a particular deformation of a particular sample. In the observer coordinate system, I will denote the components of

3. Measuring the Energy of Deformation

It is sufficient to limit experimental deformations to homogeneous deformations of a homogeneous portion of the material in order to define the energy of deformation. If the body is anisotropic, it is necessary to define the orientation of this anisotropy. This could be determined by a visual inspection (e.g. wood grain) or by a knowledge of how the material was made (e.g. rebar in concrete). Orient the anisotropy to align with the experimental coordinate system so that in the experimental coordinate system the anisotropic coordinate system of the materi-

al is

script, k, denotes which coordinate vector and the subscript, i, denotes which component.) Using the notation of Equation (3), Equation (2) in the experimental coordinates system becomes

A homogeneous deformation is a deformation in which every point in the body undergoes an affine transformation. Linear algebra defines an affine transformation as a mapping that transforms any point in space

where

Taking the derivative of Equation (5) and comparing the result with Equation (4), we find that in our experimental coordinate system

To measure the energy during experiments, record the applied forces,

The energy per original volume, E, is found by dividing the total energy by the initial volume of the sample, V.

With these measurements, an experimenter can construct a table of the stored energy per unit initial volume as a function of the 12 components of

This completely defines the energy per unit original volume for homogeneous deformations of the material sample.

4. Special Experimental Cases

We have found that in general the experimentally measured energy per unit volume, E, can be a function of as many as 12 component values (nine in

A further reduction of parameters for rotations and deformations can be found if we take a Singular Value Decomposition (SVD) of

This form will be useful in describing both experimental processes to measure the energy of deformation and the equations of elasticity. Since any deformation,

In the most general case the energy of the material can depend upon body forces from electric or magnetic forces in addition to gravity. For example, a material with an electric dipole (

If the body is isotropic, then the energy will be independent of both

and only two independent elements of

In addition to these simplifications, it is sufficient to measure the energy as a function of only those changes that are expected in a particular application. So for example, if infinitesimal deformations are sufficient to model the problem at hand, only one small displacement measurement in each direction is required. Alternatively, if the body is going to be used only in extension, there is no need to measure the energy associated with compressional forces. Rivlin [3] used this approach for rubber. For his application the rubber could be considered isotropic and incompressible, so he only deformed the material sample in extension along two perpendicular directions. This is sufficient to find the energy as a function of

Finally, if a deformation contains only rigid body motions, materials are neither compressed nor extend, so that

What we have found is that we can reduce the number of variables that the energy is a function of from 12 to as few as 2 in the case of an incompressible, isotropic material where we can ignore external body forces like gravity in our application. In general, however, all 12 variables may be required and it is helpful to find the most computationally efficient way to represent the energy for each application.

5. Some Application Issues

We have found that

In addition

where

If the material is anisotropic, the energy per unit volume is a function of the six independent values of and

Schmidt QRD algorithm instead of the more common Householder QRD, because the Householder algorithm permits inversions.)

6. Coordinate Alignment

When an anisotropic material is placed in “service” it is necessary to know the initial orientation of the anisotropy. This is because the stored energy is a function of the orientation of the isotropic material relative to the observer’s coordinate system. For example consider a laminate. If the laminate is oriented so that the lamina are parallel to the x-y plane in the observer’s coordinate system and extended in the x direction a fixed amount there will be a change in energy of the material. However, if the same laminate is initially oriented so that the lamina are parallel to the y-z plane in the observer’s coordinate system and extended in the x direction the same fixed amount there will be a different change in energy of the material. Thus the initial orientation of the lamina in the observer’s coordinate system must be known in order to correctly calculate the stored energy in the material.

When the material is placed in “service” before any deformation has occurred, the anisotropic coordinate system in which the energy measurements were made,

The local deformation which is expressed in the observer’s coordinate system,

Note that

So that in general,

7. Is This Energy a Scalar?

It may seem strange that we must transfer the coordinate values of the material in the observer’s coordinate system back into the experimental coordinate system in order to find the local change in energy, but this is exactly as it should be. Energy must be a scalar, which is independent of the choice of the coordinate system. That this is the case can be seen if we express the energy in terms dot products of vectors, which are independent of the coordinate choice. Note that the local anisotropy coordinate system vectors,

The corresponding mapping of these same vectors in the experimental coordinate system is

We can choose to express the energy as a function of the invariant,

In the observer’s coordinate system, where

Comparing Equation (19) to Equation (20) returns us to Equation (14) since

This is the same type of explanation that must be used in expressing the energy in terms of the components of displacement vectors, although we usually do not discuss it in these terms. Usually the energy associated with the displacement can be calculated from a formula instead of having to carry out individual experiments for each material. For example, a displacement in the presence of gravity changes the energy stored in the material, but it is easily expressed as

A word of caution is necessary here. The vectors

fined in the experimental coordinate system, and therefore the transformation in Equation (14) must be carried out before extracting the column vectors of

8. Simulations

I have now completely defined a method to measure the energy of deformation of a homogeneous body experimentally and how to place the material in a given application. Because engineering applications are often complex, it is usually necessary to put this information into a computer simulation. The simplest approach is to just “pasting” small pieces of the material together to define the complete material. This can be done by randomly positioning points in the material and use these to divide the material to be simulated into small tetrahedrons of volume

where k is summed over all the tetrahedra in the material. Apply the boundary conditions and move the internal points to produce minimum total energy,

An alternative method is to use a continuous Euler-Lagrange technique to minimize the functional,

The result of this approach is a set of partial differential equations which can be solved by any numerical technique (e.g. finite difference, finite element, Rayleigh-Ritz, etc.). I have called this Euler-Lagrange elasticity [5] .

9. Differential Equations

The discrete region method collapses into Euler-Lagrange elasticity if the size of each tetrahedron approaches zero as the number of tetrahedra, N, increase without bound, i.e.

To find the differential equations of elasticity we need to minimize (or find the extrema) of

With

These three equations are quite general, being appropriate for both infinitesimal and finite deformations, for isotropic and anisotropic materials, and can include surface forces, gravity, and electrical and magnetic forces.

10. Special Application Cases

If the material is homogeneous,

If only infinitesimal deformations are needed, then E can be expanded in a Taylor’s expansion which yields the same differential equations Landau derived for infinitesimal deformations [8] using classical stress and strain techniques.

If time dependence is required, define the Lagrangian,

where

results again in three Euler equations, now of the following form:

These three equations are the time dependent differential equations for hyper-elasticity [9] . All that is needed now is to include boundary conditions and force.

Boundary conditions consist of Neumann and Dirichlet boundary conditions. Dirichlet boundary conditions just set the positions of boundary points of the material. Neumann boundary conditions can be expressed in terms of applied forces on the surfaces of the material [5] ,

where

11. Comparison to Other Elasticity Theories

The most obvious difference of this approach and classical elasticity is that in this approach there is no definition of stress or strain. Here displacements and forces are the alternatives to stress and strain. This approach also requires the definition of only one second order tensor, the deformation gradient tensor. In elasticity with stress and strain more than 30 tensors have been used to describe finite elasticity [10] [11] .

For classical elasticity with stress and strain, the invariants

sented in this paper, the invariants used are

Some descriptions of elasticity define

In some descriptions of elasticity, only “objective tensors” are used to formulate the constitutive equations. Objective tensors are required to be independent of the motion of the material that is being deformed. That is, these tensors should be the same in both a fixed reference coordinate system and in a coordinate system that deforms with the material [11] . In this paper all physical quantities are expressed only in terms of one of two coordinate systems fixed in space before any deformation takes place. In this paper, neither the observer coordinates nor the experimental coordinates deform as the material deforms. Both are inertial coordinate systems fixed in space. (The anisotropy coordinates

Some details may be easily confused between this approach and the Classical approach. Three examples follow:

QRD is not the same as Polar decomposition that is used in classical elasticity theory. Polar decomposition produces

The term

12. Conclusion

A method of describing hyper-elasticity using linear algebra has been presented that uses points within the material and forces instead of stress and strain. The theory provides a straight forward way to measure material properties and allows the inclusion of magnetic and electric fields as well as gravity. This description uses the same equations for both finite and infinitesimal deformations. Neumann boundary conditions are expressed in terms of measured forces instead of computed stresses. The result is a complete theory of hyper-elasticity which includes infinitesimal and finite deformations, isotropic and anisotropic materials, quasi-static and dynamic elastic responses.

Acknowledgements

I would like to acknowledge Mr. Joshua Wood and Dr. Michael Berglund for their very fruitful discussions and helpful suggestions.

Cite this paper

H. H.Hardy, (2015) Linear Algebra Provides a Basis for Elasticity without Stress or Strain. Soft,04,25-34. doi: 10.4236/soft.2015.43003

References

- 1. Todhunter, I. (1886) A History of the Theory of Elasticity and of the Strength of Materials from Galilei to the Present Time. Cambridge University Press, Cambridge.

- 2. Spencer, A.J. (1980) Continuum Mechanics. Dover, New York.

- 3. Rivlin, R.S. and Saunders, D.W. (1951) Large Elastic Deformations of Isotropic Materials. VII. Experiments on the Deformation of Rubber. Philosophical Transactions of the Royal Society of London. Series A. Mathematical and Physical Sciences, 243, 251-288. http://dx.doi.org/10.1098/rsta.1951.0004

- 4. Hardy, H.H. and Shmidheiser, H. (2011) A Discrete Region Model of Isotropic Elasticity. Mathematics and Mechanics of Solids, 16, 317-333. http://dx.doi.org/10.1177/1081286510391666

- 5. Hardy, H.H. (2013) Euler-Lagrange Elasticity: Differential Equation for Elasticity without Stress or Strain. Journal of Applied Mathematics and Physics, 1, 26-30. http://dx.doi.org/10.4236/jamp.2013.17004

- 6. Gilbert, J.D. (1970) Elements of Linear Algebra. International Textbook Company, Scranton.

- 7. Gelfand, I.M. and Fomin, S.V. (1991) Calculus of Variations. Dover, New York.

- 8. Landau, L.D. and Lifshitz, E.M. (2005) Theory of Elasticity, Course of Theoretical Physics. Volume 7, Elsevier, London.

- 9. Hardy, H.H. (2014) Euler-Lagrange Elasticity with Dynamics. Journal of Applied Mathematics and Physics, 2, 1183-1189. http://dx.doi.org/10.4236/jamp.2014.213138

- 10. Truesdale, C. and Noll, W. (2004) The Non-Linear Field Theories of Mechanics. Springer-Verlag, New York. http://dx.doi.org/10.1007/978-3-662-10388-3

- 11. Wu, H.-C. (2004) Continuum Mechanics and Plasticity. CRC Press, New York. http://dx.doi.org/10.1201/9780203491997

- 12. Kelly, P. (2015) Mechanics Lecture Notes Part III: Foundations of Continuum Mechanics. http://homepages.engineering.auckland.ac.nz/~pkel015/SolidMechanicsBooks/Part_III/