Paper Menu >>

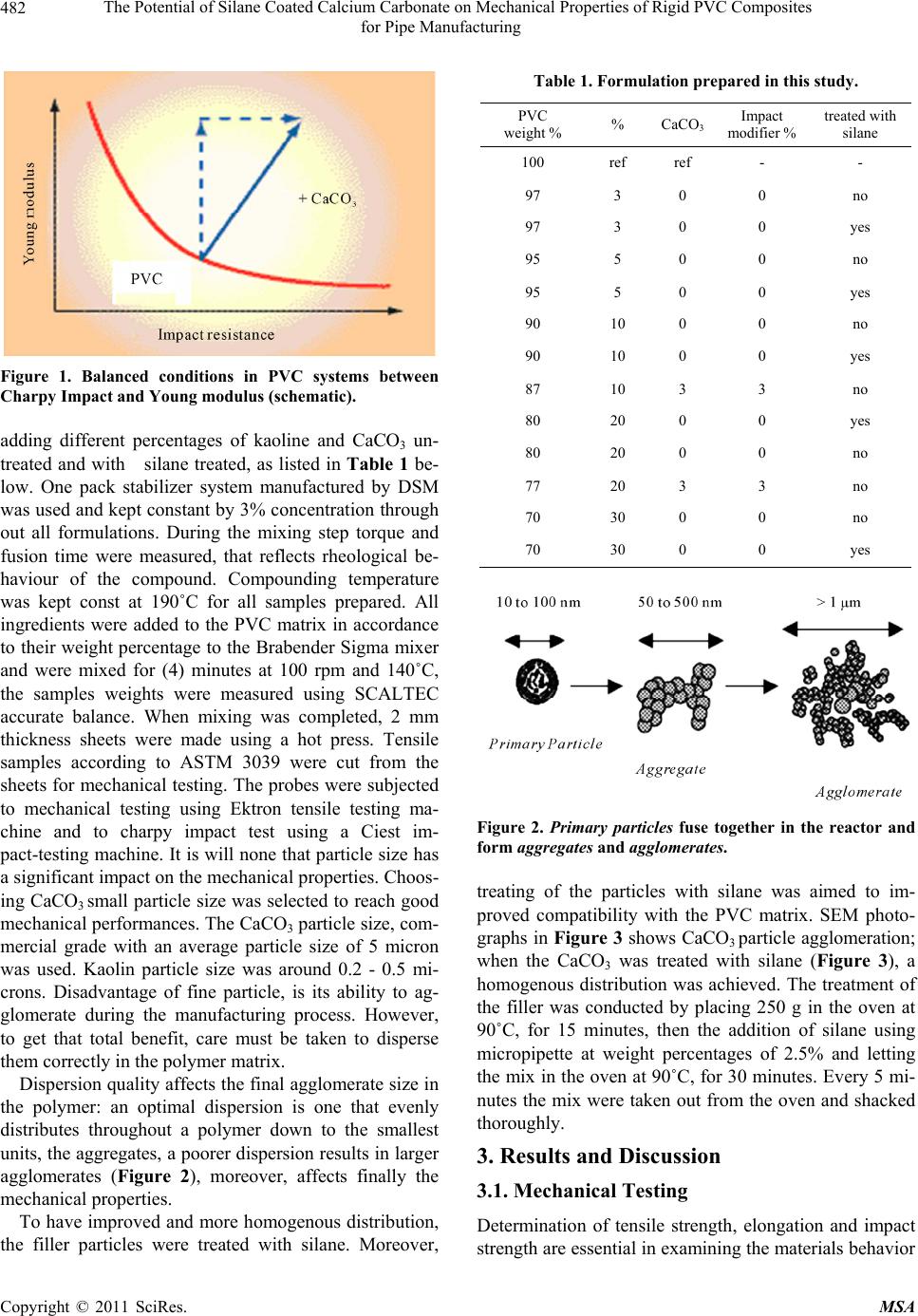

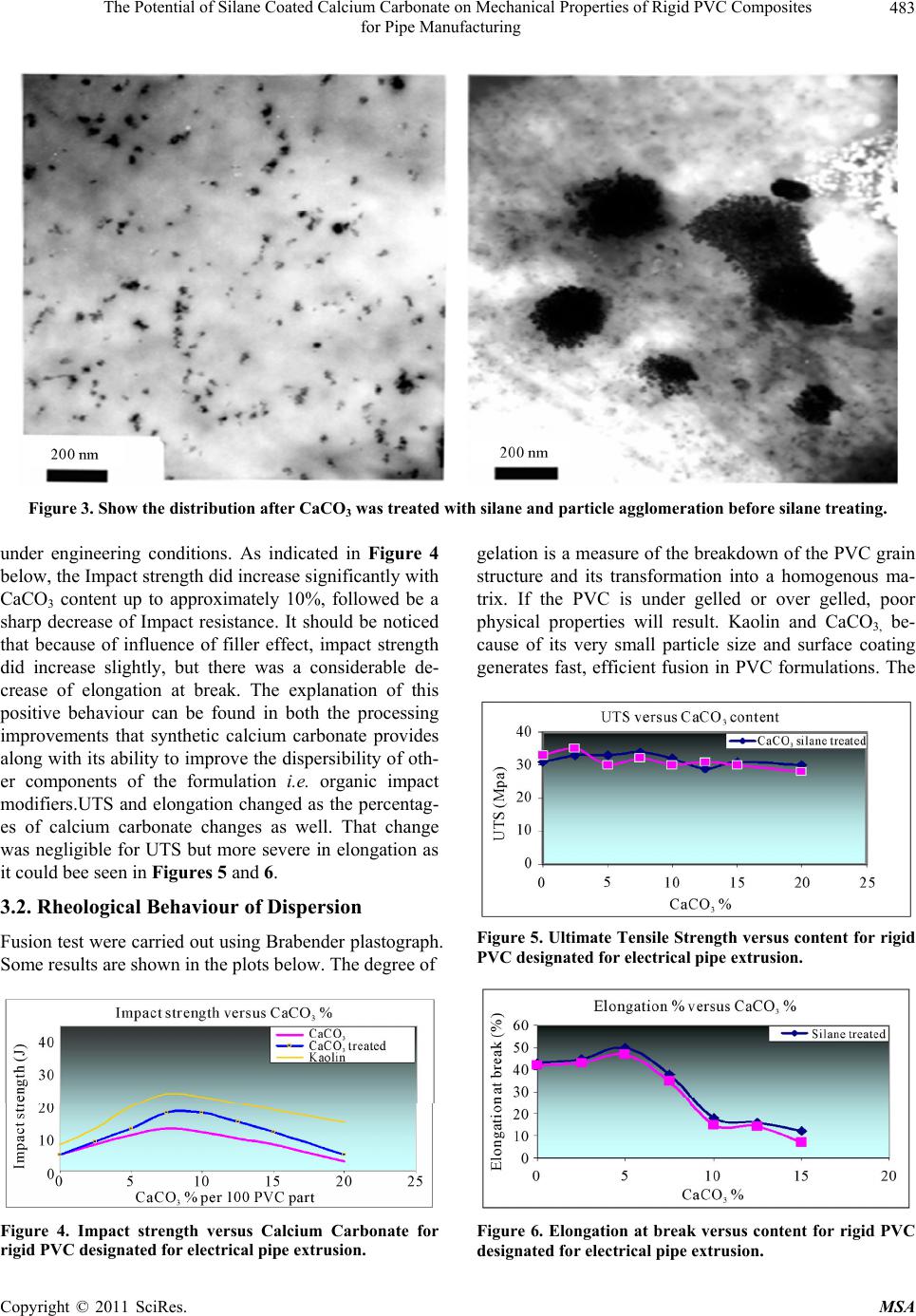

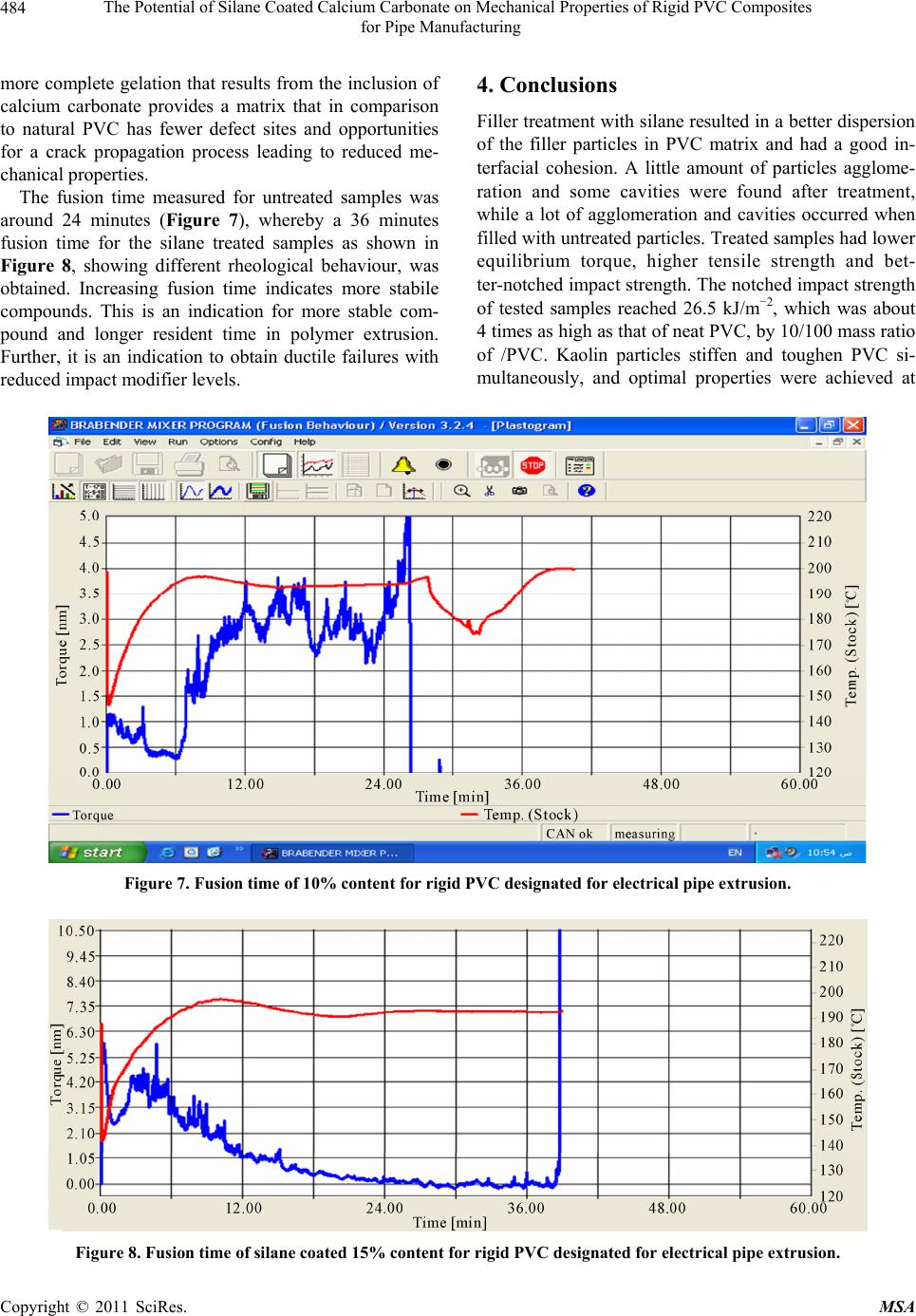

Journal Menu >>

Materials Sciences and Applications, 2011, 2, 481-485 doi:10.4236/msa.2011.25065 Published Online May 2011 (http://www.SciRP.org/journal/msa) Copyright © 2011 SciRes. MSA 481 The Potential of Silane Coated Calcium Carbonate on Mechanical Properties of Rigid PVC Composites for Pipe Manufacturing Amin Al Robaidi1, Ahmad Mousa1*, Sami Massade h 1, Ibrahim Al Rawabdeh2, Nabil Anagreh1 1Materials Department, Al-Balq'a Applied University, Salt, Jordan; 2Industrial Engineering Department, University of Jordan, Am- man, Jordan. Email: mousa@rocketmail.com Received July 7th, 2010; revised November 3rd 2010; accepted May 12th, 2011. ABSTRACT The inclusion of CaCO3 and kaolin in polyvinyl chloride (PVC) polymer matrices greatly enhances the physical and mechanical properties of the composite. In this study, the effects of kaolin and surface treatment of CaCO3 and kaolin particles on the microstructure and mechanical properties of PVC composites filled with kaolin particles via melt blending method were studied by means of SEM, tensile, Charpy impact testin g. Treated and un treated kaolin particles were dispersed in matrices of PVC resin at different conc entrations up to 30wt percentage. The tens ile strength, elastic modulus, strain to failure and morphology of the resulting composites were measured for various filler loadings. Uni- form dispersion of the fillers into the matrix proved to be a critical factor. SEM images revealed that small sized par- ticles were more agglomerated than micron-sized particles and the amount of agglomerates increased with increasing particle content. Silane treated Kaolin-CaCO3/PVC composites had superior tensile and impact strengths to untreated kaolin-CaCO3/PVC composites. The Young’s modulus of all composites increased with increasing particle content up to maximum a t 10% filler loading followed by gradually decreasing as content increased. Keywords: Polyvinyl Chloride)/Calcium Carbonate (PVC/) Nano-Composite, Particle Size, Melt Blending, Tensile Testing, Charpy Impact 1. Introduction Kaolin and calcium carbonate has long been recognized as useful additives for thermoplastics and particularly in PVC for many applications. Ground kaolin and calcium carbonate are generally used as filler with an interesting ratio performance/price. The specific structure allows this material to fulfill additional functions like Processing aid, impact modification and better weather ability. Its regular and controlled crystalline shape and ultra fine particle size together with the hydrophobic surface coating combine to the benefit of both polymer processing and subsequent physical properties. PVC is the second most consumed polymer right after PE. This low-cost material has nu- merous advantages, such as a high modulus, excellent chemical resistance and easy conversion. The addition of low-cost fillers such as calcium carbonate or talc was his- torically justified by the cost reduction; however, perfor- mance improvements and other benefits brought by the use of these materials are the cause of its increasing use in PVC systems [1-5]. The major challenge in plastic rein- forcement is to reach an optimal balance between Young Modulus and Impact resistance [6-9]. The most favorable balance could be obtained by a good control of dispersion and adhesion between the filler and polymer matrix as shown in Figure 1. Increasing filler percentages after exceeding a certain concentration will significantly affects impact resistance and modulus of elasticity [4,9]. There- fore treating of the filler to achieve a better dispersion and increase filler matrix compatibility is targeted. Silane is a material of choice due to its ability to form grafting spe- cies with the polymer matrix and its availability as a commercial product. 2. Experimental Sample Preparation: Different PVC samples were prepared using brabender plastograh. Batches were produced by the addition of one pack stabilizer system in the mixing station followed by  The Potential of Silane Coated Calcium Carbonate on Mechanical Properties of Rigid PVC Composites for Pipe Manufacturing Copyright © 2011 SciRes. MSA 482 Figure 1. Balanced conditions in PVC systems between Charpy Impact and Young modulus (schematic). adding different percentages of kaoline and CaCO3 un- treated and with silane treated, as listed in Table 1 be- low. One pack stabilizer system manufactured by DSM was used and kept constant by 3% concentration through out all formulations. During the mixing step torque and fusion time were measured, that reflects rheological be- haviour of the compound. Compounding temperature was kept const at 190˚C for all samples prepared. All ingredients were added to the PVC matrix in accordance to their weight percentage to the Brabender Sigma mixer and were mixed for (4) minutes at 100 rpm and 140˚C, the samples weights were measured using SCALTEC accurate balance. When mixing was completed, 2 mm thickness sheets were made using a hot press. Tensile samples according to ASTM 3039 were cut from the sheets for mechanical testing. The probes were subjected to mechanical testing using Ektron tensile testing ma- chine and to charpy impact test using a Ciest im- pact-testing machine. It is will none that particle size has a significant impact on the mechanical properties. Choos- ing CaCO3 small particle size was selected to reach good mechanical performances. The CaCO3 particle size, com- mercial grade with an average particle size of 5 micron was used. Kaolin particle size was around 0.2 - 0.5 mi- crons. Disadvantage of fine particle, is its ability to ag- glomerate during the manufacturing process. However, to get that total benefit, care must be taken to disperse them correctly in the polymer matrix. Dispersion quality affects the final agglomerate size in the polymer: an optimal dispersion is one that evenly distributes throughout a polymer down to the smallest units, the aggregates, a poorer dispersion results in larger agglomerates (Figure 2), moreover, affects finally the mechanical properties. To have improved and more homogenous distribution, the filler particles were treated with silane. Moreover, Table 1. Formulation prepared in this study. PVC weight % % CaCO3 Impact modifier % treated with silane 100 ref ref - - 97 3 0 0 no 97 3 0 0 yes 95 5 0 0 no 95 5 0 0 yes 90 10 0 0 no 90 10 0 0 yes 87 10 3 3 no 80 20 0 0 yes 80 20 0 0 no 77 20 3 3 no 70 30 0 0 no 70 30 0 0 yes Figure 2. Primary particles fuse together in the reactor and form aggregates and agglomerates. treating of the particles with silane was aimed to im- proved compatibility with the PVC matrix. SEM photo- graphs in Figure 3 shows CaCO3 particle agglomeration; when the CaCO3 was treated with silane (Figure 3), a homogenous distribution was achieved. The treatment of the filler was conducted by placing 250 g in the oven at 90˚C, for 15 minutes, then the addition of silane using micropipette at weight percentages of 2.5% and letting the mix in the oven at 90˚C, for 30 minutes. Every 5 mi- nutes the mix were taken out from the oven and shacked thoroughly. 3. Results and Discussion 3.1. Mechanical Testing Determination of tensile strength, elongation and impact strength are essential in examining the materials behavior  The Potential of Silane Coated Calcium Carbonate on Mechanical Properties of Rigid PVC Composites for Pipe Manufacturing Copyright © 2011 SciRes. MSA 483 Figure 3. Show the distribution after CaCO 3 was treated with silane and particle agglomeration before silane treating. under engineering conditions. As indicated in Figure 4 below, the Impact strength did increase significantly with CaCO3 content up to approximately 10%, followed be a sharp decrease of Impact resistance. It should be noticed that because of influence of filler effect, impact strength did increase slightly, but there was a considerable de- crease of elongation at break. The explanation of this positive behaviour can be found in both the processing improvements that synthetic calcium carbonate provides along with its ability to improve the dispersibility of oth- er components of the formulation i.e. organic impact modifiers.UTS and elongation changed as the percentag- es of calcium carbonate changes as well. That change was negligible for UTS but more severe in elongation as it could bee seen in Figures 5 and 6. 3.2. Rheological Behaviour of Dispersion Fusion test were carried out using Brabender plastograph. Some results are shown in the plots below. The degree of Figure 4. Impact strength versus Calcium Carbonate for rigid PVC designated for electrical pipe extrusion. gelation is a measure of the breakdown of the PVC grain structure and its transformation into a homogenous ma- trix. If the PVC is under gelled or over gelled, poor physical properties will result. Kaolin and CaCO3, be- cause of its very small particle size and surface coating generates fast, efficient fusion in PVC formulations. The Figure 5. Ultimate Tensile Strength versus content for rigid PVC designated for electric al pipe ex tr usion. Figure 6. Elongation at break versus content for rigid PVC designated for electrical pipe extrusion.  The Potential of Silane Coated Calcium Carbonate on Mechanical Properties of Rigid PVC Composites for Pipe Manufacturing Copyright © 2011 SciRes. MSA 484 more complete gelation that results from the inclusion of calcium carbonate provides a matrix that in comparison to natural PVC has fewer defect sites and opportunities for a crack propagation process leading to reduced me- chanical properties. The fusion time measured for untreated samples was around 24 minutes (Figure 7), whereby a 36 minutes fusion time for the silane treated samples as shown in Figure 8, showing different rheological behaviour, was obtained. Increasing fusion time indicates more stabile compounds. This is an indication for more stable com- pound and longer resident time in polymer extrusion. Further, it is an indication to obtain ductile failures with reduced impact modifier levels. 4. Conclusions Filler treatment with silane resulted in a better dispersion of the filler particles in PVC matrix and had a good in- terfacial cohesion. A little amount of particles agglome- ration and some cavities were found after treatment, while a lot of agglomeration and cavities occurred when filled with untreated particles. Treated samples had lower equilibrium torque, higher tensile strength and bet- ter-notched impact strength. The notched impact strength of tested samples reached 26.5 kJ/m−2, which was about 4 times as high as that of neat PVC, by 10/100 mass ratio of /PVC. Kaolin particles stiffen and toughen PVC si- multaneously, and optimal properties were achieved at Figure 7. Fusion time of 10% content for rigid PVC designated for electrical pipe extrusion. Figure 8. Fusion time of silane coated 15% content for rigid PVC designated for electrical pipe extrusion.  The Potential of Silane Coated Calcium Carbonate on Mechanical Properties of Rigid PVC Composites for Pipe Manufacturing Copyright © 2011 SciRes. MSA 485 10-wt% of CaCO3 particles in Young’s modulus, tensile yield strength, elongation at break and Charpy notched impact energy. Detailed examinations of micro-failure micro mechanisms of impact and tensile specimens showed that the CaCO3 particles acted as stress raisers leading to debonding/voiding and deformation of the matrix material around the particles. These mechanisms also lead to impact toughening of the composites. The tensile and impact strengths of CaCO3/PVC greatly increased with decreasing CaCO3 particle size, which was attributed to increased interfacial contact area and enhanced interfacial adhesion between filler particles and PVC matrix. Silane kaolin-CaCO3/PVC composites had superior tensile and impact strengths to untreated ones. REFERENCES [1] G. A. Ari and I. Aydin, “Nanocomposites Prepared by Solution Blending: Microstructure and Mechanical Prop- erties,” Journal of Macromolecular Science, Physics Part B, Vol. 47, No. 2, 2008, pp. 260-267. [2] S. Sun and C. Li, “Interfacial Structures and Mechanical Properties of PVC Composites Reinforced by CaCO3 with Different Particle Sizes and Surface Treatments,” Polymer International, Vol. 55, No. 2, 2006, pp. 158-164. doi:10.1002/pi.1932 [3] R. Krishnamoorti and R. A. Vaia, “Polymer Nanocompo- sites,” Journal of Polymer Science Part B, Vol. 45, 2007, pp. 3252-3259. doi:10.1002/polb.21319 [4] R. C. Advincula, “Encyclopedia of Polymer Science and Technology,” John Wiley & Sons, Hoboken, Vol. 11, 2004, pp. 114-134. [5] Y. Tsujii, K. Ohno, S. Yamamoto, A. Goto and T. Fukuda, “Structure and Properties of High-Density Polymer Brushes Prepared by Surface-Initiated Living Radical Polymerization,” Advances in Polymer Science, Vol. 197, 2006, pp. 1-45. [6] M. R. Buchmeiser, “Surface-Initiated Polymerization,” Advances in Polymer Science, Vol. 197, 2006, pp. 137- 171. [7] B. Radhakrishnan, R. Ranjan and W. J. Brittain, “Surface Initiated Polymerizations from Silica Nanoparticles,” Soft Matter, Vol. 2, 2006, pp. 386-396. doi:10.1039/b516508c [8] A. Al-Irobaidi and N. A. Halim, “Correlation between Rheology; Processing and Microstructure in Polymers,” Dirasat, Vol. 27, No. 2, 2000. [9] N. Khreische and A. Al-Irobaidi, “Micro Structure of Weathered Green House PE-Plastic Films,” Journal of Polymer Degradation and Stability, Vol. 32, 1991, pp. 105-114. |