Open Journal of Statistics

Vol.04 No.11(2014), Article ID:52863,6 pages

10.4236/ojs.2014.411091

Comparison of Rectangular and Elliptical Control Region EWMA Schemes for Joint Quality Monitoring

A. M. Razmy1, T. S. G. Peiris2

1Department of Mathematical Sciences, Faculty of Applied Sciences, South Eastern University of Sri Lanka, Sammanthurai, Sri Lanka

2Department of Mathematical Sciences, Faculty of Engineering, University of Moratuwa, Moratuwa, Sri Lanka

Email: amrazmy@seu.ac.lk

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 4 October 2014; revised 2 November 2014; accepted 18 November 2014

ABSTRACT

The exponential weighted moving average technique used in process mean and variance monitoring charts was combined by Gan in 1997 and proposed two combined joint monitoring schemes one with rectangular control region and the other with elliptical control region. Performance of these two schemes may very depend on the shifts in mean or variance to be detected quickly. In this paper, performances of these two schemes are evaluated with respect to the average run length properties. The results reveal that elliptical scheme is little faster in detecting the shifts in process mean and increase in variance within a limit.

Keywords:

Average Run Length, Exponential Weighted Moving Average, Joint Monitoring

1. Introduction

Exponential weighted moving average (EWMA) chart for monitoring a shift in process mean was introduced by Roberts in 1959 and the design procedure of EWMA mean charts was reported by Crowder in 1989 [1] [2] . Later Chang and Gan showed that EWMA chart can also be used to monitor the sample variance [3] . However, Gan emphasized the importance of jointly monitoring the mean and variance, as that process monitoring is a bivariate problem [4] [5] . The current practice of joint monitoring scheme consists of a mean and a variance chart to look a bivariate problem using two univariate procedures. Two combined joint monitoring schemes using EWMA charts with a rectangular control region (EEr) and an elliptical control region (EEe) were proposed by Gan [4] . When there is more than one scheme for joint monitoring, it is needed to compare the performances of the schemes under different scenarios. The performance of individual EWMA chart was studied using its run length distribution by Crowder, Lucas and Saccucci [6] [7] . In this paper the performance of the EEr and EEe schemes is evaluated different scenarios based on average run length (ARL) properties. ARL is defined as the average number of samples taken until an out-of-control signal is issued in quality control schemes.

2. Methodology

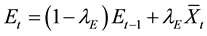

An EWMA chart for monitoring the sample mean  is obtained by plotting

is obtained by plotting  against the sample number t

against the sample number t , where E0 is usually set at target mean µ0, lE is a constant such that

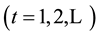

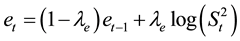

, where E0 is usually set at target mean µ0, lE is a constant such that  and it is selected based on the shift in the mean to be detected quickly. An out-of-control signal is issued if

and it is selected based on the shift in the mean to be detected quickly. An out-of-control signal is issued if  where HE and hE are the upper control limit and lower control limit respectively. The EWMA chart for monitoring the sample variance

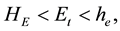

where HE and hE are the upper control limit and lower control limit respectively. The EWMA chart for monitoring the sample variance  can be obtained by plotting

can be obtained by plotting  against the sample number t, where e0 is usually set at

against the sample number t, where e0 is usually set at , le is a positive constant such that

, le is a positive constant such that  and it is selected based on the shift in the variance to be detected quickly. An out-of-control signal is issued if et is greater than the He or et is less than the he. He and he are the upper and lower control limits respectively for the EWMA variance chart.

and it is selected based on the shift in the variance to be detected quickly. An out-of-control signal is issued if et is greater than the He or et is less than the he. He and he are the upper and lower control limits respectively for the EWMA variance chart.

In the EEr scheme, EWMA mean chart and the EWMA variance chart are combined by plotting the EWMA of  against the EWMA of

against the EWMA of . The upper and lower control limits of the two charts form four sides of a rectangular control region. In EEe scheme, the distance from the point

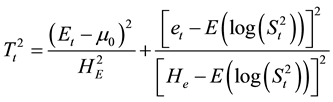

. The upper and lower control limits of the two charts form four sides of a rectangular control region. In EEe scheme, the distance from the point ,

,  will decide whether a point falls inside the elliptical control region or not. This distance is calculated using Hotelling type statistics T2 for each sample. The quantity

will decide whether a point falls inside the elliptical control region or not. This distance is calculated using Hotelling type statistics T2 for each sample. The quantity  for a point in which et is greater than

for a point in which et is greater than  is given as

is given as

(1)

(1)

and for a point in which et is less than

Figure 1 illustrates the difference between the rectangular and elliptical control regions in which point B is an in-control point with respect to the EEr scheme, but it is an out-of control point with respect to the EEe scheme. Similarly, point A is an out-of-control point with respect to the EEr scheme, but it is an in-control point with respect to the EEe scheme. In process monitoring, both the magnitude of the shift and the direction are important and therefore it advisable to plot the individual samples.

Simulated data set were used for comparing the performance of the two combined schemes. For this simulation, the in-control mean (µ0) and variance

The performances of the schemes are compared based on out of control ARLs when there is a shift in mean or variance or in both. Schemes detect various magnitudes of shifts in mean and variance based on their sensitivities. The scheme which gives smaller ARL when there is a shift in mean or variance is the better scheme. The shifts in mean and variance investigated are given by

and

Table 1. Control Chart parameters for the EEr and EEe schemes in a steady state when ARL = 250, 370 and n = 5.

Figure 1. Rectangular and elliptical control regions of the combined EWMA schemes.

where

where,

3. Results and Discussion

Table 2 and Table 3 shows the out-of-control ARLs for different magnitudes of shifts in mean and variance for in-control ARLs of 250 and 370. Figure 2 and Figure 3 compare the efficiency of the two schemes using the index

Table 2. Average run lengths of combined schemes with respect to the process mean

Table 3. Average run lengths of combined schemes with respect to the process mean

Figure 2. E∆,δ index to compare the efficiency of EEr and EEe schemes when in-control ARL = 250.

Figure 3. E∆,δ index to compare the efficiency of EEr and EEe schemes when in-control ARL = 370.

4. Conclusion

In overall the EEe scheme is faster than the EEr scheme in detecting the shifts in process mean and variance but the design procedure of EEe scheme is little complex due to its complex equations. Further less variance is signaled slowly in the EEe schemes compare to EEr scheme which is a preferred characteristic. Therefore EEe scheme outperformed the EEr scheme.

Acknowledgements

This work was supported by the South Eastern University of Sri Lanka and the Higher Education for the Twenty First Century Project, Sri Lanka [SEUSL/O-AS/N1].

References

- Roberts, S.W. (1959) Control Chart Tests Based on Geometric Moving Averages. Technometrics, 1, 239-250. http://dx.doi.org/10.1080/00401706.1959.10489860

- Crowder, S.V. (1989) Design of Exponentially Weighted Moving Average Schemes. Journal of Quality Technology, 21, 155-162.

- Chang, T.C. and Gan, F.F. (1993) Optimal Designs of One-Sided EWMA Charts for Monitoring a Process Variance. Journal of Statistical Computing & Simulations, 49, 33-48. http://dx.doi.org/10.1080/00949659408811559

- Gan, F.F. (1995) Joint Monitoring of Process Mean and Variance Using Exponentially Weighted Moving Average Control Charts. Technometrics, 37, 446-453. http://dx.doi.org/10.1080/00401706.1995.10484377

- Gan, F.F. (1997) Joint Monitoring of Process Mean and Variance. Nonlinear Analysis, Theory, Methods and Applications, 30, 4017-4024. http://dx.doi.org/10.1016/S0362-546X(97)00224-1

- Crowder, S.V. (1987) A Simple Method for Studying Run Length Distribution of Exponential Weighted Moving Average Charts. Technometrics, 29, 401-407.

- Lucas, J.M. and Saccuci, M.S. (1990) Exponentially Moving Average Control Schemes: Properties and Enhancements. Drexel University Faculty Working Series Paper, #87-5.