Harvest Residue Study of Fungicide Tebuconazole EC Formulation in Groundnut and Paddy425

sprayer equipped with WFN 40 nozzle @ 750 mLha–1

(T1) and @ 1500 mLha–1 (T2) in Randomized Block

Designed (RBD) plots and maintained untreated control

(T3) plots. Three replications were used for each

treatment. The area of every plot was 20 m2. Spraying of

fungicide was done twice at 15 days interval both for

paddy and groundnut.

2.1. Collection of Samples and Processing

Different substrates of groundnut (groundnut cropped

soil, groundnut plant and groundnut) were collected at

the time of harvest following standard sampling

procedures. Also different substrates of paddy (paddy

plant and paddy cropped soil) were collected at the time

of harvest following the same procedure. Groundnut

plant, paddy plant, groundnut (0.10 kg) and field soil

(0.25 kg) samples were collected from 5 - 7 places

randomly from each treatment plots. Samples from

untreated control plots were also collected in the same

way. Soil samples were collected from a depth of 6″ with

the help of soil auger.

3. Residue Analysis

3.1. Extraction and Clean Up of Samples

Plant samples ( Paddy stra w/Paddy g rain/Hu sk/Ground-

nut plant):

The samples were blended using Polytron homogen-

izer. In each case five gram (5 g) of the homogenized

sample was taken in a 50 mL centrifuge tube and 10 mL

(Ethyl Acetate: Cyclohexane = 9:1) mixture was added

and subjected to vortex for 2 min. After that added 5 gm

of activated Na2SO4, the sample was again vortex for

3 min. Then the sample was centrifuged for 15 min at

10,000 rpm and then 5 ml supernatant liquid was taken in

10 ml centrifuge tube. Afterwards 25 mg florisil & 25 mg

PSA was added to it and vortex for 2 min and the sample

was again centrifuged for 10 min at 5000 rpm. Then 3 ml

supernatant liquid was collected from it and evaporated

to dryness in a N2–Evaporator at 25˚C. The residue was

then reconstituted in 3 ml of [MeOH: H2O (9:1, v/v) + 5 mM

CH3COONH4] and subsequently filtered through 0.2 µ

membrane filter. Now the sample is ready for the final

analysis with LC-MS/MS.

Groundnut Oi l:

Deshelled groundnut sample (50 g) was grinded in a

grinder and was subjected to Soxhlet extraction with 150

mL of hexane for 6 hours. The extracted oil was

collected and the rest portion (deoil cake) was kept

separately. The hexane extract was concentrated in rotary

vacuum evaporator below 40˚C. The oil thus obtained

was collected and from it 1 g of oil was weighed and was

subjected to extraction. The oil taken was redissolved in

100 mL of hexane and was partitioned thrice (100 + 50 +

50) with acetonitrile. The acetonitrile fraction was

collected over anhydrous Na2SO4 and the organic phase

was evaporated in a rotary vacuum evaporator below

40˚C and was subjected to column clean up. The oil

sample thus obtained was cleaned up using silica gel

column conditioned with hexane. The sample was

applied in the column and kept for 15 min. It was then

eluted with 50 mL hexane and discarded. Then 100 mL

toluene was passed through the column and the fraction

was collected and concentrated in a rotary vacuum

evaporator below 40˚C. Finally, it was reconstituted with

[MeOH: H2O (9:1, v/v) + 5mM CH3COONH4] which is

ready for analysis in LC-MS/MS.

Groundnut Deoil cake:

The deoil cake (10 g) obtained from the oil extraction

step was analysed by following same procedure as

described for groundnut plant samples.

Soil (Both paddy and groundnut cropped soil):

Five gram (5 g) soil was taken in a 50 mL centrifuge

tube & similar method as mentioned in plant samples

was followed.

Instrumentatal Parameters:

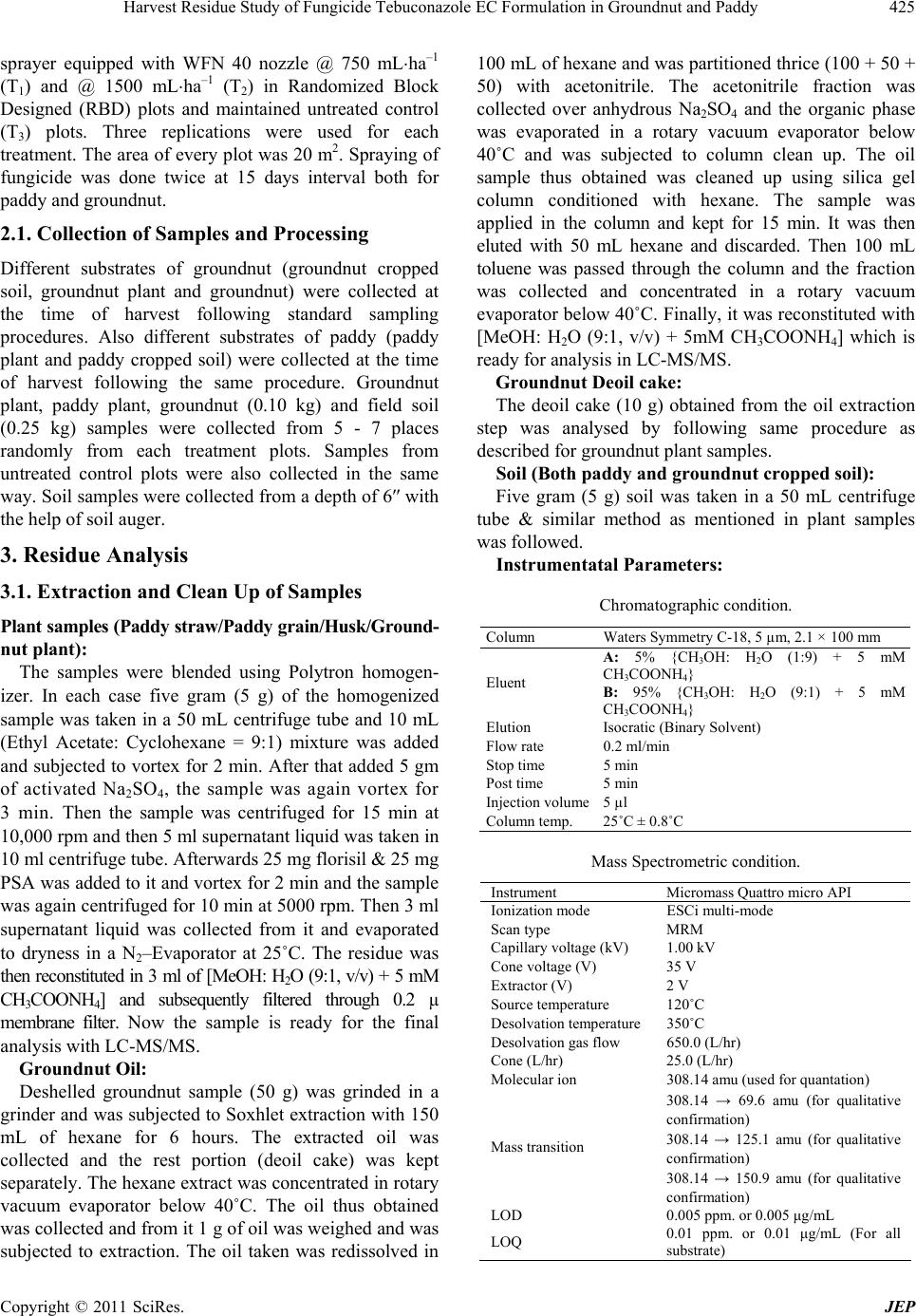

Chromatographic condition.

Column Waters Symmetry C-18, 5 µm, 2.1 × 100 mm

Eluent

A: 5% {CH3OH: H2O (1:9) + 5 mM

CH3COONH4}

B: 95% {CH3OH: H2O (9:1) + 5 mM

CH3COONH4}

Elution Isocratic (Binary Solvent)

Flow rate 0.2 ml/min

Stop time 5 min

Post time 5 min

Injection volume5 µl

Column temp. 25˚C ± 0.8˚C

Mass Spectrometric condition.

Instrument Micromass Quattro micro API

Ionization mode ESCi multi-mode

Scan type MRM

Capillary voltage (kV) 1.00 kV

Cone voltage (V) 35 V

Extractor (V) 2 V

Source temperature 120˚C

Desolvation temperature 350˚C

Desolvation gas flow 650.0 (L/hr)

Cone (L/hr) 25.0 (L/hr)

Molecular ion 308.14 amu (used for quantation)

Mass transition

308.14 → 69.6 amu (for qualitative

confirmation)

308.14 → 125.1 amu (for qualitative

confirmation)

308.14 → 150.9 amu (for qualitative

confirmation)

LOD 0.005 ppm. or 0.005 μg/mL

LOQ 0.01 ppm. or 0.01 μg/mL (For all

substrate)

Copyright © 2011 SciRes. JEP