C. L. LI ET AL.

82

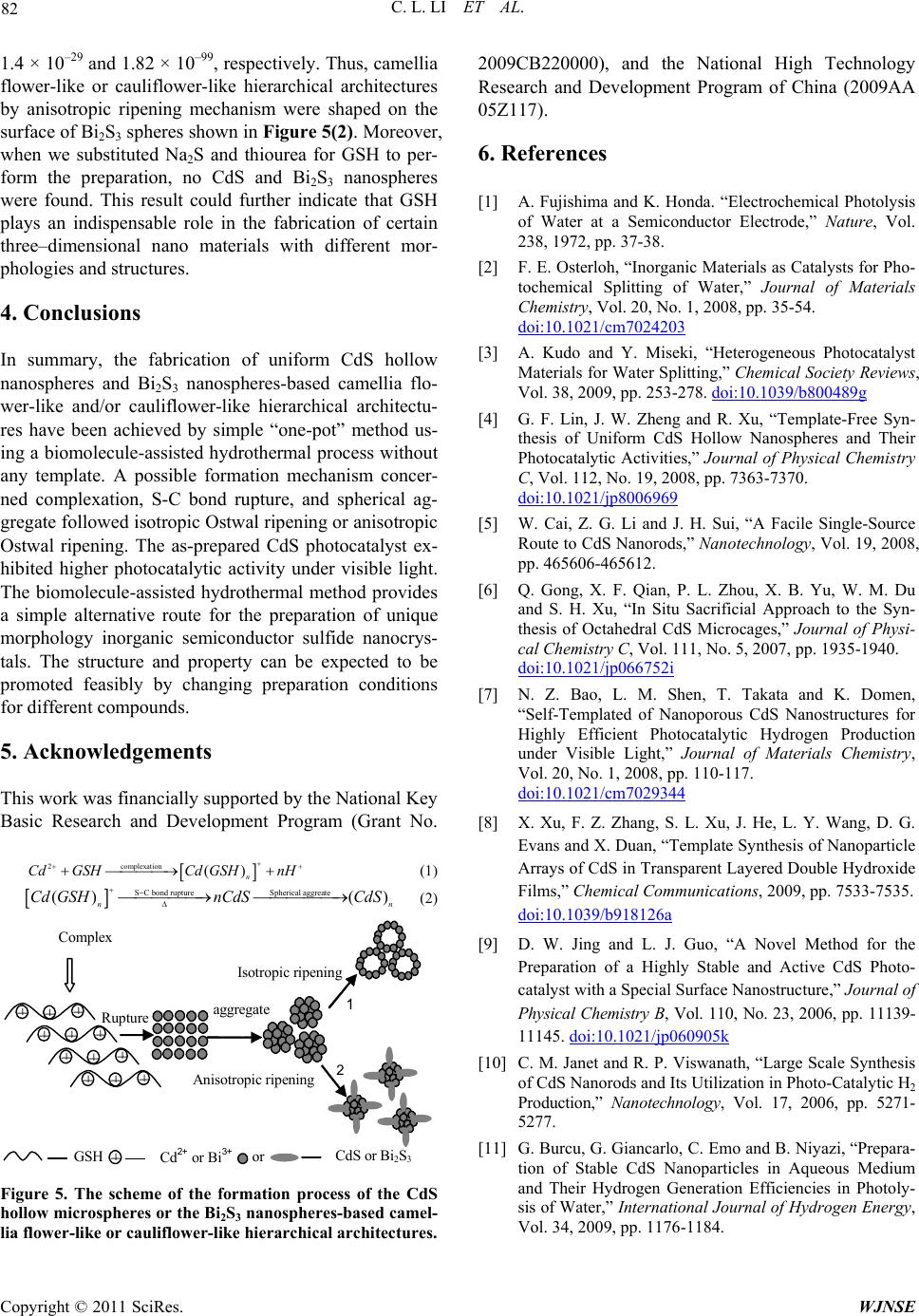

1.4 × 10–29 and 1.82 × 10–99, respectively. Thus, camellia

flower-like or cauliflower-like hierarchical architectures

by anisotropic ripening mechanism were shaped on the

surface of Bi2S3 spheres shown in Figure 5(2). Moreover,

when we substituted Na2S and thiourea for GSH to per-

form the preparation, no CdS and Bi2S3 nanospheres

were found. This result could further indicate that GSH

plays an indispensable role in the fabrication of certain

three–dimensional nano materials with different mor-

phologies and structures.

4. Conclusions

In summary, the fabrication of uniform CdS hollow

nanospheres and Bi2S3 nanospheres-based camellia flo-

wer-like and/or cauliflower-like hierarchical architectu-

res have been achieved by simple “one-pot” method us-

ing a biomolecule-assisted hydrothermal process without

any template. A possible formation mechanism concer-

ned complexation, S-C bond rupture, and spherical ag-

gregate followed isotropic Ostwal ripening or anisotropic

Ostwal ripening. The as-prepared CdS photocatalyst ex-

hibited higher photocatalytic activity under visible light.

The biomolecule-assisted hydrothermal method provides

a simple alternative route for the preparation of unique

morphology inorganic semiconductor sulfide nanocrys-

tals. The structure and property can be expected to be

promoted feasibly by changing preparation conditions

for different compounds.

5. Acknowledgements

This work was financially supported by the National Key

Basic Research and Development Program (Grant No.

2complexation ()

n

CdGSHCd GSHnH

SC bond ruptureSpherical

(1)

aggreate

() ()

n n

Cd GSHnCdSCdS

(2)

Rupture

Complex

aggregate

Isotropic ripening

Anisotropic ripening

1

2

Cd2+ or Bi3+ CdS or Bi2S3

or

GSH

Figure 5. The scheme of the formation process of the CdS

hollow microspheres or the Bi2S3 nanospheres-based camel-

lia flower-like or cauliflower-like hierarchical architectures.

2009CB220000), and the National High Technology

Research and Development Program of China (2009AA

05Z117).

6. References

[1] A. Fujishima and K. Honda. “Electrochemical Photolysis

of Water at a Semiconductor Electrode,” Nature, Vol.

238, 1972, pp. 37-38.

[2] F. E. Osterloh, “Inorganic Materials as Catalysts for Pho-

tochemical Splitting of Water,” Journal of Materials

Chemistry, Vol. 20, No. 1, 2008, pp. 35-54.

doi:10.1021/cm7024203

[3] A. Kudo and Y. Miseki, “Heterogeneous Photocatalyst

Materials for Water Splitting,” Chemical Society Reviews,

Vol. 38, 2009, pp. 253-278. doi:10.1039/b800489g

[4] G. F. Lin, J. W. Zheng and R. Xu, “Template-Free Syn-

thesis of Uniform CdS Hollow Nanospheres and Their

Photocatalytic Activities,” Journal of Physical Chemistry

C, Vol. 112, No. 19, 2008, pp. 7363-7370.

doi:10.1021/jp8006969

[5] W. Cai, Z. G. Li and J. H. Sui, “A Facile Single-Source

Route to CdS Nanorods,” Nanotechnology, Vol. 19, 2008,

pp. 465606-465612.

[6] Q. Gong, X. F. Qian, P. L. Zhou, X. B. Yu, W. M. Du

and S. H. Xu, “In Situ Sacrificial Approach to the Syn-

thesis of Octahedral CdS Microcages,” Journal of Physi-

cal Chemistry C, Vol. 111, No. 5, 2007, pp. 1935-1940.

doi:10.1021/jp066752i

[7] N. Z. Bao, L. M. Shen, T. Takata and K. Domen,

“Self-Templated of Nanoporous CdS Nanostructures for

Highly Efficient Photocatalytic Hydrogen Production

under Visible Light,” Journal of Materials Chemistry,

Vol. 20, No. 1, 2008, pp. 110-117.

doi:10.1021/cm7029344

[8] X. Xu, F. Z. Zhang, S. L. Xu, J. He, L. Y. Wang, D. G.

Evans and X. Duan, “Template Synthesis of Nanoparticle

Arrays of CdS in Transparent Layered Double Hydroxide

Films,” Chemical Communications, 2009, pp. 7533-7535.

doi:10.1039/b918126a

[9] D. W. Jing and L. J. Guo, “A Novel Method for the

Preparation of a Highly Stable and Active CdS Photo-

catalyst with a Special Surface Nanostructure,” Journal of

Physical Chemistry B, Vol. 110, No. 23, 2006, pp. 11139-

11145. doi:10.1021/jp060905k

[10] C. M. Janet and R. P. Viswanath, “Large Scale Synthesis

of CdS Nanorods and Its Utilization in Photo-Catalytic H2

Production,” Nanotechnology, Vol. 17, 2006, pp. 5271-

5277.

[11] G. Burcu, G. Giancarlo, C. Emo and B. Niyazi, “Prepara-

tion of Stable CdS Nanoparticles in Aqueous Medium

and Their Hydrogen Generation Efficiencies in Photoly-

sis of Water,” International Journal of Hydrogen Energy,

Vol. 34, 2009, pp. 1176-1184.

Copyright © 2011 SciRes. WJNSE