Advances in Microbiology

Vol.2 No.4(2012), Article ID:25685,5 pages DOI:10.4236/aim.2012.24057

Effect of Enzymes on the Quality of Beer/Wort Developed from Proportions of Sorghum Adjuncts

College of Food Sciences, Bells University of Technology, Ota, Nigeria

Email: *oludaremalomo1951@yahoo.com

Received July 24, 2012; revised October 19, 2012; accepted November 1, 2012

Keywords: Wort; Commercial Enzymes; Saccharification; Free Amino Nitrogen; Gelatinization

ABSTRACT

The effect of commercial enzymes on quality of wort developed from replacement of malted barley (100%) with sorghum as adjunct 50%, 60%, 70%, and 80% was investigated for pH, colour, filteration rate, extract asin, dry extract, viscosity, total soluble nitrogen and free amino nitrogen. The wort pH (5.6 - 6.0) is relatively stable with no significant changes at all levels of replacements. The colour is lighter with increment in proportion of the sorghum as it appears as colour diluents. Wort filteration rate is reduced with the sorghum replacement and the wort produced tends to be turbid which affects the utilization of the wort. The total soluble nitrogen and free amino nitrogen value increased with the use of commercial enzymes while the viscosity decreases with enzymes. The use of ceremix and cereflo have been found to be relatively more effective in the preparation of beer wort as observed for the result obtained in proportions of sorghum and malt barley. The use of high percentage sorghum as adjunct with commercial enzymes are found to be useful in production of high quality wort with low cost and profitability.

1. Introduction

Beer is the World’s most widely consumed alcoholic beverage; it is the third most popular drink after water and tea [1]. The process of beer production involved saccharification of starch by enzymes and fermentation of the resulting sugar. The starch and saccharification enzymes are usually derived from malting in which enzymes needed for the degradation of starch into fermentable sugars are produced [2]. Malted cereal grains mostly barley and wheat are used while unmalted cereals such as rice, maize, sorghum, sometimes millet are widely used as adjuncts mainly to lighten the flavour and to reduce cost of production, however the use of cassava for beer production has also been documented. The use of sorghum as brewing adjunct could be a major socioeconomic advantage in the developing countries in Africa. Limitations for its use, however, include its low amylolytic potential, high gelatinization temperatures, and the presence of tannins [3].

Much interest has been generated in the use of sorghum in brewing. The use of malted sorghum in the production of kaffir beer, a traditional beverage has been well documented [4]. There have also been reports on the use of sorghum in the production of Western-type beer [5]. It has been the basis of traditional African beers such as the clear beers of West Africa (dolo and pito) and the opaque beers of southern Africa. These beers are part of the African tradition and remain very popular but today Africans also enjoy lager and stout beers. These beers, of European origin, use barley as their major ingredient. This presents a major problem as barley is a temperate cereal and the African climate is unsuitable for cultivation [6].

The traditional source of enzymes used for the conversion of cereals into beer is barley malt. If too little enzyme activity is present in the mash, there will be several undesirable consequences: the extract yield will be too low; wort separation will take too long; the fermentation process will be too slow; too little alcohol will be produced; the beer filtration rate will be reduced; and the flavour and stability of the beer will be inferior [7]. Brewers who desire raw material cost savings or use of local raw materials may source under-modified malts or increase the ratio of adjunct. The limiting factor is to ensure an adequate complex of enzymatic activities for high-quality wort. Exogenous enzymes are used to supplement the malt’s own enzymes in order to prevent these problems. Furthermore, industrial enzymes are used to ensure better adjunct liquefaction, to produce low-carbohydrate beer (“light beer”), to shorten the beer maturation time, and to produce beer from cheaper raw materials. The substitution of a varying proportion of malt with sorghum introduces new dimensions to the grist composition [8]. It is not however clear how far mashing enzyme supplements in sorghum cultivar mashes could help alleviate the levels of fermentable sugars in its worts [9].

Therefore, the objective of this study is to investigate the brewing qualities of sorghum (variety SK 5912) as an adjunct at various proportion with the addition of Industrial enzymes

2. Materials and Methods

The sorghum variety SK 5912 was sourced from seed production unit of the Institute Agricultural Research, Zaria, Nigeria. The commercial enzymes Ban, Ceremix, Cereflo, Celluclast, Neutrase and Pentosanase were purchased from Novo chemicals. Ban is a bacterial amylase; ceremix is a mixture of bacterial amylase, proteinase, and glucanase. Cereflo is a bacterial glucanase; celluclast is from fungal while neutrase is a proteinase from bacteria. The malt used was sourced from Heneken while the yeast was from Davenport’s brewery.

3. Experimental Design

In the experiment, barley malt was used as the main ingredient in the laboratory scale production of wort while sorghum was used as adjunct in various proportions to substitute the barley. The quality characteristics of sorghum substitute was investigated under different proportions i.e., 50 percent barley; 50 percent sorghum, 40 percent barley; 60 percent sorghum, 30 percent barley; 70 percent sorghum and 20 percent barley; 80 percent sorghum.

Preparation of Hot Wort Extract

The method of [10] was used for the preparation of the hot water extract for the proportions of sorghum and malt i.e. 50% sorghum and 50% malt; 60% sorghum and 40% malt; 70% sorghum and 30% malt; 80% sorghum and 20% malt. For 50% sorghum and 50% malt, the sorghum grains (raw) was milled (coarse) with Buhler-Miag Universal laboratory disc mill at position 7. At 50% replacement, 25 g of sorghum milled and 5 g of malt is placed in a mortal and brought to evenly dispersed slurry by gradual addition of 50 mL water during grinding. 150 mL of water was used to wash the mortal content into a preweighed stainless steel bearer and agitated using a magnetic stirrer. The content was placed in a water bath for 60 minutes. The content was latter removed, cooled to 65˚C and addition 20 g of milled malt plus 5 g of malt and 150 mL of water (68˚C). Enzymes was added at this stage and kept in water bath at 65˚C for 2 hours followed by rapid cooling to 20˚C. After cooling the stainless steel was carefully weighed and the content made up to 450 g. The content was thoroughly mixed and filtered through Watmann 113 V and the volume of the wort collected in 30 min was determined. For 60% sorghum to 40% malt. 30 g of sorghum plus 5 g of malt (milled) was boiled with 200 mL of water before 15 g of mat (milled) was added. For 70% sorghum and 30% malt, 35 g of sorghum and 5 g of malt was boiled with 200 mL of water and 10 g of malt added for mashing for 2 hours. For 80% of sorghum, 40 g of sorghum and 5 g of malt was boiled with 200 mL of water and 5 g of malt added for mashing for 2 hours.

4. Physico-Chemical Analysis of Wort

The total soluble nitrogen, wort viscosity, total nitrogen, free alpha amino nitrogen, were determined as described by [10]. The pH was determined using ACT pH meter delta 340 standardized with buffer solutions of pH 7 and 4 respectively and beer head retention as described by [11]. Carbohydrate profile was estimated by the use of column chromatography as described by [12].

The nitrogen content was determined using micro Kjedhal method for protein analysis as described by [13]. Approximately 1 mL of the sample was weighed into the digestion tube of Kjeltec 2200 FOSS Tector Digestion unit (Foss Tecator Analytical AB Hoganas, Sweden). Two tablets of catalyst (containing 5 g of K2SO4 and 5 mg of Se) were added and also 12 mL of concentrated H2SO4 added. Digestion was done for one hour at 420˚C. The distillation was done using 2200 FOSS distillation unit with addition of 80 mls of water, 40 mls NaOH (40%). The distillate was collected in 4% boric acid prepared with bromocresol green and melthyl red indicators. Titration was done using 0.1 M HCl.

Calculation:

5. Statistical Analysis

Each analytical determination was carried out in duplicate with average mean recorded. Data were subjected to analysis of variance (ANOVA) using SPSS (Statistical Package for the Social Sciences, version 16) at p < 0.05. The means were separated using Duncan’ Multiple Range Test.

6. Results and Discussion

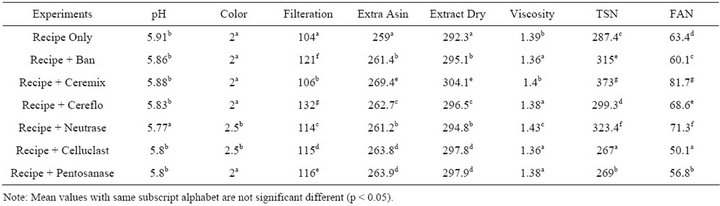

6.1. Effect of Industrial Enzymes on 80% Sorghum and 20% Malt Mash-Wort Analysis

There is a slight increase in the pH with enzyme additions with the exception of the celluclast which shows slight decrease (Table 1). A commonly accepted optimal range for mash pH is 5.2 - 5.7 with 5.5 being optimal for starch conversion activity but many authors report wort and beer quality benefits if the pH is lowered into the 5.2 - 5.4 range [14,15]. [8] recorded pH 5.70 for the same proportion of 80% sorghum and 20% malt. The difference in the value documented might have been influenced by the enzyme added and other proteolytic reaction which might have been involved. There exist difference between the control (no enzyme) and the samples with enzymes. There is increase in filtrations rate with all enzyme additions with neutrase addition highest followed closely by cereflo and celluclast. High filtration of neutrase may be as result of hydrolytic properties of neutrase to increase dispersibilty, solubility, palatability and digestibility. There is an increase in extract with enzyme, Ban, Ceremix, Cereflo and Pentosanase while the Neutrase and Celluclast showed decrease in extract yield when compared with the control. The viscosity decreases with most of the enzymes with the exception of the Ban which shows very slight increase and the Neutrase which shows significant increase. The total soluble nitrogen (TSN) significantly increases in samples with enzymes. The total soluble nitrogen was recorded in neutrase. Highest amount of free amino nitrogen was also documented in sample with neutrase while the control recorded the smallest.

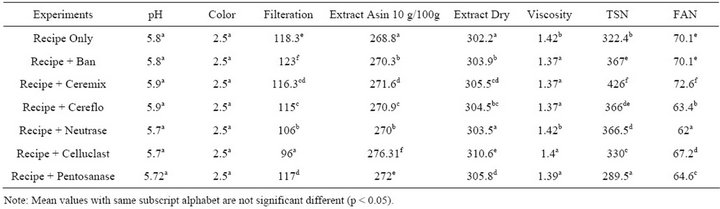

6.2. Effect of Industrial Enzymes on 70% Sorghum and 30% Malt Mash-Wort Analysis

The pH decreases with enzymes additions from 5.91 (control) to between 5.86 - 5.77 (Table 2). There was no effect of enzyme on colour for bran, ceremix, cereflo, pentosanase compared with the control (2.0) but increased to 2.5 for both neutrase and celluclast. The filtrations rate increased from 104 (control) to the range between 106 and 132 in samples with enzymes and the highest filteration rate was recorded in the cereflo. The extract increased with all the enzymes with the highest recorded in ceremix with no significance differences between the values recorded for both cellaclast and pentosanase. The synergy of various proportions of enzymes in ceremix (amylase, proteinase and glucanase) with differs functions may be responsible for the highest extract recorded. There was a decrease in viscosity with enzyme additions, ban, cereflo, neutrase, celluclast, pentosanase, while ceremix and neutrase showed slight increase when compared with the control. [8] recorded similar viscosity when investigating the effect of 80% raw sorghum on mash wort. The total soluble nitrogen (TSN) decreases with enzymes ceremix, neutrase, ban, cereflo and control respectively while pentosan and celluclast are below the control. Free amino nitrogen (FAN) was high with cere-

Table 1. Effect of industrial enzymes on 80% sorghum; 20% mash-wort.

Table 2. Effect of industrial enzymes on 70% sorghum; 30% mash-wort.

mix, cereflo, neutrase, followed by control compared with the values obtained for the enzymes ban, pentosanase and celluclast which are below the control. Addition of different activities or combinations of activities gave no significant advantages, however, to obtain levels of FAN of 100 - 140 mg/L excessive amounts of enzymes are required [8].

6.3. Effect of Industrial Enzymes on 60% Sorghum and 40% Malt Mash-Wort Analysis

The result for the analysis on the 60% sorghum and 40% malt mash wort were presented (Table 3). There were no significant differences in the values obtained for both pH and colour. The result of rate filteration revealed control has having the highest rate followed by ban, pentosanase, ceremix, cereflo, neutrase and celluclast respectively. The extract increases with all the samples with enzymes. Highest wort extract and extract dry was obtained with celluclast with the control lowest in the control. The viscosity drops with the enzyme ban, ceremix, cereflo, cerelluclast and pentosanase but that of the neutrase remains at 1.42 the same as control. The TSN ranged between 289.5 and 426, ceremix produced the highest amount of total soluble nitrogen but the lowest was found in sample with pentonase. The free amino nitrogen (FAN) ranged between 62 and 70.1. Ceremix produced the highest value followed by Ban and control that shared the same value (70.1) while there is a decrease in value with the celluclast, pentosanase, cereflo and neutrase respectively.

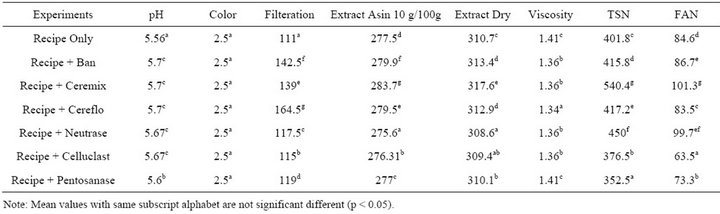

6.4. Effect of Industrial Enzymes on 50% Sorghum and 50% Malt Mash-Wort Analysis

The result of analysis of equal proportion of sorghum and malt wort (50%) were presented (Table 4). The pH of the wort increased slightly with the addition of enzymes with the exception of the pentosanase which showed the same value with the control. The result on colour analysis revealed that there was neither effect of substrates proportions nor that of the enzymes on the colour of the wort. The filteration rate increased with all the samples with enzymes, cereflo recorded highest filteration rate while sample with enzyme celluclast was the lowest. The extract yield for both extracasin and dry extract were low in neutrase while ceremix was the highest for the two respectively. The viscosity of the wort decreased with enzyme addition in all cases except the pentosanase which recorded the same viscosity with the control while the lowest was the wort with cereflo. Total soluble nitrogen (TSN) increases with ban, cereflo, neutrase, and ceremix

Table 3. Effect of industrial enzymes on 60% sorghum; 40% mash-wort.

Table 4. Effect of industrial enzymes on 50% sorghum; 50% mash-wort.

which have the highest increase. There is a decrease in the TSN of celluclast and pentosanase addition. The FAN increased with the ban, cereflo, neutrase and ceremix and there was a decrease with celluclast and pentosanase.

7. Conclusion

The overall experiments recorded no significant changes in pH, colour, and viscosity with 5.6 - 6.0, 2.0 - 2.5, 1.34 - 1.46 respectively. The filteration rate, extract yield, total soluble nitrogen and free amino nitrogen improved with every increment in the proportion of barley malt while the viscosity drops in the same trend. The use of ceremix and cereflo have been found to be more effective in the preparation of beer wort as observed for the result obtained in equal proportion of sorghum and malt barley. The low performance of some of the enzymes may be as a result of the environmental changes such as temperature, ion strength and they could alter the proportion of enzymes, and consequently, produce certain changes in substrate hydrolysis pattern [16]. Therefore, stabilisation is important during the process. Although, the absence of commercial enzyme does not mean poor wort preparation but it will enhance the quality characteristics of the wort, increase yield and profitability due to high efficiency, specificity and ability to control their activities in the brewing process. Therefore, the use of high proportion of sorghum as adjunct in brewing will be a welcome development that enhance better utilisation of sorghum and reduces importation of barley with more profit.

REFERENCES

- M. Nelson, “The Barbarian’s Beverage: A History of Beer in Ancient Europe,” Routledge Publication, New York, 2005, p. 1.

- S. Aastrup, B. Noel, J. Elmar and D. Kurt, “Choice of Enzyme Solution Should Determine Choice of Raw Materials and Process,” Presentation Given at World Brewing Conference, San Diego, 2004.

- J. Helena, “Sorghum Hot Water Extract: Influence of Grain Physic-Chemical Characteristics,” Master’s Dissertation, Department of Food Science, University of Pretoria, 2009.

- G. H. Palmer, “Cereals in Malting and Brewing,” In: G. H. Palmer, Ed., Cereal Science and Technology, Aberdeen University Press, Scotland, 1989, pp. 61-242.

- A. O. Aisien and G. Muts, “Brewing with Raw Sorghum,” Journal of the Institute of Brewing, Vol. 93, 1987, p. 328.

- INTSORMIL, “Sorghum Lager and Stout Beer: A Boost to the African Economy,” INSORMIL Report No. 17, 2008. http://intsormil.org

- J. R. N. Taylor and J. Dewar, “Developments in Sorghum Food Technologies,” Advance in Food and Nutrition Research, Vol. 43, 2001, pp. 217-264. doi:10.1016/S1043-4526(01)43006-3

- M. F. Bajomo and T. W. Young, “Development of a Mashing Profile for the Use of Microbial Enzymes in Brewing with Raw Sorghum (80%) and Malted Barley or Sorghum Malt (20%),” Journal of the Institute of Brewing, Vol. 98, 1992, pp. 515-523.

- Z. S. Desogbo, E. Nso and T. Dzudie, “Use of Response Surface Methodology for Optimising the Action of Mashing Enzymes on Wort Reducing Sugars of the Madjeru Sorghum Cultivar,” African Journal of Food Scence, Vol. 5, 2011, pp. 91-99.

- Institute of Brewing, “Recommended Methods of Analysis,” 1989.

- A. O. Rudin, “Measurement of the Foam Stability of Beers,” Journal of the Institute of Brewing, Vol. 63, 1957, pp. 506-509.

- C. J. Dale, T. W. Young and A. T. Omole, “ Small Scale Mashing Experiments with Grist Containing High Proportions of Raw Sorghum,” Journal of the Institute of Brewing, Vol. 96, 1990, pp. 403-409.

- AOAC, “Official Method of Analysis,” 17th Edition, Horowitz Edition Intern, Baltimore, Vol. 1, 2000, pp. 452-456.

- K. Wolfang, “Technologie Brauer and Maizer,” VLB, Berlin, 2007. (German Language)

- L. Narziss and H. Werner Back, “Abriss der Bierbrauerei,” Technische Universitaet Muenchen (Fakultaet fuer Brauwesen, Weihenstephan), WILEY-VCH Verlags GmbH, Weinheim, 2005.

- I. Markovic, B. Markovic-Devcic, S. Gamuli and N. Paviovic, “Stabilisation of B-Glucanase and Its Effect on the Substrate Hydrolysis Pattern,” Progress in Biotechnology (Elsevier), Vol. 15, 1998, pp. 53-58. doi:10.1016/S0921-0423(98)80009-9

NOTES

*Corresponding author.