Interaction of 8 MeV Electron beam with P31 Bombyx mori Silk Fibers

832

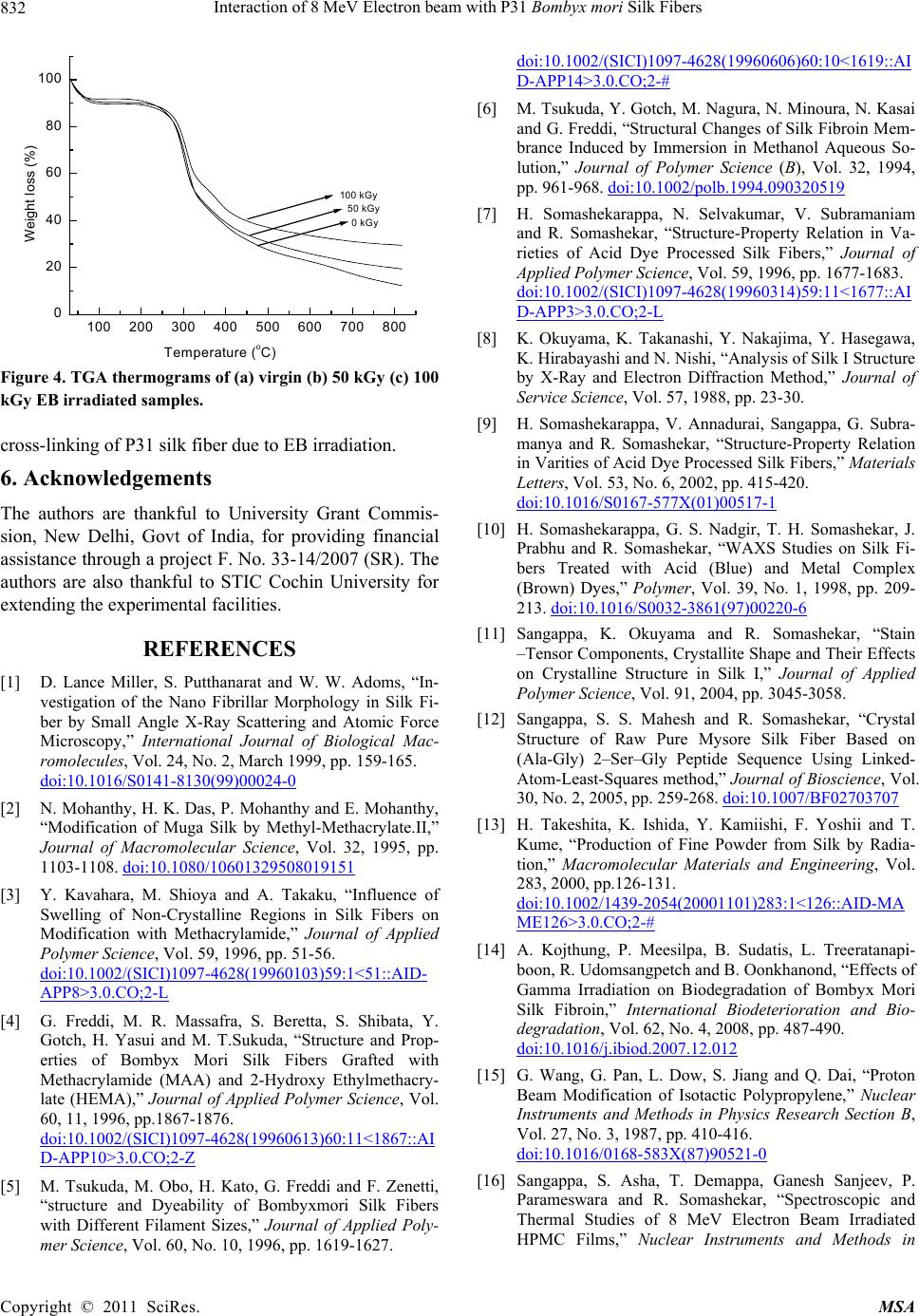

100 200 300 400 500 600 700 800

0

20

40

60

80

100

100 kGy

50 kGy

0 kGy

Weight loss (%)

Temperature (oC)

Figure 4. TGA thermograms of (a) virgin (b) 50 kGy (c) 100

kGy EB irradiated samples.

cross-linking of P31 silk fiber due to EB irradiation.

6. Acknowledgements

The authors are thankful to University Grant Commis-

sion, New Delhi, Govt of India, for providing financial

assistance through a project F. No. 33-14/2007 (SR). The

authors are also thankful to STIC Cochin University for

extending the experimental facilities.

REFERENCES

[1] D. Lance Miller, S. Putthanarat and W. W. Adoms, “In-

vestigation of the Nano Fibrillar Morphology in Silk Fi-

ber by Small Angle X-Ray Scattering and Atomic Force

Microscopy,” International Journal of Biological Mac-

romolecules, Vol. 24, No. 2, March 1999, pp. 159-165.

doi:10.1016/S0141-8130(99)00024-0

[2] N. Mohanthy, H. K. Das, P. Mohanthy and E. Mohanthy,

“Modification of Muga Silk by Methyl-Methacrylate.II,”

Journal of Macromolecular Science, Vol. 32, 1995, pp.

1103-1108. doi:10.1080/10601329508019151

[3] Y. Kavahara, M. Shioya and A. Takaku, “Influence of

Swelling of Non-Crystalline Regions in Silk Fibers on

Modification with Methacrylamide,” Journal of Applied

Polymer Science, Vol. 59, 1996, pp. 51-56.

doi:10.1002/(SICI)1097-4628(19960103)59:1<51::AID-

APP8>3.0.CO;2-L

[4] G. Freddi, M. R. Massafra, S. Beretta, S. Shibata, Y.

Gotch, H. Yasui and M. T.Sukuda, “Structure and Prop-

erties of Bombyx Mori Silk Fibers Grafted with

Methacrylamide (MAA) and 2-Hydroxy Ethylmethacry-

late (HEMA),” Journal of Applied Polymer Science, Vol.

60, 11, 1996, pp.1867-1876.

doi:10.1002/(SICI)1097-4628(19960613)60:11<1867::AI

D-APP10>3.0.CO;2-Z

[5] M. Tsukuda, M. Obo, H. Kato, G. Freddi and F. Zenetti,

“structure and Dyeability of Bombyxmori Silk Fibers

with Different Filament Sizes,” Journal of Applied Poly-

mer Science, Vol. 60, No. 10, 1996, pp. 1619-1627.

doi:10.1002/(SICI)1097-4628(19960606)60:10<1619::AI

D-APP14>3.0.CO;2-#

[6] M. Tsukuda, Y. Gotch, M. Nagura, N. Minoura, N. Kasai

and G. Freddi, “Structural Changes of Silk Fibroin Mem-

brance Induced by Immersion in Methanol Aqueous So-

lution,” Journal of Polymer Science (B), Vol. 32, 1994,

pp. 961-968. doi:10.1002/polb.1994.090320519

[7] H. Somashekarappa, N. Selvakumar, V. Subramaniam

and R. Somashekar, “Structure-Property Relation in Va-

rieties of Acid Dye Processed Silk Fibers,” Journal of

Applied Polymer Science, Vol. 59, 1996, pp. 1677-1683.

doi:10.1002/(SICI)1097-4628(19960314)59:11<1677::AI

D-APP3>3.0.CO;2-L

[8] K. Okuyama, K. Takanashi, Y. Nakajima, Y. Hasegawa,

K. Hirabayashi and N. Nishi, “Analysis of Silk I Structure

by X-Ray and Electron Diffraction Method,” Journal of

Service Science, Vol. 57, 1988, pp. 23-30.

[9] H. Somashekarappa, V. Annadurai, Sangappa, G. Subra-

manya and R. Somashekar, “Structure-Property Relation

in Varities of Acid Dye Processed Silk Fibers,” Materials

Letters, Vol. 53, No. 6, 2002, pp. 415-420.

doi:10.1016/S0167-577X(01)00517-1

[10] H. Somashekarappa, G. S. Nadgir, T. H. Somashekar, J.

Prabhu and R. Somashekar, “WAXS Studies on Silk Fi-

bers Treated with Acid (Blue) and Metal Complex

(Brown) Dyes,” Polymer, Vol. 39, No. 1, 1998, pp. 209-

213. doi:10.1016/S0032-3861(97)00220-6

[11] Sangappa, K. Okuyama and R. Somashekar, “Stain

–Tensor Components, Crystallite Shape and Their Effects

on Crystalline Structure in Silk I,” Journal of Applied

Polymer Science, Vol. 91, 2004, pp. 3045-3058.

[12] Sangappa, S. S. Mahesh and R. Somashekar, “Crystal

Structure of Raw Pure Mysore Silk Fiber Based on

(Ala-Gly) 2–Ser–Gly Peptide Sequence Using Linked-

Atom-Least-Squares method,” Journal of Bioscience, Vol.

30, No. 2, 2005, pp. 259-268. doi:10.1007/BF02703707

[13] H. Takeshita, K. Ishida, Y. Kamiishi, F. Yoshii and T.

Kume, “Production of Fine Powder from Silk by Radia-

tion,” Macromolecular Materials and Engineering, Vol.

283, 2000, pp.126-131.

doi:10.1002/1439-2054(20001101)283:1<126::AID-MA

ME126>3.0.CO;2-#

[14] A. Kojthung, P. Meesilpa, B. Sudatis, L. Treeratanapi-

boon, R. Udomsangpetch and B. Oonkhanond, “Effects of

Gamma Irradiation on Biodegradation of Bombyx Mori

Silk Fibroin,” International Biodeterioration and Bio-

degradation, Vol. 62, No. 4, 2008, pp. 487-490.

doi:10.1016/j.ibiod.2007.12.012

[15] G. Wang, G. Pan, L. Dow, S. Jiang and Q. Dai, “Proton

Beam Modification of Isotactic Polypropylene,” Nuclear

Instruments and Methods in Physics Research Section B,

Vol. 27, No. 3, 1987, pp. 410-416.

doi:10.1016/0168-583X(87)90521-0

[16] Sangappa, S. Asha, T. Demappa, Ganesh Sanjeev, P.

Parameswara and R. Somashekar, “Spectroscopic and

Thermal Studies of 8 MeV Electron Beam Irradiated

HPMC Films,” Nuclear Instruments and Methods in

Copyright © 2011 SciRes. MSA