Turbidimetric Determination of Hydrocarbon Contamination in Passaic River Sediments and Refinery Polluted Soils921

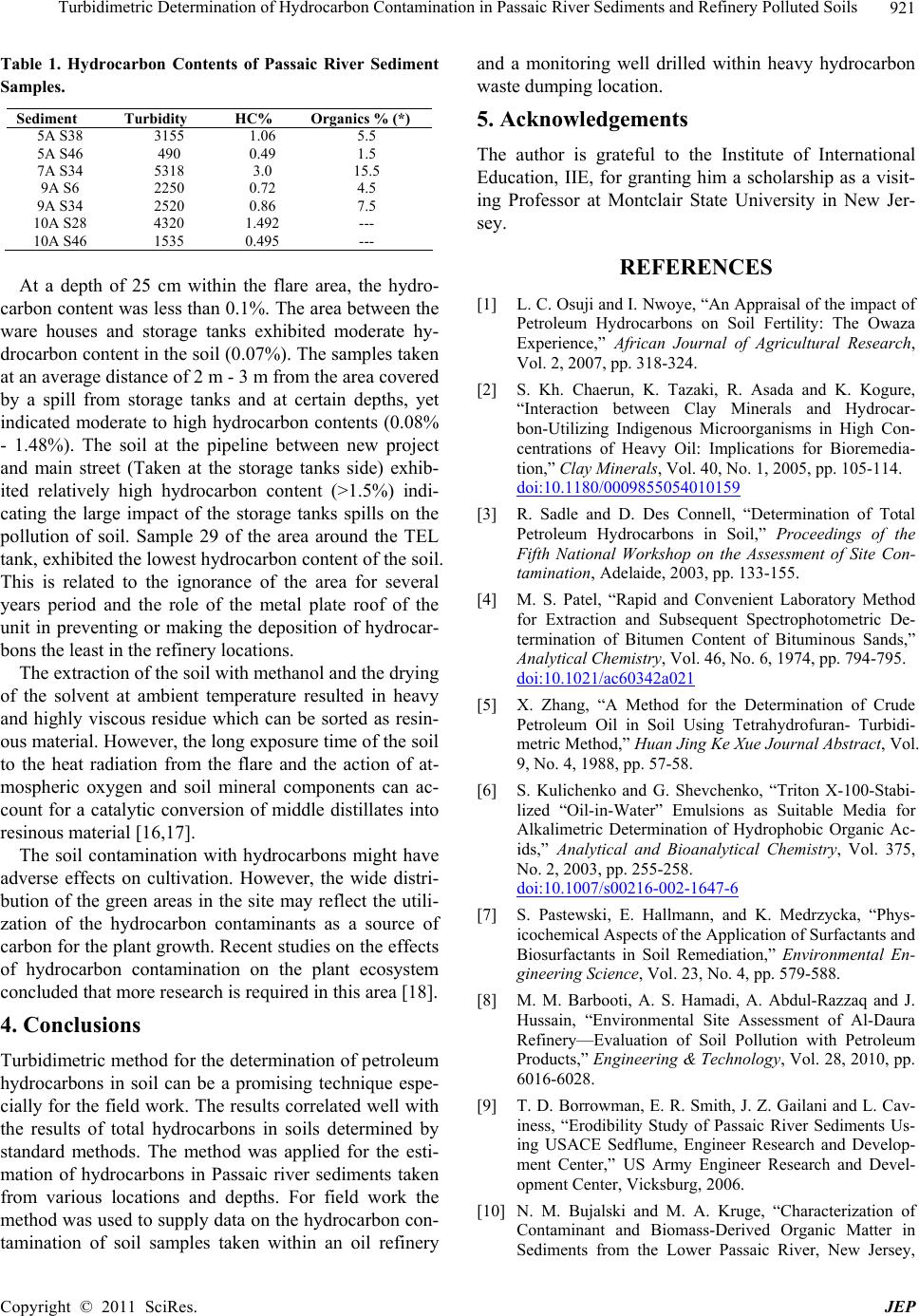

Table 1. Hydrocarbon Contents of Passaic River Sediment

Samples.

Sediment Turbidity HC% Organics % (*)

5A S38 3155 1.06 5.5

5A S46 490 0.49 1.5

7A S34 5318 3.0 15.5

9A S6 2250 0.72 4.5

9A S34 2520 0.86 7.5

10A S28 4320 1.492 ---

10A S46 1535 0.495 ---

At a depth of 25 cm within the flare area, the hydro-

carbon content was less than 0.1%. The area between the

ware houses and storage tanks exhibited moderate hy-

drocarbon content in the soil (0.07%). The samples taken

at an average distance of 2 m - 3 m from the area covered

by a spill from storage tanks and at certain depths, yet

indicated moderate to high hydrocarbon contents (0.08%

- 1.48%). The soil at the pipeline between new project

and main street (Taken at the storage tanks side) exhib-

ited relatively high hydrocarbon content (>1.5%) indi-

cating the large impact of the storage tanks spills on the

pollution of soil. Sample 29 of the area around the TEL

tank, exhibited the lowest hydrocarbon content of the soil.

This is related to the ignorance of the area for several

years period and the role of the metal plate roof of the

unit in preventing or making the deposition of hydrocar-

bons the least in the refinery locations.

The extraction of the soil with methanol and the drying

of the solvent at ambient temperature resulted in heavy

and highly viscous residue which can be sorted as resin-

ous material. However, the long exposure time of the soil

to the heat radiation from the flare and the action of at-

mospheric oxygen and soil mineral components can ac-

count for a catalytic conversion of middle distillates into

resinous material [16,17].

The soil contamination with hydrocarbons might have

adverse effects on cultivation. However, the wide distri-

bution of the green areas in the site may reflect the utili-

zation of the hydrocarbon contaminants as a source of

carbon for the plant growth. Recent studies on the effects

of hydrocarbon contamination on the plant ecosystem

concluded that more research is required in this area [18].

4. Conclusions

Turbidimetric method for the determination of petroleum

hydrocarbons in soil can be a promising technique espe-

cially for the field work. The results correlated well with

the results of total hydrocarbons in soils determined by

standard methods. The method was applied for the esti-

mation of hydrocarbons in Passaic river sediments taken

from various locations and depths. For field work the

method was used to supply data on the hydrocarbon con-

tamination of soil samples taken within an oil refinery

and a monitoring well drilled within heavy hydrocarbon

waste dumping location.

5. Acknowledgements

The author is grateful to the Institute of International

Education, IIE, for granting him a scholarship as a visit-

ing Professor at Montclair State University in New Jer-

sey.

REFERENCES

[1] L. C. Osuji and I. Nwoye, “An Appraisal of the impact of

Petroleum Hydrocarbons on Soil Fertility: The Owaza

Experience,” African Journal of Agricultural Research,

Vol. 2, 2007, pp. 318-324.

[2] S. Kh. Chaerun, K. Tazaki, R. Asada and K. Kogure,

“Interaction between Clay Minerals and Hydrocar-

bon-Utilizing Indigenous Microorganisms in High Con-

centrations of Heavy Oil: Implications for Bioremedia-

tion,” Clay Minerals, Vol. 40, No. 1, 2005, pp. 105-114.

doi:10.1180/0009855054010159

[3] R. Sadle and D. Des Connell, “Determination of Total

Petroleum Hydrocarbons in Soil,” Proceedings of the

Fifth National Workshop on the Assessment of Site Con-

tamination, Adelaide, 2003, pp. 133-155.

[4] M. S. Patel, “Rapid and Convenient Laboratory Method

for Extraction and Subsequent Spectrophotometric De-

termination of Bitumen Content of Bituminous Sands,”

Analytical Chemistry, Vol. 46, No. 6, 1974, pp. 794-795.

doi:10.1021/ac60342a021

[5] X. Zhang, “A Method for the Determination of Crude

Petroleum Oil in Soil Using Tetrahydrofuran- Turbidi-

metric Method,” Huan Jing Ke Xue Journal Abstract, Vol.

9, No. 4, 1988, pp. 57-58.

[6] S. Kulichenko and G. Shevchenko, “Triton X-100-Stabi-

lized “Oil-in-Water” Emulsions as Suitable Media for

Alkalimetric Determination of Hydrophobic Organic Ac-

ids,” Analytical and Bioanalytical Chemistry, Vol. 375,

No. 2, 2003, pp. 255-258.

doi:10.1007/s00216-002-1647-6

[7] S. Pastewski, E. Hallmann, and K. Medrzycka, “Phys-

icochemical Aspects of the Application of Surfactants and

Biosurfactants in Soil Remediation,” Environmental En-

gineering Science, Vol. 23, No. 4, pp. 579-588.

[8] M. M. Barbooti, A. S. Hamadi, A. Abdul-Razzaq and J.

Hussain, “Environmental Site Assessment of Al-Daura

Refinery—Evaluation of Soil Pollution with Petroleum

Products,” Engineering & Technology, Vol. 28, 2010, pp.

6016-6028.

[9] T. D. Borrowman, E. R. Smith, J. Z. Gailani and L. Cav-

iness, “Erodibility Study of Passaic River Sediments Us-

ing USACE Sedflume, Engineer Research and Develop-

ment Center,” US Army Engineer Research and Devel-

opment Center, Vicksburg, 2006.

[10] N. M. Bujalski and M. A. Kruge, “Characterization of

Contaminant and Biomass-Derived Organic Matter in

Sediments from the Lower Passaic River, New Jersey,

Copyright © 2011 SciRes. JEP