Journal of Water Resource and Protection

Vol. 2 No. 3 (2010) , Article ID: 1495 , 10 pages DOI:10.4236/jwarp.2010.23027

Photocatalytic Degradation of Isoproturon Pesticide on C, N and S Doped TiO2

Inorganic and Physical Chemistry Division, Indian Institute of Chemical Technology,

Hyderabad, India

E-mail: subrahmanyam@iict.res.in

Received December 15, 2009; revised December 29, 2009; accepted January 22, 2010

Keywords: Isoproturon, Pesticide Degradation, C, N and S Doped TiO2, Visible Light Active Catalysts

ABSTRACT

TiO2 doped with C, N and S (TCNS photocatalyst) was prepared by hydrolysis process using titanium isopropoxide and thiourea. The prepared samples were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), X-ray photo electron spectroscopy (XPS), BET surface area, FTIR and diffuse reflectance spectra (DRS). The results showed that the prepared catalysts are anatase type and nanosized particles. The catalysts exhibited stronger absorption in the visible light region with a red shift in the adsorption edge. The photocatalytic activity of TCNS photocatalysts was evaluated by the photocatalytic degradation of isoproturon pesticide in aqueous solution. In the present study the maximum activity was achieved for TCNS5 catalyst at neutral pH with 1 g L-1 catalyst amount and at 1.14 x 10-4 M concentration of the pesticide solution. The TCNS photocatalysts showed higher phtocatalytic activity under solar light irradiation. This is attributed to the synergetic effects of red shift in the absorption edge, higher surface area and the inhibition of charge carrier recombination process.

1. Introduction

Organic compounds are widely used in industry and in daily life, have become common pollutants in water bodies. As they are known to be noxious and carcinogenic, an effective and economic treatment for eliminating the organic pollutants in water has been found to be an urgent demand. The treatment of water contaminated with recalcitrant compounds is an important task to attend every country in the world. To attain the standards, there is a need for new treatment. It is very much important that the treatment should be safe and economically feasible. The wastewater purification technologies are classified as physical, biological, and chemical methods. All the above processes are having some flaws during their usage. The limitations include relative slow degradation, incomplete transformations and their inability to cover many organic compounds that do not occur naturally. Several chemical processes which use oxidizing agents such as ozone, hydrogen peroxide, H2O2/UV, H2O2/ozone/UV etc. have been carried out to mineralize many synthetic organic chemicals. Sometimes intermediates formed are more hazardous than the parent compound. Therefore, alternative technologies are in demand for development to treat recalcitrant compounds in wastewater effluents. Photocatalytic process has been found to be very active in the treatment of wastewaters for the mineralization of broad range of organic pollutants. Thus, heterogeneous mediated photocatalysis treatment technique gained noteworthy importance for the treatment of wastewaters.

Semiconductor mediated photocatalytic oxidation of water pollutants offers a facile and cheap method. Among various oxide semiconductor phtocatalysts, TiO2 has proved to be the most suitable catalyst for wide spread environmental applications because of its biological and chemical inertness, strong oxidizing power, non toxicity, long term stability against photo and chemical corrosion [1,2]. However, its applications seems to be limited by several factors, among which the most restrictive one is the need of using an UV wavelength of < 387 nm, as excitation source due to its wide band gap (3.2 eV), and this energy radiation availability is less than 5 % in solar light.

Several works reported that doping TiO2 with anions such as carbon, nitrogen, sulphur, boron and fluorine shifts the optical absorption edge of TiO2 towards lower energy, there by increasing the photocatalytic activity in visible light region [3–9]. The preparation of doped TiO2 resulting in a desired band gap narrowing and an enhancement in the phtocatalytic activity under visible light.

In earlier reported studies, N doping of TiO2 is achieved by different methods such as sputtering of TiO2 in a gas mixture followed by annealing at higher temperatures [3], treating anatase TiO2 powders in an NH3/ Ar atmosphere [10], solution based methods like precipitation [11,12], sol-gel [13,14], solvothermal [15], hydrothermal processes [16] and direct oxidation of the dopent containing titanium precursors at appropriate temperatures [17]. In our earlier studies, we have concentrated on degradation of isoproturon using TiO2 supported over various zeolites. The main idea of using Zeolite support for TiO2 is to enhance the adsorption capacity of the pollutant over the combinate photo catalyst systems [18–20]. In the present case the main focus is on shifting the absorption edge of TiO2 to visible light region by introducing C, N and S into the TiO2 lattice structure. The present results obtained provides a simple route for the preparation of C, N and S doped TiO2 with enhanced photocatalytic activity under visible light irradiation for isoproturon pesticide degradation.

2. Experimental Details

2.1. Materials and Methods

All the chemicals in the present work are of analytical grade and used as such without further purification. Isoproturon (IPU) (>99% pure, Technical grade) was obtained from Rhône-Poulenc Agrochemie, France and titanium isopropoxide was from Sigma-Aldrich chemie GmbH, Germany. HCl, NaOH and acetonitrile were obtained from Ranbaxy Limited, India. All the solutions were prepared with deionized water obtained using a Millipore device (Milli-Q).

2.2. Preparation of C, N and S Doped TiO2 Photocatalyst

C, N and S doped TiO2 photocatalyst was prepared by a simple hydrolysis process using titanium isopropoxide as the precursor for titanium and thiourea as the source for carbon, nitrogen and sulphur [26,34]. In a typical preparation, 10 mL of titanium isopropoxide solution was mixed with 30 mL of isopropyl alcohol solution. This solution was added drop wise to 20 mL deionized water containing in a 250 mL beaker. The solution was thoroughly mixed using a magnetic stirrer for 4 h. To this solution, required amount of thiourea, dissolved in 5 mL deionized water was added. The mixture was stirred for 6 h and dried in oven at 80 0C for 12 h. The solid product formed was further calcined at 400 0C temperature for 6 h in air to get C, N, and S doped TiO2 photocatalyst. The weight (%) of thiourea doped TiO2 was controlled at 0, 1, 3, 5, 10 and 15 wt% and the samples obtained were labeled as TCNS0, TCNS1, TCNS3, TCNS5, TCNS10 and TCNS15 respectively.

2.3. Characterization

The catalysts were characterized by various techniques like XRD, XPS, FTIR, SEM, BET surface area and UV-Vis DRS. The XRD of catalysts were obtained by Siemens D 5000 using Ni Filtered Cu K α radiation (√ = 1.5406 A0) from 2θ = 1-600. XPS spectra were recorded on a KRATOS AXIS 165 equipped with Mg Kα radiation (1253.6 eV) at 75 W apparatus using Mg Kα anode and a hemispherical analyzer, connected to a five channel detector. The C 1s line at 284.6 eV was used as an internal standard for the correction of binding energies. The Fourier transform-infra red spectra (FTIR) were recorded on a Nicolet 740 FTIR spectrometer (USA) using KBr self-supported pellet technique. The SEM analysis samples were mounted on an aluminum support using a double adhesive tape coated with gold and observed in Hitachi S-520 SEM unit. BET data was generated on (Auto Chem) Micro Maritics 2910 instrument. UV–Vis diffused reflectance spectra (UV–Vis DRS) was from UV–Vis Cintra 10e spectrometer.

2.4. Photocatalytic Experiments

IPU solution (0.114 mM) was freshly prepared by dissolving in double distilled water. All the phtocatalytic experiments were carried out at same concentration until unless stated. The pH of the solution was adjusted with HCl and NaOH. Prior to light experiments, dark (adsorption) experiments were carried out for better adsorption of the herbicide on the catalyst. For solar experiments, isoproturon solution of 50 mL was taken in an open glass reactor with known amount of the catalyst. The solution was illuminated under bright solar light. Distilled water was added periodically to avoid concentration changes due to evaporation. The solar experiments were carried out during 10.00 A.M. to 3.00 P.M. in May and June 2009 at Hyderabad.

2.5. Analyses

The IPU degradation was monitored by Shimadzu SPD-20A HPLC using C-18 phenomenex reverse phase column with acetonitrile/water (50/50 v/v %) as mobile phase at a flow rate of 1 mL min-1. The samples were collected at regular intervals, filtered through Millipore micro syringe filters (0.2 μm).

3. Results and Discussion

3.1. Characterization

3.1.1. XRD

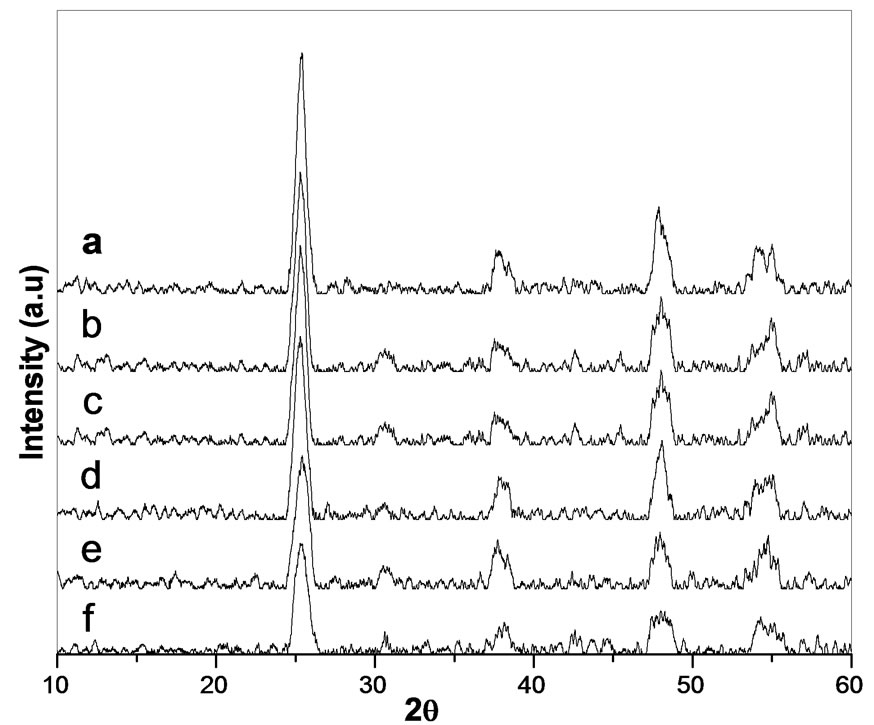

To investigate the phase structure of the prepared samples XRD was used and the results are shown in Figure 1. It can be seen that TCNS exhibits only the characteristic peaks of anatase (major peaks at 25.410, 380, 480, 550) and no rutile phase is observed. The results are in good agreement with earlier studies [21]. By applying DebyeScherrer equation, the average particle size of the TCNS catalysts is found to be about 3.8 to 5.8 nm. It can be inferred that the ratio of thiourea to titania slightly influence the crystallization of the mesoporous titania. Also the peak intensity of anatase decreases and the catalyst becomes more amorpous. It might be due to the fact that the doped nonmetals can hinder the phase transition (anatase to rutile) and restricts the crystal growth. It is noteworthy that, even the doped samples exhibit typical structure of TiO2 crystal without any detectable dopant related peaks. This may be caused by the lower concentration of the doped species, and moreover, the limited dopants may have moved into either the interstitial positions or the substitutional sites of the TiO2 crystal structure [22,23].

3.1.2. XPS

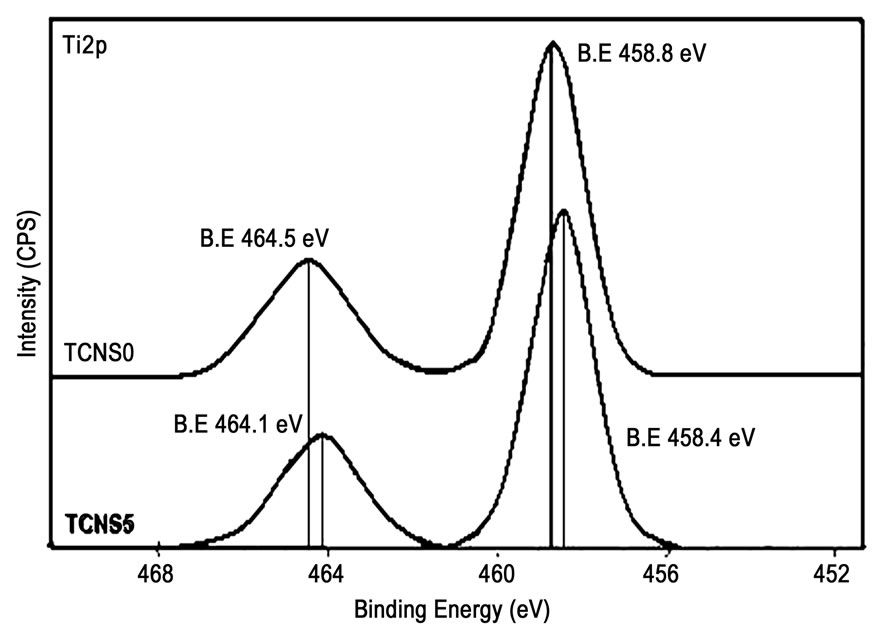

To investigate the chemical sates of the possible dopants incorporated into TiO2, Ti2p, O1s, C1s, N1s, and S2p binding energies are studied by measuring the XPS spectra. The results are shown in Figure 2.

The high resolution spectra of Ti2p3/2 and Ti2p1/2 core levels are given in the Figure 2(a). The binding energy for the Ti2p3/2 and Ti2p1/2 core level peaks for TCNS0 appeared at 458.8 and 464.5 eV respectively which are attributed to O-Ti-O linkages in TiO2. Ti2p3/2 and Ti2p1/2 core level peaks for TCNS5 are observed at 458.4 and 464.1 eV with a decrease in the binding energy value compared to TiO2 indicating that the TiO2 lattice is considerably modified due to C, N and S doping [24].

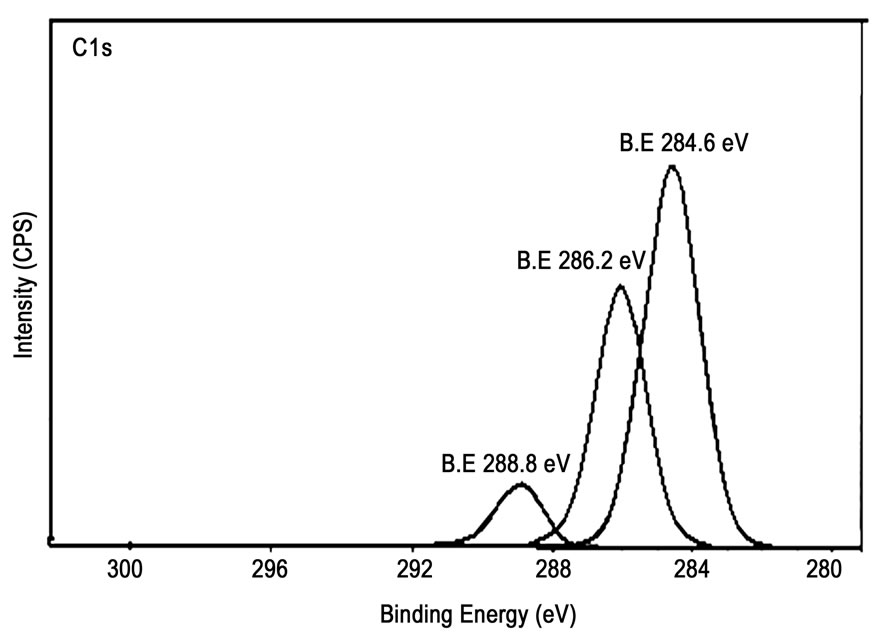

The chemical environment of carbon is investigated by the XPS of C1s core levels as shown in the Figure 2(b). Three peaks are observed for the C1s at 284.6, 286.2 and 288.8 eV. The first peak observed at 284.6 eV is assigned to elemental carbon present on the surface, which is also in agreement with the reported studies [25]. The second and third peaks at 286.2, 288.8 eV are attributed to C-O and C=O bonds respectively [21,26].

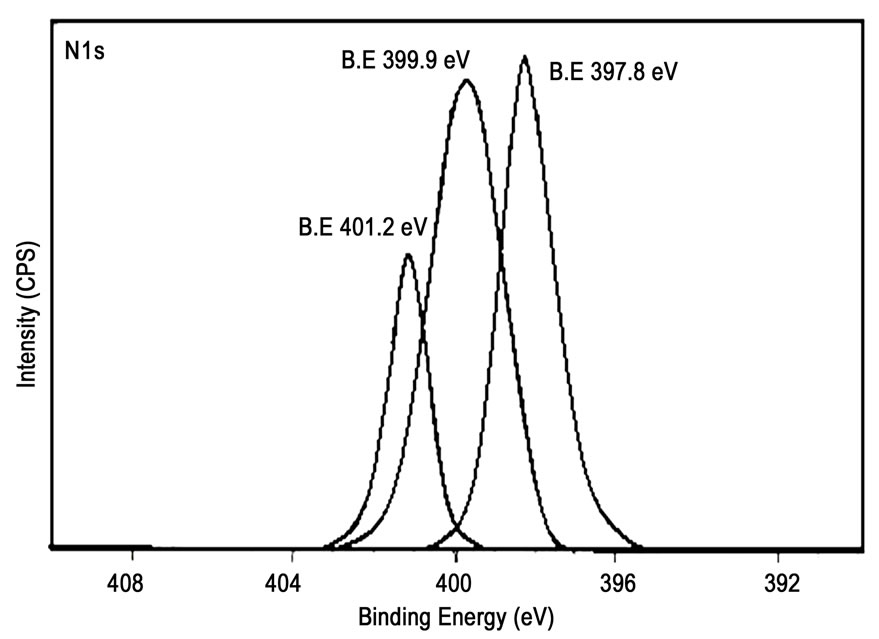

The high resolution XPS spectra of N1s core level is shown in Figure 2(c). Generally, N1s core level in N doped TiO2 shows binding energies around 369-397.5

Figure 1. XRD patterns of TCNS catalysts: (a) TCNS0, (b) TCNS1, (c) TCNS3, (d) TCNS5, (e) TCNS10, (f) TCNS15.

eV that are attributed to substitutionally doped N into the TiO2 lattice or β nitrogen [3,27]. N1s peaks, with high intensity observed at and above 400 eV are assigned to NO, N2O, NO2-, NO3-. Sakthivel et al. [28] observed an intense peak at 400.1 eV that was assigned to hyponitrile species and concluded that the higher binding energy is due to the lower valence state of N in N doped TiO2. Many researches pointed out that intense peak at 400 eV are due to oxidized nitrogen like Ti-O-N or Ti-N-O linkages. Dong et al. [26] observed three peaks of N1s at 397.8, 399.9 and 401.9 eV and has attributed to N-Ti-N, O-Ti-N and Ti-N-O linkage respectively. Recently, Gopinath observed N1s binding energy at 401.3 eV and claimed the presence of Ti-N-O linkage on the surface of N doped TiO2 nano particles [29]. Figure 2(c) shows the N1s spectra of TCNS5 catalyst and three peaks are observed at 397.8, 399.9 and 401.2 eV. Taking the literature support, here in the present investigation, the first peak at 397.8 eV is attributed to N-Ti-N linkages and the second and third peaks at 399.9 and 401.2 eV are ascribed to O-Ti-N, Ti-N-O linkages in the TiO2 lattice respectively.

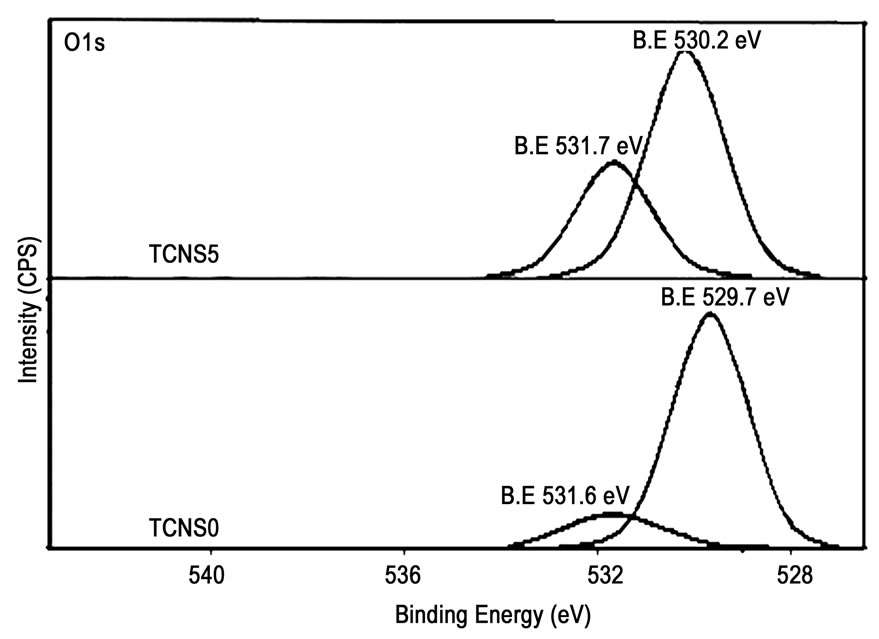

The O1s spectra of TCNS0 and TCNS5 are shown in Figure 2(d). The O1s peak for TCNS0 is observed at 529.7 and 531.6 eV. The corresponding values are 530.2 and 531.7 eV for the TCNS5 sample. The first peak is mainly attributed to the O-Ti-O linkage in the TiO2 lattice, and the second peak is closely related to the hydroxyl groups (-OH) resulting mainly from chemisorbed water. It can be seen that the content of surface hydroxyl groups is much higher in the TCNS5 sample than in the TCNS0 sample. The increase in surface hydroxyl content is advantageous for trapping more photogenerated holes and thus preventing electron–hole recombination [26].

(a)

(a) (b)

(b) (c)

(c) (d)

(d) (e)

(e)

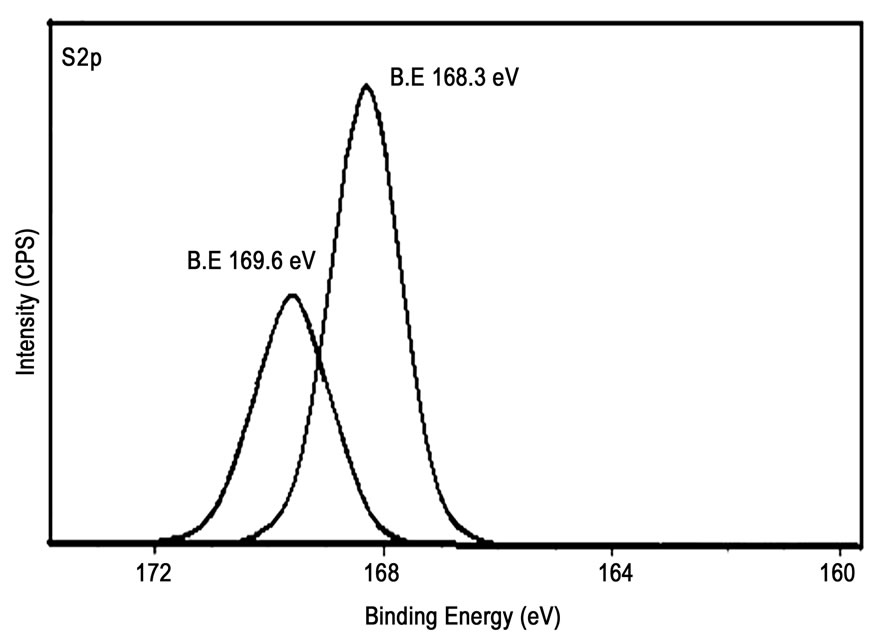

Figure 2. High resolution XPS of TCNS5 catalyst: (a)Ti2p, (b)C1s, (c)N1s, (d)O1s, (e)S2p.

S2p XPS spectra for TCNS5 are shown as Figure 2(e). The oxidation state of the S-dopant is dependent on the preparation routes and sulfur precursors. Previous studies have reported that if thiourea was used, the substitution of Ti4+ by S6+ would be more favorable than replacing O2− with S2− [4]. S2p spectra can be resolved into four peaks, S2p1/2 6+, S2p3/26+, S2p1/2 4+ and S2p3/24+. The Figure 2(e) shows two peaks at 168.3 and 169.6 eV corresponding to S2p3/2 6+, S2p1/26+ binding energies [30]. It is clear from the figure that S was doped mainly as S6+ and not S4+or S2− peaks. The sulfur doping further can be substantiated by the decrease in binding energies of the Ti2p1/2 and Ti2p3/2 of TCNS5 sample compared to the binding energies Ti2p1/2 and Ti2p3/2 of the TCNS0 sample respectively (Figure 2(a)). This may be caused due to the difference of ionization energy of Ti and S. Therefore, it could be concluded that the lattice titanium sites of TiO2 were substituted by S6+ and formed as a new band energy structure.

3.1.3. FTIR Spectra

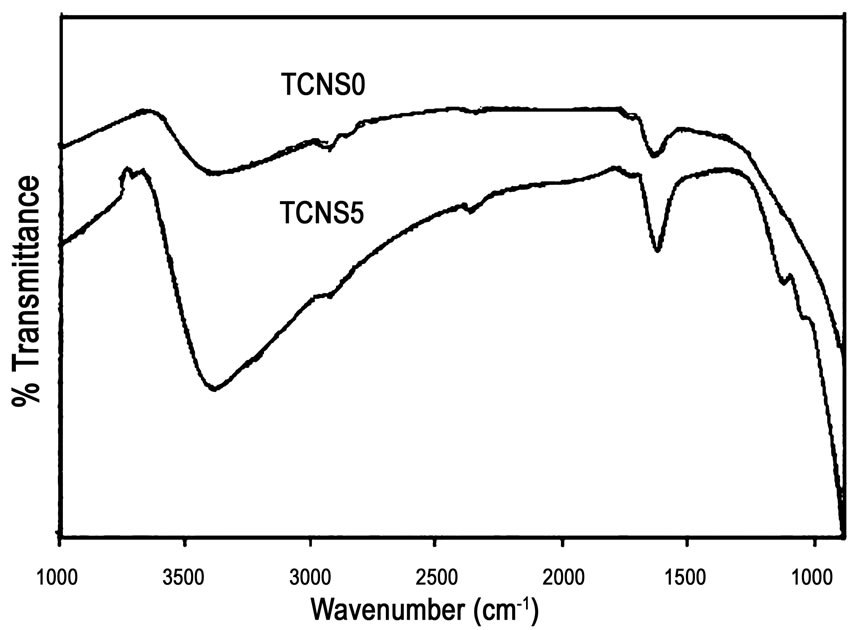

Figure 3 shows the FTIR spectra of TCNS0 and TCNS5 catalysts calcined at 400 ◦C. The absorption bands 2800–3500 cm-1, 1600–1680 cm-1 are assigned to the stretching vibration and bending vibration of the hydroxyl group respectively present on the surface of TiO2 catalyst [31,32]. The presence of surface hydroxyl groups are substantiated by XPS of O1s spectra (Figure 2(d)). The band around 1730 cm-1 is attributed to carbonyl group and bands at 1130, 1040 cm-1 are corresponding to nitrite and hyponitrite groups present in TCNS5 and they are absent in TCNS0 which shows successful doping of nitrogen into the lattice of TiO2 [33,34]. No peak corresponding to NH4+ absence (3189 and 1400 cm-1) shows that N is present only in the form of nitrite and hyponitrite species [32].

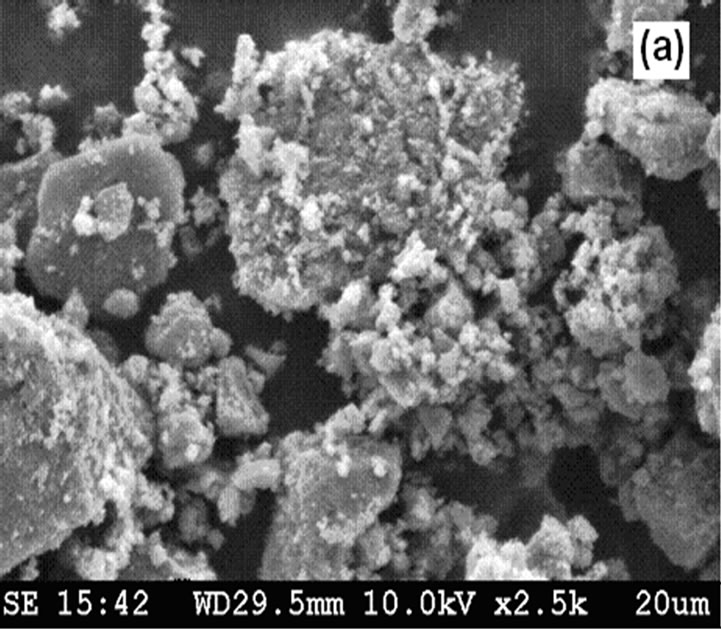

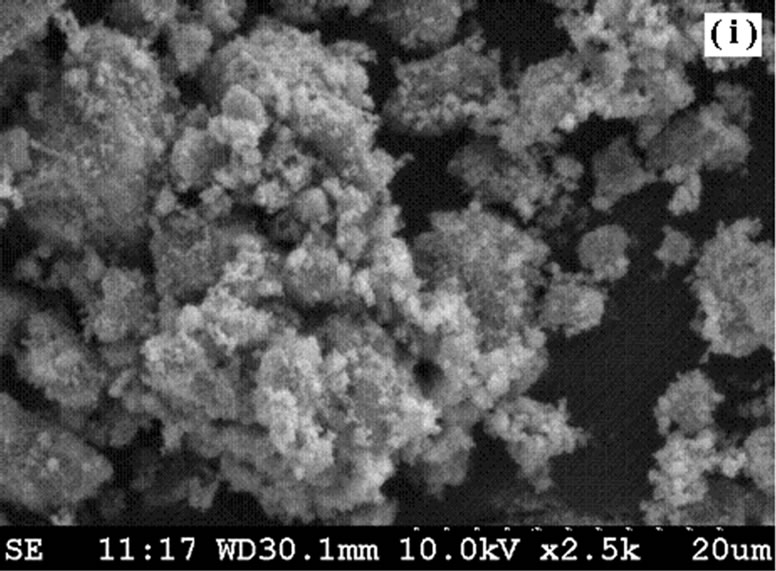

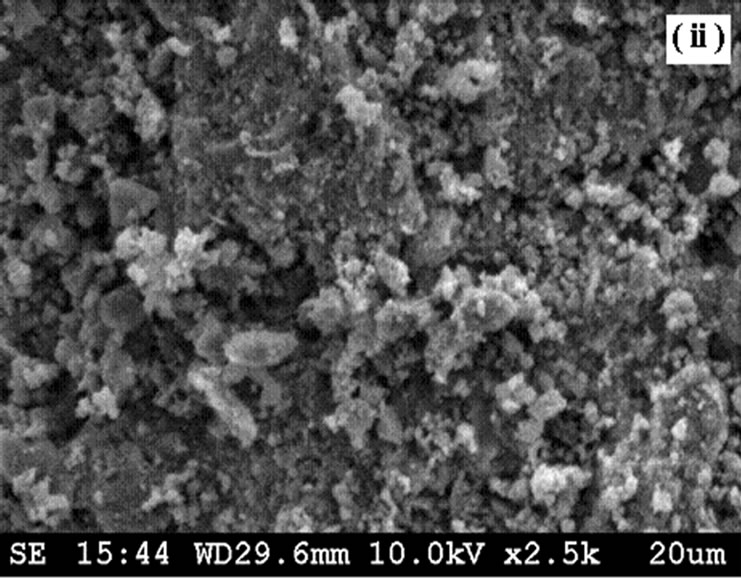

3.1.4. SEM

The surface morphology of TCNS photocatalyst is studied by scanning electron microscopy and the micrographs are presented in Figure (4). The samples appeared are agglomeration of smaller particles. From this image, we can see that the surface is rough and large number of pores found to be seen. SEM images for the undoped (TCNS0) and CNS-doped (TCNS5) shows that

Figure 3. FTIR spectra of TCNS catalysts.

Figure 4. SEM images of (a) TCNS0 and (b) TCNS5 catalysts.

the particle morphology seems to be as spherical in both the images and there is no considerable change in morphology of both. The photograph of thiourea doped TiO2 (TCNS5) sample is exhibiting well-dispersed crystals and the particle is homogeneous with the formation of fine and well dispersed particles.

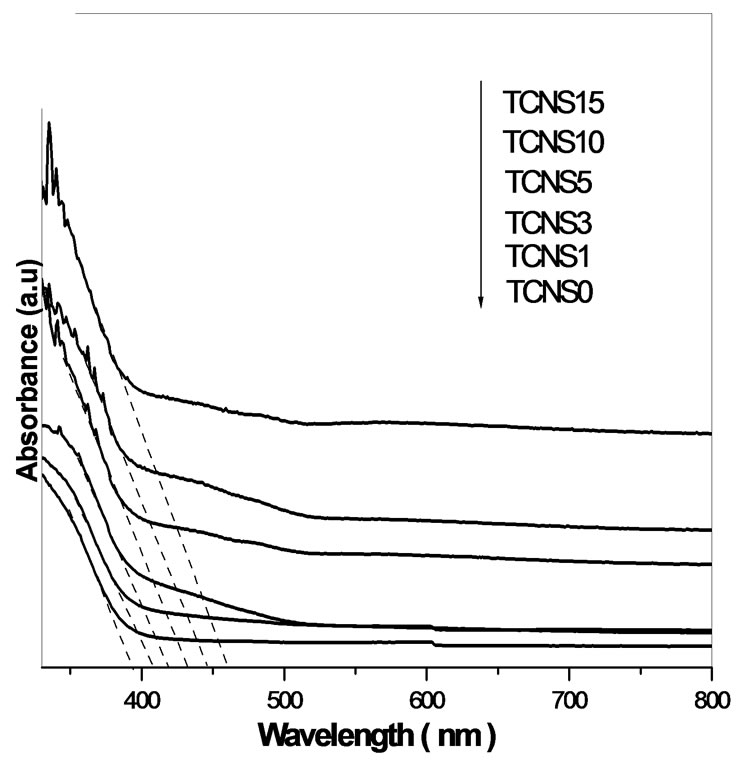

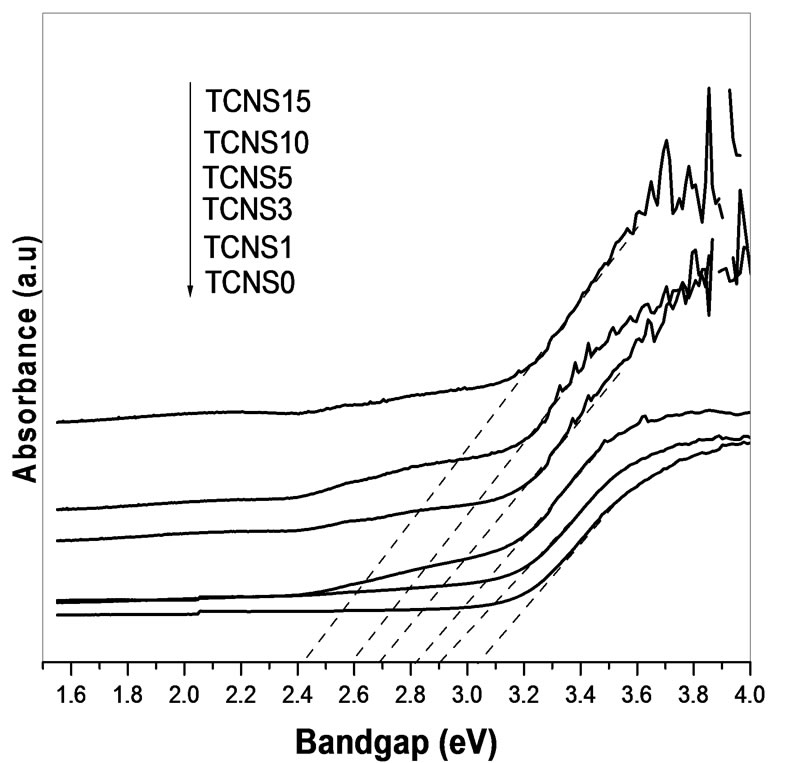

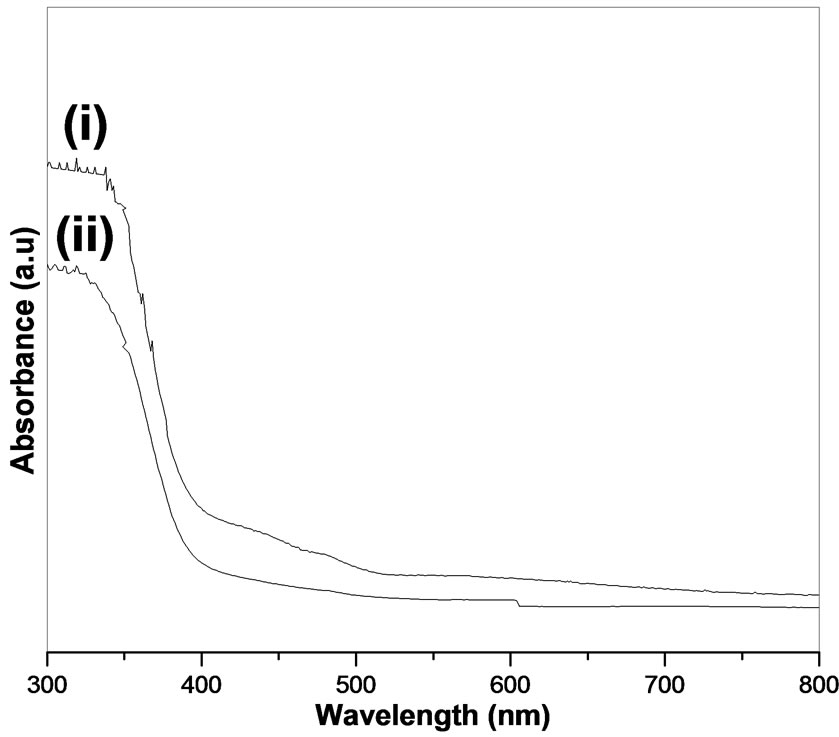

3.1.5. UV-VIS DRS

The UV-Vis diffuse reflectance spectra (DRS) of TCNS catalysts are shown in Figure 5. It is seen from Figure 5(a) that the undoped TiO2 nano catalyst (TCNS0) showed strong absorption band around 380 nm in the ultraviolet region. But, TCNS sample is showing absorbance at 400-470 nm with red shift (about 100 nm) towards visible region. This shift in the absorption edge decreases the direct band gap of TCNS catalyst compared to undoped TiO2 (TCNS0) and this may be due to the insertion of C, N and S into the TiO2 lattice [13,25,35]. Furthermore, the red shift in the DRS band increases with the increase in doped elements content into TiO2 lattice. Band gap energy (Eg value) of all the catalysts is estimated from the plot of absorbance versus photon energy (hv). The

(a)

(a) (b)

(b)

Figure 5. UV-Vis diffusion reflectance spectra of TCNS catalysts.

(a) Absorbance versus Wavelength; (b) Absorbance versus Bandgap.

absorbance is extrapolated to get the bandgap energy for the TCNS catalyst with good approximation as observed in Figure 5(b). The estimated bandgap energies of TCNS0, TCNS1, TCNS3, TCNS5, TCNS10 and TCNS15 are 3.05, 2.91, 2.82, 2.7, 2.6 and 2.41 respectively. From the DRS results, it is clear that the C, N and S doping can shift the absorption edge of TiO2 to the visible range and reduce the band gap, which is beneficial for improving the photo absorption and ultimately photo catalytic performance of TiO2.

3.1.6. BET Surface Area

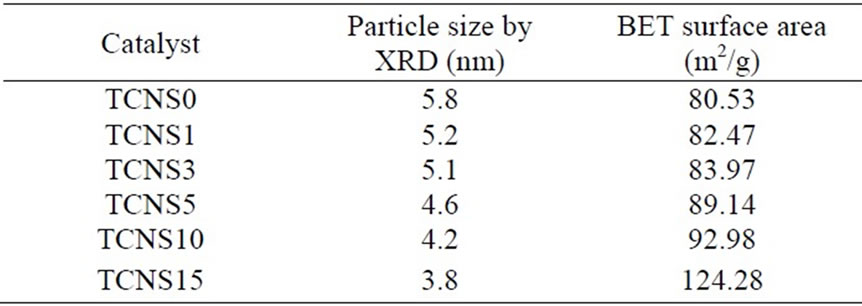

The surface area of TCNS catalysts calcined at 400 0C is shown in Table 1. The TCNS catalysts are showing high surface area. The high surface area of the prepared catalysts is due to nanosize of the particles. It is also observed that the surface area of the catalysts increases with the increase in the ratio of thiourea to TiO2. This can be attributed to decreasing of the crystallite sizes, as discussed in XRD analysis.

3.2. Photocatalytic Activity

3.2.1. Adsorption Studies

Prior to photocatalytic experiments adsorption and photolysis studies are carried out. The isoproturon solution was kept in dark without catalyst for 10 days and no degradation is observed. Fifty milligrams of the catalyst in 50 mL of isoproturon (1.14×10−4 M) solution is allowed under stirring in dark. Aliquots were withdrawn at regular intervals and the change in isoproturon concentration is monitored by HPLC. Maximum adsorption is reached within 30 min for all the catalysts prepared. This illustrates the establishment of adsorption equilibrium as 30 min and is chosen as the optimum equilibrium time for all the future experiments. The photolysis (without catalyst) experiment is carried out under the solar light taking 50 mL of isoproturon solution in glass reactor and only 2–4 % of degradation is observed after 10 h of solar irradiation.

3.2.2. Determination of Thiourea Loading over TiO2

To compare the phtotcatalytic activity of the as-prepared samples, phtocatalytic degradation of isoproturon under solar light irradiation is performed. All the studies are carried out at 1 g L−1 catalyst amount in 1.14×10−4 M isoproturon solution. The photocatalytic activity of TCNS catalysts under solar light irradiation is shown in Figure 6. Among all the catalysts prepared, TCNS5 is showing better phtocatalytic activity and complete degradation. The visible light activity of the samples has increased gradually with the increasing amount of dopent and it reaches optimum at 5 wt % loading (TCNS5) and further increase results an activity decrease gradually.

Table 1. BET surface area and particle size of the TCNS catalysts.

Figure 6. Photocatalytic activity of C, N and S doped TiO2 for the degradation of isoproturon aqueous solution (1.14 ×10-4 M) under solar-light irradiation.

The different samples photo catalytic activity can be attributed to the following factors. It is known that the doping of C, N and S elements in titania brings visible light absorption photocatalytic activity of titania. It can be seen from the DRS spectra that C, N, and S doping resulted in an intense increase in absorption in the visible light region and a red shift in the absorption edge of the titania (Figure 5(a)). The band-gap narrowing of titania by C, N, S doping lead to enhanced photocatalytic activity of the titania under visible light. Because the prepared doped samples can be activated by visible light, thus more electrons and holes can be generated and participate in the photocatalytic redox reactions [21]. All together, the C, N, and S doped samples show much higher photocatalytic activity than undoped tiantia. But we can also see that at higher loadings photocatalytic activity of TCNS samples has decreased though they show more red shift in the absorption edge. It might be due to the fact that, the excess dopent acts as recombination centers which facilitates electron-hole recombination thus lowering the activity. So, the photocatalytic activity is depressed to a certain extent. To conclude, the higher activity of the TCNS5 sample can be ascribed to the high surface area, strong adsorption in visible region and lower recombination of electron-hole pair due to high concentration of surface hydroxyl groups (Figure 2(d)) which can trap the photo generated holes and thus decreasing the electron hole recombination process [26].

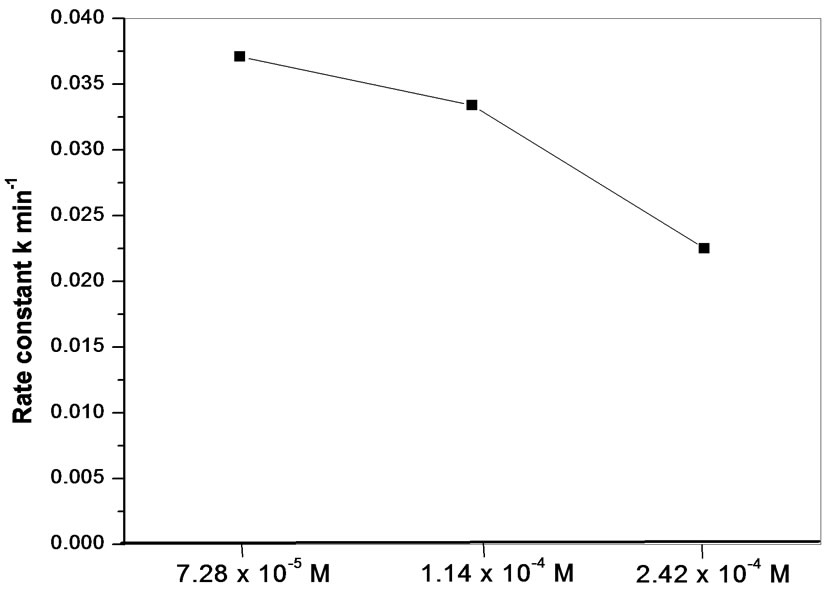

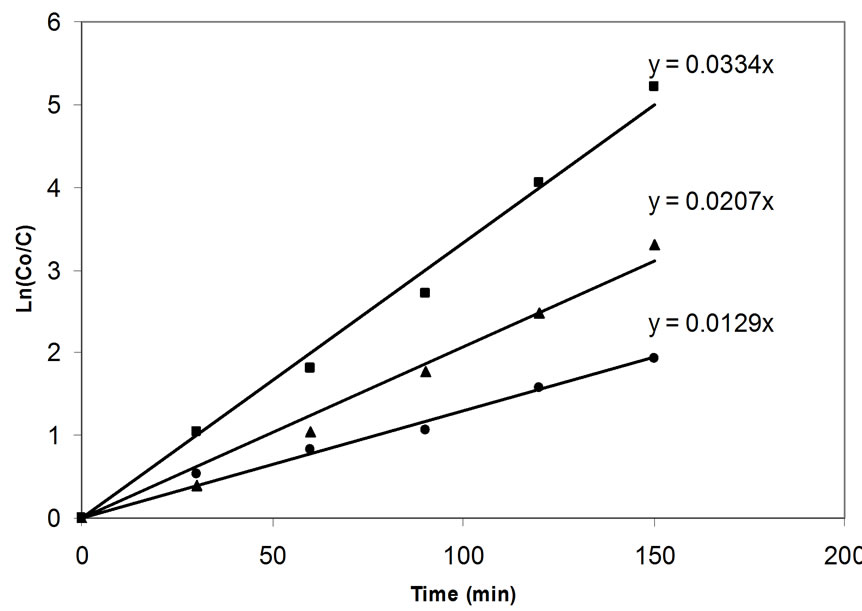

3.2.3. Effect of Substrate Concentration

The effect of substrate concentration is an important parameter for photocatalytic degradation activity over known catalyst amount. The 7.28×10−5, 1.14×10−4 and 2.42×10−4 M concentrations of isoproturon are studied over TCNS5 catalyst with 1.0 g L−1 catalyst amount. It is seen from Figure 7 a slight difference in degradation rate over titania supported catalyst for 7.28×10−5, 1.14×10−4 M concentrations are observed compared to 2.42×10−4 M. This indicates, at higher concentrations OH radicals produced by the catalyst are not sufficient to degrade the pollutant molecules which are adsorbed or near to the catalyst surface. Hence, 1.14 × 10−4 M solutions is chosen for the degradation as there is an equilibrium between adsorption of reactant molecules and the gene- ration of OH radicals from the active sites.

3.2.4. Effect of Catalyst Amount

The catalyst amounts 0.5, 1.0 and 2.0 g L−1 of TCNS5 are investigated for effective isoproturon degradation (Figure 8). It is observed that, increasing amounts 0.5–1.0 g L−1, the photocatalytic activity has increased and at the higher amounts the activity trend is not encouraging. This is due to the higher amounts of the catalyst makes the solution turbid which obstructs the light path into the solution and inturn reducing the formation of OH radicals. In the present study, 1.0 g L−1 is found to be the optimum catalyst amount for efficient degradation of isoproturon.

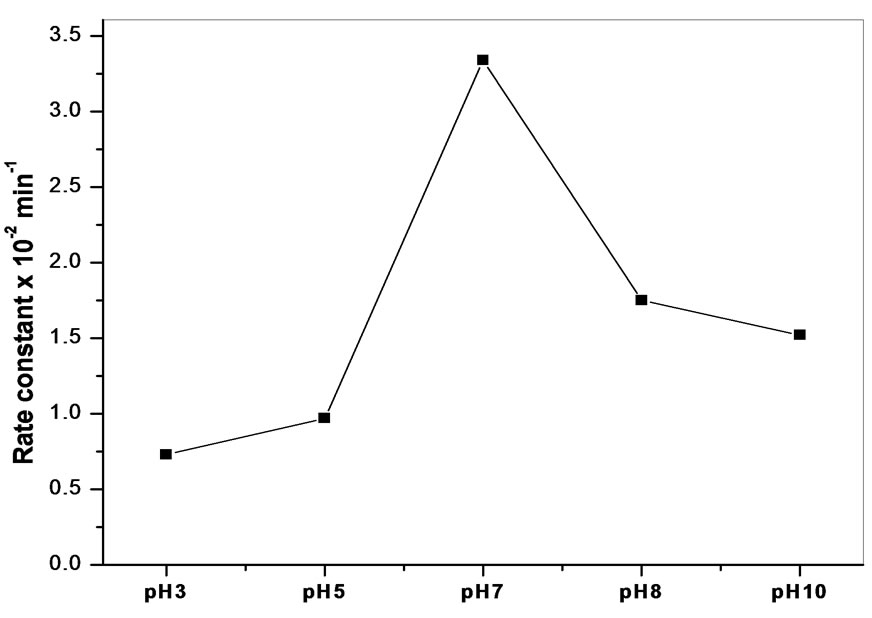

3.2.5. Effect of pH

The effect of pH is an important parameter because it commands the surface charge properties of the catalyst and therefore the adsorption of the pollutant. The pH studies at 3–10 are carried over TCNS5 catalyst using 1.0 g L−1 of 1.14×10−4 M isoproturon solution. The adsorption capacity of the catalyst in different pH ranges is not much affected due to the non-ionic nature of isoproturon. The results depicted in Figure 9 are showing that at neutral pH, the rate of degradation is faster compared to acidic or basic medium [36]. This may be due to the non-ionic nature of isoproturon. In basic medium, there is a slight increase in degradation rate and is observed when compared to the acidic medium. This may be because, the OH radicals are mainly attacking methyl groups

Figure 7. Effect of initial concentration on the rate of solar photocatalytic degradation of isoproturon over TCNS5.

Figure 8. Effect of catalyst amount on photocatalytic degradation of isoproturon over TCNS5 catalyst under solar light irradiation: 0.5 g L-1 (●), 1g L-1(■) and 2 g L-1 (▲).

Figure 9. Effect of pH on solar photocatalytic isoproturon degradation over TCNS5. (Experimental conditions: C0 =1.14×10−4 M; catalyst amount = 1.0 g L−1.)

(a)

(a) (b)

(b)

(c)

(c)

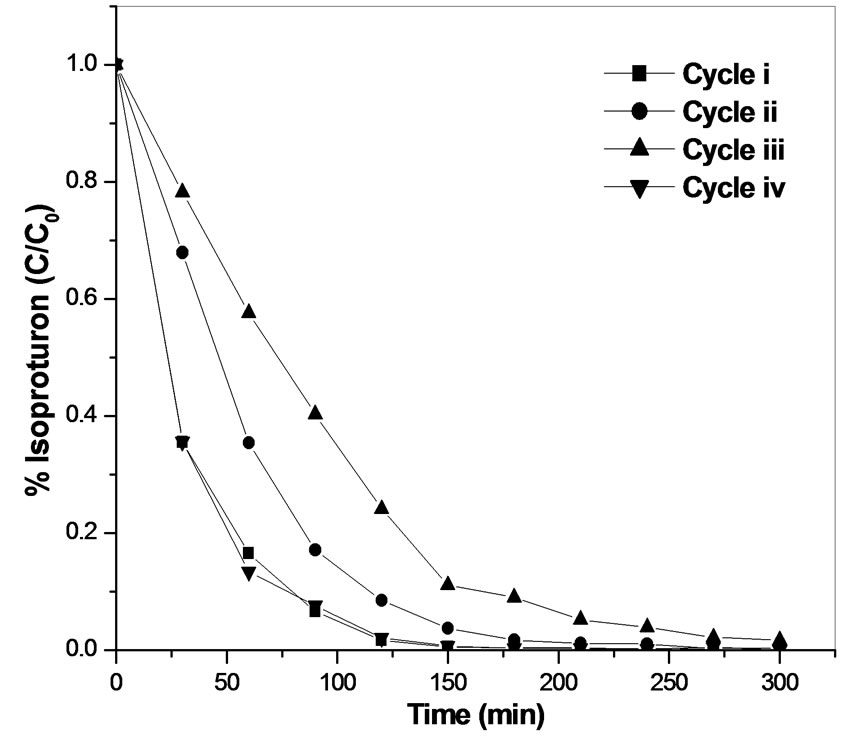

Figure 10. Isoproturon degradation over TCNS5 catalyst. (a) Recycling activity studies. (Experimental conditions: C0 =1.14×10−4 M; pH 7; catalyst amount = 1.0 g L−1.) Characterization of 1) Fresh and 2) Used (after 4th cycle) catalysts (b) UV–Vis DRS spectra and (c) SEM photographs.

and the hydroxylation of aromatic ring is clearly unfavored with decrease in pH, whereas in basic medium the hydroxylation of aromatic ring is favored but not the methyl groups. In neutral medium, the OH radicals attack both on the aromatic ring and on the methyl groups. This cumulative effect results a maximum degradation rate of the pollutant [20].

3.2.6. Catalyst Recycling Studies

To evaluate stability/activity of the catalyst for photocatalytic degradation, the recycling studies are conducted over TCNS5 using 1.0 g L−1 catalyst and the results are provided in Figure 10(a). After completion of the 1st cycle, the catalyst is recovered, dried and is reused as such (without any calcination) for the 2nd cycle, a slight decrease in the rate of degradation is observed compared to the first cycle. When same catalyst is reused without calcination for the third cycle, there is a slight decrease in degradation rate observed compared to first and second cycle. The differences in rates are due to the accumulated organic intermediates on the surface of the catalyst, affecting the adsorption in turn reducing the activity. This is confirmed by calcining the 3rd cycle used sample at 400 0C for 3 h and reused for the 4th cycle activity. The original activity of the catalyst for degradation is restored. This indicates that calcination of the used catalyst is necessary in order to regain the activity. Furthermore, this is substantiated by comparison of the surface characterization studies like SEM and UV–Vis DRS techniques on the fresh and 4th cycle used samples Figures 10(b)-10(c). The band gap as well as wavelength excitations are not having any changes in the UV–Vis DRS spectra of the fresh and used catalysts. From SEM photographs, it is clear that the surface morphology is not changed much and it indicates that catalyst is intact even after the 4th cycle. Thus, the above studies prove that the catalyst is reusable for number of cycles without any loss in activity and stable for longer life.

4. Conclusions

The present study demonstrates preparation of a C, N, and S doped TiO2 photocatalyst and its role in photocatalytic pesticide degradation. The results conclude that 5 wt% thiourea doped TiO2 (TCNS5) is an efficient catalyst for the photocatalytic degradation of isoproturon. The higher activity of TCNS5 catalyst may be due to the high surface area, lower electron-hole recombination and the stronger adsorption in visible light region. The substrate concentration of 1.14 × 10−4 M, catalyst amounts 1 g L−1 and neutral pH are found to be favorable for higher degradation rates of isoproturon. The catalyst activity is found to be sustainable even after the 4th cycle (as evidenced by SEM and UV–Vis DRS techniques).

5. Acknowledgements

The authors PAKR, MS thank CSIR, New Delhi for funding this work under Emeritus Scientist Scheme.

REFERENCES

- A. Fujishima, K. Hashimoto, and T. Watanabe, “TiO2 photocatalysis: Fundamentals and applications,” BKC, Tokyo, 1999.

- L. Q. Wu, N. Xu, and J. Shi, “Leak growth mechanism in composite Pd membranes,” Industrial & Engineering Chemistry Research, Vol. 39, pp. 342–348, 2000.

- R. Asahi, T. Morikawa, T. Ohwaki, K. Aoki, and Y. Taga, “Visible-light photocatalysis in Nitrogen-Doped titanium oxides,” Science, Vol. 293, pp. 269–71, July 2001.

- T. Ohnoa, M. Akiyoshi, T. Umebayashi, K. Asai, T. Mitsui, and M. Matsumura, “Preparation of S-doped TiO2 photocatalysts and their photocatalytic activities under visible light,” Applied Catalysis A: General, Vol. 265, pp. 115–121, February 2004.

- X. Chen and S. S. Mao, “Titanium dioxide nano-materials: Synthesis, properties, modifications, and applications,” Chemical Review, Vol. 107, pp. 2891–2959, 2007.

- H. Irie, Y. Watanabe, and K. Hashimoto, “Carbon-doped anatase TiO2 powders as a visible-light sensitive photocatalyst,” Chemistry Letters, Vol. 32, pp. 772–773, May 2003.

- W. Ho, J. C. Yu, and S. Lee, “Synthesis of hierarchical nanoporous F-doped TiO2 spheres with visible light photocatalytic activity,” Chemical Communications, pp. 1115–1117, January 2006.

- L. Lin, W. Lin, Y. Zhu, B. Zhao, and Y. Xie, “Phosphordoped titania —A novel photocatalyst active in visible light,” Chemistry Letters, Vol. 34, pp. 284–285, November 2004.

- T. Ohno, T. Mitsui, and M. Matsumura, “Photocatalytic activity of S-doped TiO2 photocatalyst under visible light,” Chemistry Letters, Vol. 32, pp. 364–365, January 2003.

- H. Irie, Y. Watanabe, and K. Hashimoto, “Nitrogenconcentration dependence on photocatalytic activity of TiO2-xNx powders,” Journal of Physical Chemistry B, Vol. 107, pp. 5483–5486, January 2003.

- J. G. Yu, M. H. Zou, B. Cheng, and X. J. Zhao, “Preparation, characterization and photocatalytic activity of in situ N, S-codoped TiO2 powders,” Journal of Molecular Catalysis A: Chemical, Vol. 246, pp. 176–184, December 2005.

- Y. Q. Wang, X. J. Yu, and D. Z. Sun, “Synthesis, characterization, and photocatalytic activity of TiO2−xNx nanocatalysts,” Journal of Hazardous Materials, Vol. 144, pp. 328–333, October 2006.

- J. L. Gole and J. D. Stout, C. Burda, Y. Lou, and X. Chen, “Highly efficient formation of visible light tunable TiO2-xNx photocatalysts and their transformation at the nanoscale,” Journal of Physical Chemistry B, Vol. 108, pp. 1230–1240, September 2003.

- C. Burda, Y. Lou, X. Chen, A. C. S. Samia, J. Stout, and J. L. Gole, “Enhanced nitrogen doping in TiO2 nanoparticles,” Nano Letters, Vol. 3, pp. 1049–1051, June 2003.

- B. Chi, L. Zhao, and T. Jin, “One-step template-free route for synthesis of mesoporous N-doped titania spheres,” Journal of Physical Chemistry C, Vol. 111, pp. 6189– 6193, February 2007.

- X. W. Bao, S. S. Yan, F. Chen, and J. L. Zhang, “Preparation of TiO2 photocatalyst by hydrothermal method from aqueous peroxotitanium acid gel,” Material Letters, Vol. 59, pp. 412–415, October 2004.

- T. Morikawa, R. Asahi, T. Ohwaki, K. Aoki, and Y. Taga, “Band-gap narrowing of titanium dioxide by nitrogen doping,” Japan Journal of Applied Physics, Vol. 40, pp. 561–563, April 2001.

- M. V. Phanikrishna Sharma, V. Durgakumari, and M. Subrahmanyam, “Solar photocatalytic degradation of isoproturon over TiO2/H-MOR composite systems,” Journal of Hazardous Materials, Vol. 160, pp. 568–575, March 2008.

- M. V. Phanikrishna Sharma, V. Durga Kumari, and M. Subrahmanyam, “Photocatalytic degradation of isoproturon herbicide over TiO2/Al-MCM-41 composite systems using solar light,” Chemosphere, Vol. 72, pp. 644– 651, April 2008.

- M. V. Phanikrishna Sharma, G. Sadanandam, A. Ratnamala, V. Durga Kumari, and M. Subrahmanyam, “An efficient and novel porous nanosilica supported TiO2 photocatalyst for pesticide degradation using solar light,” Journal of Hazardous Materials, Vol. 171, pp. 626–633, June 2009.

- Y. Ao, J. Xu, D. Fu, and C. Yuan, “Synthesis of C,N,Stridoped mesoporous titania with enhanced visible lightinduced photocatalytic activity,” Microporous and Mesoporous Materials, Vol. 122, pp. 1–6, November 2008.

- S. I. Shah, W. Li, C. P. Huang, O. Jung, and C. Ni, “Study of Nd3+, Pd2+, Pt4+, and Fe3+ dopant effect on photo reactivity of TiO2 nanoparticles,” Proceedings of the National Academy of Sciences, Vol. 99, pp. 6482– 6486, January 2002.

- J. Sun, L. Qiao, S. Sun, and G. Wang, “Photocatalytic degradation of orange G on nitrogen-doped TiO2 catalysts under visible light and sunlight irradiation,” Journal of Hazardous Materials, Vol. 155, pp. 312–319, November 2007.

- F. Peng, L. Cai, H. Yu, H. Wang, and J. Yang, “Synthesis and characterization of substitutional and interstitial nitrogen-doped titanium dioxides with visible light photocatalytic activity,” Journal of Solid State Chemistry, Vol. 181, pp. 130–136, November 2007.

- Y. Park, W. Kim, H. Park, T. Tachikawa, T. Majima, and W. Choi, “Carbon-doped TiO2 photocatalyst synthesized without using an external carbon precursor and the visible light activity,” Applied Catalysis B, Vol. 91, pp. 355–361, June 2009.

- F. Dong, W. Zhao, and Z. Wu, “Characterization and photocatalytic activities of C, N and S co-doped TiO2 with 1D nanostructure prepared by the nano-confinement effect,” Nanotechnology, Vol. 19, pp. 365–607, July 2008.

- I. C. Kang, Q. Zhang, S. Yin, T. Sato, and F. Saito, “Novel method for preparation of high visible active N-doped TiO2 photocatalyst with its grinding in solvent,” Applied Catalysis B, Vol. 84, pp. 570–576, May 2008.

- S. Sakthivel and H. Kisch, “Daylight photocatalysis by carbon-modified titanium dioxide,” Angewandte Chemie International Edition, Vol. 42, pp. 4908–4911, 2003.

- C. Gopinath, “Comment on photoelectron spectroscopic investigation of nitrogen-doped titania nanoparticles,” Journal of Physical Chemistry B, Vol. 110, pp. 7079– 7080, January 2006.

- S. Liu and X. Chen, “A visible light response TiO2 photocatalyst realized by cationic S-doping and its application for phenol degradation,” Journal of Hazardous Materials, Vol. 152, pp. 48–55, June 2007.

- J. Geng, D. Yang, J. Zhu, D. Chen, and Z. Jiang, “Nitrogen-doped TiO2 nanotubes with enhanced photocatalytic activity synthesized by a facile wet chemistry method,” Material Research Bulletin, Vol. 44, pp. 146– 150, March 2008.

- Y. Li, C. Xie, S. Peng, G. Lub, and S. Li, “Eosin Y-sensitized nitrogen-doped TiO2 for efficient visible light photocatalytic hydrogen evolution,” Journal of Molecular Catalysis A: Chemical, Vol. 282, pp. 117–123, December 2007.

- S. Sakthivel, M. Janczarek, and H. Kisch, “Visible light activity and photoelectrochemical properties of nitrogen-doped TiO2,” Journal of Physical Chemistry B, Vol. 108, pp. 19384–19387, September 2004.

- Y. Yokosuka, K. Oki, H. Nishikiori, Y. Tatsumi, N. Tanaka, and T. Fujii, “Photocatalytic degradation of trichloroethylene using N-doped TiO2 prepared by a simple sol–gel process,” Research on Chemical Intermediates, Vol. 35, pp. 43–53, January 2009.

- J. A. Rengifo-Herrera, K. Pierzchała, A. Sienkiewicz, L. Forro, J. Kiwi, and C. Pulgarin, “Abatement of organics and escherichia coli by N, S co-doped TiO2 under UV and visible light. Implications of the formation of singlet oxygen (1O2) under visible light,” Applied Catalysis B, Vol. 88, pp. 398–406, November 2008.

- H. S. Lee, T. Hura, S. Kimb, J. H. Kima, and H. I. Lee, “Effects of pH and surface modification of TiO2 with SiOx on the photocatalytic degradation of a pyrimidine derivative,” Catalysis Today, Vol. 84, pp. 173–180, July 2003.