Open Journal of Safety Science and Technology

Vol.06 No.01(2016), Article ID:64455,10 pages

10.4236/ojsst.2016.61001

Underlying Factors of Occupational Accidents: The Case of Turkey

Fatih Yilmaz, Selcuk Alp

Department of Industrial Engineering, Yildiz Technical University, Istanbul, Turkey

Copyright © 2016 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 9 February 2016; accepted 8 March 2016; published 11 March 2016

ABSTRACT

An average of 80 thousand occupational accidents occurs each year in Turkey and 1500 workers are lost their lives. In accordance to “policy of preventive approach”, many legal arrangements have been made in Turkey. In this context, weight to issues such as risk assessment and preventive OHS services is given; however, employee training, employee participation, labour inspect, and periodic checks in working areas such as maintenance and audit have not been achieved. The level of implementation of legal arrangements was inadequate. Research was carried out to determine the significance rate of the factors that cause accidents in 5 sectors with the highest number of occupational accidents in Turkey. Questionnaires administered to experienced safety specialists were reviewed by analyzing with the fuzzy TOPSIS method. According to the results, especially in the construction and coal mining sectors and all sectors in general, employee training, employee participation and periodic maintenance in the workplace are more important accident prevention factors than risk assessment and preventive OH & S services. It is seen that for the prevention of accidents, all measures should be implemented by systematic and by a multidisciplinary approach.

Keywords:

Safety, Fuzzy TOPSIS, Occupational Accident, Risk Assessment

1. Introduction

Occupational accidents cause important social and economic problems by the loss of life and physical injuries. In every year, 2 million fatal accidents occur worldwide and 2 workers die because of occupational accident in every minute. Many sectors such as construction, coal mining, textile etc. involve high risk due to its production processes and labour intensive characteristic and occupational accidents bring up financial loss in large scale in these sectors. In developing countries, these risky sectors are the most important sectors that have a great contribution to economic development with its employment capacity and an added-value to the economy. On the other hand, due to the lack of preventive measures, occupational accidents occur frequently [1] - [3] .

According to the official sources, 65 - 80 thousand occupational accidents occur in Turkey every year and as a result of these accidents, 700 - 1700 workers die and approximately 2000 workers become permanently incapable. Occupational accidents cause approximately $3 billion income loss in social security system. Majority of occupational accidents are not recorded and because 99% of occupational diseases are not identified, they are not considered in statistics. Estimations of Turkish Statistical Institute and Turkish Social Security Institution indicate that the expected number of occupational accidents and diseases can be 4 times more than the recorded data [4] [5] .

Table 1 shows the numbers of accidents at work and the fatalities of 5 sectors with the highest incidence rate of occupational accidents in Turkey. Occupational accidents, fatalities and disabilities in Turkey are at the alarming levels. Metal products sector ranks first in the number of accidents in Turkey. Also, construction industry is ranked first in the number of fatalities. 30% of the fatal accidents occur in construction sector every year. Transportation sector at which many of the fatal accidents occur as a result of vehicle accidents, takes the second place after construction sector. Fabric sector is one of the highest employment sectors in Turkey. Accordingly, the number of accidents in this sector is high.

Turkey has ratified the ILO Convention No. 155 and 161 and in order to ensure compliance with European Union directives, it has made a number of legislations in occupational health and safety (OH & S). After the “Labour Act” enacted in 2003 and the related directives came into force, the “preventive approach based on risk assessment” is adopted and all directives revised in accordance with these principle. New legal obligations, such as making risk assessment in workplaces, preventive OH & S services, safety representatives, committees, and providing training to employees, were introduced. In particular, great importance is given to issues such as risk assessment, safety specialist assignments and workplace OH & S units. All enterprises were classified according to the hazard class and obliged to provide these preventive services via physician, technical staff and engineers according to workplace hazard class. In addition, qualifications, duties, working hours and responsibilities of “External OH & S Service Units” were identified and implemented.

However, despite more than 10 years have passed, the expected benefits of the regulations have not been achieved. Occupational accidents began to rise again. Especially in high risky sectors and the overall work-re- lated accidents showed a slight decrease trend until 2008, but after 2008 it was seen that started to rise again (also see Table 1).

Table 1. Accidents and fatalities in the sectors that most occupational accidents occur in Turkey.

Significant improvements have been provided related to “risk assessment” and “preventive services” in the last 10 year, however, labour inspection, training, employee participation, maintenance and control (supervision) services were inadequate. Arrangements are not given enough attention to these issues. After the directives, “preventive services” can be obtained from outside of workplace from “external” health and safety units. A “market” emerged consisting of these enterprises; however, due to competition of these firms, quality of the services has decreased rapidly. Although enacted “Occupational Health and Safety Act” in 2012, the arrangements and practices of participation of employees were inadequate.

The obligations imposed by the Act are not sufficiently inspected. Therefore, work-related accidents have been increased in last 3 years. Defective policies were also caused great accidents which resulted deaths of hundreds of workers in coal mining and the construction industries. The purpose of the article; to identify the significance of the risk factors that cause accidents at work in Turkey, both in general and also the most work-re- lated accidents sectors with fuzzy TOPSIS method. Based on the obtained results, the study aims to make a critical evaluation of occupational health and safety policy in Turkey, and to offer suggestions.

2. Material and Method

The data used in this article was obtained from the results of a survey applied to 6 safety consultants experienced in 5 industries. Participants are requested to evaluate the causes of accidents in the 5 sectors with the highest number of accidents in Turkey according to the Social Security Institute’s statistics. The data were analysed with Fuzzy TOPSIS method and interpreted.

Decision-making is a process for finding the best option out of suitable alternatives. Multi-criteria decision-making (MCDM) is used in the ranking of the alternatives in terms of multiple criteria and has a very wide range of applications [6] [7] . The methods developed for solving MCDM problems, are often used in cases where a large number of decision-making process and with conflicting criteria [8] [9] . TOPSIS (Technique for Order Preference by Similarity to Ideal Solutions) is one of the MCDM methods which don’t takes relations between criteria into account but the benefits or costs of the features will impose to the results to be obtained of the criteria discussed. Method analyses the results in terms of proximity to positive ideal solution and negative ideal solution results. These two alternatives for the proximity measure obtained by using the proximity index, is obtained an accurate ranking results from large to small, the best alternative is designated with this ranking [7] [10] [11] .

MCDM methods, is a method used in research related to health and safety in the workplace. For example; to examine the safety of workers in hot and humid environment conditions [12] , to measure the safety factor and performance in road construction [13] , in determining the increase in chemical tanker safety requirements [14] , in determination of faulty behavioural risks in behavioural based safety management in the workplace [15] , in determining the risk of occupational safety in the manufacturing industry [16] , in working in dusty environments for determining the risk of workplace safety [17] , the excavation of construction safety risks and the determination of losses arising from occupational accidents [18] , the evaluation of health and safety risks of working in hazardous waste recycling services [19] various MCDM methods are used. This method is widely used for occupational safety, occupational health, issues related to the efficiency and performance measurement [20] - [23] .

In this study, the responses are analysed obtained from safety specialists who has practical experience over than 30 years in 5 industries. They were requested to identify deficiencies, important factors of preventing work-related accidents and determine their significance rates in 5 sectors based on the individual experiences. The resulting data were analysed by using the Chen et al. (2006) proposed fuzzy TOPSIS model algorithm.

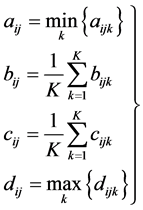

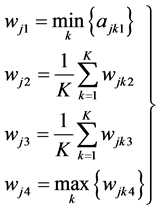

The Fuzzy TOPSIS model’s which developed by Chen et al. (2006), algorithm will be explained in this part of the study. In the implementation of this model, decision-makers consisting of experts in the field assess criteria and available alternatives according to these criteria, primarily. The assessments made by linguistic variables are converted to trapezoidal fuzzy numbers by using the values in Table 2 and Table 3.

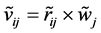

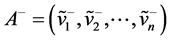

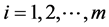

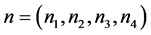

Decision-makers have made the decision criteria relating to weight the importance of some of the alternatives and the evaluation criteria, respectively:  and

and , including

, including  and

and  as the accepted decision makers of fuzzy criterion values obtained with the alternative assessment of the criteria

as the accepted decision makers of fuzzy criterion values obtained with the alternative assessment of the criteria  and decision criteria importance value

and decision criteria importance value  will be displayed. These values in this step,

will be displayed. These values in this step,

Table 2. Linguistic variable for decision criteria and Trapezoidal fuzzy numbers.

Table 3. Linguistic variable for decision criteria and Trapezoidal fuzzy numbers.

(1)

(1)

(2)

(2)

are calculated using equations above.

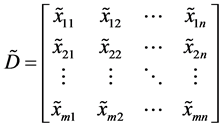

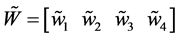

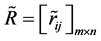

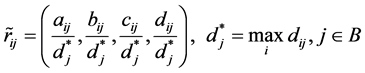

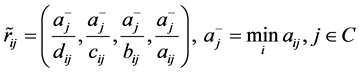

Decision problem, in the form of the matrix is shown as follows,

(3)

(3)

. (4)

. (4)

Here  and

and  is trapezoidal fuzzy numbers,

is trapezoidal fuzzy numbers,

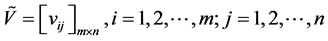

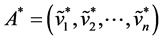

The weighted normalized fuzzy decision matrix

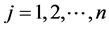

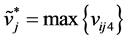

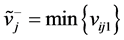

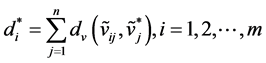

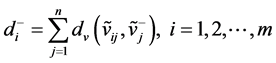

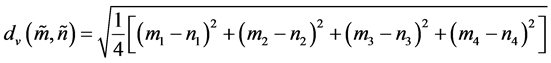

After calculating the weighted normalized fuzzy decision matrix, fuzzy positive ideal solution

Here

where

Relative closeness is calculated to determine the ranking of the alternatives after the calculation of the distance. Relative closeness,

is calculated by the equation above. According to relative closeness, the alternatives are ranked from highest value to lowest value [9] [24] [25] .

3. Results

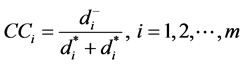

The data obtained from questionnaires filled in by the experts were analysed by fuzzy TOPSIS model. According to results of the analysis impact of accident criteria’s that cause accidents at work in 5 sectors is determined generally. Weighted value of importance of the criteria was found as shown in Table 4. The results are also provided in Figure 1.

Table 4 and Figure 1, shows that “Inadequacy of Education” and “Inadequacy of Employee Participation” criteria have the highest impact on occupational accidents with values closed to each other. “Inadequacy of Supervision”, “Inadequacy of OH & S Preventive Services”, “Inadequacy of Maintenance” criteria have the highest values after those two highest criteria. The third part criteria which have relatively lower weights are obtained as; “Inadequacy of Risk Assessment”.

Following the estimation of weights, the importance of alternatives was determined according to the criteria. The inadequacy determined is presented in Table 5.

As examined in Table 5, the most important criteria for causing occupational accidents in the construction industry is seen “Inadequacy of Supervision” criterion that engineers, technical staff or field control personnel to be done. The important causes of the accidents for the construction industry are, “Inadequacy of Maintenance” and “Inadequacy of Employee Participation” criteria, respectively.

Figure 1. Distribution of impact ratings of occupational accidents factors in Turkey.

Table 4. Impact ratings of occupational accidents factors in Turkey.

Table 5. Occupational accident factors impact ratings by sector in Turkey.

Construction sector is the most fatal occupational accidents occur in Turkey. Construction is high risky sector which has labour-intensive features, conducted in outdoors and different climatic conditions, requiring the use of a large number of equipment and materials. Poor maintenance and improper use of equipments, improper and careless work operations cause serious accidents at construction sites. Therefore; maintenance and periodic controls of equipment, site audits and safety trainings plays a decisive role in construction accidents.

“Inadequacy of Employee Participation” criterion is the forefront criterion for Coal Mining Industry. Then the “Inadequacy of Education” and “Inadequacy of Maintenance” comes. Coal mines is operated in rural areas, workers with low levels of education and wages and in poor conditions in Turkey. Some coal mines are old and incapable of technologically. Coal enterprises, increase the production and increase the workload accordingly to resolve the growing energy demand. Some of the coal mine operators has no experience of mining and has not sufficient information on issues related to safety, experience and sensitivity. After the privatization of coal mines in Turkey, private sector enterprises did not also take the necessary measures after privatization. There is no adequate labour inspection in mines. Therefore, the coal mining industry has become the sector the most occupational accidents occurring in Turkey. Thus, especially Soma and Ermenek, as a result of major accidents occurring in 2014, 354 workers lost their lives [26] - [30] .

In the metal products industry, “Inadequacy of Education”, “Inadequacy of Employee Participation” and “Inadequacy of Preventive OH & S Services” criteria were considered important. “Inadequacy of Preventive OH & S Services”, “Inadequacy of Employee Participation” and “Inadequacy of Education” criterias proportions are calculated very close together in Transportation/Logistics industry. “Inadequacy of Education”, “Inadequacy of Employee Participation” criteria came to the forefront in textile industry. “Inadequacy of Education” is proportionally higher degree of importance in textile industry. Textile industry is labour-in- tensive, creating high levels of employment, however, using the unskilled labour force. Textile sector has low level of fatalities, but the injury rate is more than the other sectors. In this case, the sector causes much more workday losses and costs. Metal Products, Textile and Transport sectors, has better conditions in terms of safety relative to construction and the coal mining. These sectors are composed of more favourable enterprises to improvements with effective inspection and low cost investments.

In Transportation/Logistics industry “Inadequacy of Employee Participation”, “Inadequacy of Preventive OH & S Services” and “Inadequacy of Education” criteria were calculated close. Without exception, the lowest impact criteria in all sectors “Inadequacy of Risk Assessments” are seen as the criteria.

Before the new regulations brought in preventive OH & S services, many large enterprises had been organized “preventive services” within the workplace itself. After providing the opportunity to external services, in order to reduce costs, many enterprises have begun to supply these services from the outside of workplaces. Time and the quality of the services has dropped. 98% of workplaces in Turkey are small and medium-sized enterprise. 70% of work-related accidents occur each year in these enterprises. Insufficient external services weaken the workplace control processes particularly in medium-sized and hazardous industrial and construction enterprises. This situation leads to increase in work-related accidents.

Regulations cannot be applied to practice in Turkey. Despite the legislative work in safety in recent years, applications and needs with those written on formally is quite different. Today OH & S policy is based on the preventive principles and risk assessment. In this context, to provide preventive OHS services in the workplace is one of the most important applications in this regard. However, to prevent occupational accidents and improve the safety of the conditions can be possible with the determination and implementation of an OH & S policy which covers all the necessary criteria. Occupational safety requires a multi-criteria, interdisciplinary and systematic approach. Importance should be given to all preventive measures and all legal arrangements should be inspected. While the policies and measures are identified, industrial conditions and their influence levels of risk in the workplace must be taken into consideration. Applications focusing on specific issues on overall quality are not sufficient to prevent occupational accidents.

4. Conclusions

Considering the statistics in Turkey, safety and health practices cannot achieve the expected benefits. Except for legislation, assignment of safety specialists and risk analysis, and other preventive activities were insufficient. Prevention of occupational accidents are impossible if establishments do not take necessary precautions such as allocating necessary financial funds for the measures, establishing a permanent monitoring system to audit for all works, creating a work discipline, appointing enough technical staff and engineers, doing enough labour inspect, and keeping records of accidents in the workplace.

In Turkey, occupational health and safety is approached with a general overview. Uniform regulations covering all sectors are made. Production conditions and tools in different sectors, status of employees, regional differences, the risks in different sectors, impact levels and results are not considered to be affected. These deficiencies also reduce the effectiveness of regulations and labour inspection. According to statistics, it is understood that separate perspective, policy and planning are needed for risky sectors such as coal mining, construction and metal product.

Risk analysis should be carried out in mines and construction sites, the enterprises in very poor condition must be stopped. Particularly in mining and construction sector, enterprises should not be licensed until fully provided all necessary safety conditions.

Preventive health and safety services are insufficient in terms of time and quality. It reduces the effectiveness of the control mechanism and increases the risk of accidents. In addition, many “External OH & S Units” are insufficient about staff, technical facilities and expertise. The service prices of the external OH & S units are determined by the competition in the market. In this case, external OH & S units have no other task than to prepare necessary documents such as risk assessment report, emergency action plans, safety expert contracts and safety training for a fee and sending those to workplaces.

Due to insufficiency of labour inspector and inspection times, hundred thousands of enterprises cannot be inspected at all. In this case the obligations and penalties are not applied, occupational accidents cannot be prevented.

Risk assessment becomes legally obliged to all workplaces in Turkey. However, there is no uniformity in practice. Which risk assessment method will be used according to various parameters such as sector, type of enterprise, number of employees, raw materials and equipment used, and at what intervals it will be done are not clearly defined. The knowledge and experience of employers, safety specialists and physicians in this field are insufficient. In addition, regulations on this subject have been prepared poorly and is not guiding.

Occupational health and safety trainings done in the workplaces in the corporate firm emphasis on safety culture but most of the medium and small businesses are insufficient on this subject. Education is seen as a legal obligation or does not given in many workplaces. Starting with the external OH & S units offering these services, especially in SME’s educations has turned out to be “participation certificates of education” prepared and archived.

Regulations have been made on “employee participation” which is a significant deficiency in Turkey in recent years. According to the Occupational Health and Safety Act, “OH & S Representatives” have an important function in Turkey. Representatives have rights to inform the hazards associated with occupational safety to employer and government, and to demand preventive actions. But employers and managers are not giving enough importance to this issue. This topic is not inspected enough by labour inspectors.

According to the results obtained in our research, especially in construction industry, “Inadequacy of Maintenance” is also has a significant importance. In September, the elevator accident occurred in construction site which resulted in the death of 10 people is demonstrated that the importance of “maintenance services”. Employers, site supervisors and engineers are not care enough on this issue. There are many regulations and hesitations about what will be implemented. The qualification of periodic inspection firms and duration of the periodic inspection of equipments is not clear. In many construction sites, periodic inspection and maintenance is neglected. In some cases it is still used even though it is known that the equipment is defective.

According to our research results, preventive actions that weight for both general and sectoral differ from each other. In Turkey, significant efforts have been made regarding the preventive OHS services and risk assessments in recent years. However, other necessary measures are not applied adequately such as labour inspection, maintenance, education, employee participation and workplace supervision. Occupational health and safety is a system of both enterprises and national level. If any stage of this system remains inadequate, it decreases the level of prevention of other measures.

Cite this paper

Fatih Yilmaz,Selcuk Alp, (2016) Underlying Factors of Occupational Accidents: The Case of Turkey. Open Journal of Safety Science and Technology,06,1-10. doi: 10.4236/ojsst.2016.61001

References

- 1. International Labour Office (ILO) (2004) Labour Statistics. ILO Publication, Geneva.

- 2. Rubio, M.C., Martinez, G. Rubio, J. and Ordoñez. J. (2008) Role of the Civil Engineer as a Coordinator of Safety and Health Matters within the Construction Sector. Journal of Professional Issues in Engineering Education and Practice, 134, 152-157.

http://dx.doi.org/10.1061/(ASCE)1052-3928(2008)134:2(152) - 3. Takala, J. (1999) Global Estimates of Fatal Occupational Accidents. Epidemiology, 10, 640-646.

http://dx.doi.org/10.1097/00001648-199909000-00034 - 4. Turkey Social Security Institute (2000-2012) Statistical Yearbooks. Social Security Institute Publication, Turkey.

- 5. Turkey Statistical Institute (2013) Occupational Accidents and Work Related Health Issues Research Report. Turkey Statistical Institute Publication, Turkey.

- 6. Tilehnoei, M.H. and Aref, M.A. (2013) Temporal Dimension Evaluation by Fuzzy TOPSIS Method. International Journal of Architecture and Urban Development, 3, 55-60.

- 7. Özdemir, A.I. and Seçme, N. (2009) Analysis of Two-Stage Strategic Supplier Selection with Fuzzy TOPSIS Method. Afyon Kocatepe Universitesi I.I.B.F. Dergisi, 10, 79-112.

- 8. Baskaya, Z., and Öztürk, B.A. (2012) Group Decision Making with Fuzzy TOPSIS in Supplier Evaluation Problem and Relationships between Decision Maker’s Individual Decisions. Uludag Journal of Economy and Society, 21, 153-178.

- 9. Santos, F.J.J. and Camargo, H.A. (2010) Fuzzy Systems for Multicriteria Decision Making. CLEI Electronic Journal, 13, 1-8.

- 10. Nang Idayu, N.Z. and Lazim, A. (2012) Evaluation of Sustainable Development Indicators with Fuzzy Topsis Based on Subjective and Objective Weights. IIUM Engineering Journal, 13, 13-26.

- 11. Mahdavi, I., Mahdavi-Amiri, N. Heidarzade, A. and Nourifar. R. (2008) Designing a Model of Fuzzy Topsis in Multiple Criteria Decision Making. Applied Mathematics and Computation, 206, 607-617.

http://dx.doi.org/10.1016/j.amc.2008.05.047 - 12. Guozhong, Z., Neng, Z., Zhe, T., Ying, C. and Binhul, S. (2012) Application of a Trapezoidal Fuzzy AHP Method for Work Safety Evaluation and Early Warning Rating of Hot and Humid Environments. Safety Science, 50, 228-239.

- 13. Janackovic, G.L., Savic, S.M. and Stankovic, M.S. (2013) Selection and Ranking of Occupational Safety Indicators Based on Fuzzy-AHP: A Case Study in Road Construction Companies. South African Journal of Industrial Engineering, 24, 175-189.

http://dx.doi.org/10.7166/24-3-463 - 14. Celik, M. (2010) Enhancement of Occupational Health and Safety Requirements in Chemical Tanker Operations: The Case of Cargo Explosion. Safety Science, 48, 195-203.

http://dx.doi.org/10.1016/j.ssci.2009.08.004 - 15. Dagdeviren, M. and Yüksel, I. (2008) Developing a Fuzzy Analytic Hierarchy Process (AHP) Model for Behavior-Based Safety Management. Information Sciences, 178, 1717-1733.

http://dx.doi.org/10.1016/j.ins.2007.10.016 - 16. Tadic, D., Djapan, M., Misita, M., Stefanovic, M. and Milanovic, D.D. (2012) A Fuzzy Model for Assessing Risk of Occupational Safety in the Processing Industry. International Journal of Occupational Safety and Ergonomics, 18, 115-126.

http://dx.doi.org/10.1080/10803548.2012.11076922 - 17. Jiang, Z.-A. and Wang, P. (2012) Evaluation System and Method for Analyzing Occupational Hazards in Dust Workplace. Proceedings of the International Conference on Computer Distributed Control and Intelligent Environmental Monitoring (CDCIEM), Zhangjiajie, Hunan China, 5-6 March 2012, 301-304.

- 18. Kim, D.I., Yoo, W.S. Cho, H. and Kang, K.I. (2014) A Fuzzy AHP-Based Decision Support Model for Quantifying Failure Risk of Excavation Work. KSCE Journal of Civil Engineering, 18, 1966-1976.

http://dx.doi.org/10.1007/s12205-014-0538-7 - 19. Hatami-Marbini, A., Tavana, M., Moradi, M. and Kangi, F. (2013) A Fuzzy Group Electre Method for Safety and Health Assessment in Hazardous Waste Recycling Facilities. Safety Science, 51, 414-426.

http://dx.doi.org/10.1016/j.ssci.2012.08.015 - 20. Huang, Y.F., Hsu, K.H. Chen, P.S. and Dong, S.H. (2011) Discussing Performance Index of Human Resource Valuation with AHP-Occupational Safety Section in T Company in Taiwan as the Case Study. Information Technology Journal, 10, 549-556.

http://dx.doi.org/10.3923/itj.2011.549.556 - 21. Janaçkoviç, G.L. (2013) Delphi-Fuzzy AHP Ranking of the Occupational Safety Community of Practice Performance Indicators. Journal of Management and Marketing, 1, 9-16.

- 22. Novin, V., Givehchi, S. and Hoveidi, H. (2014) A Novel Fuzzy-Based Modelling for Route Safety Management of Hazardous Materials. International Journal of Scientific & Engineering Research, 5, 277-282.

- 23. Sadoughi, S., Yarahmadi, R., Taghdisi, M.H. and Mehrabi, Y. (2012) Evaluating and Prioritizing of Performance Indicators of Health, Safety, and Environment Using Fuzzy TOPSIS. African Journal of Business Management, 6, 2026-2033.

- 24. Ataei, E. (2013) Application of TOPSIS and Fuzzy TOPSIS Methods for Plant Layout Design. World Applied Sciences Journal, 24, 908-913.

- 25. Liao, C.N. and Kao, H.P. (2011) An Integrated Fuzzy TOPSIS and MCGP Approach to Supplier Selection in Supply Chain Management. Expert Systems with Applications, 38, 10803-10811.

http://dx.doi.org/10.1016/j.eswa.2011.02.031 - 26. Argoglu, E. and Argoglu, N. (1997) Statistical Evaluation and Minimizing of Occupational Accidents in the Turkish Construction Sector. Concrete-Prefabrication Magazine, 2, 16-21.

- 27. Ercan, A. (2010) Assessment of the Occupational Health and Safety in Construction Sector in Turkey. Journal of Polytechnic, 13, 49-53.

- 28. Güyagüler, T. (2002) Analyses of the Firedamp Explosions in Turkey and Suggested Preventive Measures. Proceedings of the 13th Turkish Coal Congress, Zonguldak , 29-31 May 2002, 45-51.

- 29. Chamber of Mining Engineers (2003) Closure of Authority of Coal Enterprises regional offices and Redevance Applications. Mining Bulletin, 3, 61-66,

- 30. Sari, M., Düzgün, H.S.B., Karpuz, C. and Selçuk, A.S. (2004) Accident Analysis of Two Turkish Underground Coal Mines. Safety Science, 42, 675-690.

http://dx.doi.org/10.1016/j.ssci.2003.11.002