Journal of Environmental Protection

Vol.09 No.05(2018), Article ID:84939,14 pages

10.4236/jep.2018.95036

Investigation of the Source Relationship between Benzene Vapor and Alkylate-Containing Light Non-Aqueous Phase Liquid at Adjacent Industrial Facilities

Frank S. Muramoto1, Jun Lu2

1Muramoto: AECOM, Long Beach, California, USA

2School of Resources and Environment, Hefei University of Technology, Hefei, China

Copyright © 2018 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: March 16, 2018; Accepted: May 27, 2018; Published: May 30, 2018

ABSTRACT

This study describes the investigations undertaken at two adjacent properties for known contaminants of concern and for resolution of other “unexpected” contaminant sources. One property is a manufacturing facility with impacts from chlorinated solvent compounds releases at the site. During site investigations, benzene was found present in subslab and multi-depth soil vapor probes installed beneath the basement floor of on-site buildings. Additional investigations at the manufacturing site were initiated in response to a recent, unexpected appearance of an unknown light non-aqueous phase liquid (LNAPL) in three on-site perched water zone wells as observed during sequential quarterly monitoring events and in a soil vapor extraction well. The other property is an adjacent petroleum facility that has ongoing LNAPL recovery operations from past releases at its site. A claim was made that benzene vapor at the manufacturing property was solely related to the LNAPL that migrated onto the facility. Multiple lines of evidence, including LNAPL migration pathways and chemical fingerprints, were used to show that the LNAPL was sourced from the petroleum facility. Further, benzene vapor present in subslab vapor probes installed for vapor intrusion purposes was believed to be sourced from the LNAPL and not from historical operations at the manufacturing facility. However, detailed analysis of vapor distributions, the subsurface stratigraphy, and LNAPL characteristics indicate that spills during past operations at the manufacturing facility itself were likely the source of the benzene vapor found in the subslab vapor probes.

Keywords:

Preferential Pathways, LNAPL, Chemical Fingerprinting, Alkylate, Benzene, Vapor Intrusion, Conceptual Site Model

1. Introduction

At many petroleum refineries, fuel storage facilities, retail fuel stations and, similarly, chemical, aerospace, and dry cleaning facilities, impacts to soil, soil vapor and groundwater from former and current operations may have occurred beneath these facilities. Depending upon the magnitude and duration of the release(s) and geologic/hydrogeologic conditions underlying these facilities, it is not uncommon for a release(s) to migrate through and impact subsurface media at an adjacent property. This paper describes the analyses and results undertaken at a manufacturing facility and an adjacent petroleum facility following the unexpected appearance of light non-aqueous phase liquid (LNAPL) in three monitoring wells M-1, M-13, M-14 and SVE-1 at the manufacturing facility to determine the source of the LNAPL and benzene vapor impacting the manufacturing facility (Figure 1). The manufacturing facility, located in the western United States, has occupied the site since 1960 for industrial manufacturing of aerospace components. Site operations included the use of chlorinated solvents as degreasing agents for cleaning equipment and parts. Solvent usage ceased around the mid-1990s. Due to former site operations, soil, soil vapor, and groundwater had been impacted with chlorinated volatile organic compounds (cVOCs). To the south of the manufacturing facility is an active petroleum facility. Over the history of operation at the petroleum facility, releases of various petroleum products have occurred impacting soil, soil vapor, and groundwater beneath the facility as manifested by the presence of LNAPL on the perched water zone and

Figure 1. Well location map.

regional water table and associated dissolved-phase petroleum hydrocarbon volatile organic compounds (VOCs).

At both facilities, investigations were conducted to delineate the vertical and horizontal extent of petroleum hydrocarbons impacts found in perched zone wells through comprehensive Cone Penetrometer Test/Ultraviolet Screening Tool (CPT/UVOST) investigations, evaluating historic fluid levels in wells, investigating other potential on-site and off-site sources, and sampling and forensically analyzing LNAPL found in wells. The objectives of the investigations were to assess the source and correlation of the LNAPL impacting both facilities and resolve the source of benzene vapor impacts at the manufacturing facility.

2. Near Surface Site Geology and Hydrogeology

Previous investigation at the manufacturing and petroleum facilities indicate that the upper 6 meters of the soil column consist primarily of lower permeability clay and silt. From approximately 6 to 21 meters below ground surface (bgs), alternating or interbedded sand, silt, and clay are generally encountered where the silt and clay form a low permeability zone allowing water under perched conditions to accumulate. CPT and soil boring data also indicate that a 1.2 to 1.5-meter thick, north-south oriented, poorly graded sand interval is present from approximately 10 to 11 meters bgs on the petroleum site and extends across a portion of the manufacturing site as shown in Figure 2.

Figure 2. Lithologic correlation of UVOST response and aquitard underlying perched zone indicating the continuous nature of the perched zone aquitard across both sites.

Figure 3 shows the current perched water elevations in wells installed at both sites. The elevations are interpreted to show an overall easterly water flow across both sites. However, review of the historical data from the petroleum facility prior to installation of the perched zone wells on the manufacturing site show that the perched zone flow was to the north toward the manufacturing site (Figure 3).

Figures 4(a)-(f) show historical fluid levels (or hydrographs) with time associated with wells with LNAPL across both sites. LNAPL was initially detected on the manufacturing site in wells M-1 and M-14 in August 2014 and in well M-13 in November 2014 (Figures 4(a)-(c), respectively), even though all three wells were previously free of LNAPL detections. Well A-1 on the petroleum facility, the well farthest south of the property line, had historical detections of LNAPL since the well was installed in 1993 (Figure 4(d)). Well A-2, installed in 1993 and located approximately midway between well A-1 and well A-3, has had periodic detections of LNAPL, from 1995 through 1999 and again from September 2013 to present (Figure 4(e)). Well A-5, located near the north boundary of the petroleum facility, was installed in 1985 and had nearly 30 years of no LNAPL detections until October 2014 (Figure 4(f)). Review of the hydrographs for wells A-2, A-3, M-1, M-13, and M-14 shows that the occurrence of LNAPL in these wells appears to coincide with the drop in perched water levels in each well. The drop in water levels in the perched zone is likely due to lack of recharge of the perched zone from several years of drought conditions in the region.

Figure 3. Lithologic facies map and perched zone-current and historical groundwater flow determinations.

Figure 4. (a)-(f) Hydrograph of wells A-3, A-2, A-1, M-1, M-14, and M-13.

3. Source Correlation of LNAPL between Facilities

Multiple lines of evidence supporting the correlation of LNAPL between the two facilities exist. The lines of evidence include evaluation of the near surface geology/hydrogeology that affects subsurface migration of contaminants, the lateral and vertical distribution of hydrocarbon responses, and the similarity or dissimilarity of the chemical characteristics of LNAPL found at the manufacturing and petroleum facilities. These lines of evidence are described below.

3.1. Lithofacies and Preferential Pathways

A lithofacies map was constructed across the perched interval from approximately 7.6 to 12.5 meters bgs using available CPT and soil boring logs from both sites (Figure 3). The lithofacies map indicates that a north-south trending, poorly graded sand zone is present across both sites. The poorly graded sand zone is generally surrounded to the west, east, and north by lower permeability silts and clays. UVOST responses are found in this poorly graded sand zone in both the petroleum and manufacturing sites (Figure 2). This fact, combined with the north-south oriented poorly graded sand and the historical northerly groundwater gradient, indicates that this sand is a likely pathway for contaminant movement in the perched zone.

3.2. UVOST Responses

A CPT/UVOST investigation was conducted at the manufacturing facility to evaluate the horizontal and vertical extent of hydrocarbon-impacted soil within the facility area where LNAPL was detected in site monitoring wells. The UVOST data indicated the presence of hydrocarbons at 14 locations that provided a hydrocarbon footprint on the manufacturing facility (Figure 5). The

Figure 5. LNAPL chromatographs of wells A-1, A-2, A-3, M-1, M-13, SVE-1.

footprint includes the three monitoring wells (M-1, M-13, and M-14) where LNAPL was first observed in 2014. The UVOST hydrocarbon footprint is approximately 60 meters wide at the manufacturing facility’s southern boundary and extends northward approximately 180 meters, at which point no UVOST responses are recorded (Figure 5).

At the petroleum facility, a CPT/UVOST investigation consisting of 27 locations was conducted along four east-west transects starting along the petroleum facility’s northern property line and moving southward to investigate the presence and lateral extent of hydrocarbons on the perched water (Figure 5). The most northern transect on the petroleum facility was aligned with the UVOST responses found along the southern property boundary of the manufacturing facility. UVOST response show that hydrocarbon impacts are first encountered in the perched zone at approximately 10 meters, with the thickness of hydrocarbon-affected soils ranging between 0.4 and 1.5 meters. The UVOST responses along the four transects delineate the east-west extent of hydrocarbon impacts in this area of the petroleum site.

Juxtaposing the UVOST responses between the two sites shows the apparent connection of impacts on the petroleum and manufacturing sites through alignment of the UVOST and shows a north-south elongation coinciding with the poorly graded sand zone in the perched zone (Figure 5). Overall, the hydrocarbon footprint delineated by UVOST responses falls within the sand zone of the perched water zone, clearly indicating that the sand zone was a preferential migration pathway for LNAPL. The UVOST responses also indicate that the thickness of the LNAPL impacts decreases north-northeast of well SVE-1 along with the thinning of the sand interval.

3.3. LNAPL Characteristics

LNAPL samples were collected for chemical analyses from wells M-1 and SVE-1 on the manufacturing site and from wells A-2, A-1, and A-3 on the petroleum site in order to determine if the LNAPL had similar characteristics (Figure 1). Analyses of the LNAPL samples included: gas chromatography/flame ionization detection (GC/FID) analysis for quantitative measurement of C9 to C44 normal and branched chain alkanes; purge and trap gas chromatography/mass spectrometry method that measures volatile C5-C12 hydrocarbons from five compound classes―paraffins, isoparaffins, aromatics, naphthenes, and olefins (PIANO) and various volatile oxygen-containing compounds historically used in oxygenated and reformulated gasolines; gas chromatography/mass spectrometry (GC/MS) technique for alkyl polycyclic aromatic hydrocarbons (PAH) and Biomarker Quantification; and GC/MS operated in a selected ion monitoring (SIM) acquisition mode for analysis of organic lead species.

Based on GC/FID chromatograms, the LNAPL from four wells (A-1, A-5, M-1, and SVE-1) of the five wells sampled appear similar with a predominance of gasoline range hydrocarbons (Figure 6). The LNAPL sample from the well

Figure 6. UVOST locations on facilities and interpreted extent of hydrocarbon impacted soil based on UVOST responses.

(A-1), the southernmost well on the petroleum site, is characterized as primarily a broad boiling, moderately weathered crude oil or heavy petroleum distillate like gasoil containing <1% by weight of alkylate-related isoparaffin isomers. In contrast, the four other LNAPL samples contained 43% to 84% alkylate-related isoparaffin isomers. In particular, the data showed that an increase in percentage of total isoparaffins from well A-1 to well A-3 (both on the petroleum site) to well M-1 (on the manufacturing site). A concomitant decrease in heavier-end hydrocarbons (Table 1) is also evident in this these wells. Based upon the chemical composition, the LNAPL found in all wells except A-1 is characterized predominantly as an alkylate.

Table 1 shows the analytical results for benzene, other aromatic compounds (toluene, ethylbenzene, and total xylenes), and two CVOCs in the LNAPL samples. The data show the presence of benzene in all of the LNAPL samples in concentrations ranging from 119 milligrams per kilogram (mg/kg) to 3800 mg/kg. The spatial distribution of benzene in LNAPL shows a decrease in concentration from south to north to the petroleum facility’s boundary well A-3. An order of magnitude increase in benzene concentrations occurs in well M-1 located 53 meters north of boundary monitoring well A-3.

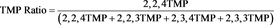

The calculated tri-methyl pentane (TMP) ratios in all five LNAPL samples are shown in Table 1. The ratios between 0.54 and 0.73 are diagnostic for a hydrofluoric acid catalyzed alkylation process used to produce alkylate [1] . This suggest that the alkylate is likely from a single source.

Table 1. Chemical analyses of LNAPL samples.

1For well SVE-8-2 and MW-1A TPH range is from C9-C40 where TPH is total petroleum hydrocarbons. ; mg/kg = milligrams per kilogram; U = Analyte Not Detected; J = Analyte detected below sample Reporting Limit; NA = Compound Not Analyzed.

; mg/kg = milligrams per kilogram; U = Analyte Not Detected; J = Analyte detected below sample Reporting Limit; NA = Compound Not Analyzed.

3.4. LNAPL Conceptual Site Model

The geologic/hydrogeologic evaluation using CPT and boring log data indicate the presence of a poorly graded sand within the perched zone. This poorly graded sand, oriented generally north-south, extends across both facilities and appears to “pinch out” northward on the manufacturing facility. Based on UVOST response data and wells containing LNAPL, the sand appears as the migration pathway of an LNAPL release. Chemical analyses of the LNAPL samples show that the LNAPL is predominantly an HF-catalyzed alkylate found in wells on both facilities. With the manufacturing facility records showing the lack of storage and use of this type of LNAPL, the source of the LNAPL likely is the petroleum facility, which has stored HF-catalyzed alkylate.

The occurrence of LNAPL across both facilities nearly contemporaneously is explained as follows. In-well measured LNAPL thickness under unconfined conditions will vary inversely with water table elevation due to the redistribution of mobile LNAPL [2] [3] [4] . Under unconfined conditions, LNAPL exists in a vertical interval called the smear zone produced through the rise and fall of the water table. When the water table falls, LNAPL follows the water table, leaving LNAPL in pore spaces at a low, three-phase (air, LNAPL, and water) residual LNAPL saturation. When the water table rises, the buoyant LNAPL will rise with the water table; however, LNAPL is trapped in the soil pores at a higher, two-phase (LNAPL and water) residual LNAPL saturation. If the water table rises to an elevation where all the mobile LNAPL is trapped at residual saturation, LNAPL will not accumulate in a monitoring well. At this site, the perched water exists under unconfined conditions. Based on the above mechanism and review of hydrographs, the perched water is present at approximately 9 meters mean sea level (MSL), which is likely higher than when the initial release occurred; LNAPL then is trapped within pore spaces and unable to flow into the monitoring well (residual LNAPL saturation under a two-phase system). During the recent drought conditions, the perched water level fell within the historical LNAPL smear zone creating a three-phase system, allowing LNAPL to accumulate in the monitoring well. Based on the above, it is hypothesized that the LNAPL was sourced from the petroleum site prior to installation of well A-1 in 1993 and potentially prior to installation of well A-3 in 1985.

4. Source of Benzene Detected in Subslab and Multi-Depth Vapor Probes

As part of the manufacturing site’s cVOC investigation, subslab and multi-depth soil vapor probes were installed at various locations (Figure 7). The purpose for the subslab and multi-depth probes was to assess the potential impacts to indoor air quality of occupied buildings and the vertical and horizontal distribution of cVOCS in the subsurface, respectively. Benzene with other fuel-related VOCs (e.g., other aromatic compounds, saturated and unsaturated hydrocarbons) were also analyzed. Since the buildingshad basements, the subslab vapor samples were collected at 0.15 meters bgs (Building Two) and 4.3 meters bgs (Building One). Additionally, multi-depth vapor probes were installed through the concrete floor of Building One. The multi-depth probes were installed at multiple depths below the basement floor ranging from a subslab location to approximately 5 meters below the basement floor. All others were multi-depth vapor probes installed outside of the building.

Figure 7 shows the benzene concentrations detected in both subslab and multi-depth vapor probes beneath the slab. The data show that benzene concentrations ranged from 1600 to 13,000 micrograms per meter3 (µg/m3) at subslab locations. In contrast, benzene was not detected above the laboratory reporting limit in soil vapor monitoring points installed at 1.8 and 4.9 meters below the slab.

A preliminary benzene vapor conceptual model (BVCM) was developed to explain the distribution of benzene vapor concentrations with depth. The BVCM shows that the source for benzene detected in the subslab vapor probes are associated with a shallow source rather than upward migration of benzene vapor from perched LNAPL originating and eventually migrating to the adjacent site.

Figure 7. Benzene Soil vapor concentrations from subslab and multi-depth vapor probes.

Figure 8 shows a geologic cross-section with benzene, toluene, ethylbenzene, and total xylenes (BTEX) concentrations from subslab and multi-depth vapor probes. Figure 7 shows the location of the geologic cross-section. The geologic section based on CPT data shows a predominant low permeability clay and silty clay zone from the surface to depths ranging from 6 to 9 meters bgs beneath a building at the manufacturing site. This low-permeability clay and silty clay zone is underlain by higher permeability interbeds of sands, silty sands, and sandy silts.

Based on the site data, the maximum benzene and toluene vapor concentrations are found in subslab vapor probes that are located within this low-permeability clay and silty clay zone.

Upward migration of benzene vapor from LNAPL is an unlikely mechanism for the presence of the benzene concentrations detected in the subslab probes for the following reasons: 1) multi-depth probes present below the subslab probes show non-detect concentration for benzene suggesting that the underlying LNAPL is not a source for the benzene vapor; and 2) the clay-silt zone across the upper 6 meters of the site provides a low-permeability zone, which will likely retard upward vertical vapor migration from a deeper vapor source and similarly will retard downward migration of vapors from a shallow source due to its low permeability. Further the lack of high benzene vapor concentrations at depth

Figure 8. Cross section A-A’ showing BTEX vapor concentrations (in micrograms per meter3) and CPT interpreted lithologies.

may be partially attributable to the fact that the LNAPL is predominantly an alkylate which typically does not contain high concentrations of benzene. Based on the above, the benzene vapors found in the subslab vapor probes are likely sourced from historical use of benzene at the manufacturer site. The distribution of toluene vapor as shown in Figure 8 is similar to benzene, and suggests that the source for toluene vapor is from the manufacturing site. Figure 9 shows a diagrammatic BVCM for the manufacturer site.

5. Summary and Conclusions

The LNAPL CSM was developed to identify the source and migration pathway for LNAPL existing on adjacent properties based on geological/hydrogeological information, investigatory efforts using CPT/UVOST data, and forensics chemistry. Multiple lines of evidence indicate LNAPL was sourced from the petroleum facility with the release occurring prior to 1993 and potentially prior to 1985. Once released, the LNAPL then migrated in the perched water zone preferentially following the permeable sand zone northward onto the manufacturing property. Due to rising water levels in the perched zone, the mobile LNAPL became trapped at residual saturation in the formation, thus not allowing any

Figure 9. Benzene soil vapor conceptual model diagram.

LNAPL accumulation in a monitoring well. During the recent drought, the perched water level fell within the historical LNAPL smear zone allowing LNAPL to drain and accumulate in the monitoring well.

It was claimed the benzene vapor present in subslab vapor probes was sourced from LNAPL that had migrated beneath site buildings from adjacent petroleum facility. Review of the benzene vapor distribution showed that benzene vapor in subslab probes ranged from 1600 to 13,000 µg/m3. In contrast, benzene was not detected in deeper multi-depth vapor probes beneath the building. Upward migration of benzene vapor sourced from LNAPL at depth is an unlikely mechanism since multi-depth probes present below the subslab show non-detect concentrations for benzene. Additionally, the LNAPL beneath the building has been characterized as predominantly an alkylate, which contains low concentrations of benzene, and the low-permeability clay-silt layer present in the upper 6 meters of the soil column likely retards upward migration of vapors from a deeper source (alkylate). Because the manufacturing facility stored and used benzene, it is likely that the shallow benzene detected in the subslab vapor probes is the result of localized spills of benzene.

Acknowledgements

The authors wish to thank Steven Gaito with regards to questions on the occurrence of LNAPL at the site and Kim Olsen for her editing and formatting of text, tables, and figures.

Cite this paper

Muramoto, F.S. and Lu, J. (2018) Investigation of the Source Relationship between Benzene Vapor and Alkylate-Containing Light Non-Aqueous Phase Liquid at Adjacent Industrial Facilities. Journal of Environmental Protection, 9, 567-580. https://doi.org/10.4236/jep.2018.95036

References

- 1. Morrison, R.D. and Murphy, B. (2006) Environmental Forensics, Contaminant Guide. Elsevier, Inc., Amsterdam, 478.

- 2. Huntley, D., Hawk, R.N. and Corley, H.P. (1994) Nonaqueous Phase Hydrocarbon in a Fine-Grained Sandstone: 1. Comparison Between Measured and Predicted Saturations and Mobility, Groundwater July.

- 3. Interstate Research Council (2009) Evaluating LNAPL Remedial Technologies for Achieving Project Goals, December. http://www.itrcweb.org/

- 4. Interstate Technology & Regulatory Council (2011) LNAPL Training Part 1: An Improved Understanding of LNAPL Behavoir in the Subsurface. http://www.itrcweb.org/