M. Pekedis, H. Yildiz / J. Biomedical Science and Engineering 4 (2011) 643-650 649

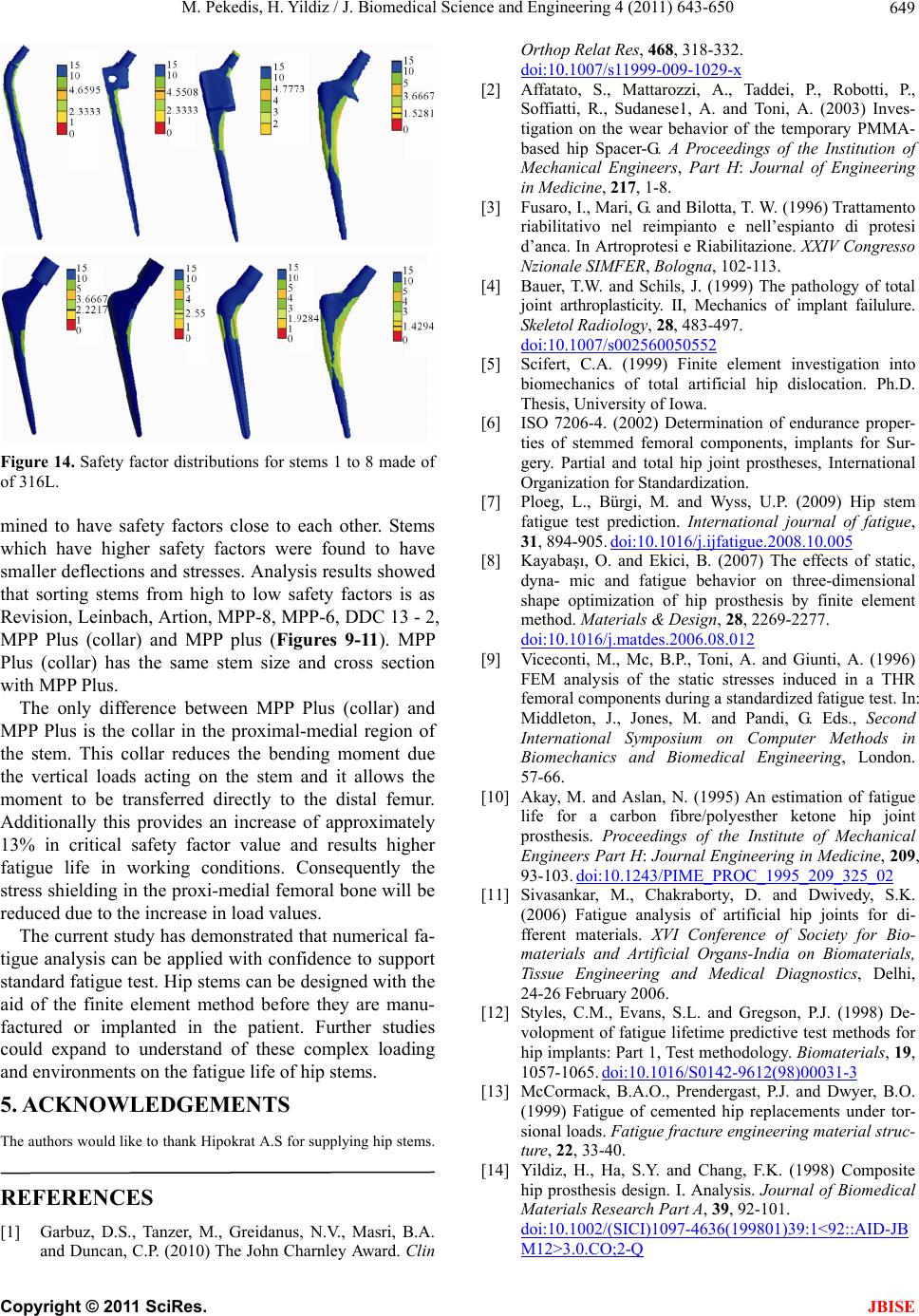

Figure 14. Safety factor distributions for stems 1 to 8 made of

of 316L.

mined to have safety factors close to each other. Stems

which have higher safety factors were found to have

smaller deflections and stresses. Analysis results showed

that sorting stems from high to low safety factors is as

Revision, Leinbach, Artion, MPP-8, MPP-6, DDC 13 - 2,

MPP Plus (collar) and MPP plus (Figures 9-11). MPP

Plus (collar) has the same stem size and cross section

with MPP Plus.

The only difference between MPP Plus (collar) and

MPP Plus is the collar in the proximal-medial region of

the stem. This collar reduces the bending moment due

the vertical loads acting on the stem and it allows the

moment to be transferred directly to the distal femur.

Additionally this provides an increase of approximately

13% in critical safety factor value and results higher

fatigue life in working conditions. Consequently the

stress shielding in the proxi-medial femoral bone will be

reduced due to the increase in load values.

The current study has demonstrated that numerical fa-

tigue analysis can be applied with confidence to support

standard fatigue test. Hip stems can be designed with the

aid of the finite element method before they are manu-

factured or implanted in the patient. Further studies

could expand to understand of these complex loading

and environments on the fatigue life of hip stems.

5. ACKNOWLEDGEMENTS

The authors would like to thank Hipokrat A.S for supplying hip stems.

REFERENCES

[1] Garbuz, D.S., Tanzer, M., Greidanus, N.V., Masri, B.A.

and Duncan, C.P. (2010) The John Charnley Award. Clin

Orthop Relat Res, 468, 318-332.

doi:10.1007/s11999-009-1029-x

[2] Affatato, S., Mattarozzi, A., Taddei, P., Robotti, P.,

Soffiatti, R., Sudanese1, A. and Toni, A. (2003) Inves-

tigation on the wear behavior of the temporary PMMA-

based hip Spacer-G. A Proceedings of the Institution of

Mechanical Engineers, Part H: Journal of Engineering

in Medici ne, 217, 1-8.

[3] Fusaro, I., Mari, G. and Bilotta, T. W. (1996) Trattamento

riabilitativo nel reimpianto e nell’espianto di protesi

d’anca. In Artroprotesi e Riabilitazione. XXIV Congresso

Nzionale SIMFER, Bologna, 102-113.

[4] Bauer, T.W. and Schils, J. (1999) The pathology of total

joint arthroplasticity. II, Mechanics of implant failulure.

Skeletol Radiology, 28, 483-497.

doi:10.1007/s002560050552

[5] Scifert, C.A. (1999) Finite element investigation into

biomechanics of total artificial hip dislocation. Ph.D.

Thesis, University of Iowa.

[6] ISO 7206-4. (2002) Determination of endurance proper-

ties of stemmed femoral components, implants for Sur-

gery. Partial and total hip joint prostheses, International

Organization for Standardization.

[7] Ploeg, L., Bürgi, M. and Wyss, U.P. (2009) Hip stem

fatigue test prediction. International journal of fatigue,

31, 894-905. doi:10.1016/j.ijfatigue.2008.10.005

[8] Kayabaşı, O. and Ekici, B. (2007) The effects of static,

dyna- mic and fatigue behavior on three-dimensional

shape optimization of hip prosthesis by finite element

method. Materials & Design, 28, 2269-2277.

doi:10.1016/j.matdes.2006.08.012

[9] Viceconti, M., Mc, B.P., Toni, A. and Giunti, A. (1996)

FEM analysis of the static stresses induced in a THR

femoral components during a standardized fatigue test. In:

Middleton, J., Jones, M. and Pandi, G. Eds., Second

International Symposium on Computer Methods in

Biomechanics and Biomedical Engineering, London.

57-66.

[10] Akay, M. and Aslan, N. (1995) An estimation of fatigue

life for a carbon fibre/polyesther ketone hip joint

prosthesis. Proceedings of the Institute of Mechanical

Engineers Part H: Journal Engineering in Medicine, 209,

93-103. doi:10.1243/PIME_PROC_1995_209_325_02

[11] Sivasankar, M., Chakraborty, D. and Dwivedy, S.K.

(2006) Fatigue analysis of artificial hip joints for di-

fferent materials. XVI Conference of Society for Bio-

materials and Artificial Organs-India on Biomaterials,

Tissue Engineering and Medical Diagnostics, Delhi,

24-26 February 2006.

[12] Styles, C.M., Evans, S.L. and Gregson, P.J. (1998) De-

volopment of fatigue lifetime predictive test methods for

hip implants: Part 1, Test methodology. Biomaterials, 19,

1057-1065. doi:10.1016/S0142-9612(98)00031-3

[13] McCormack, B.A.O., Prendergast, P.J. and Dwyer, B.O.

(1999) Fatigue of cemented hip replacements under tor-

sional loads. Fatigue fracture engineering material struc-

ture, 22, 33-40.

[14] Yildiz, H., Ha, S.Y. and Chang, F.K. (1998) Composite

hip prosthesis design. I. Analysis. Journal of Biomedical

Materials Research Part A, 39, 92-101.

doi:10.1002/(SICI)1097-4636(199801)39:1<92::AID-JB

M12>3.0.CO;2-Q

C

opyright © 2011 SciRes. JBISE