World Journal of Engineering and Technology

Vol.02 No.04(2014), Article ID:51803,7 pages

10.4236/wjet.2014.24033

Vibration Control for Two air Compressor units Used in Tandem

Viorel-Mihai Nani1,2, Ioan Cireş2

1Faculty of Engineering, University ″Ioan Slavici″ Timisoara, Timisoara, Romania

2Research Department, SC PRO ATLAS ING SRL Timisoara, Timisoara, Romania

Email: viorelnani@yahoo.com, proatlasing@yahoo.com

academic Editor: Gwang-Hee Kim, Department of Plant & Architectural Engineering, College of Engineering, Kyonggi University, Republic of Korea

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 23 September 2014; revised 18 October 2014; accepted 5 November 2014

ABSTRACT

The paper presents the vibration control for two air compressors used in tandem to an oxygen generating station. The compressors are identical in terms of constructive and functional proper- ties, and are both located on similar foundations. Each compressor is supported on a foundation made from one massive block of concrete, provided with some elastic and damping parts. This anti vibrating structure insulates the machines compared to other station equipment. During opera- tion, were observed dangerous levels of vibration at one of the machines, which forced some un- wanted stoppages for the station. Two hypotheses have been promoted. One of them referred to a pronounced wear of one compressor, although this was relatively new. The second hypothesis has taken in consideration the appearance of some cracks in the foundation massive concrete block. Experimental research conducted on the spot led to the identification of some errors done at foundation fabrication. The experimental results and some theoretical investigations are pre- sented in this paper.

Keywords:

foundation, harmonic disturbing Forces, Amortized forced Vibration, Vibration isolation, Coefficient of transmissibility

1. Introduction

In general, operating industrial equipments produce vibrations under the action of some disturbing forces. These are usually, periodic time dependent external forces. Common source for disturbing forces are the inertia forces. Virtually every moving body―(movements like: rotation, linear displacement, linear―alternative, oscillatory etc.)―is subject to inertial forces and therefore produces vibrations [1] and [2] .

Vibrations are transmitted to the foundation on which is installed the equipment. From dynamic stability con- siderations, these vibrations should be isolated. To isolate the vibrations it means to identify some technical measures, so that the foundation does not vibrate when the industrial equipment creates these forces. So, is re- quired that the disturbing forces transmitted to the foundation to be zero or as low as possible with the help of some damping measures [3] .

In the paper we studied a real case that occurred to an oxygen station. The replacement of two air compressors with a new model concurrently with restoration the foundation had generated unforeseen situation. During commissioning tests, there were identified dangerous levels of vibration which led the temporary shutdown of the compressors, and thus the oxygen station. In this context, our research team was asked to correct the non- compliance.

2. Theoretical Considerations on Forced Vibration

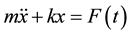

A particular important case in practical applications is the situation where the damping forces are negligible and over the mechanical system is acting only the disturbing force . Being independent of system characteris- tics, the differential equation of motion is [4] and [5] :

. Being independent of system characteris- tics, the differential equation of motion is [4] and [5] :

(1)

(1)

where ―the mass of the mechanical system (industrial equipment);

―the mass of the mechanical system (industrial equipment); ―the elastic constant of the mechani- cal system;

―the elastic constant of the mechani- cal system; ―coordinate of motion.

―coordinate of motion.

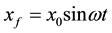

In practice, is often encountered situations where the disturbing force is harmonic. If the pulsation of this force is , then equation (1) is:

, then equation (1) is:

(2)

(2)

This equation has the particular solution

(3)

(3)

where ―the amplitude for the forced vibration in the mechanical system;

―the amplitude for the forced vibration in the mechanical system; ―the amplitude of the vibra-

―the amplitude of the vibra-

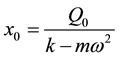

tion; Substituting (3) in (2) and putting condition , we obtain:

, we obtain:

(4)

(4)

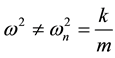

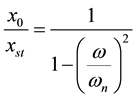

With the notation , where

, where  is the static deformation of the vibrating system under the action of a

is the static deformation of the vibrating system under the action of a

disturbing force equal with the maximum value , Equation (4) can be written in dimensionless [3] :

, Equation (4) can be written in dimensionless [3] :

(5)

(5)

We can observe that the amplitude of vibration

shown in Figure 1 [6] .

Note that for

In this situation, the forced vibration

For

or they are in opposition. The vibration amplitude is

tive sign and we will consider the dashed drawn curve (see Figure 1).

For

For high frequencies

Figure 1. Diagram amplitudes depending pulses of the mecha- nical system.

In the point a, the disturbance force frequency is very low,

Resonance is practically avoided either by changing frequency for disturbing force when it coincides with the resonance frequency, either by modifying the structure of the system, by modifying the parameters

3. Theoretical Considerations on Vibration Isolation

To reduce or eliminate the forces transmitted to the foundation, it is inserted between the mechanical system and foundation different elastic materials: metal coil springs, cork, rubber, polystyrene, expanded sheets etc. If we note with

Transmissibility coefficient

basically by adopting constructive solutions with their own pulsation

springs supple with elastic constant k small).

If industrial equipment is placed directly on the foundation without elastic elements,

For

Figure 2. The mechanical vibration isolation with elastic ele- ments.

where

If disturbing force is harmonic, namely

where

At resonance, the maximum forced amplitude is given [6]:

where

Discussions:

・ In case

・ Where

・ If

In the forced harmonic motion of industrial equipment, damping force lags by an angle

4. Mathematical Modeling of the Air Compressor Unit

The mechanical model for vibration and isolation with elastic elements and damping viscous elements is pre- sented in Figure 3 [3] and [8] .

The curves from the diagram of transmissibility coefficient (see Figure 3(b)) show the effect of damping forces, which is a reduction for the amplitude of forced vibration.

Figure 3. Experimental test plan, a) simplified mechanical model of the air compressor located on the foundation; b) diagram the coefficient of trans- missibility in function ratio pulsation.

The vibration amplitude not becomes infinitely larger comparing with the case when

The machines for compressing air and its mounting scheme on the foundation are presented in Figure 4. A multi-cylinder compressor, as a five stage air compressor 1, is composed from two parts, law pressure stage (cy- linders I, II and III) and high pressure stage (cylinders IV and V), both being driven by an electric machine 2 via an elastic coupling

The massive block foundation is used for two reasons: to machine axis line stiffening and to diminishing ma- chine-foundation vibration excited by residual inertial unbalanced forces

To determined the distribution of vibration was measured the vibration motions components,

where

・

of the structure;

・

chosen arbitrarily and is given by:

・

Figure 4. Mounting scheme of a machine for air compression (with more cylinders).

Distribution law for the rigid body vibration given by relationship (13), can be extended to the distribution of amplitudes:

where with the letters

5. Experimental Researches

Experimental investigations have been focused on study of isolating vibration for two air compressor units from an oxygen station. Although the two aggregates were identical in terms of construction and were also placed on the identical foundations, one of them presented higher levels of vibration than the other.

Was emitted the hypothesis that one of aggregates had hidden defects at installation, which led to its prema- ture wear. But the two aggregates were new, and verification tests done before entering into service did not re- veal any hidden defect.

Has been also hypothesised that the concrete massive block interposed between aggregate and foundation, has “cracked” during the technological tests, and as result it was amplifying the disturbance forces generated by the mechanical (vibrating) system.

In the first phase was carried out a dimensional static verification of the two units, but no structural differ- ences were found between them. Tolerances of the active elements―pistons, cylinder shirts, rod-crank mechanism have been found to be into the prescribed limits. There were not found abnormal wear of these compo- nents and the mechanism rod-crank it is was working smoothly, evenly and without shocks at change of di- rection.

These results had supported the hypothesis that disruptive forces

To determine the vibration distribution, we measured the components for the vibration movements

The experimental measurements we made with a comprehensive installation type DELTA TRON®, have al- lowed the effective determination of vibration amplitudes, and out of phase according to the model shown in Figure 4. The vibration motion distribution for the two air compression machines is shown in Figure 5.

Were used 8 tri-axial transducers

The values for the vibration motion amplitude and out of phase for the first harmonic, corresponding to the two machines are given in the table below:

If we analyze these results, we cannot observe significant differences between the two aggregates. Therefore the hypotheses of premature wear, or the hypothesis of some cracks in the massive concrete block at one of the two units, were rejected.

Experimental researches performed in a longer time, showed however, random occurrence of some dangerous frequencies at different moments and speeds for the electric motor 2. Because the disturbance forces

This hypothesis was accepted by the oxygen station management, which has assumed responsibility for the foundation work quality. Due to the difficulties encountered during the work for gravel compaction, it was not followed exactly the technological recipe at one of the two foundations.

6. Conclusions

The study on vibration isolation has highlighted the importance of a strict compliance with the technical re- quirements for the foundation execution technology. To explain the large difference between vibration of the two aggregates, we focused on the integrity of the concrete foundation verify which as a massive mass must to has vibration of rigid body motions. In case of a possible hidden crack the significant deviation from the rigid body motions may occurs.

The damping forces variation during operation of the equipment, leads to some variations for the transmissibility coefficient values (see Figure 3(b)):

・ For

cludes the case of resonance, viscous damping is advantageous because it reduces the transmissibility coeffi-

Figure 5. Scheme distribution of vibrational motion of the foundations for the two air com- pression aggregates.

cient and therefore the amplitude of vibration;

・ For

・ Whereas in the period starting and stopping, industrial equipments are passing through critical speeds, there is the possibility of the uncontrolled appearance of some dangerous vibrations; for this reason is recommended to use viscous damping with ratio

References

- Achenbach, J.D. (1984) Wave Propagation in Elastic Solid. North Holland, New York.

- Beards, C.F. (1995) Engineering Vibration Analysis with Application to Control Systems. Edward Arnold, London.

- Blevins, R.D. (1979) Formulas for Natural Frequency and Mode Shape. Van Nostrand Reinhold, New York.

- Cioara, T.Gh., Nicolae, I., Cires, I., Cristea, D., Cires, D. and Caplanescu, C. (2010) Consideration on Structure Vibra- tion Isolation Asymmetry. Two Funny Cases. Proceedings of the IMAC-XXVIII, Jacksonville, 1-4 February 2010.

- Craig, R.R. and Kurdila, A. (2006) Fundamentals of Structural Dynamics. John Wiley and Sons, New York.

- Silas, Gh. (1968) Mechanics. Mechanical Vibration. Didactic and Pedagogical Publishing, Bucharest.

- Geradin, M. and Rixon, D. (1997) Theory and Application to Structural Dynamics. 2nd Edition, John Wiley and Sons, New York.

- Hussey, M. (1983) Fundamentals of Mechanical Vibrations. Mac Milan Press Ltd., London.

- Meirovitch, L. (2001) Fundamentals of Vibration. McGraw-Hill, New York.

- Rades, M. (2008) Mechanical Vibration. Publishing Printech Bucharest.