Natural Science

Vol.6 No.11(2014), Article

ID:47907,7

pages

DOI:10.4236/ns.2014.611084

Physical and Chemical Properties and Crystal Structure Transformation of Beeswax during Heat Treatment

T. Espolov1, J. Ukibayev1, D. Myrzakozha1, P. Perez-Lopez1, Y. Ermolaev2

1Kazakhstan-Japan Innovation Center, Kazakh National Agrarian University, Almaty, Kazakhstan

2Kazakh National Technical University, Almaty, Kazakhstan

Email: zhandosu@mail.ru

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 18 May 2014; revised 25 June 2014; accepted 7 July 2014

ABSTRACT

The object of research is the wax as a waste product of bees in the steppe and mountain areas of Almaty region of Kazakhstan. Purpose: To study the structure parameters and the homologous phase composition, morphology waxes of alpine and mountain areas of Kazakhstan and the establishment temperature-dependent patterns of their atomic-crystalline state. Methods: Radiography, gas chromatography, scanning electron microscopy and chemical methods of separation of multicomponent systems. The results were obtained in the atomic crystal and molecular structures of beeswax depending on the districts collecting materials. The technique of obtaining radiographs after dissolving beeswax in benzene, hexane and xylene was used. Submitted thermo-radiographic study samples were obtained. Batch analysis thermo-radiographs waxes after treatment with benzene, hexane and xylene showed that their structure is essentially different from the source and closer to the spectra of the crystallized wax melted and due to annihilation of stacking faults waxes native atoms after their dissolution in hexane, benzene and xylene and subsequent their recrystallization. The results obtained allow expanding the amount of information on the physicochemical processes and structural transformations in beeswax as a composite of different genesis biomaterial. Scope: Beekeeping, plant, structural and analytical chemistry, biotechnology and biocomposites.

Keywords:Wax, Composite Biomaterial, Radiography, Defect Structure

1. Introduction

Bees and beekeeping play an important role in human life and society as an example of a harmonious and positive relationship between nature and man.

Indeed, there is a surprising variety of components in the relationship between bees and humans, including plant and crop pollination, the production of honey, propolis, bee bread, royal jelly, wax, the treatment of diseases with bee products and derivatives and finally, bee venom, with which many people are familiar after careless contact with bees and the subsequent sting.

The useful properties of the main products of bee activity engender a desire for a deeper understanding of their physico-chemical properties, structure and the options for novel practical applications in fields, for example, agriculture, biotechnology, medicine and ecology. In the first place it is agriculture because the primary symbiosis of bees and plants is the pollination by these insects of plants in the wild and crops that are used for human and livestock nutrition.

The physico-chemical properties, atomic crystal structure and morphology of the main products of bee activity can serve as indicators of bee health and the ecological conditions of areas in which bees live and forage. Also these analyses are of independent value in deepening our knowledge of the mechanisms of the genesis and structure of honey, propolis, bee bread, royal jelly and bee venom, etc.

The objective of this study is to increase our knowledge of the homologous composition and mechanism of crystallization and phase transformation of bee waxes from different climatic and ecological zones of the Republic of Kazakhstan, using a suite of advanced chromatographic techniques and radiography.

2. Materials and Methods

The material for the study was bee wax samples, taken from mountain and steppe honey collection areas in the Almaty region.

The mountain samples were taken from a stationary apiary in the upper reaches of the Kastek mountain river, near the village of Kastek in Almaty region. Bees from this apiary, are local bees cross bred with a German species and have low aggression and good resistance to major bees diseases.

The Steppe samples were taken from a mobile apiary located near the village Bakanas, in the floodplain of the lower reaches of the river Ili. Bees from this apiary are resistant to diseases typical for the local steppe breed.

A highly sensitive gas chromatograph, Zhimadzu (Japan) GC-2010 Plus with add-on device Agilent 6850, was used to study the physical and chemical properties of the waxes, in particular their homologous composition. The investigation of the atomic crystal structure of the waxes was performed with a ray diffractometer, Phillips X’PertPRO (Holland), together with a high temperature add-on device, Anton Paar НХТ-1600 (Austria). Morphological pictures of wax walls were obtained with a scanning electron microscope, JEOL JSM-6510 LA (Japan). The physical-chemical methods employed for the analysis of the beeswax, are widespread and well described.

The samples of beeswax were studied in the GC-2010 Plus gas chromatograph, which is equipped with two detectors: flame ionization and flame photometric.

The homological composition of the beeswax samples was defined using chromatography.

Chromatographic separation was carried out by programming a rise in column temperature from 80˚C to 270˚C. The rate of temperature rise was 15˚C/min. The velocity of gas flow through the column was 27.4 cm/sec.

The radiographic examination of wax from the honeycombs was carried out as follows: the specimen was prepared by cutting a 2.5 × 10 mm section from the honeycomb wall with a sharpened razor. The section was mounted on a special holder of silicon mono-crystal, cut along the crystallographic direction, providing the absence of diffraction peaks in the Bragg angles in the operating spectrum of the X’PertPRO diffractometer.

The thermal radiography of the wax samples was carried out as follows: the specimen was prepared by cutting a 2.5 × 10 mm section from the honey comb wall with a sharpened razor. The section was packed in a special envelope of aluminum foil, 0.01 mm thick, which was mounted on the platinum substrate-heater of the НХТ-16 high temperature add-on device. The main reflection peaks of the waxes in the research temperature range were not overlapped by diffraction reflections of the FCC lattices of platinum and aluminum when using the copper anode of the X-ray tube in the diffractometer. The temperature increments between the spectra during the thermal radiography were 10˚C during the heating from room temperature to the wax melting point or higher as well as during the cooling process. The time to temperature stabilization in this case was 1 min. The length of recording of spectrum (a) in a given range of Bragg angles was 10 min.

The studies were conducted at accelerating voltages at X-ray tube 30 and 40 kV and currents of 10 and 30 mA. X-ray exposure was made using X’Pert Data Collector operating software. The processing of radiographs was performed using X’Pert HighScore software.

The preparation of fused wax samples for radiographic examinations was carried out with standard methods used for polymer materials.

Scanning electronic microscopy was used to study the surface morphology of the honeycomb wax walls and the microstructure of grains of pollen embedded in the wax walls. Methods of exposure were perfected by varying both the accelerating voltage from 5 to 30 kV, and a conductive layer of metal (gold) and amorphous carbon. In this last case the thickness of the applied layers was varied experimentally and 3 - 5 nm was selected as optimal.

3. Results and Discussion

The overall objective of the chromatographic research was to study the homologous composition and structure of beeswax originating from mountain and steppe regions of Almaty oblast.

For the chromatographic analysis, wax was heated in a water bath to 70˚C for 15 minutes. During this time a thin film of wax floated on the water surface. The paraffin was dissolved in hexane and the chromatographic separation was carried out by programming a rise in column temperature from 80˚C to 270˚C at a rate of 15˚C/min. The velocity of gas flow through the column was 27.4 cm/sec.

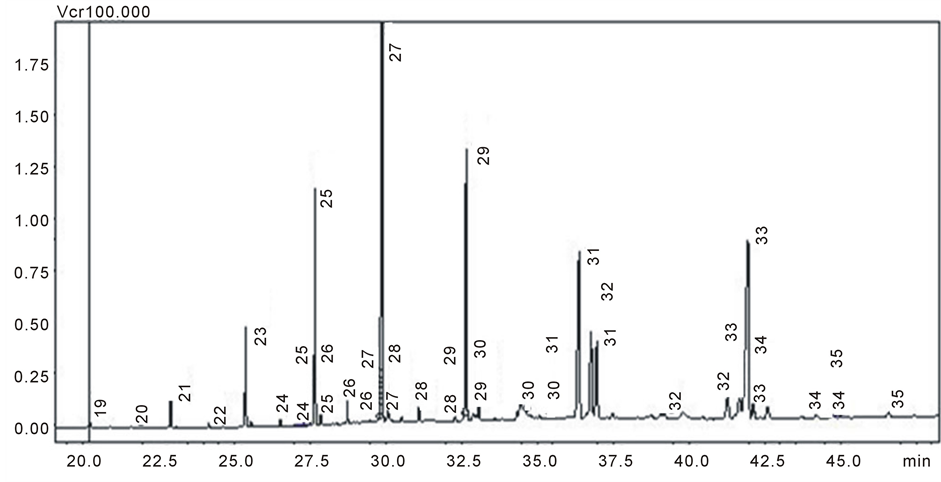

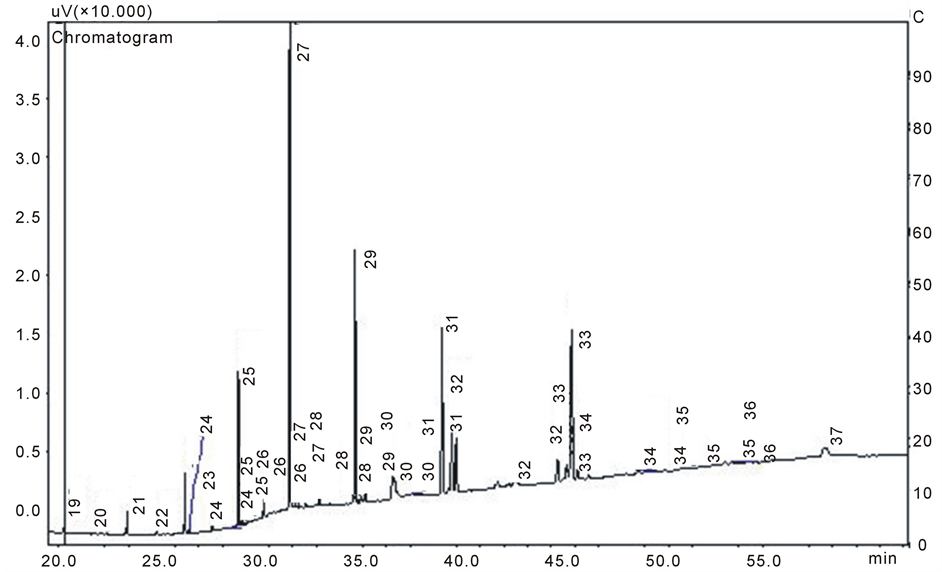

Figure 1 and Figure 2 show the chromatograms of the mountain and steppe waxes.

It can be seen in the chromatograms shown that the odd homologues, with numbers n = 23, 25, 27, 29, 31, 33, generally dominated. Chromatographic data obtained earlier shows that the composition of beeswax paraffin include only odd homologues with numbers n = 23, 25, 27, 29, 31, 33 and the maximum distribution of homologues (by carbon atom number) in all cases corresponds to homologue with n = 27 [1] . It is surprising that the chromatograms, Figure 2 and Figure 3, show that together with odd homologues are also even-numbered homologues with numbers n = 22, 24, 28, 30, 32, 34.

The chromatographic results that were obtained by this study, complement existing data on the homologous composition of beeswax, depending on the place of origin. There is insufficient reliable existing data to assert that bioparaffin of beeswax always contain only odd homologues in their composition. Our results show that bioparaffin of wax may contain also even-numbered homologues.

To obtain information on the thermal transformation of beeswax of different origins we performed temperature radiography experiments with a small range of temperatures from one to another radiograph. This step was 1˚C in some areas of the temperature range from room temperature to the melting point or higher.

The starting point in the study of structural phase transitions of beeswax of different origins is the analysis of commercial wax by temperature radiography.

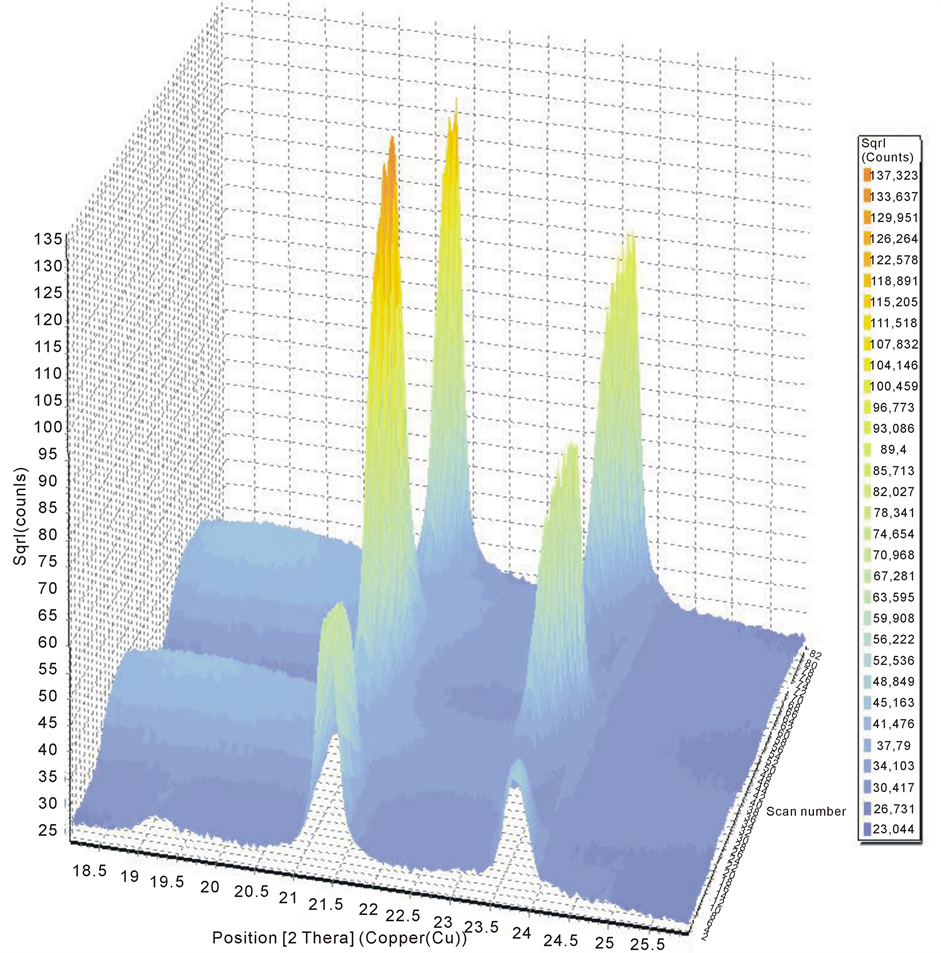

Segments of radiographs in the Bragg angles from 18 to 25 degrees were analyzed. Source wax was cut from the cell wall of dry, freshly made honeycomb and not subjected to any thermal stresses exceeding a maximum temperature 25˚C. The wax was placed in a holder plate and heated until it melted. The temperature radiographs were obtained during the defined program. The melted wax was exposed on the holder for 30 min and cooled to room temperature [2] [3] . Radiographs were taken during the cooling period. The procedure was then repeated.

The results are shown in Figure 3, Figure 4.

The three-dimensional topographical representation in figure 3 was obtained under the following radiograph recording mode: the sample was heated from room temperature until melted, the melt was exposed for 30 minutes and cooled to room temperature [4] . The procedure was then repeated.

Figure 4 shows the two-dimensional radiograph fragments, at Bragg angles 23˚ to 24˚, as thin (1 mm) strips placed horizontally one under another. The start of the experiment is shown by the upper radiograph and the end of the experiment end is shown by the lower radiograph. A zigzag light bar, divided by two broad areas parallel to the y-axis gives information about the phase transformations that occurred during the experiment.

Detailed analysis of the radiographs allows the conclusion that the source beeswax has a highly defective layered structure. After melting the degree of defectiveness is minimized and the packing of the molecular crystals of beeswax paraffin takes on a more regular ordered character [5] .

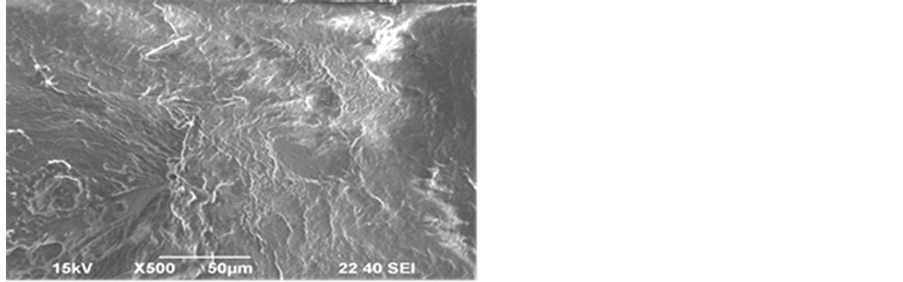

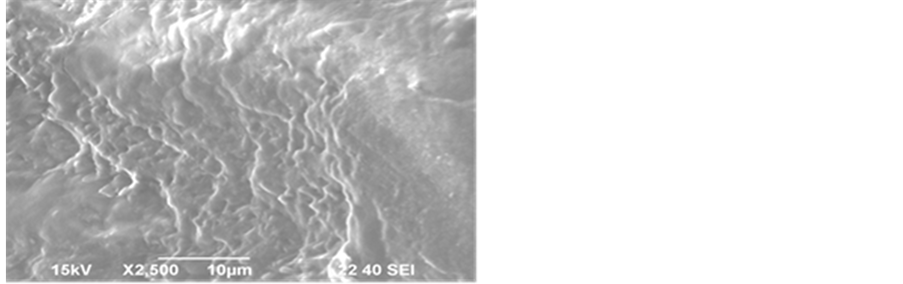

Figure 5 and Figure 6 show electron microscopic images of the morphology of a honeycomb wax wall, cut from the sample, taken from the steppe apiary, at 500 and 2500 multiplication. Similar patterns were obtained from the walls of cells taken from the mountain apiaries. We conclude that this represents typical morphology. Figure 5 shows, at a relatively low magnification of 500, that the wax microstructure is extremely heterogeneous and it is almost impossible to describe the geometric shape of the “building blocks” from which the wall of the honeycomb is composed. Analysis of the images at 2500 multiplication (Figure 6) shows that the structure

Figure 1. Chromatogram of the mountain wax.

Figure 2. Chromatogram of the steppe wax.

of the wax walls has a layered nature.

Honeycomb is constructed by bees secreting wax in a liquid state, which then hardens in the air. A micro process occurs, which is broadly analogous with the formation of ice on the surface of water, when small amounts of additional water are repeatedly added, spreading on the solidified surface and forming structures similar to those described here for wax. This morphology is also promoted by the layered molecular packing of wax bioparaffin [5] [6] .

Figure 3. Three-dimensional topographical representation of radiographs of mountain beeswax at different temperatures.

4. Conclusions

Chromatography, X-ray diffraction and electron microscopic techniques were used to study beeswax and obtain new data on the homologous composition, morphology and basic parameters of the atomic crystal structure of beeswax.

The differences in the homologous composition of waxes from steppe and alpine zones were defined. According to the chromatography, the samples of beeswax are composed mainly of odd numbered homologues with n = 23, 25, 27, 29, 31, 33. Approximately half of the total homologue content is accounted for by the dominant homologue with n = 27. As well as odd homologues even numbered homologues n = 22, 24, 28, 30, 32, 34 have been identified. The differences in the concentrations of paraffin homologues distribution between wax samples from alpine and semi-arid zones were established. The concentration of homologous composition of wax from alpine zones is predominantly greater than that of wax from semiarid zones.

The study revealed the layered microstructure of the honeycomb cells walls caused by crystallization of the

Figure 4. Two-dimensional representation of radiographs of the source beeswax (mountain sample), at different temperatures, arranged above one another (heating from room temperature to the melting temperature), cooling to room temperature, and repetition of the process.

Figure 5. Morphology of wax wall (steppe apiary) ×500.

Figure 6. Morphology of wax wall (steppe apiary) ×2500.

primary wax from the live organic solution produced by bees.

The study also determined that the source beeswax has a highly defective layered structure. After melting, the degree of defectiveness is minimized and the packing of the molecular crystals of beeswax bio-paraffins takes on a more regular structure.

References

- Kotelnikova E.N. and Filatov S.K. (2002) Crystal Chemistry of Paraffin’s. Research Methods, Results, Behavior in Nature. Saint-Petersburg, 352.

- Kitaygorodsky, A.I. (1971) Molecular Crystals. Science, 424.

- Zabelkin, O.A. (2003) Beekeeping. Moscow, 352.

- Asakura, T., Yamane, T., Nakazawa, Y., Kameda, T. and Ando, K. (2001) Structure of Bombyxmori Silk Fibroin before Spinning in Solid State Studied with Wide Angle X-Ray Scattering and C-13 Cross-Polarization/Magic Angle Spinning NMR. Biopolymers, 58, 521-525. http://dx.doi.org/10.1002/1097-0282(20010415)58:5<521::AID-BIP1027>3.0.CO;2-T

- Dorset, D.L. (1983) The Crystal Structure of Waxes. Acta Crystallogr, 8, 1021-1028.

- Dorset, D.L. (1999) Development of Lamellar Structures in Natural Waxes—An Electron Diffraction Investigation. Journal of Physics D: Applied Physics, 32, 1276-1280. http://dx.doi.org/10.1088/0022-3727/32/11/315