New Journal of Glass and Ceramics

Vol.05 No.04(2015), Article ID:59993,9 pages

10.4236/njgc.2015.54009

Optimization of Parameters CO2 Laser for Drilling Different Types of Glass

Nafissa Khennafi-Benghalem1*, Walid Allag2

1Unité de Recherche des Matériaux Emergents, Institut d’Optique et Mécanique de Précision, Université Ferhat Abbas Sétif 1, Sétif, Algérie

2Laboratoire des Systèmes Photoniques et Optique Non Linéaire, Institut d’Optique et Mécanique de Précision, Université Ferhat Abbas Sétif 1, Sétif, Algérie

Email: *n_khanafi@yahoo.fr

Copyright © 2015 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 25 June 2015; accepted 25 September 2015; published 28 September 2015

ABSTRACT

The aim of this work is to study in detail the drilling process on glass by CO2 laser. The study parameters considered in the present experiments are based on the laser beam power of range (30% - 80% of 25 W) and an exposure time for drilling (2 - 8 s). The measured diameters of holes by optical methods are between [300 - 800 mm]. The results obtained by optical observations suggest that ordinary and mineral glasses cannot withstand to a contact of the laser beam and crack during the formation of the drilling hole. The minimum power and duration of exposure are the optimal parameters for drilling the organic glass, we observe no micro-cracks, and again we see that the edges of the holes have a good surface quality with a high aspect ratio.

Keywords:

Glass, CO2 Laser, Optical Machining, Laser Drilling

1. Introduction

Drilling is a machining process of the material; it consists in removing the material for making a hole. To achieve diameters holes of less than a millimeter, several methods exist, classified into two categories: conventional drilling who is the most practiced in the workshops and drilling exotic in despite its designation represents a significant share of this type of machining [1] . Historically, the laser drilling process was the first industrial application of the laser (1966), the bore diameter of 4.7 mm was machined with 2 mm deep into the diamond. This operation was carried out in 15 minutes while a mechanical drilling took 24 h [2] - [4] . The laser is focused on the surface of an absorbent target. The irradiated and heated material, melted and vaporized, ejecting the liquid bath during drilling. It involves many mechanisms such as melting, vaporization, photo-ablation, the molten material ejection and the formation of absorbing plasma. This technology has become one of the leading non-traditional drilling processes alongside EDM, ultrasound and electron beam [5] - [7] . The advantages of laser drilling method over conventional methods are numerous, high production rate include the quick and accurate positioning, the ability to drill small diameters up to 10 microns, no tools and the absence of contact with the sample to be drilled [8] - [10] . Carbon dioxide lasers, neodymium and argon based on the easy use of the light beams on the focusing accuracy of the coherent light, and permit to obtain a dramatic effect. The use of laser proves superior to traditional techniques, because the control is done by computer and tools are not dull [11] .

2. Experimental Procedure

2.1. Materials

The material on which we made our holes is a glass. We choose three types of glass: Ordinary glass, organic and mineral lenses of glass. All the blades have the same dimension in the order of 76 × 26 × 1 mm as shown in Figure 1.

2.2. Description of the Laser Marking System Available at Advanced Technology Development Center (CDTA)

The laser is new techniques for marking, engraving, cut, weld and drill different materials with precision. The system that was used for the drilling operation is a CO2 laser marking system with a 25 W power (Figure 2). In

Figure 1. Geometry and dimension of the glass sample drilling by laser.

Figure 2. Laser marking system available in (CDTA) adapted for drilling glass.

this system the orientation or the laser beam guide is provided with enslaved galvanometer mirrors. The entire system is powered with excitation source DC (a switching power supply PWM controlled by a PC). The following figure shows the marking system suitable for drilling glass samples.

2.3. Constitution of the Marking System by CO2 Laser

The device shown in Figure 2 consists of the following elements:

1) Micro computer (application software).

2) Static marking head.

3) Type CO2 laser source.

4) Power Source.

5) An optical fiber for the transmission of data.

6) Plexiglas enclosure in glass for protection.

7) Table to support the system.

2.4. Lens Marking Head

Table 1 lists the symbolic and maximum field size, the operating distance, the concentration of mark size and specification of depth of field FH lenses. We used two lenses, those whose focal length is 80 to 200 mm.

2.5. Drilling Made by CO2 Laser

To carry out the drilling by variable power CO2 laser 0 - 25 W on ordinary glass, mineral and organic lenses, we followed the following steps:

• We choose the best focus lens of the marking head, to limit the field.

• We put the sample on the drilling table and we made the focal adjustment using a system for moving the table along the axes X, Y, Z.

• Open the marking software “Winmark® pro”.

• Open the window “Digital I/O scope”.

Before completion of drilling on the lenses, we began drilling preliminary tests on paper, for this, we used 10% of power. We adapted a systematic study by varying two parameters, the laser power and the time of drilling. Tables 2-5 have the drilling conditions of CO2 laser samples:

Table 1. The specifications of the marking beam lenses FH.

Table 2. Condition of drilling ordinary glass.

Table 3. Conditions of organic glass lenses.

2.6. Characterization of Drilling Samples

For assess and interpret the results of tests carried out by the CO2 laser specimens (blades and lentils) for different selected drilling conditions, where we varied the laser power and the drilling time to determine their effects and choose the optimal parameters of drilling. We used the optical microscope in the laboratory’ (materials characterization) “ZEISS AXIO. Imager: A1m” with a magnification of “1000×” to view the various transformations of the glass laser-drilled and distinguish cracks in and out of the bore field. Figures 3-6 illustrate the obser- vations for the two different parameters such as laser power and time of drilling.

Table 4. Drilling of organic glass lenses by varying the power and exposure time 2 s.

Table 5. Drilling of mineral glass lenses by varying the power and exposure time: 5 s.

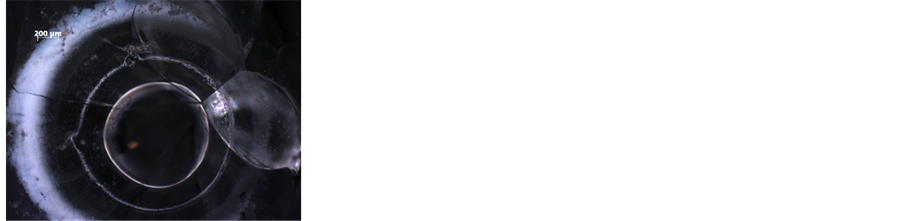

Figure 3. Optical observation of the ordinary glass blades drilling by CO2 laser as function of power and the exposure time.

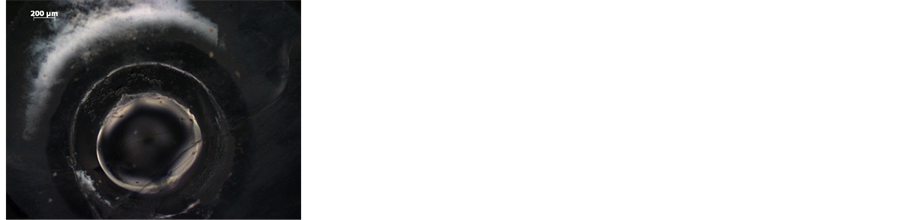

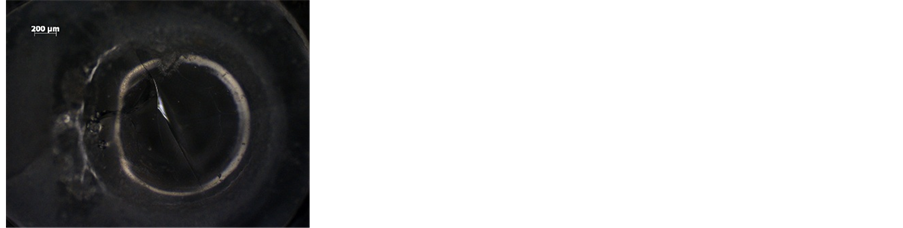

Figure 4. Effect of the laser power on the drilling mineral glass lenses.

3. Observations and Interpretations

We present in the following the results of observations conducted followed by their interpretations of the three types of glass pierced starting respectively by the ordinary mineral and finally the organic. Figure 3 show planking observed by optical microscopy at varying drilling conditions. We present particular views of the drilled holes for different laser powers and drilling time (exposure time). These observations show that in the drill field cracking were observed whatever the power and drilling time, but the cracking becomes more important for the highest powers, as for the longer durations (20 s). We observe cracks in all the directions.

This cracking is certainly due to:

• The nature of the materials of the blades (usually glass);

• The adjustment of the focal length;

• The heat transfer phenomenon occurs;

• The thickness of the blades is quite large contribution to the applied power.

3.1. Effect of the Laser Power on the Drilling Mineral Glass Lenses

In Figure 4 we present the optical micrographs of four drilling mineral glass lenses, we observed that the cracks are quite large. The hole is formed, but the fact that the thickness of the lens is a little large compared to the applied power prevents the laser beam to go in depth. we must take into account the residual cracks to higher carbon vibrations propagate along the sample surface, so that the heat transfer that occurs in the first contact between the laser beam and the surface to be drilled. In these figures, the influence of power is clear. We can explain that by the increase in the power increases crunches and they are much more pronounced and spread on the environment of the hole and appear clearer.

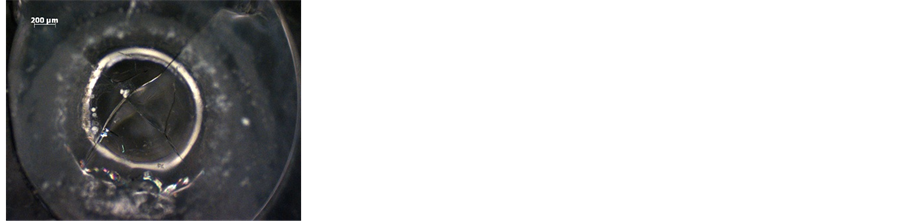

Figure 5. Effect of exposure time on drilling organic glass.

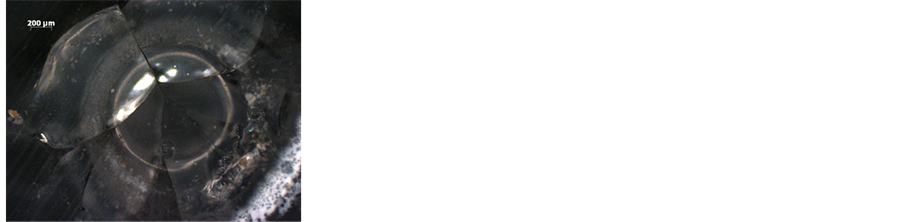

Figure 6. Optical observation of the organic glass lenses pierced by CO2 laser at different powers and exposure time = 2 s.

3.2. Effect of Exposure Time on the Drilling Organic Glass

We observe well in Figure 5 the influence of drilling time on the drilling organic glass lenses, the time was varied from 2 to 8 seconds for four different powers, drilling lenses have the same thickness (even convergence). It is observed that for a minimum drilling time equal to (2 s) the shape of the hole is fairly uniform, and we note that the plastic flow of the material in the vicinity of the holes is almost nonexistent, but beyond two second drill hole contour deforms and takes any shape (oval, ellipse). Although we note that with this type of glass cracking is absent. The drilling time has an influence on the bore diameter; it increases with time of exposure, under the effect of heat propagation in the material surrounding the bore.

3.3. Effect of Power on the Drilling Organic Glass

In Figure 6 we expose boards observed by optical microscopy where we varied the power and maintaining fixed the exposure time. The chosen few holes micrographs are drilled at variable power ranging from 30% to 80% of 25 W at 2 s of drilling time. These rather peculiar views show that the laser power has a direct influence on uniformity, roundness and drilled holes diameter, we note that when the laser power increases the diameter increases progressively with plastic deformation at the edges of holes. This can be explained by the fact that when the laser beam attack the surface to be drilled, the heat imported by the beam propagates in all directions, this spread will widen the hole and create plastic flows over the entire contour of the holes and contaminates the vicinity of the hole.

4. Discussion

Figure 5 and Figure 6 show the drilling conducted on organic glass lenses, all observations show no cracks or fractures but reveal another phenomenon that can be explained by a plastic flow of material which transforms the surface state of matter around the bores. We can also see that the laser matter interaction changes the surface structure of the glass during the heat transfer surfaces and the adjoin surfaces bore are not spared. The expected result is observed in the micrograph where the power is 30% and the exposure time is equal to 2 s, since we clearly see the formation of an uniform hole provided with a well traced contour and quite clean, which allows us to conclude that the power 30% equals exactly to 7.5 W and 2 s time exposure are identified as optimal parameters for drilling the organic glass. The great powers and the highest drilling time are not recommended because together carried the plastic deformation of the material in the vicinity of the hole.

5. Conclusion

Works done in this project have as principal aim the exploitation of laser technology to perform micro-holes glasses lenses to facilitate mounting of the arms in the holes at the edges for the best solutions to our visual needs. The quality of our vision and our well being are intimately tied to visual quality lenses and frames, adapt precisely to the shape of the face gives us total comfort. We used the marking system CO2 laser available at Advanced Technology Development Center (CDTA) Baba Hassen (Algiers), for the drilling of three types of glass. The select laser parameters were limited in the intention to protecting the marking system and avoid damage or destroy it, since it was only suitable for drilling. Generally, the laser glass drilling requires special accessories designed for micro machining of the glass. It was found that ordinary glass blades crack at the first contact with the laser regardless of the power and drilling time applied, thus notices the same thing for the mineral glass. The select of laser parameters was limited in the intention to protecting the marking system and avoids damage or destroy it, since it was only suitable for drilling. Generally, the laser glass drilling requires special accessories designed for micro machining of the glass. It was found that ordinary glass blades crack at the first contact with the laser regardless of the power and drilling time applied, thus notices the same thing for the mineral glass. We are interest only to the drilling of organic glass; it was found that the diameter of drilled holes is proportional to the powers and the drilling time. Based on observations and interpretations, we concluded that for organic glass optimum parameters are 30% of power and 2 s is the best time and give the most favorable choices, against the increase in power and time exposure widen the holes and create a distortion in the vicinity of these bores (influence of power and the drilling time on the quality of the drilled holes) due to the plastic flow of the material, the latter is generated by increasing the heat imported by the laser beam.

Cite this paper

Nafissa Khennafi-Benghalem,Walid Allag, (2015) Optimization of Parameters CO2 Laser for Drilling Different Types of Glass. New Journal of Glass and Ceramics,05,75-83. doi: 10.4236/njgc.2015.54009

References

- 1. Schneider, M. (2006) Perage Profond par Laser: Analyse des Processus Physiques. Thèse de Doctorat, Université Paris VI.

- 2. Ilson, W. and Hawkes, J.F.B. (1987) Laser Principles and Application. International Series in Optoelectronics, Prentice Hall, Englewood Cliffs.

- 3. Roulet, N., Dubois, P. and Aoussat, A. (2003) Le laser! Intégration d’une nouvelle technologie de fabrication dans une PME, Laboratoire Conception de Produits et Innovation.

- 4. Cipriani, J. and Hasmonay, H. (1997) Optique, ondes, atome et noyau. Université de Pierre et Marie.

- 5. Khanafi-Benghalem, N., Benghalem, K. and Boudoukha, H. (2008) Effet des paramètres laser CO2 sur le marquage sur verre CP1047, les applications du laser et du plasma dans la science des matériaux. Edité par E-Amara, 2008 de l’American Institute of Physics.

- 6. Dider, D., Daniel, H. and Véronique, Z. (2004) “Les lasers” Edition DNEL.

- 7. Sobczak, S. and Leblanc (2003) Le laser, applications: Lecture et gravure de différents types de CD’s Printemps des sciences 2003.

- 8. Maillet, H. (1986) Le laser principe et technique d’application, Edition Lavoisier 1986.

- 9. Mouthon, G. and Ravussin, P. (2006) Introduction aux lasers, Laboratoire de Physique et Chimie Biologique et Médi- cale Ecole Nationale Vétérinaire d’Alfort.

- 10. Cornelis, J. and Verhoeven, J. (2004) Modelling Laser Percussion Drilling. Eindhoven University.

- 11. Wee, L.M., Ng, E.Y.K., Prathama, A.H. and Zheng, H. (2010) Micro-Machining of Silicon Wafer in Air and under Water. Singapore Institute of Manufacturing Technology.

NOTES

*Corresponding author.