Paper Menu >>

Journal Menu >>

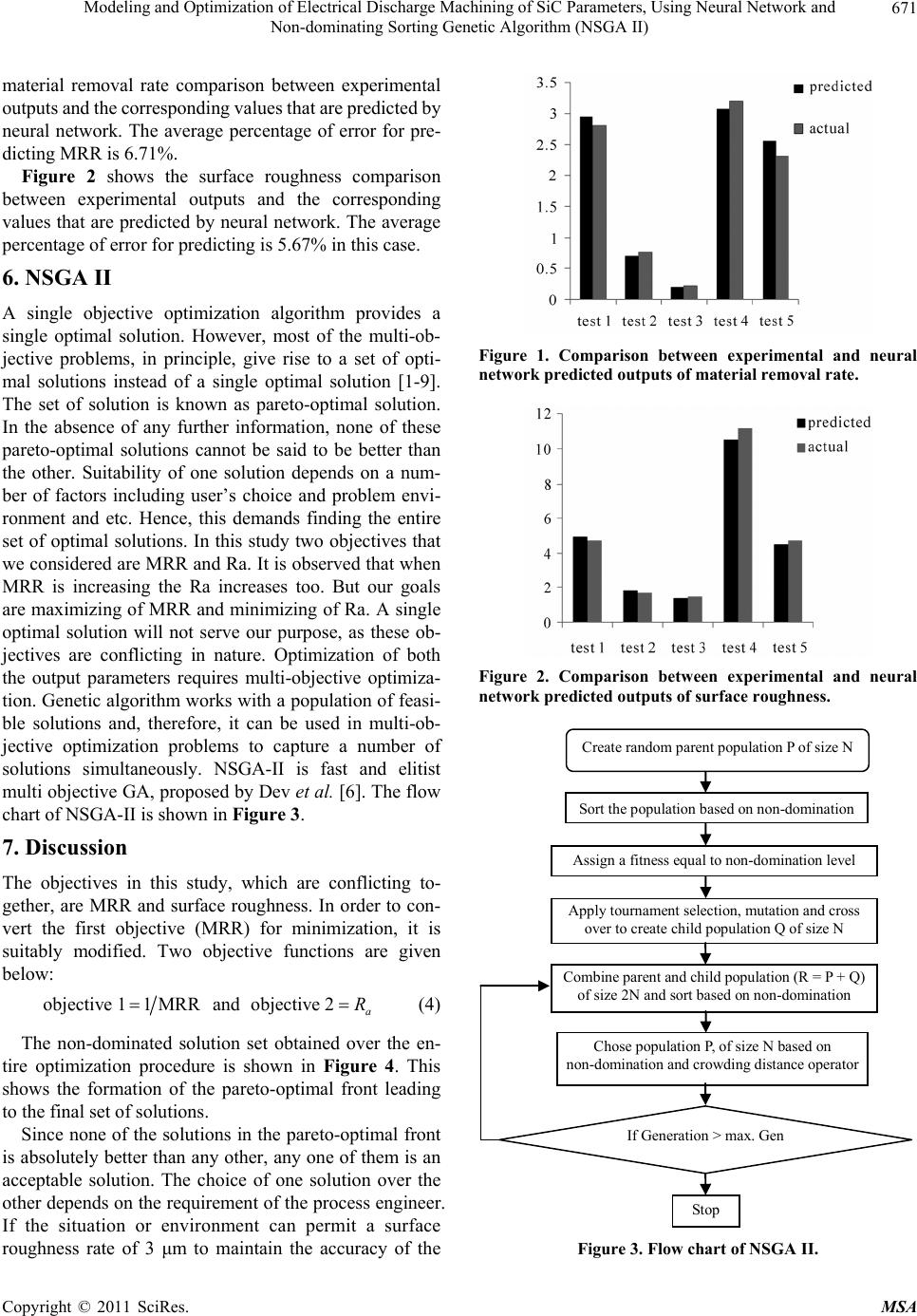

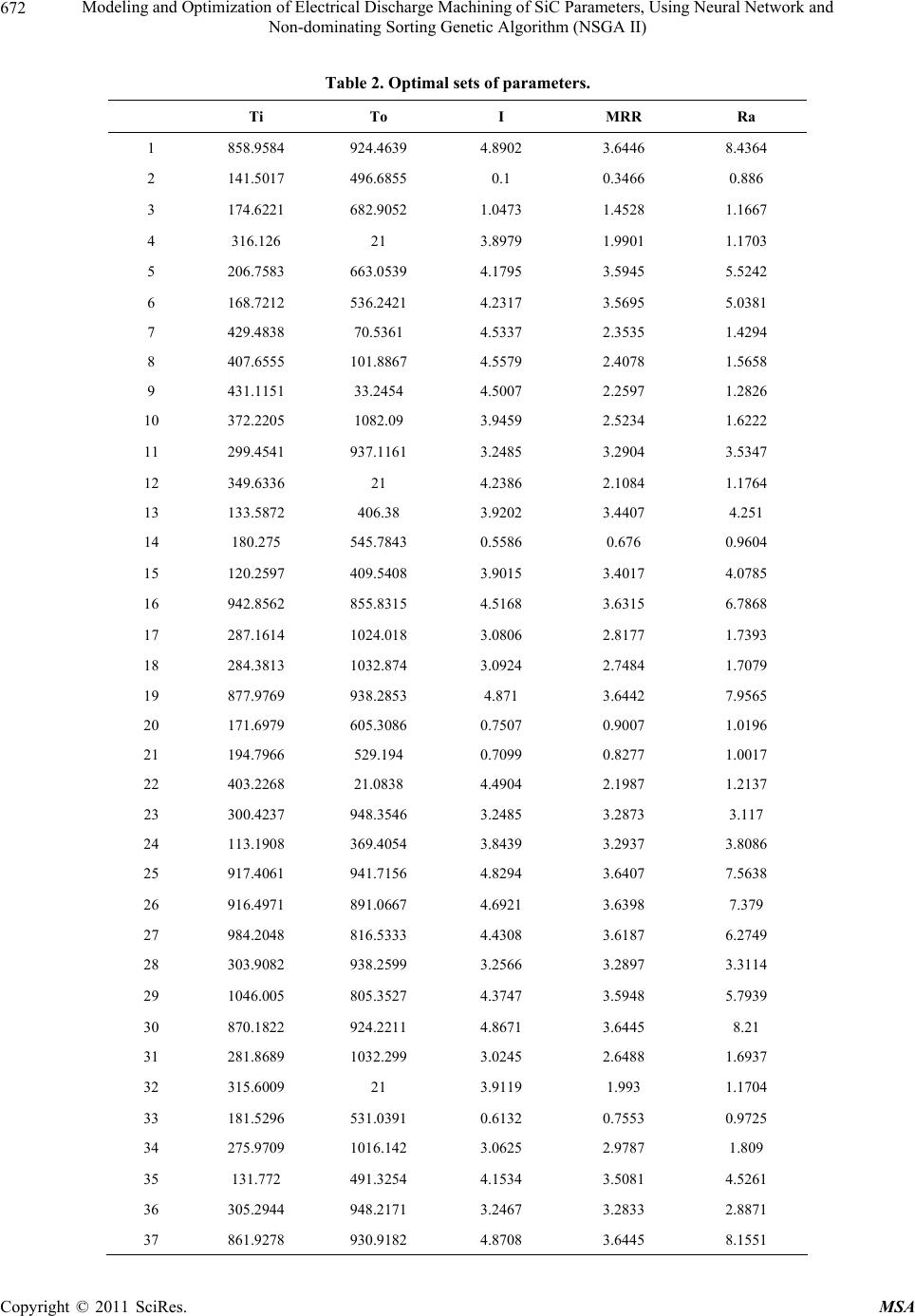

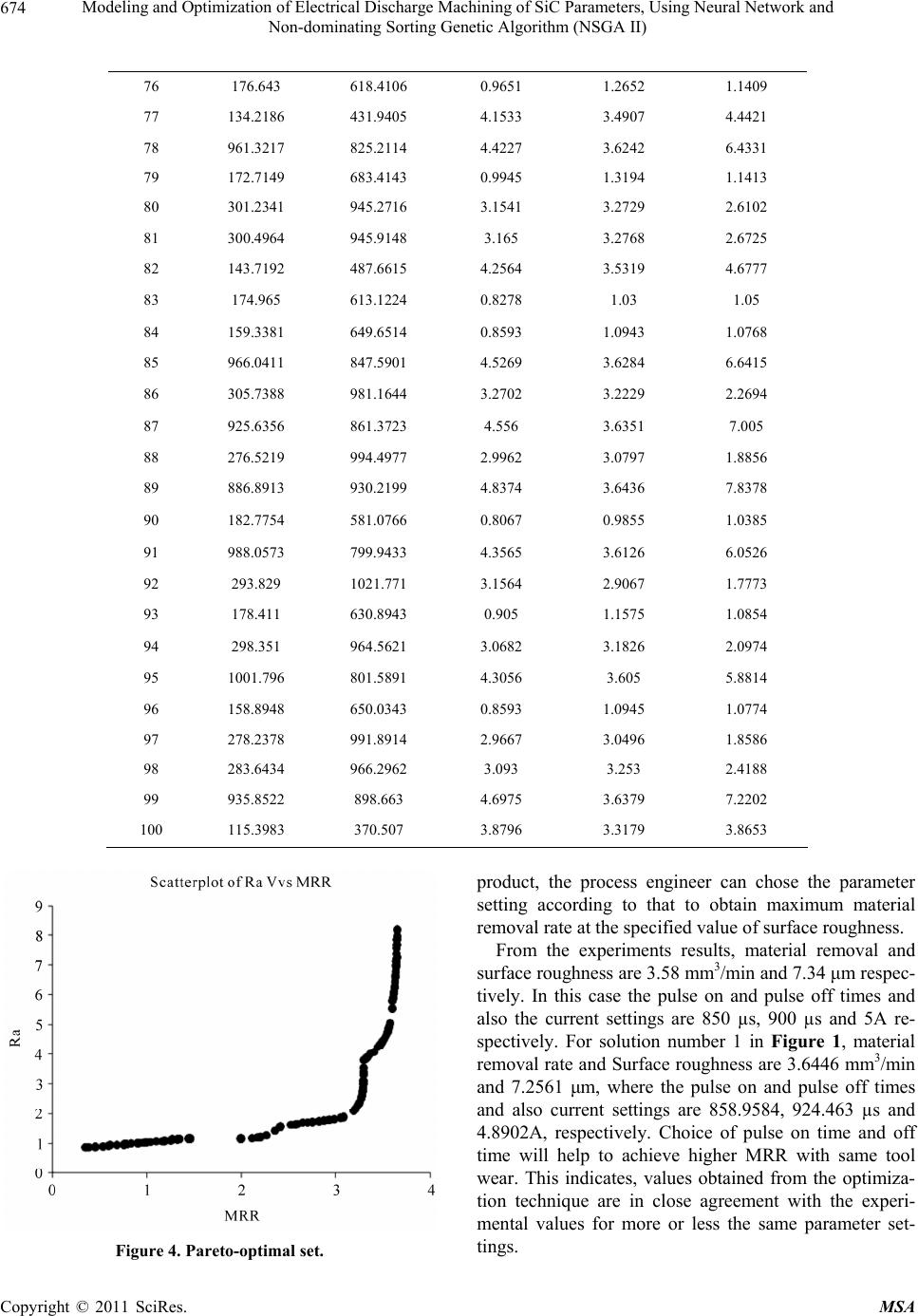

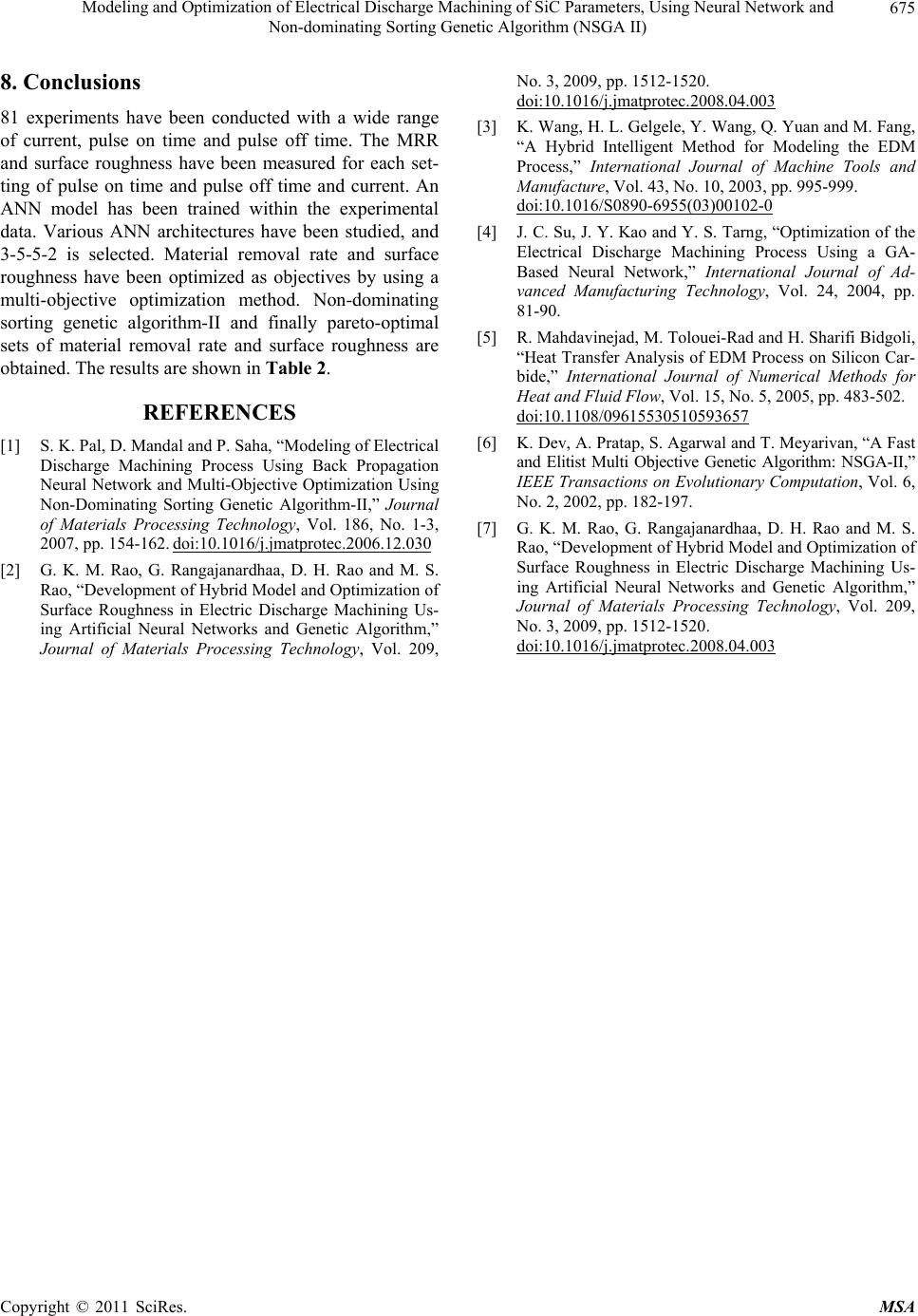

Materials Sciences and Applicatio ns, 2011, 2, 669-675 doi:10.4236/msa.2011.26092 Published Online June 2011 (http://www.SciRP.org/journal/msa) Copyright © 2011 SciRes. MSA 669 Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and Non-dominating Sorting Genetic Algorithm (NSGA II) Ramezan Ali MahdaviNejad School of mechanical Engineering, College of Engineering, University of Tehran, Tehran, Iran. Email: mahdavin@ut.ac.ir Received December 29th, 2010; revised March 28th, 2011; accepted May 18th, 2011. ABSTRACT Silicon Carbide (SiC) machining by traditional methods with regards to its high hardness is not possible. Electro Dis- charge Machining, among non-tradition al machining methods, is used for machining of SiC. The pr esent work is aimed to optimize the surface roughness and material removal rate of electro discharge machining of SiC parameters simul- taneously. As the output parameters are conflicting in nature, so there is no single combination of machining parame- ters, which provides the best ma ch ining p erforman ce. Artificia l n eural network (ANN) with ba c k pr opa gatio n a lgo rithm is used to model the process. A multi-objective optimization method, non-dominating sorting genetic algorithm-II is used to optimize the process. Affects of three important input parameters of process viz., discharge current, pulse on time (Ton), pulse off time (Toff) on electric discharge machining o f SiC are considered . Exp erim ents have b een condu cted over a wide range of considered input parameters for training and verification of the model. Testing results demon- strate that the model is suitable fo r predicting the response parameters. A pareto-optima l set has been predicted in this work. Keywords: Electro Discharge Machining, Non- Dominating Sorting Algorithm, Neural Network, REFEL SiC 1. Introduction Electrical discharge machining (EDM) is one of the most extensively used non-conventional material removal process. Its unique feature of using thermal energy to machine electrically conductive parts regardless of hard- ness has been its distinctive advantage in the manufac- ture of mould, die, automotive, aerospace and surgical component [1]. The selection of appropriate parameters for maximum material removal rate and minimum sur- face roughness during the EDM process traditionally carried out by the operator’s experience or conservative technological data provided by the EDM equipment manufacturers, which produced inconsistent machining performance.[2] Some researchers carried out various investigations to improve the stock material removal rate and surface fin- ishing in EDM process. Proper selection of machining parameters for the best process performance is still a challenging job. Wang et al. [3] used genetic algorithm (GA) with arti- ficial neural network (ANN) to find out optimal main output parameters such as material removal rate and sur- face roughness. They used ANN to model the process and Hunter Software to solve multi-objective optimiza- tion problem. Using ANN and GA, Su et al. [4] opti- mized EDM parameters, roughing and finishing machin- ing stages. They utilized artificial neural network to es- tablish the relationship between the process parameters and outputs. GA with properly defined objective func- tions was then adapted to the neural network to deter- mine the optimal process parameters. They transformed material removal rate, tool wear and surface roughness into a single objective. Rao et al. [7] used ANN and GA to optimize the surface roughness of die sinking electric discharge machining (EDM) by considering the simulta- neous affect of various input parameters. Genetic algo- rithm concept was used to optimize the weighting factors  Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and 670 Non-dominating Sorting Genetic Algorithm (NSGA II) of the network. Pal et al. [1] used non dominating sorting genetic al- gorithm-II to optimize the process. They conducted some experiments on C40 Steel to generate input and output data for training an ANN model. Material removal rate and tool wear were two objectives to be optimized. So they predicted a pareto-optimal set for outputs. In this study material removal rate and surface rough- ness have been considered to produce a pareto-optimal set for EDM of REFEL SiC. Some related properties of this material are shown in Table 1. 2. Experimentations In this study, Deckel CNC Spark, ISO frequency system, with gap control system was used to carry out the ex- periments. Copper electrode was selected to drill holes in the REFEL SiC blocks. For evaluating the EDM process the MRR and surface roughness (Ra) are mentioned with input machining parameters such as pulse on time (Ton), pulse off time (Toff), discharge current (I). Proper selec- tion of the machining parameters can result a higher ma- terial removal rate and lower Ra. Using an orthogonal array L25 according Taguchi method decreased the num- ber experiments effectively. Hence 25 sets of experi- ments have been conducted with five levels of each pa- rameter (current, pulse on time and off time) to collect for training of the neural network model. Moreover five sets of experiments have been for testing the trained neural network. For each experiment, a new set of tool and work-piece has been used. For normal polarity the work-piece is connected to the negative terminal and the tool is connected to the positive terminal of the source, where as for reverse polarity it is just the opposite. Ex- periment has been performed with normal polarity. The current range is 0.1 - 5 A and the pulse on time and pulse off time ranges are 21 - 1125 µs. 3. Material Removal Rate (MRR) Material removal rate and surface roughness have been used to evaluate machining performance. Material re- moval rate (MRR) is calculated from the difference of weight of work piece before and after experiment. SiC MRR if ww t mm3/min (1) where, wi is the initial weight of workpiece in g; wf the weight of workpiece after machining in g; t the machin- ing time in minutes; SiC is the density of SiC (3.1× 10–3 g/mm3). 4. Surface Roughness The surface roughness Ra is the arithmetic average of collected roughness data points and given by the sum of the absolute values of all the areas above and below the mean line (in integrally form). A mean line is found that is parallel to the general surface direction and divides the surface in such a way that the sum of the areas formed above the line is equal to the sum of the areas formed below the line. When sample points were taken, R a is calculated as follows: 1 1n a i R n i y (2) where yi is the distance between the ith sample point on the profile from the mean line, and n is the number of sample points. 5. Neural Network Modeling of EDM with feed forward neural network is composed of two stages: training and testing of the net- work with experimental machining data. The scale of the input and output data is an important matter to consider, especially, when the operating ranges of process pa- rameters are different. The scaling or normalization en- sures that the ANN will be trained effectively. By searching in different network architectures using a MATLAB code, multilayer-perceptron (3-5-5-2) was chosen as the network architecture. The networks were trained using a back-propagation algorithm. The selected network architecture had the minimum value of the error. The error E indicates the difference between the actual and the desired output of the neural network, as follows: 2 1min az jj j Eya (3) where yj is the desired output, aj is the calculated output, az the number of testing data. Five sets of experiments allocated to test the network’s error value. Pulse on-time, pulse off-time and the current are the inputs of neural network and material removal rate and surface roughness are the outputs of the neural network. Figure 1 shows the Table1. Some characteristics of REFEL SiC [5]. Density (gr/cm3) Hardness (HV) Young modulus (E) (GN/m) Thermal expansion 1 × 10–6˚C Thermal conductivity (k) at 100˚C (W/m·˚C) at 1200˚C Specific heat (J/g˚C) Electrical resistance (Ω·cm) Thermal shock (cal/cm·s) at 500˚C 3.10 2500 413 4.3 83.6 38.9 670.710 0.42 (at 25˚C) 0.016 (at 1200˚C) 59 Copyright © 2011 SciRes. MSA  Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and 671 Non-dominating Sorting Genetic Algorithm (NSGA II) material removal rate comparison between experimental outputs and the corresponding values that are predicted by neural network. The average percentage of error for pre- dicting MRR is 6.71%. Figure 2 shows the surface roughness comparison between experimental outputs and the corresponding values that are predicted by neural network. The average percentage of error for predicting is 5.67% in this case. 6. NSGA II A single objective optimization algorithm provides a single optimal solution. However, most of the multi-ob- jective problems, in principle, give rise to a set of opti- mal solutions instead of a single optimal solution [1-9]. The set of solution is known as pareto-optimal solution. In the absence of any further information, none of these pareto-optimal solutions cannot be said to be better than the other. Suitability of one solution depends on a num- ber of factors including user’s choice and problem envi- ronment and etc. Hence, this demands finding the entire set of optimal solutions. In this study two objectives that we considered are MRR and Ra. It is observed that when MRR is increasing the Ra increases too. But our goals are maximizing of MRR and minimizing of Ra. A single optimal solution will not serve our purpose, as these ob- jectives are conflicting in nature. Optimization of both the output parameters requires multi-objective optimiza- tion. Genetic algorithm works with a population of feasi- ble solutions and, therefore, it can be used in multi-ob- jective optimization problems to capture a number of solutions simultaneously. NSGA-II is fast and elitist multi objective GA, proposed by Dev et al. [6]. The flow chart of NSGA-II is shown in Figure 3. 7. Discussion The objectives in this study, which are conflicting to- gether, are MRR and surface roughness. In order to con- vert the first objective (MRR) for minimization, it is suitably modified. Two objective functions are given below: objective 11MRR and o (4) bjective 2a R The non-dominated solution set obtained over the en- tire optimization procedure is shown in Figure 4. This shows the formation of the pareto-optimal front leading to the final set of solutions. Since none of the solutions in the pareto-optimal front is absolutely better than any other, any one of them is an acceptable solution. The choice of one solution over the other depends on the requirement of the process engineer. If the situation or environment can permit a surface roughness rate of 3 μm to maintain the accuracy of the Figure 1. Comparison between experimental and neural network predicted outputs of material removal rate. Figure 2. Comparison between experimental and neural network predicted outputs of surface roughness. Apply tournament selection, mutation and cross over to create child population Q of size N Create random parent population P of size N Assign a fitness equal to non-domination level Sort the population based on non-domination Combine parent and child population (R = P + Q) of size 2N and sort based on non-domination Chose population P, of size N based on non-domination and crowding distance operator If Generation > max. Gen Stop Figure 3. Flow chart of NSGA II. Copyright © 2011 SciRes. MSA  Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and 672 Non-dominating Sorting Genetic Algorithm (NSGA II) Table 2. Optimal sets of parameters. Ti To I MRR Ra 1 858.9584 924.4639 4.8902 3.6446 8.4364 2 141.5017 496.6855 0.1 0.3466 0.886 3 174.6221 682.9052 1.0473 1.4528 1.1667 4 316.126 21 3.8979 1.9901 1.1703 5 206.7583 663.0539 4.1795 3.5945 5.5242 6 168.7212 536.2421 4.2317 3.5695 5.0381 7 429.4838 70.5361 4.5337 2.3535 1.4294 8 407.6555 101.8867 4.5579 2.4078 1.5658 9 431.1151 33.2454 4.5007 2.2597 1.2826 10 372.2205 1082.09 3.9459 2.5234 1.6222 11 299.4541 937.1161 3.2485 3.2904 3.5347 12 349.6336 21 4.2386 2.1084 1.1764 13 133.5872 406.38 3.9202 3.4407 4.251 14 180.275 545.7843 0.5586 0.676 0.9604 15 120.2597 409.5408 3.9015 3.4017 4.0785 16 942.8562 855.8315 4.5168 3.6315 6.7868 17 287.1614 1024.018 3.0806 2.8177 1.7393 18 284.3813 1032.874 3.0924 2.7484 1.7079 19 877.9769 938.2853 4.871 3.6442 7.9565 20 171.6979 605.3086 0.7507 0.9007 1.0196 21 194.7966 529.194 0.7099 0.8277 1.0017 22 403.2268 21.0838 4.4904 2.1987 1.2137 23 300.4237 948.3546 3.2485 3.2873 3.117 24 113.1908 369.4054 3.8439 3.2937 3.8086 25 917.4061 941.7156 4.8294 3.6407 7.5638 26 916.4971 891.0667 4.6921 3.6398 7.379 27 984.2048 816.5333 4.4308 3.6187 6.2749 28 303.9082 938.2599 3.2566 3.2897 3.3114 29 1046.005 805.3527 4.3747 3.5948 5.7939 30 870.1822 924.2211 4.8671 3.6445 8.21 31 281.8689 1032.299 3.0245 2.6488 1.6937 32 315.6009 21 3.9119 1.993 1.1704 33 181.5296 531.0391 0.6132 0.7553 0.9725 34 275.9709 1016.142 3.0625 2.9787 1.809 35 131.772 491.3254 4.1534 3.5081 4.5261 36 305.2944 948.2171 3.2467 3.2833 2.8871 37 861.9278 930.9182 4.8708 3.6445 8.1551 Copyright © 2011 SciRes. MSA  Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and 673 Non-dominating Sorting Genetic Algorithm (NSGA II) 38 119.1833 477.8889 4.0229 3.4609 4.3141 39 376.0995 24.0189 4.3534 2.1632 1.1971 40 173.1123 685.8219 1.0394 1.4358 1.1631 41 284.2434 1035.765 3.0867 2.6966 1.6946 42 286.2831 1021.49 3.0881 2.8707 1.7557 43 148.4211 482.6119 0.1 0.3784 0.886 44 298.755 937.8997 3.1764 3.2873 3.0139 45 308.5639 948.8102 3.1985 3.2631 2.5244 46 366.4247 1078.362 3.9262 2.593 1.6522 47 996.3369 816.5368 4.4229 3.6152 6.1633 48 115.4423 368.0682 3.9275 3.3269 3.8915 49 168.5636 634.8079 0.9029 1.183 1.095 50 176.8979 645.9134 0.9506 1.2511 1.1102 51 172.9696 685.0409 1.0058 1.3451 1.1468 52 304.4127 946.2207 3.2116 3.2803 2.772 53 157.1823 527.6218 4.3731 3.5523 4.8573 54 925.4805 861.5791 4.5397 3.6341 6.9647 55 149.998 493.2173 4.2715 3.5425 4.7609 56 306.9045 981.8667 3.249 3.2036 2.1755 57 302.2196 938.9002 3.2589 3.2901 3.3997 58 908.0573 923.543 4.8141 3.6424 7.6703 59 927.5109 896.1882 4.6304 3.6355 7.13 60 113.3054 371.2426 4.1168 3.36 4.0045 61 163.5354 448.252 0.1 0.4499 0.8898 62 161.4533 546.5079 4.2317 3.5642 4.9386 63 175.078 447.2047 0.3503 0.5919 0.9336 64 190.6357 418.0032 0.4155 0.6059 0.9571 65 184.3604 585.3931 0.7912 0.9543 1.0309 66 968.7002 849.109 4.5269 3.6279 6.6203 67 138.972 500.3413 4.1505 3.5256 4.6216 68 179.8468 438.7951 0.2235 0.5309 0.9089 69 305.3556 971.6719 3.2454 3.2423 2.3567 70 285.3319 1012.133 3.0527 2.9273 1.7853 71 133.0257 431.1921 4.0818 3.4829 4.3986 72 959.5319 825.0148 4.421 3.6244 6.4444 73 183.5624 532.4206 0.6413 0.7817 0.9806 74 368.9871 1078.629 3.9218 2.5689 1.6401 75 1009.683 804.5483 4.4012 3.6083 6.0169 Copyright © 2011 SciRes. MSA  Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and Non-dominating Sorting Genetic Algorithm (NSGA II) Copyright © 2011 SciRes. MSA 674 76 176.643 618.4106 0.9651 1.2652 1.1409 77 134.2186 431.9405 4.1533 3.4907 4.4421 78 961.3217 825.2114 4.4227 3.6242 6.4331 79 172.7149 683.4143 0.9945 1.3194 1.1413 80 301.2341 945.2716 3.1541 3.2729 2.6102 81 300.4964 945.9148 3.165 3.2768 2.6725 82 143.7192 487.6615 4.2564 3.5319 4.6777 83 174.965 613.1224 0.8278 1.03 1.05 84 159.3381 649.6514 0.8593 1.0943 1.0768 85 966.0411 847.5901 4.5269 3.6284 6.6415 86 305.7388 981.1644 3.2702 3.2229 2.2694 87 925.6356 861.3723 4.556 3.6351 7.005 88 276.5219 994.4977 2.9962 3.0797 1.8856 89 886.8913 930.2199 4.8374 3.6436 7.8378 90 182.7754 581.0766 0.8067 0.9855 1.0385 91 988.0573 799.9433 4.3565 3.6126 6.0526 92 293.829 1021.771 3.1564 2.9067 1.7773 93 178.411 630.8943 0.905 1.1575 1.0854 94 298.351 964.5621 3.0682 3.1826 2.0974 95 1001.796 801.5891 4.3056 3.605 5.8814 96 158.8948 650.0343 0.8593 1.0945 1.0774 97 278.2378 991.8914 2.9667 3.0496 1.8586 98 283.6434 966.2962 3.093 3.253 2.4188 99 935.8522 898.663 4.6975 3.6379 7.2202 100 115.3983 370.507 3.8796 3.3179 3.8653 product, the process engineer can chose the parameter setting according to that to obtain maximum material removal rate at the specified value of surface roughness. From the experiments results, material removal and surface roughness are 3.58 mm3/min and 7.34 μm respec- tively. In this case the pulse on and pulse off times and also the current settings are 850 µs, 900 µs and 5A re- spectively. For solution number 1 in Figure 1, material removal rate and Surface roughness are 3.6446 mm3/min and 7.2561 μm, where the pulse on and pulse off times and also current settings are 858.9584, 924.463 µs and 4.8902A, respectively. Choice of pulse on time and off time will help to achieve higher MRR with same tool wear. This indicates, values obtained from the optimiza- tion technique are in close agreement with the experi- mental values for more or less the same parameter set- tings. Figure 4. Pareto-optimal set.  Modeling and Optimization of Electrical Discharge Machining of SiC Parameters, Using Neural Network and 675 Non-dominating Sorting Genetic Algorithm (NSGA II) 8. Conclusions 81 experiments have been conducted with a wide range of current, pulse on time and pulse off time. The MRR and surface roughness have been measured for each set- ting of pulse on time and pulse off time and current. An ANN model has been trained within the experimental data. Various ANN architectures have been studied, and 3-5-5-2 is selected. Material removal rate and surface roughness have been optimized as objectives by using a multi-objective optimization method. Non-dominating sorting genetic algorithm-II and finally pareto-optimal sets of material removal rate and surface roughness are obtained. The results are shown in Table 2. REFERENCES [1] S. K. Pal, D. Mandal and P. Saha, “Modeling of Electrical Discharge Machining Process Using Back Propagation Neural Network and Multi-Objective Optimization Using Non-Dominating Sorting Genetic Algorithm-II,” Journal of Materials Processing Technology, Vol. 186, No. 1-3, 2007, pp. 154-162. doi:10.1016/j.jmatprotec.2006.12.030 [2] G. K. M. Rao, G. Rangajanardhaa, D. H. Rao and M. S. Rao, “Development of Hybrid Model and Optimization of Surface Roughness in Electric Discharge Machining Us- ing Artificial Neural Networks and Genetic Algorithm,” Journal of Materials Processing Technology, Vol. 209, No. 3, 2009, pp. 1512-1520. doi:10.1016/j.jmatprotec.2008.04.003 [3] K. Wang, H. L. Gelgele, Y. Wang, Q. Yuan and M. Fang, “A Hybrid Intelligent Method for Modeling the EDM Process,” International Journal of Machine Tools and Manufacture, Vol. 43, No. 10, 2003, pp. 995-999. doi:10.1016/S0890-6955(03)00102-0 [4] J. C. Su, J. Y. Kao and Y. S. Tarng, “Optimization of the Electrical Discharge Machining Process Using a GA- Based Neural Network,” International Journal of Ad- vanced Manufacturing Technology, Vol. 24, 2004, pp. 81-90. [5] R. Mahdavinejad, M. Tolouei-Rad and H. Sharifi Bidgoli, “Heat Transfer Analysis of EDM Process on Silicon Car- bide,” International Journal of Numerical Methods for Heat and Fluid Flow, Vol. 15, No. 5, 2005, pp. 483-502. doi:10.1108/09615530510593657 [6] K. Dev, A. Pratap, S. Agarwal and T. Meyarivan, “A Fast and Elitist Multi Objective Genetic Algorithm: NSGA-II,” IEEE Transactions on Evolutionary Computation, Vol. 6, No. 2, 2002, pp. 182-197. [7] G. K. M. Rao, G. Rangajanardhaa, D. H. Rao and M. S. Rao, “Development of Hybrid Model and Optimization of Surface Roughness in Electric Discharge Machining Us- ing Artificial Neural Networks and Genetic Algorithm,” Journal of Materials Processing Technology, Vol. 209, No. 3, 2009, pp. 1512-1520. doi:10.1016/j.jmatprotec.2008.04.003 Copyright © 2011 SciRes. MSA |