Engineering, 2011, 3, 470-477 doi:10.4236/eng.2011.35054 Published Online May 2011 (http://www.SciRP.org/journal/eng) Copyright © 2011 SciRes. ENG Evaluation of Energy Consumption for Heating of Industrial Building in-Situ Dušan Katunský1, Azra Korjenic2, Jana Katunská1, Martin Lopušniak1 1Technical University of Košice, Faculty of Civil Engineering, Košice, Slovakia 2Vienna University of Technology, Institute for Building Construction and Technology, Research Center of Building Physics and Sound Protection, Vienna, Austria E-mail: jana.katunska@tuke.sk, dusan.katunsky@tuke.sk, martin.lopusniak@tuke.sk, azra.korjenic@tuwien.ac.at Received March 15, 2011; revised March 30, 2011; accepted April 18, 2011 Abstract Because of the high energy demand required to heat a production hall, the aim of this project is to find out whether it is possible to verify the heating consuming process for heating with the standard simplified calcu- lation method [1], especially for cold regions such as Kosice (Slovakia). The energy requirement for heating a case study industrial building was evaluated using measurements and calculations. During the winter pe- riod, energy consumption was measured in the selected industrial building according to a validation standard [2]. The building is comprised of two halls. The measurements were analyzed according to the criteria used for validating residential and public buildings, with several regression dependencies taken into account in the resulting evaluation of heating energy consumption. The mathematical dependencies of measured values in real conditions are shown in this paper. In addition, the building’s heating energy demand was calculated according to the Austrian standard [3], ÖNORM EN ISO 13790, the simplified calculation method for non-residential buildings. It was investigated whether the measured values could be replicated using this calculation. It was found that the precise definition of the internal heat gains is very important. Keywords: Industrial Buildings, Heating Energy Consumption, Production Halls, In-Situ Measurements, Envelope Structures 1. Introduction For decades, increasing productivity was the ultimate goal of industrial engineering. Because of additional ex- ternal demands such as public pressure to minimize CO2 emissions and rising energy costs, energy efficiency has become an increasingly important topic in industrial en- gineering [4]. Recently, many companies have been streamlining the economical and intelligent use of elec- tricity and heat to reduce costs and thereby increase their competitiveness. Despite increasingly stringent energy conservation requirements in all another sectors, new factories are only required to meet minimum pre-registered U-values of the building envelope in both Austria and Slovakia. There are no official programs in place for energy certi- fication of industrial buildings and energy certificates are not required by law for this building type. According to workplace regulations, specific internal climate conditions must be met. Space heating in indus- trial halls runs constantly in most buildings. The aim of this joint project between TU Kosice and TU Vienna was to evaluate the heating energy consumption using meas- urements and calculations applied to the case study of an industrial building with two production halls. The goal was to determine whether the energy consumption for heating can be approximated using the simplified method. The results will determine if the heating energy demand can be easily calculated for all new factories and renova- tion projects, and if the building envelope may be rapidly optimized. The motivation of this project was the high heating energy consumption for production halls, especially in cold regions like Kosice. In Slovakia, there are no ex- plicit heating energy measurement or calculation stan- dards for industrial production facilities. The first part of the analysis deals with in-situ measurements in an indus- trial hall, applying standard Slovak heating calculations for residential buildings [5], [6]. The intended results are to establish the mathematical dependencies of measured  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 471 values in real conditions. In the second part, the heating energy demand of the building was calculated according to the Austrian simplified method of ÖNORM EN ISO 13790 for non-residential buildings. The heating energy consumption of the selected pro- duction facilities was evaluated using measurements and calculations. During the winter period, heating energy consumption was measured in-situ in the chosen build- ings. The measurements were evaluated according to criteria valid for residential and public buildings, with several regression dependencies taken into consideration in the resultant evaluation of heating energy consumption. Many calculation methods exist for measuring energy consumption of residential buildings. It is also possible to perform on-site measurements of the energy consump- tion of residential buildings. 2. Requirements for Monitoring in-Situ Energy Consumption The halls were monitored in compliance with the Slovak Standard, STN 73 0550 [2]. This standard outlines bind- ing preconditions for of resulted values of energy con- sumption on the heat exchanger before entering into a building (usually at the base of a house). The purpose of this standard is to verify the operative energy required for all residential building types, outlining the same as- sumptions for internal conditions. In industrial buildings, the occupancy and uses are different. For this reason, another task was to assess the extent that the binding criteria for the energy consumption measurements are applicable to industrial factory assessments. Some ex- amples with the analysis of energy use in industrial sec- tor was published in [7,8]. 3. Building Construction of Selected Industrial Halls The halls were monitored within the framework of a grant research project. The investigation was conducted in one industrial building with two production halls. Each hall contains development workshops, one classi- fied as light industrial, and the other semi-heavy indus- trial [9]. The main structural system of both halls is de- signed as steel-concrete skeleton. One hall dimension is 36 m (6 × 6 meters), with an 18m span; the overall height of the industrial building is 7 m. See Figure 1. The hall envelope is 375 mm thick composed of “CDm” bricks and lime mortar. Glazed elements are comprised of single-paned glazed walls with wire-insert Figure 1. Location plan and sections of the industrial halls.  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 472 reinforcement and single paned skylights with wire-insert reinforcement, with steel framing. In one hall, the transparent constructions have a southern orientation, in the other, a northern orientation. Location plan and sections of the two industrial halls, and the data logger locations are presented in Figure 1. The two halls are connected via an office building. The building envelopes of the halls were reconstructed and heat energy demand calculated in the ESP-r simula- tion program, Figure 2. 3. Monitoring Conditions Energy consumption was monitored from December 23rd, 2009 to January 24th, 2010 for a total of 32 days. The halls were measured during the winter period when exte- rior air temperatures were below zero. This duration was chosen as standard STN 73 0550 [2] states that the measurement interval must be over 30 days. The internal and external climate parameters were recorded with av- erage daily interior and exterior air temperatures for both halls. The interior air temperature was measured at seven heights, in the middle of the considered operation, which is not in compliance with the requirement for a sensor to measure a maximum space of 50 m2. Determining gener- ally valid calculation criteria of the average daily interior temperature of an industrial hall is difficult, in view of the fact that the dynamics of the temperature parameters in the space is very high, e.g. in horizontal and vertical axes. The hall interior is shown in Figure 3. The total heating energy consumption measured dur- ing operation is an attempt to evaluate the validity of the binding criteria for measuring energy consumption on-site for industrial operations. 4. Results of Site Measurements According to the Standards The heating energy consumption values were obtained from the Kosice heat exchanger station N.1607 and are given in Table 1. 5. Calculations According to the Austrian Standards At present, there is no regulation that requires an energy certificate for industrial buildings. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 requires that, “Member States may decide not to set or apply the re- quirements of improvement of the energy performance of buildings to the following categories of buildings: (c) temporary buildings with a time of use of two years or less, industrial sites etc. The heating and cooling needs of a building / building elements in Austria are calculated in accordance with ÖNORM EN ISO 13790 [3] using the monthly balance method. The energy certificate, i.e., the monthly heating Figure 2. Simulation model of one industrial hall.  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 473 Figure 3. View into hall interior. demands, are required to be calculated only for non- residential buildings listed in Table 2. For non-residential buildings, the heat gain from lighting is identified and separated from heat transmitted by people and equipment. Table 2 shows the typical values for the internal gain from appliances and persons, and the typical electrical lighting output for non-residential buildings following Austrian standard ÖNORM B 8110-6. The two industrial halls were calculated following the Austrian monthly balance method using the typical val- ues from other non-residential building types: convention centres, sports arenas, or retail. The results are presented in Table 5. 6. Evaluation of Measured and Calculated Values The measurements have been evaluated by validated calculation relations for the monitoring period per day, i.e., for 32 points [2]. An alternative evaluation has been conducted per file for two days, i.e.16 points, and for four days, i.e. 8 points. From the drawn graphs, it was evident that the energetic-thermal relations have a linear character gained by linear regression dependence. This has been attained from the file of heating energy consumption gains reading and from the temperature difference θai – θae, or from day/degrees—Dper. The energy consumption for heating as a function of day/degrees is sought by means of linear regression in the form: 2 bp per EaDb (1) where a, b are regression coefficients for the equation of a linear calculation according to relations (11) and (12) from the STN 73 0550 standard (see Table 3). σ is a conclusive deviation of the file calculated ac- cording to the relation (13) of the standard STN 73 0550. Dper—day/degrees. Heating energy consumption for condominium storeys under standard conditions is determined for a prescrip- tive (directive) number of day/degrees according to the relation, 3422 bp bp Eab MwhVyear (2) The purpose of the measurement evaluation was to compare the calculated specific heating consumption for 1 m3 found by calculating the heating value of a built up space for the whole heating period using the climatic day/degrees of Košice D = 2834 K. The daily output is determined according to the relation: 3422 bpD bp Eab MwhVyear (3) Table 1. Recorded heating energy consumption value s in the sele cted production hall. Date Recorded heat exchanger value (MWh) Date Recorded heat exchanger value (MWh) Date Recorded heat exchanger value (MWh) 12.23. 105,013 01.03.121,004 01.14. 134,517 12.24. 106,477 01.04.122,135 01.15. 135,533 12.25. 108,051 01.05.123,588 01.16. 136,435 12.26. 109,312 01.06.124,587 01.17. 137,749 12.27. 110,688 01.07.125,773 01.18. 139,016 12.28. 112,789 01.08.126,927 01.19. 140,183 12.29. 114,813 01.09.128,069 01.20. 141,859 12.30. 116,325 01.10.129,554 01.21. 142,892 12.31. 117,624 01.11.130,476 01.22. 143,248 01.01. 118,871 01.12.131,674 01.23. 144,392 01.02. 119,959 01.13.133,060 01.24. 145,524 Total monthly consumption 40,511 MWh  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 474 Table 2. Typical internal gain values from appliances and persons, qp, and typical average lighting levels for non- residential buildings, ÖNORM B 8110-6. W/m² W/m²GFA Office building 3.75 3.7 Kindergarten and Primary School 3.75 2.8 Secondary School and Universities 7.5 2.8 Hospital Facilities 7.5 9.4 Nursing Homes 3.75 5.8 Pensions 3.75 3.9 Hotels 7.5 7.4 Restaurants 7.5 3.1 Conference Centres 7.5 3.1 Sports Arenas 7.5 4.3 Retail 3.75 8.1 Table 3. Energy consumption evaluation according to STN 73 0550. Reading period per (# of days) 1 day 2 days 4 days a 0.0743 0.0779 0.0665 b 0.1859 0.2677 1.1967 Ebp [MWh/(Vbp·year)] 254.441 266.842 228.759 E1 [kWh/(m3·year)] 54.578 57.238 49.069 EbpD [MWh/(Vbp·year)] 210.752 221.036 189.658 E1D [kWh/(m3·year)] 45.206 47.412 40.682 IED (-) 0.9889 0.9904 0.9916 σ (-) 0.2982 1.3500 2.2746 The energy consumption for heating, E1, is determined using 1m3 of built up volume for one year according to the relation: 3 11000 bp bp EaEVkWh myear (4) To prove measurement accuracy, the correlation index, EED, is calculated according to relation 15 of the standard STN 73 0550 [2]. The measurement can be considered if the correlation index, IED ≥ 0.7. The heating energy con- sumption measurement evaluation is given according to various intervals (per = 1, 2, 4 days) in Table 3. The in-situ heating energy consumption measurement can be considered proven in this given case as the corre- lation index, IED , is higher than 0.7 for all reading in- tervals as required by the standard. The highest correla- tion index is for the reading interval per 4 days. This is why the data at this interval can be considered for the result of the heating energy consumption measurement evaluation for in-situ conditions. The in-situ energy consumption measurement calcula- tion was conducted considering various types of regres- sion [10]. The calculations were carried out for regres- sion shapes with the resultant coefficients a, b, eventu- ally c. Their values are given in Table 4. The calculation results of the investigated industrial halls using the Austrian monthly balance method with typical values from other non-residential building types: convention centres, sports arenas, or retail is shown in Table 5. In the second step, the average hourly load of the used ten turning machine (10 × 400 W = 4000 W) and the heat of twenty persons (20 × 200 W = 4000 W) were assumed as internal heat gains in the calculation. Per unit area, the internal heat gains are 12.35 W/m2 from machines, and 4.5 W/m2 from lighting. This variant is presented in the second line of Table 5. Evaluating the difference in values shows that knowl- edge of internal gains is important for the calculation accuracy and should be defined as precisely as possible. The user profile of similar non-residential buildings can also be used as estimation in the planning phase. 7. Discussion of Conclusions It is possible to consider the increase in energy consump- tion when reading the increasing energy consumption in-situ values, from the lowest to the highest, besides the Table 4. Coefficients found considering regression dependences of energy consumption according to readings on individual days. Current number Considered regression type coefficient “a” coefficient “b” coefficient “c” 1. Power 1.7839 −0.1493 0.0000 2. polynomial 0.0005 −0.0324 1.6255 3. exponential −0.0146 1.5522 0.0000 4. logarithmic −0.1736 1.7084 0.0000 5. Linear-descending −0.0162 1.5336 0.0000 6. Linear-ascending 0.0546 0.0000 0.0000  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 475 Table 5. Measured and calculated heat energy demand by different user-profiles of interior gains. Heat Energy Demand kWh/M Difference kWh Measured 40 511.0 - Calculated with real interior gains 40 145.4 365.6 User Profile for Retail 41 963.6 1452.6 User Profile for Sports Arenas 41 982.1 1471.1 User Profile for Conference Centres 42 426.5 1915.5 energy consumption dependences on the number of day/degrees when the graphic dependence is not always ascending. In such cases, energy consumption considered with linear regression, can be calculated according to the linear equation, 0.0292 0.7832yx x (-) (5) Theoretically, the in-situ energy consumption calcula- tion can be considered if the coefficients a = 0.0292. b = 0.7835 are substituted in relation (2). Then the calculated value, E1 = 21.6 [kWh/(m3.year)] may be used which is far lower energy consumption than that determined by the calculations from the standard. The monitored energy consumption from December 23rd, 2009 to January 23th, 2010 is presented in Figure 4. Figures 5-7 show a very strong correlation between heating energy use and degree days. Figure 4. Measured energy consumption values in the case study hall from 23rd of December, 2009 to 23rd of January, 2010. Figure 5: Measured energy consumption values in the c a se study hall—daily reading period.  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 476 Figure 6. Measured energy consumption values in the case study hall—2 day reading period. Figure 7. Measured energy consumption values in the case study hall—4 day reading period. 8. Conclusions This investigation aimed at describing the use of heating energy and the potential heating energy savings in the industry sector, using calculations and measures in two case study halls. The location, use, and internal environ- ment, as well as the construction details of the building play an important role in the overall energy consumption of an industry hall. These factors establish the hall de- signs and many of the individual factors affecting energy use. Rising energy costs forced modern industry hall design to consider energy efficiency, but no regulation currently exist with defined values for heating energy. When seeking influential energy use factors, analysis shows that heating energy use is more or less constant. If, despite that, the real increase is considered, e.g. the daily energy input increase based on measured days, then the considered regression results will be as shown in Table 4. In calculation, E1, it can be stated that no considered re- gression shape leads to correct results, with the exception  D. KATUNSKÝ ET AL. Copyright © 2011 SciRes. ENG 477 of linear ascending regression. This regression can be considered for comparison with the energy consumption calculation according to values read from the heat ex- changer station. The heating energy consumption values calculated according to the current standard, STN 73 0550 [2], most closely correlate to the measured energy consumption values if the calculation is conducted with the aid of co- efficients “a” and “b” as the product of the line gradient in the linear regression dependence considering day/degrees. No other functional dependence regression shape of the energy increase per day/degrees leads to the correct prediction of energy consumption measurement in-situ. It is not easy to benchmark or to define ‘the standard hall’ because of the high diversity in the shape and type of industrial halls. There are several types of industry hall where energy use is comparable. However, varia- tions in use and equipment type should be identified and categorized to define the regulations for heating energy consumption. Energy can also be saved by adjusting set- tings and better maintenance of the heating system. For evaluation of energy consumption in industrial buildings it can be multi-criterion analysis used [11]. 9. Acknowledgements This contribution originated in the development and so- lution of the project ITMS “26220220050”—Architectural, Structural, technological and economical aspects of energy efficiency building design“. The project is financially supported by the EU structural resources within operative program of research and development OPVaV-2008/2.2/01-SORO. 10. References [1] STN 73 0540, “Thermodynamic Properties of Structures and Buildings,” Thermal Protection of Buildings, Part 1-4. 2002 [2] STN 73 0550, “Measurement of Energy Consumption in Situ”. [3] ÖNORM EN ISO 13790, “Energy Performance of Buildings—Calculation of Energy Use for Space Heating and Cooling,” ISO 13790, 2008. [4] Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010. [5] K. Jana and K. Dušan, “Špecifiká Pri Výpočte Potreby Energie Výrobnej Budovy,” Zborník z Konferencie s MedzinÁRodnou ÚČasťou Budova a Energia 6, Vysoké Tatry, Podbanské, 12-14 October 2006, pp. 195-200. [6] K. Jana and K. Dušan, “Hodnotenie Energetickej Nároč- nosti Výrobných Priemyselných Budov,” 32 Medz- inárodná Konferencia Katedier/Ústavov Pozemných Sta- vieb SR A ČR: Zborník Príspevkov z Konferencie s Medzinárodnou Účasťou: Košice, Košice, 17-19, Sep- tember, 2008, pp. 45-49. [7] H. Akbari and O. Sezgen, “Analysis of Energy Use in Building Services of the Industrial Sector in California: Two Case Studies,” Energy and Buildings, Vol. 19, No. 2, 1992, pp. 133-141. doi:10.1016/0378-7788(92)90007-4 [8] S.-I. Gustafsson, “Refurbishment of Industrial Build- ings,” Energy Conversion and Management, Vol. 47, No. 15-16, 2006, pp. 2223-2239. [9] STN 73 5105, “Industrial manufacturing buildings,” 1995. [10] Lopušniak, Martin, Katunský, Dušan, “Interaction of Selected Parameters within Design of Suitable Working Environment,” Healthy Buildings 2006: Design and Op- eration of Healthy Buildings, 4-8 June 2006, Lisboa, pp. 147-152. [11] D. Chinese, G. Nardin and O. Saro, “Multi-Criteria Analysis for the Selection of Space Heating Systems in an industrial Building,” Energy, Vol. 36, No. 1, 2011, pp. 556-565. doi:10.1016/j.energy.2010.10.005

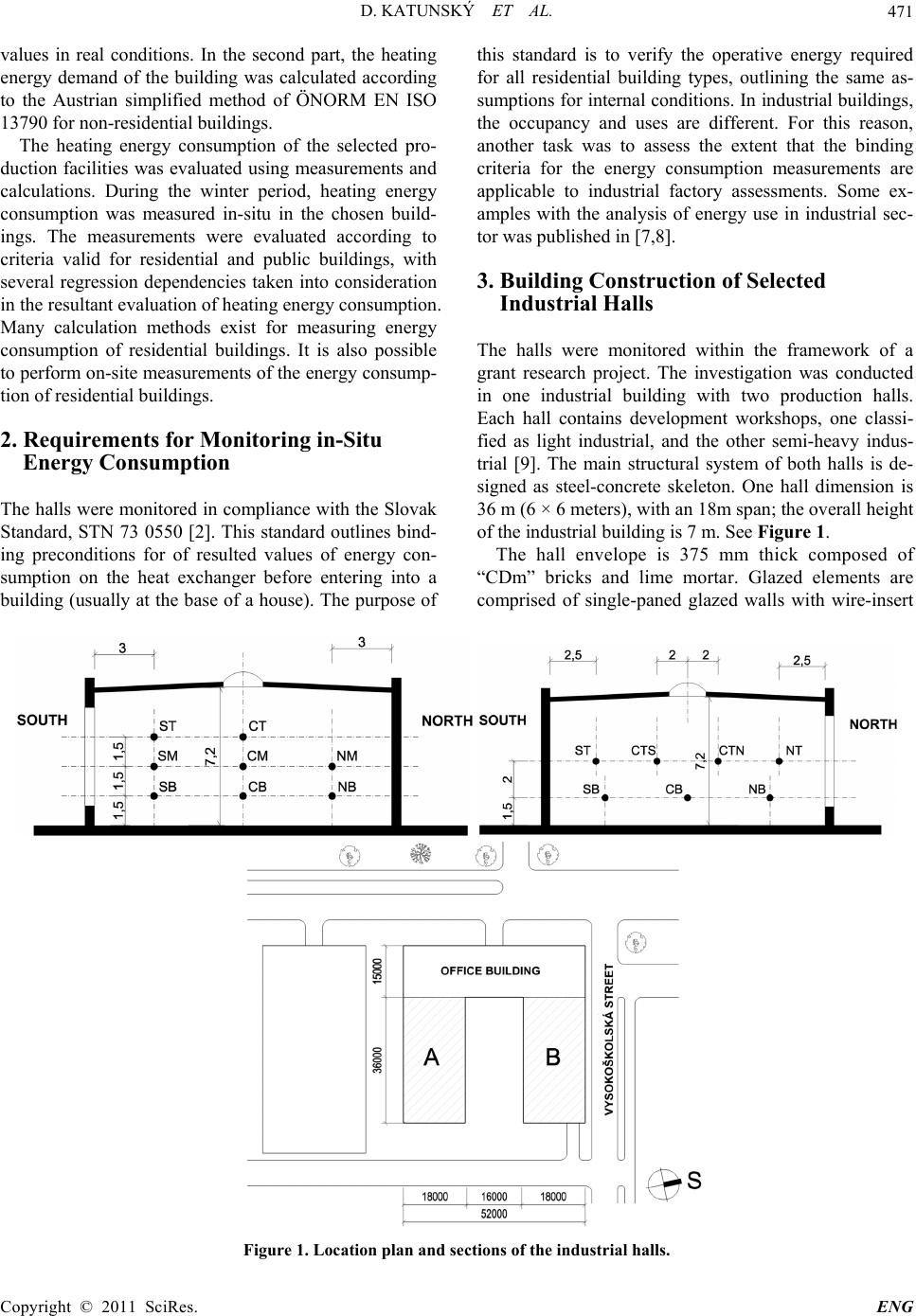

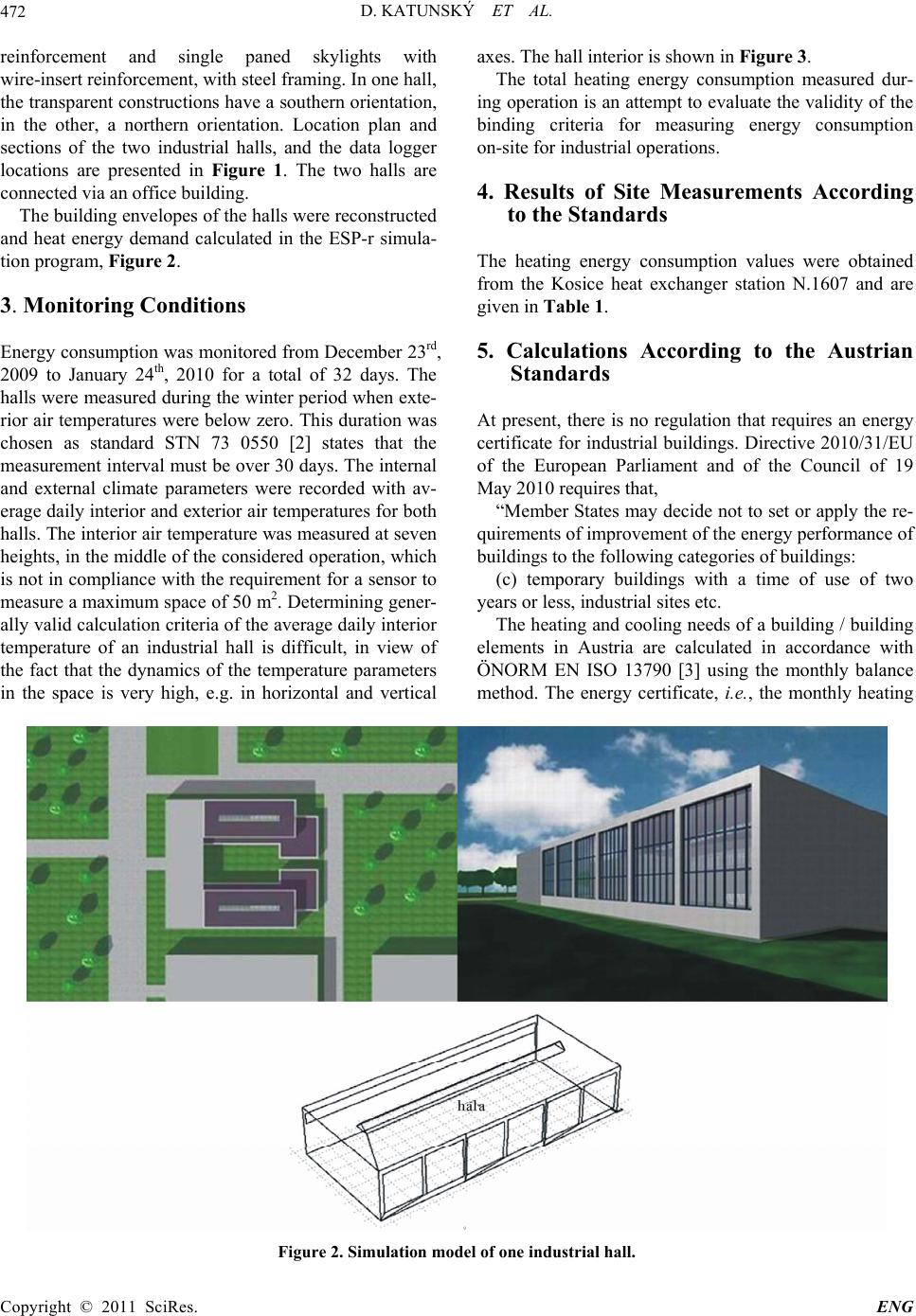

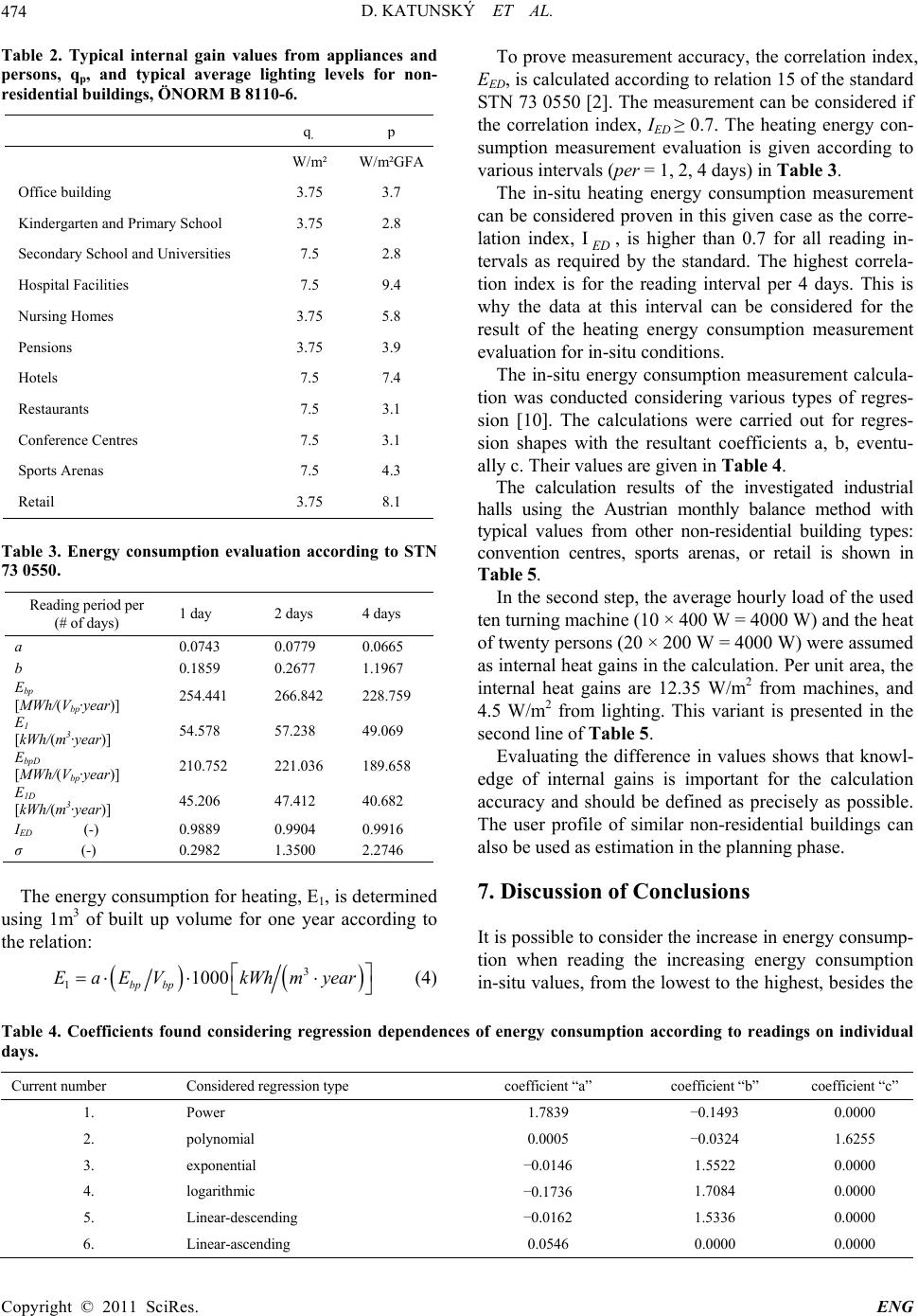

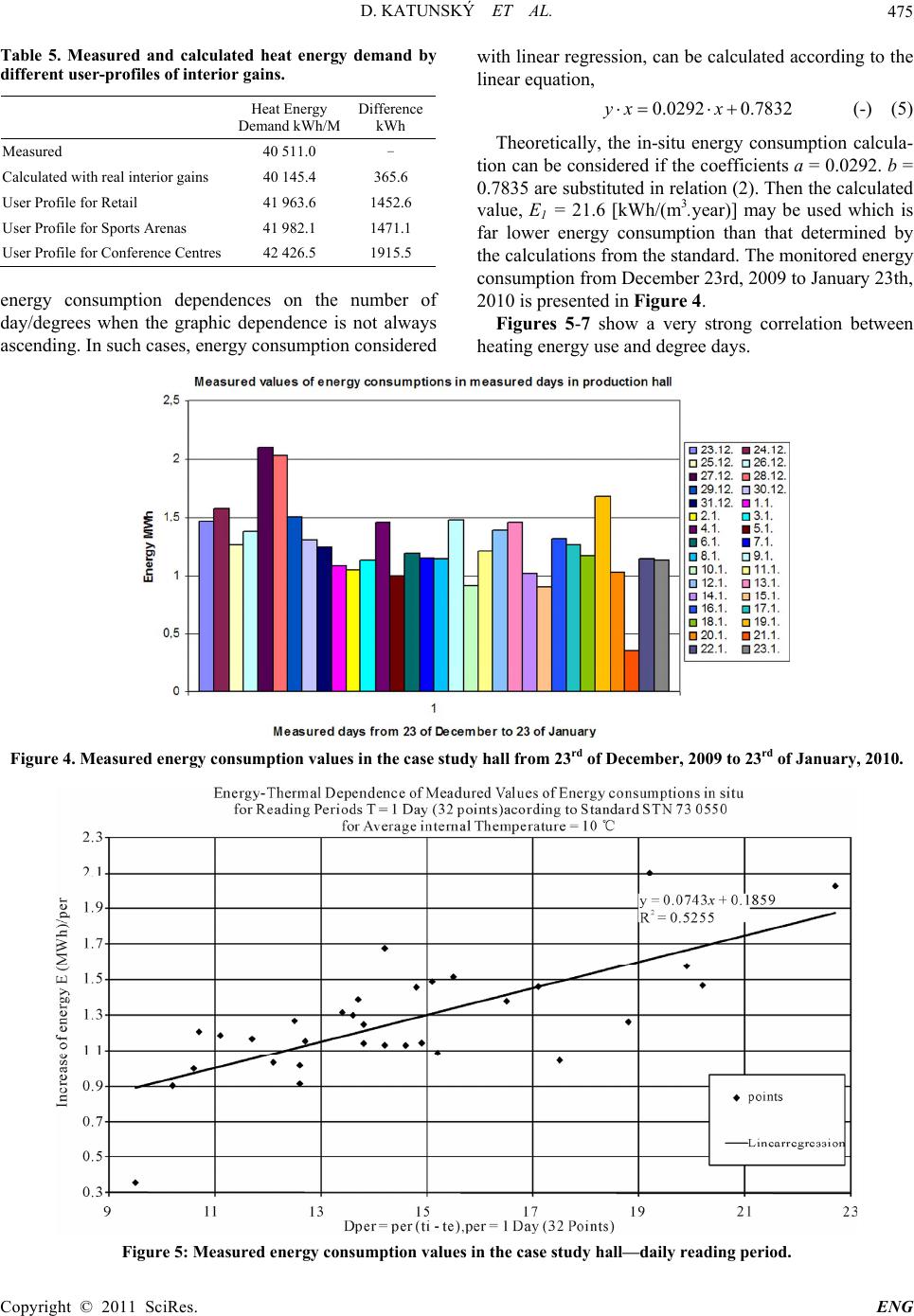

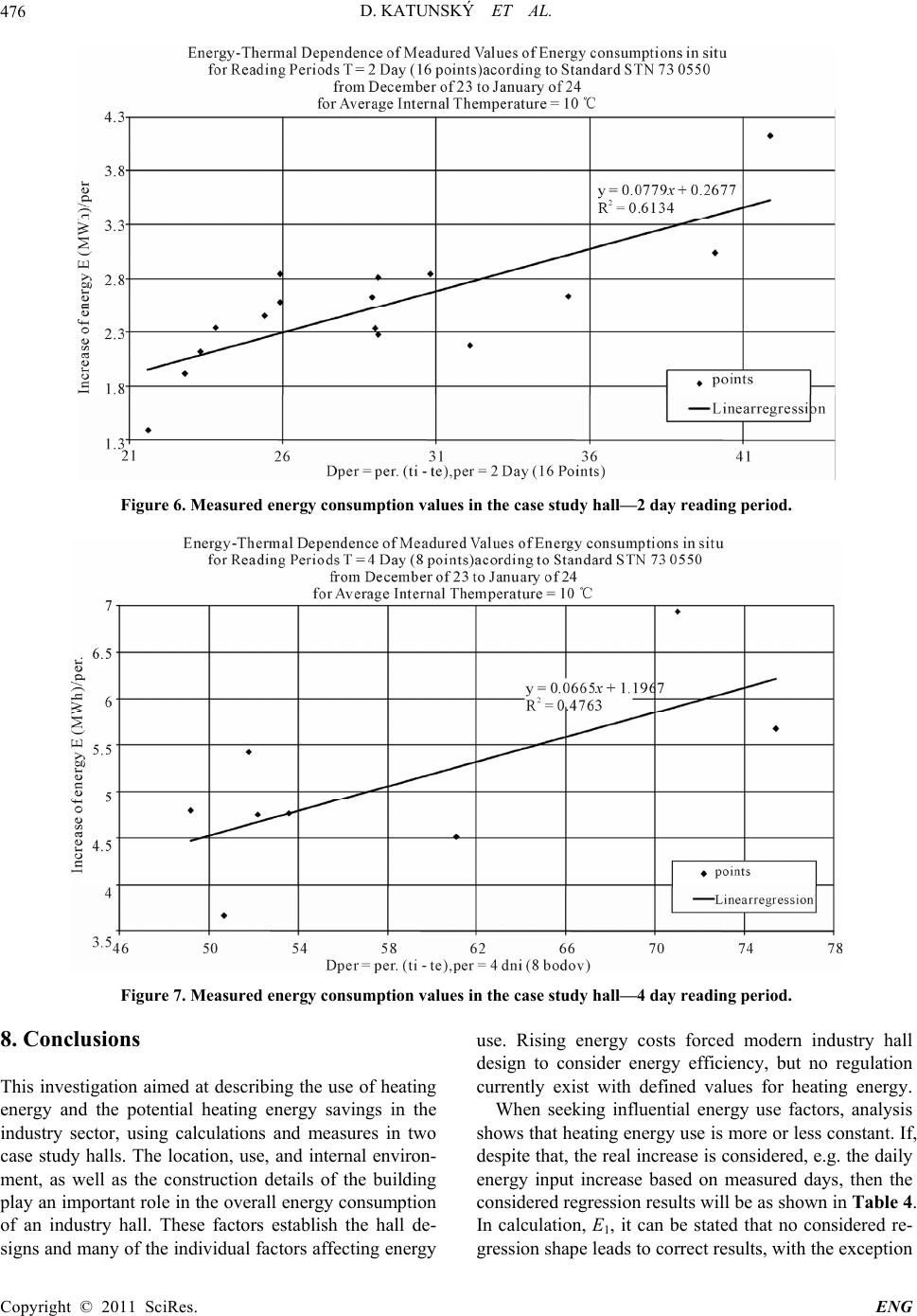

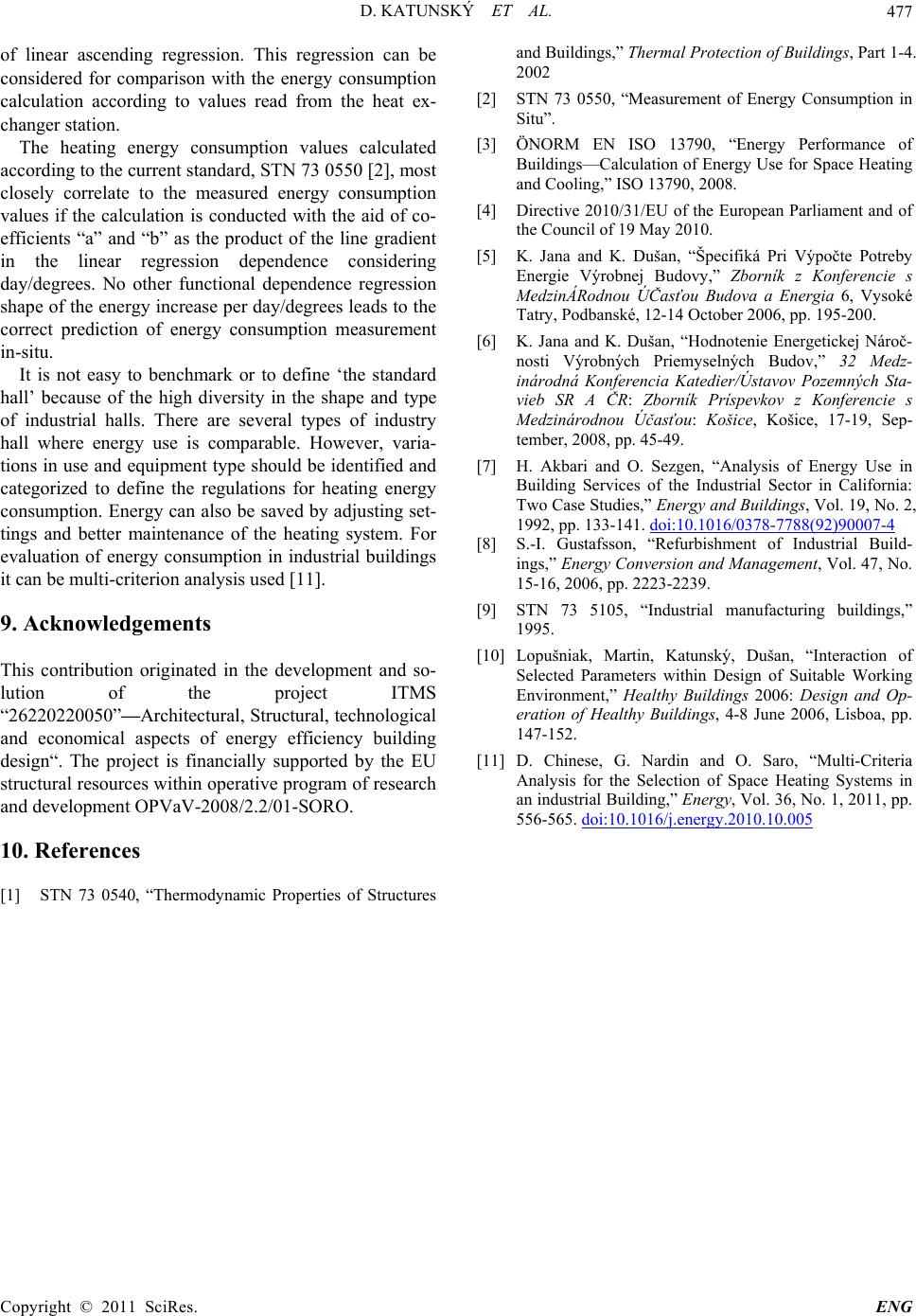

|