Paper Menu >>

Journal Menu >>

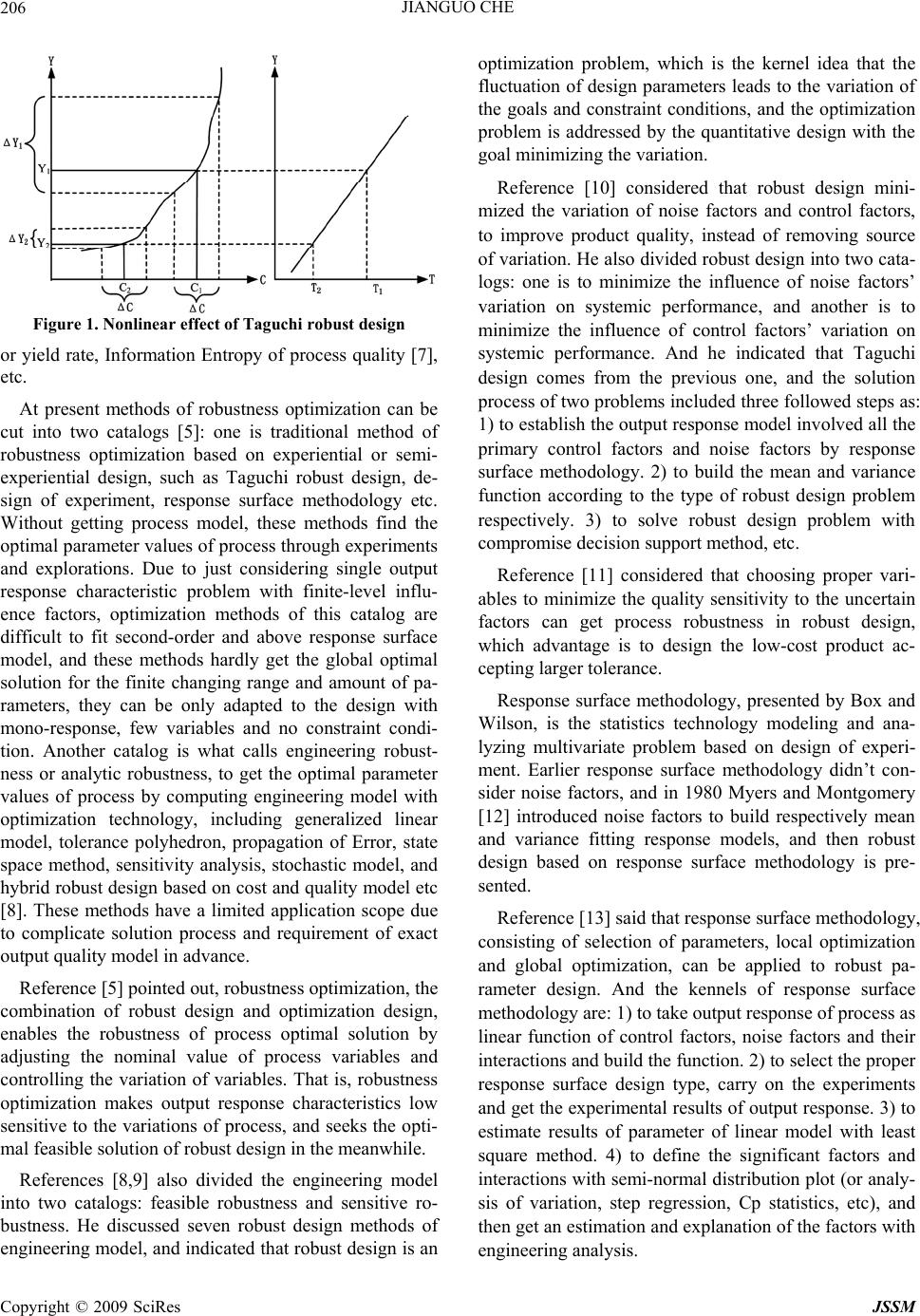

J. Service Scie nce & Management, 2009, 3: 204-208 doi:10.4236/jssm.2009.23024 Published Online September 2009 (www.SciRP.org/journal/jssm) Copyright © 2009 SciRes JSSM A Primary Robustness Optimization Strategy of Multi-Item and Low-Volume Process* Jianguo CHE Department of Industry Engineering, Nankai University, Tianjin, China. Email: cjg7705@yahoo.com.cn Received February 8th, 2009; revised April 12th, 2009; accepted June 15th, 2009. ABSTRACT Multi-item and low-volume process is a production system with multi-input sour ce, interactio ns between inp ut va riab les, and frequently changes of system state, etc. Strong interactions between input variables and time-varying of input vari- ables cause poor robustness and large variation range of output quality, which produces high cost, heavy waste and low efficiency of multi-item and low-volume process. Robustness optimization o f multi-item and low-volume process is a new, important and need-to-deep research field with multi-item and low-volume production system prevails. It proposed a strategy enhancing robustness of multi-item and low-volume process by Taguchi robust design. Firstly, build and analyze a fitting output response model of multi-item and low-volume process after taking the ad justable variables (o r time-varying variables) correspond ing to each item and interaction between inpu t variables into fitting output response model of multi-item and low-volume process as input variables uniformly, and treating the parameter value of time-varying variables corresponding to each item as level value of the adjustable variables (or signal factors) of proc- ess. Secondly, present robustness evaluation index based on evidential theory, desirability function and dual response surface etc. Finally, choose the proper experiment type and optimize the process. And then the robustness op timization of multi-item and low-volume process can be reached. Keywords: multi-item and low-volume process, robustness optimization, robust design, time-varying, interaction 1. Question Presenting The mass production system cannot meet customer’s demand on product’s quality, item, price and delivery time for rigescent, low-efficient and laggard resource allocation system. Multi-item and low-volume produc- tion system becomes popular with the increasing cus- tomer’s diversified, individual demand. In multi-item and low-volume process (MILV proc- ess), there exist followed questions as: 1) There are various production items, materials and complicated process routes in MILV process, and the process is affected by man, machine, material, method of operation, measurement, environment and other influ- ence factors (5M1E factors), which bring quality fluctua- tion of process output, so multi-variation of MILV proc- ess is a key problem. 2) Usually for MILV process, the parameter values of input variables(or factors) have to be renewed (such as replacing material, adjusting the level values of process variables, etc.) with one item being shifted, which brought time-varying of MILV process (here we called the adjustable influence factors time-varying variables). Normally, even if MILV process is in control, due to low volume of each item and frequent change of produc- tion boundary and system state, the production process can have been completed while the process didn’t get stabilization, which leads to unstable output quality. So time-varying is the second key problem of MILV proc- ess. 3) The process is affected by the 5M1E factors, and there exist interactions between the factors. When one item has been shifted to another, the interaction will change with this process state alters, which brings output quality of next item unsteady and hard-to-control, and increases source and range of variation. So interaction between input variables of MILV process is third key problem. *This paper is financially funded by the Social Science Program o f Tianjin (TJJJ06-010), Doctoral Fund of Ministry of Education of China (200800551012) and National Natural Science Foundation of China (No.70871087).  JIANGUO CHE 205 From the view of system, MILV process is a typical production system with multi-input source, multi-stage, multi-response, time-varying, and strong interaction be- tween input source variables of the process. Multi-varia- tion, time-varying and strong interaction bring badly robustness of the process, and increases variation of the process and cost of poor quality of the firm. Since the premise of monitoring the process with the Shewhart control chart is steady-state stochastic process, sufficient process capability, adequate and independent identically distributed process data, and if MILV process cannot meet these conditions, to monitor MILV process with control chart will lead to heavy false alarms and missing alarms, and greatly cut down the average run length of in-control process. To some extent, MILV process cannot reach indeed in-control state, and due to quality control is a non-value added activity and pas- sively adaptive quality policy. Simple quality control of MILV process is not only difficult but less significant. Robustness optimization is a systemic method to en- hance output quality of MILV process, which can sys- temically prevent and reduce out-of-control and output quality fluctuation of process. Robustness optimization of MILV process is more complicated and significant than that of mass production process. Now MILV process is mostly applied to vehicle, machine and electronic industries and so on. Study on robustness optimization of MILV process can not only improve output efficiency and quality of process and reduce waste and production cost of the firm, but have an important theoretical significance and application value. 2. Literature Reviews The principle of robustness optimization is early pre- sented by the Japan scholar Dr. Genichi Taguchi, and it is widely recognized and employed for its advantage improving product quality [1]. Taguchi parameter design better enables a product or process to perform consistently as intend over a wide range of operating conditions. The primary principle of Taguchi parameter design with dynamic output charac- teristics is to find an optimal level combination of control factors (i.e. controllable influence factors of process) which makes the output response of the production process insensitive to variation of noise factors and sen- sitive to variation of signal factors (i.e. variation of the adjustable influence factors or time-varying input vari- ables of the process). Systematic changing of the combi- nation and levels of control factors, consistent with the nonlinear relationships between those control factors and output response and the linear relationships between the signal factors and output response, leads to more robust designs [1,2]. A graphical presentation of the concept is shown in the Figure 1. The output response has a nonlinear relation- ship with control factor C, and a linear relationship with control factor T . The target value of the output response Y (i.e. critical to quality) of the process when factor C is located at level 1 C and signal factor is given to a certain value is labeled Y1. At this point, a small fluctuation C around 1 C would cause a relatively large oscillation 1 Y of , which makes output quality of the process highly unstable. When control factor C has a value of C2, the output response value is shown as Y2. A control factor fluctuation of the same magnitude (i.e. ΔC) produces a less-pronounced oscillation of Y, shown as ΔY2. The goal of Taguchi parameter design with robustness (also called Taguchi robust design) is to find a level combination of influence factors with the strongest anti-interference ability through design of experiment and analysis of data, which will minimize fluctuation of the output response , and then to adjust value of the output response Y Y2 Y to the original target output by changing the level of the linear influence factor 1 Y T (also called signal factor or time-varying input variables of the process) from 2 T to . 1 T For the study of robustness optimization, the meas- urement of process robustness is an important issue, and signal to noise ratio (SN ratio) is early introduced by Dr. Taguchi to define the robustness of production system. Many criticisms are got to SN ratio for lack of mathe- matical logic fundamental, and Reference [2] pointed out that SN ratio was low efficient for losing more than sev- enty percent data of process. In 1987, Leon, Shoemaker and Kacker introduced Performance Measure Independ- ent of Adjustment (PerMIA) by studying SN ratio, and proved SN ratio was a PerMIA [3]. Reference [4] found that most criticisms on Taguchi method were focused on use of SN ratio by examining the viewpoints in the field of robust design. Since SN ratio didn’t tell from control factors’ influence on mean and variance, other people also tried to build and analyze the models of criti- cal-to-quality’s mean and variance respectively. And many people presented many indexes measuring the ro- bustness of process respectively [5], such as extension of SN ratio, standard deviation or variance of output re- sponse characteristics, vibration range of output response characteristics or the ratio of vibration range to expecta- tion of output response characteristics [6], rejection rate Copyright © 2009 SciRes JSSM  JIANGUO CHE 206 Figure 1. Nonlinear effect of Taguchi robust design or yield rate, Information Entropy of process quality [7], etc. At present methods of robustness optimization can be cut into two catalogs [5]: one is traditional method of robustness optimization based on experiential or semi- experiential design, such as Taguchi robust design, de- sign of experiment, response surface methodology etc. Without getting process model, these methods find the optimal parameter values of process through experiments and explorations. Due to just considering single output response characteristic problem with finite-level influ- ence factors, optimization methods of this catalog are difficult to fit second-order and above response surface model, and these methods hardly get the global optimal solution for the finite changing range and amount of pa- rameters, they can be only adapted to the design with mono-response, few variables and no constraint condi- tion. Another catalog is what calls engineering robust- ness or analytic robustness, to get the optimal parameter values of process by computing engineering model with optimization technology, including generalized linear model, tolerance polyhedron, propagation of Error, state space method, sensitivity analysis, stochastic model, and hybrid robust design based on cost and quality model etc [8]. These methods have a limited application scope due to complicate solution process and requirement of exact output quality model in advance. Reference [5] pointed out, robustness optimization, the combination of robust design and optimization design, enables the robustness of process optimal solution by adjusting the nominal value of process variables and controlling the variation of variables. That is, robustness optimization makes output response characteristics low sensitive to the variations of process, and seeks the opti- mal feasible solution of robust design in the meanwhile. References [8,9] also divided the engineering model into two catalogs: feasible robustness and sensitive ro- bustness. He discussed seven robust design methods of engineering model, and indicated that robust design is an optimization problem, which is the kernel idea that the fluctuation of design parameters leads to the variation of the goals and constraint conditions, and the optimization problem is addressed by the quantitative design with the goal minimizing the variation. Reference [10] considered that robust design mini- mized the variation of noise factors and control factors, to improve product quality, instead of removing source of variation. He also divided robust design into two cata- logs: one is to minimize the influence of noise factors’ variation on systemic performance, and another is to minimize the influence of control factors’ variation on systemic performance. And he indicated that Taguchi design comes from the previous one, and the solution process of two problems included three followed steps as: 1) to establish the output response model involved all the primary control factors and noise factors by response surface methodology. 2) to build the mean and variance function according to the type of robust design problem respectively. 3) to solve robust design problem with compromise decision support method, etc. Reference [11] considered that choosing proper vari- ables to minimize the quality sensitivity to the uncertain factors can get process robustness in robust design, which advantage is to design the low-cost product ac- cepting larger tolerance. Response surface methodology, presented by Box and Wilson, is the statistics technology modeling and ana- lyzing multivariate problem based on design of experi- ment. Earlier response surface methodology didn’t con- sider noise factors, and in 1980 Myers and Montgomery [12] introduced noise factors to build respectively mean and variance fitting response models, and then robust design based on response surface methodology is pre- sented. Reference [13] said that response surface methodology, consisting of selection of parameters, local optimization and global optimization, can be applied to robust pa- rameter design. And the kennels of response surface methodology are: 1) to take output response of process as linear function of control factors, noise factors and their interactions and build the function. 2) to select the proper response surface design type, carry on the experiments and get the experimental results of output response. 3) to estimate results of parameter of linear model with least square method. 4) to define the significant factors and interactions with semi-normal distribution plot (or analy- sis of variation, step regression, Cp statistics, etc), and then get an estimation and explanation of the factors with engineering analysis. Copyright © 2009 SciRes JSSM  JIANGUO CHE 207 Now two methods of robust design based on response surface methodology is brought as followed: one is to establish mean and variance fitting models involved the design variables (or control factors) respectively, which is usually called dual response surface methodology. Another is to establish response surface model involved control factors and noise factors by experiments, and the output response model of mean and variance is presented based on Lucas’s propagation of error [14]. Dual response surface methodology is a robustness optimization method building mean and variance fitting response model respectively by design of experiments and optimizing the model as a minimized constraints problem. There are the advantages that strict mathemati- cal logic fundamental, consideration of error distribu- tions and interactions between influence factors, more accurate solutions, higher optimization efficiency, higher reliability and robustness and the disadvantages that ob- taining some key parameters by experience can bring repeated experiments and calculations when building the response model for dual response surface methodology. Again, to fit model will be highly complicated and diffi- cult if interference variables or some High-dimensional variables are involved in dual response surface model [15]. The problems often arose in engineering optimization are as followed: 1) random factors’ influence to quality fluctuation. 2) The nonlinear implicit function relations between design variables and response do not make for optimization. 3) Continuous correction of design vari- ables in optimization evidently increases experimental or computational cost. For above problems, Reference [16] introduced the six sigma robustness optimization method by combining six sigma and dual response surface methodology and illustrated with drawing and shaping case of the ancon and tube-shape piece. 3. Robustness Optimization Strategy of MILV Process Robustness optimization of MILV process is a new, im- portant and need-to-deep research field. We had a work on quality improvement of MILV process with Taguchi robust design, but due to a nonlinear function relation or implicit function relation between input variables and output response variable exist in MILV process, which cannot meet the requirement of a linear function rela- tionship for Taguchi robust design, and Taguchi robust design cannot manage the strong interaction between input variables and output response variable, and time-varying variable problem, which only applies Ta- guchi design in some specific MILV processes, and greatly narrowed the applicable field of Taguchi robust design. Furthermore, the robustness evaluation index of Taguchi design SN ratio cannot tell the contribution of high SN ratio from output response mean or variance, etc, which leads to many criticisms, and due to there are dif- ferent output target value and error requirement for each different item of MILV process, and therefore there are no comparability of SN ratio between different items, so we have to find a revised Taguchi design method or other methods to improve robustness of MILV process. Generally, robustness design of MILV process need to solve two primary problems followed: one is to build fitting model of MILV process, another is to introduce the robustness evaluation index of MILV process. And we can realize the robustness optimization of MILV process by design of experiment after solving two prob- lems. For the above problems, we believe that the interaction and time-varying between/of input variables causes the poor robustness of MILV process. Since the identical modal of time-varying variables, we can take the fol- lowed steps to obtain the robustness of MILV process as: 1) to treat time-varying variables and other input vari- ables as input variables of MILV process uniformly, and take the interaction between input variables into MILV process model, and then establish MILV process fitting output response model involved input variables, the in- teractions between input variables and output response variables. 2) to present robustness evaluation index of MILV process. 3) according to the idea of Taguchi ro- bust design with dynamic output characteristics, take time-varying variables as input signal factors of MILV process model, and take time-varying variable value corresponding to each item and output response mean of each item as the corresponding level of input signal fac- tor and the corresponding parameter level of output re- sponse variable of MILV process respectively, and then design and optimize the robustness experiments. 4) the fitting surface model of MILV process can be got by solution and optimization of the model, and MILV proc- ess robustness optimization with time-varying variables and interactions between the input variables. In robustness optimization of MILV process, it is very important and difficult to propose robustness optimiza- tion index of MILV process. And then we will try to propose the index based on evidential theory, desirability function and dual response surface and other methods. Furthermore, since Taguchi design with the inter-outer array structure is difficult to solve the interactions be- Copyright © 2009 SciRes JSSM  JIANGUO CHE Copyright © 2009 SciRes JSSM 208 tween design variables in design of experiment, we have to select other design type of experiments according to the interactions. And in general, if we consider all the interactions of input variables adequately, the best one is full factorial design. But full factorial design will cause high number and cost of experiments if there are many input variables of MILV process, we have to choose few variables for full factorial design. Since not all the in- ter-actions between the input variables exist, and usually we can know the variables between which the interac- tions exists in advance, we can choose the proper design such as Taguchi design, response surface methodology etc, and then take the factors between which interaction exists in the specific array to estimate the interactions, or we can choose fractional factorial design with small ex- periment number to optimize the MILV process. Fur- thermore, if we cannot know the interactions between all the factors, we can estimate the known interactions, and analyze the goodness-of-fit of fitting model, and then do the experiments until the satisfactory goodness-of-fit of fitting model is obtained. REFERENCES [1] R. Jeyapaul, P. Shahabudeen, and K. Krishnaiah, “Qual- ity management research by considering multi-response problems in the Taguchi method-a review,” International Journal of Advanced Manufacturing Technology, No. 26, pp. 1331-1337, 2004. [2] G. E. P. Box, “Signal-to-noise ratios, performance criteria, and transformations,” Technometrics, No. 30, pp. 1-40, 1988 [3] R. V. León, A. C. Shoemaker, and R. N. Kacker, “Per- formance measures independent of adjustment: An ex- planation and extension of Taguchi’s signal-to-noise ra- tios,” Technometrics, No. 29, pp. 253-285, 1987. [4] V. N. Nair, “Taguchi’s parameter design: A panel discus- sion,” Technometrics, No. 34, pp. 127-161, 1992. [5] L. Z. Chen, “Robust design,” Machine Industry Press, Beijing, 1999. [6] D. B. Parkinson, “The application of a robust design method to tolerancing,” Journal of Mechanical Design, No. 122, pp. 149-154, 2000. [7] J. C. Xu and Y. Z. Ma, “Measurement methods for robust multivariate quality characteristics,” Systems Engineer- ing-Theory & Practice, No. 19, pp. 45-48, 1999. [8] A. Parkinson, “Robust mechanical design using engi- neering models,” Journal of Mechanical Design, No. 117, pp. 48-54, 1995. [9] A. Parkinson, C. Sorensen, and N. Pourhassan, “A gen- eral approach for robust optimal design,” Journal of Me- chanical Design, No. 115, pp. 74-80, 1993. [10] W. Chen, J. K. Allen, K. -L. Tsui, and F. Mistree, “Pro- cedure for robust design minimizing variations caused by noise factors and control factors,” Journal of Mechanical Design, No. 118, pp. 478-485, 1996. [11] A. D. Belegundu and S. H. Zhang, “Robustness of design through minimum sensitivity. Journal of Mechanical de- sign,” No. 114, pp. 213-217, 1992. [12] R. H. Myers and D. C. Montgomery, “Response surface methodology: Process and product optimization using de- signed experiments,” Wiley Interscience Publication, New York, 2002. [13] A. C. Shoemaker, K. -L. Tsui, and C. F. J. Wu, “Eco- nomical experimentation methods for robust parameter design,” Technometrics, No. 33, pp. 415-427, 1991. [14] J. M. Lucas, “How to achieve a robust process using re- sponse surface methodology,” Journal of Quality Tech- nology, No. 26, pp. 248-260, 1994. [15] R. V. Geof and H. M. Raymond, “Combining Taguchi and response surface philosophies: A dual response ap- proach,” Journal of Qualify Technology, No. 22, pp. 38- 45, 1990. [16] Y. Q. Li, Z. S. Cui, J. Chen, et al., “Six sigma robust design methodology based on response surface model,” Journal of Shanghai Jiaotong University, No. 40, pp. 201-205, 2006. |