V. K. SHINOJ ET AL.

89

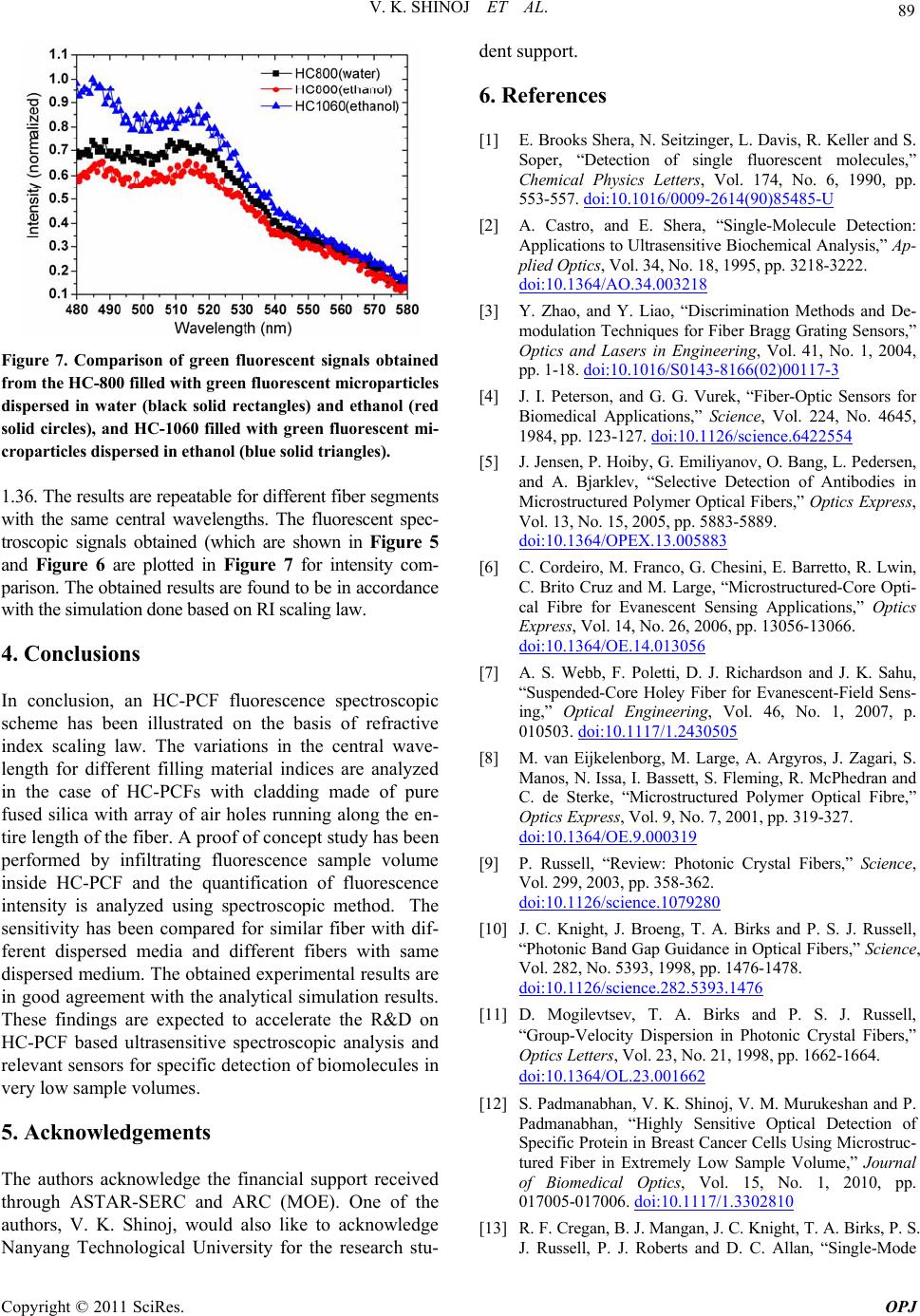

Figure 7. Comparison of green fluorescent signals obtained

from the HC-800 filled with green fluorescent microparticles

dispersed in water (black solid rectangles) and ethanol (red

solid circles), and HC-1060 filled with green fluorescent mi-

croparticles dispersed in ethanol (blue solid triangles).

1.36. The results are repeatable for different fiber segments

with the same central wavelengths. The fluorescent spec-

troscopic signals obtained (which are shown in Figure 5

and Figure 6 are plotted in Figure 7 for intensity com-

parison. The obtained results are found to be in accordance

with the simulation done based on RI scaling law.

4. Conclusions

In conclusion, an HC-PCF fluorescence spectroscopic

scheme has been illustrated on the basis of refractive

index scaling law. The variations in the central wave-

length for different filling material indices are analyzed

in the case of HC-PCFs with cladding made of pure

fused silica with array of air holes running along the en-

tire length of the fiber. A proof of concept study has been

performed by infiltrating fluorescence sample volume

inside HC-PCF and the quantification of fluorescence

intensity is analyzed using spectroscopic method. The

sensitivity has been compared for similar fiber with dif-

ferent dispersed media and different fibers with same

dispersed medium. The obtained experimental results are

in good agreement with the analytical simulation results.

These findings are expected to accelerate the R&D on

HC-PCF based ultrasensitive spectroscopic analysis and

relevant sensors for specific detection of biomolecules in

very low sample volumes.

5. Acknowledgements

The authors acknowledge the financial support received

through ASTAR-SERC and ARC (MOE). One of the

authors, V. K. Shinoj, would also like to acknowledge

Nanyang Technological University for the research stu-

dent support.

6. References

[1] E. Brooks Shera, N. Seitzinger, L. Davis, R. Keller and S.

Soper, “Detection of single fluorescent molecules,”

Chemical Physics Letters, Vol. 174, No. 6, 1990, pp.

553-557. doi:10.1016/0009-2614(90)85485-U

[2] A. Castro, and E. Shera, “Single-Molecule Detection:

Applications to Ultrasensitive Biochemical Analysis,” Ap-

plied Optics, Vol. 34, No. 18, 1995, pp. 3218-3222.

doi:10.1364/AO.34.003218

[3] Y. Zhao, and Y. Liao, “Discrimination Methods and De-

modulation Techniques for Fiber Bragg Grating Sensors,”

Optics and Lasers in Engineering, Vol. 41, No. 1, 2004,

pp. 1-18. doi:10.1016/S0143-8166(02)00117-3

[4] J. I. Peterson, and G. G. Vurek, “Fiber-Optic Sensors for

Biomedical Applications,” Science, Vol. 224, No. 4645,

1984, pp. 123-127. doi:10.1126/science.6422554

[5] J. Jensen, P. Hoiby, G. Emiliyanov, O. Bang, L. Pedersen,

and A. Bjarklev, “Selective Detection of Antibodies in

Microstructured Polymer Optical Fibers,” Optics Express,

Vol. 13, No. 15, 2005, pp. 5883-5889.

doi:10.1364/OPEX.13.005883

[6] C. Cordeiro, M. Franco, G. Chesini, E. Barretto, R. Lwin,

C. Brito Cruz and M. Large, “Microstructured-Core Opti-

cal Fibre for Evanescent Sensing Applications,” Optics

Express, Vol. 14, No. 26, 2006, pp. 13056-13066.

doi:10.1364/OE.14.013056

[7] A. S. Webb, F. Poletti, D. J. Richardson and J. K. Sahu,

“Suspended-Core Holey Fiber for Evanescent-Field Sens-

ing,” Optical Engineering, Vol. 46, No. 1, 2007, p.

010503. doi:10.1117/1.2430505

[8] M. van Eijkelenborg, M. Large, A. Argyros, J. Zagari, S.

Manos, N. Issa, I. Bassett, S. Fleming, R. McPhedran and

C. de Sterke, “Microstructured Polymer Optical Fibre,”

Optics Express, Vol. 9, No. 7, 2001, pp. 319-327.

doi:10.1364/OE.9.000319

[9] P. Russell, “Review: Photonic Crystal Fibers,” Science,

Vol. 299, 2003, pp. 358-362.

doi:10.1126/science.1079280

[10] J. C. Knight, J. Broeng, T. A. Birks and P. S. J. Russell,

“Photonic Band Gap Guidance in Optical Fibers,” Science,

Vol. 282, No. 5393, 1998, pp. 1476-1478.

doi:10.1126/science.282.5393.1476

[11] D. Mogilevtsev, T. A. Birks and P. S. J. Russell,

“Group-Velocity Dispersion in Photonic Crystal Fibers,”

Optics Letters, Vol. 23, No. 21, 1998, pp. 1662-1664.

doi:10.1364/OL.23.001662

[12] S. Padmanabhan, V. K. Shinoj, V. M. Murukeshan and P.

Padmanabhan, “Highly Sensitive Optical Detection of

Specific Protein in Breast Cancer Cells Using Microstruc-

tured Fiber in Extremely Low Sample Volume,” Journal

of Biomedical Optics, Vol. 15, No. 1, 2010, pp.

017005-017006. doi:10.1117/1.3302810

[13] R. F. Cregan, B. J. Mangan, J. C. Knight, T. A. Birks, P. S.

J. Russell, P. J. Roberts and D. C. Allan, “Single-Mode

Copyright © 2011 SciRes. OPJ