Journal of Materials Science and Chemical Engineering Vol.03 No.04(2015),

Article ID:55098,5 pages

10.4236/msce.2015.34001

Interaction of the Linear-Connected Pittings

Saif A. Mouhammad

Physics Department, Faculty of Science, Taif University, Taif, Kingdom of Saudi Arabia

Email: saifnet70@hotmail.com

Copyright © 2015 by author and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 2 March 2015; accepted 25 March 2015; published 27 March 2015

ABSTRACT

In this work, the mechanism of interaction of pittings, occurring on the heterogeneous surface of the passivated metal at presence in an aqueous electrolyte solution the activating (halide) anions is developed. A mathematical scheme describing this mechanism is presented. The equations for the currents density of the anodic dissolution of pitting as a function of concentration of activating anions and free water are obtained. The closed system of the equations representing a basis theory of an interaction of pittings is obtained.

Keywords:

Pitting, Electrolyte, Depassivation, Metal, Dissolution

1. Introduction

Pittings are called, as is known, local, i.e., small on the area (with a radius of r ~ 10-2 to 0.5 cm), but deeply penetrating, often through the destruction of the metal lattice in the electrolytes, occurring on the mechanism of its anodic dissolution.

Pittings spontaneously appear as a result of the interaction of the metal surface

with an electrolyte with the values of the anode potential, which corresponds to

the region of the passiveness of metal and the presence in electrolyte a sufficiently

high concentration of activating anions. The most dangerous of them are

ions.

ions.

The internal surface of a pitting is dissolved at a rate by (102 to 104) times greater than the rate of dissolution of the surrounding metal surface.

Therefore at the small on mass loss of metal, pittings render inoperable large metal structures, limiting the periods of their exploitation service in different production technologies and other regions.

Consequently, there are many experimental studies concerning pittings but the pitting process theory is underdeveloped. It is necessary to highlight the problem of the localization mechanism of pitting, the mechanism of their interaction and the mechanism of their growth. These tasks can be considered independently.

In [1] [2] , the problem of the growth of a single pitting is examined. In fact,

on the metal surface

there arise many [3] pittings, only a few of which survive and develop due to their

interactions, for the first time considered in the article.

there arise many [3] pittings, only a few of which survive and develop due to their

interactions, for the first time considered in the article.

Relative to this interaction in [1] [2] is expressed only the idea about the fact

that, for survival and increase of an emerged pitting ( the development of its nucleus,

i.e. a locally depassivated section

of the surface

of the surface )

is necessary the particular volume

)

is necessary the particular volume

of the electrolyte solution, from which the developing pitting is capable to obtain

the necessary for its increase reagents, precisely, the water molecules and the

activating anions, for example halide. For them, the boundary of the region

of the electrolyte solution, from which the developing pitting is capable to obtain

the necessary for its increase reagents, precisely, the water molecules and the

activating anions, for example halide. For them, the boundary of the region

may not coincide and in process of development of pitting to be displaced. Interaction

considerably of pittings is reduced to competitive fight for volume

may not coincide and in process of development of pitting to be displaced. Interaction

considerably of pittings is reduced to competitive fight for volume . This idea is developed below, taking into account the results

of [1] [2] , for example system Fe in the aqueous solution HCl used in [4] in the

case of chrome.

. This idea is developed below, taking into account the results

of [1] [2] , for example system Fe in the aqueous solution HCl used in [4] in the

case of chrome.

2. Laws of Interaction of Two Pittings

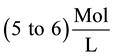

According to [5] , the density

current in the model of pitting reaches

current in the model of pitting reaches . The related utilisation of the aqueous solvent for the hydration

of metal ions

. The related utilisation of the aqueous solvent for the hydration

of metal ions

leads to dehydration of the electrolyte near the bottom of pitting. In [1] [2] it

is shown that in the layer with a thickness of

leads to dehydration of the electrolyte near the bottom of pitting. In [1] [2] it

is shown that in the layer with a thickness of

equal to the depth of the diffusional penetration for a characteristic time

equal to the depth of the diffusional penetration for a characteristic time

[5] the development of the pitting of concentration

[5] the development of the pitting of concentration

of metal

of metal

ions

reaches

reaches . The

solution of such a concentration simulating pitting is obtained, for ex-

. The

solution of such a concentration simulating pitting is obtained, for ex-

ample in [6] [7] . Therefore, when the value of the hydration number is , a significant portion of water molecules is included in the

hydration shell and current

, a significant portion of water molecules is included in the

hydration shell and current

Under these conditions, it is known [8] [9] , the Fick’s law discontinues to work

in the transfer equations commonly used in electrochemistry. The concentration

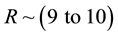

where

The above assessment of the concentration

Therefore, the volume of electrolyte solution is divided into areas

In [1] [2] the areas

At first let us consider the mechanism of this process by the example of a model of two coupled pittings, Figure 1. it is simplified geometrical part of the problem while maintaining all physical factors and obtained is a closed self-consistent system of relations describing the mechanism of interaction.

In this model, two interacting pittings are modelled by the anodic dissolving surfaces

As outlined above, by dissolving the water flows arise

ions

On it are continuous the values of free water concentrations in volumes

where

Figure 1. Geometry of the

two-dimensional model of interacting pittings S1 and S2; Cylindrical

areas ΔV1 and ΔV2 represent their “living spaces”; plane

Similar conditions for convection flows

According to the mathematical physics [10] in the Equation (2) the value of q on

the right means the function of the hydrogen flow caused by its participation in

the cathode reaction. According to its meaning q is equal to the amount of hydrogen

utilised in

where xk―cathode plane coordinate,

If

where the upper signs (+) and (−) mean the opposite sides of the interface

They are considered in the coordinate system, connected with metal electrodes. The

initial conditions for them determine the composition of the electrolyte, that allows

to study its influence on the pitting formation. In (1)-(6) current density

where the stoichiometric number

where the index

3. Conclusion

In conclusion, we should note that apparently only with the model on Figure 1, the dehydration effects, which stop weak pitting

growing, can be identified and explicitly observed. In the case of the more complicated

actual geometry, an arrangement of interacting pittings in the same anodic horizontal

plane of the interface areas

References

- Kolotyrkin, Y.M. and Popov, Y.A. (1982) Advances in Physical Chemistry. Current Development in Electrochemistry and Corrosion. In: Kolotyrkin, Y.M., Ed., Mir Publisher, Moscow, 11.

- Kolotyrkin, Y.M., Popov, Y.A. and Alekceev, Y.V. (1982) Bases of the theory of development of pittings. Results of Science and Technology, 9, 88.

- Freiman, L.I. (1985) Corrosion and Corrosion Protection. Results of Science and Technology, 11, 3.

- Kolotyrkin, Y.M. and Kossy, G.G. (1965) The Influence of Water on the Anodic Behavior of Chromium in Direct Methanol Solutions of Hydrogen Chloride. Protection of Metals, 1, 272.

- Strehblow, H. and Wenners, J. (1975) Determination of the Growth of Corrosion Pits on Iron and Nickel in an Early Stage of Development and its Relation to the Metal Dissolution in Concentrated Chloride Media. Zeitschrift für Physikalische Chemie, 98, 199-214. http://www.dissercat.com/content/nauchnye-i-prikladnye-aspekty-primeneniya-vodno-organicheskikh-i-nevodnykh-rastvorov-elektro http://dx.doi.org/10.1524/zpch.1975.98.1-6.199

- Mankowski, J. and Szklarska-Smialowska, Z. (1975) Studies on Accumulation of Chloride Ions in Pits Growing during Anodic Polarization. Corrosion Science, 15, 493-501. http://dx.doi.org/10.1016/0010-938X(75)90015-3

- Szklarska-Smialowska, Z. (1972) Influence of Sulfide Inclusions on the Pitting Corrosion of Steels. Corrosion, 28, 388-396. http://dx.doi.org/10.5006/0010-9312-28.10.388

- Newman, J. (1977) Electrochemical System. Mir Publisher, Moscow, 463.

- Hirschfelder, J., Curtis, H. and Byrd, R. (1961) Molecular Theory of Gases and Liquids. Mir Publisher, Moscow, 929.

- Tikhonov, A.N. and Samara, A.A. (1951) Equations of Mathematical Physics. SPTAT, Moscow, 650.

- Kolotyrkin, Y.M. (1962) Effect of Anions on the Dissolution Kinetic of Metals. The Successes of Chemistry, 31, 322.

- Kolotyrkin, Y.M. (1963) Pitting Corrosion of Metals. Chemical Industry, 9, 38.

- Kolotyrkin, Y.M. (1967) Influence of Nature of Anions on Kinetics and Mechanism of the Dissolution (Corrosion) of Metals in the Solutions of Electrolytes. Protection of Metals, 3, 131.

- Kolotyrkin, Y.M. (1985) Metal and Corrosion. Metallurgy, Moscow, 88.

- Kolotyrkin, Y.M., Popov, Y.A. and Alekceev, Y.V. (1973) About the Mechanism of Influence of Anions of Solution on Kinetics of Dissolution of Metals. Interaction Role. Electrochemistry, 9, 624.

- Kolotyrkin, Y.M., Popov, Y.A. and Alekceev, Y.V. (1973) About the Mechanism of Influence of Anions on Process of Dissolution of Nickel in the Acid Solutions of Electrolytes. Electrochemistry, 9, 629.

- Popov, Y.A. and Mouhammad, S.A. (2008) Theory of the Nucleation of Pitting. Mechanism of the Local Depassivation of Metal. Material Science Research India, 5, 1-6. http://materialsciencejournal.org/absread.php?snoid=210&month=June2008&year

- Mouhammad, S.A. and Popov, Y.A. (2010) Theoretical Model of Formation and Growth of Pitting. Material Science Research India, 7, 1-9. http://materialsciencejournal.org/absread.php?snoid=374&month=June2010&year