Materials Sciences and Applications

Vol.09 No.06(2018), Article ID:85020,11 pages

10.4236/msa.2018.96040

Black Photoresist for Patterning Pixel Define Layer of Organic Light Emitting Diode with Polyimide as Thermal Stabilizer

Genggongwo Shi1, Jin Woo Park2, Lee Soon Park3*

1CC Tech, Cheonan, South Korea

2Samsung Display Co., Ltd., Yongin, South Korea

3School of Materials Science and Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan, South Korea

Copyright © 2018 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: March 20, 2018; Accepted: May 28, 2018; Published: May 31, 2018

ABSTRACT

In order to improve the visibility for outside use of organic light emitting diodes (OLEDs), the polarized film and black matrix pattern have been used in the small and medium sized OLEDs; however, these cause problem of reducing the emission efficiency of OLED. Changing the color of pixel define layer (PDL) from brown to black is an important point for improving the efficiency and visibility of OLEDs. In this work we studied the photoresist material containing black pigment and the photolithographic process for patterning of black PDL on OLEDs. The black PDL patterns made with our synthesized polyimides as thermal stabilizer were found to give high thermal stability over 300˚C.

Keywords:

Organic Light Emitting Diode, Pixel Define Layer, Black Pixel Define Layer, Photolithography

1. Introduction

Organic light emitting diodes (OLEDs) have extended their applications from small size mobile devices to large OLED TVs, flexible OLED, and lightings. The changes have become possible due to such merits of OLEDs as fast response time, low operating voltage, wide viewing angle as well as light weight and thin-film features [1] [2] [3] [4] . The panel of small size OLED has separate subpixel structure of red (R), green (G), and blue (B) light emission from pixel define layer (PDL) which is fabricated by photolithographic process.

Currently positive-tone photosensitive polyimide is used to make three dimensional pixel microstructures in the PDL. So that the color of the PDL is yellowish brown, the usual color of polyimide films. Since the yellowish brown polyimide layer of PDL can reflect the ambient light, the visibility of the OLED display is reduced, especially used outdoors. In order to improve the visibility of OLED display, black matrix patterns need to be fabricated on top of the pixel define layer in addition to the 1/4λ polarizing film on top of the black matrix pattern layer as shown in the cross-sectional view of OLED panel in Figure 1.

If the pixel define layer could be patterned with a black photoresist, the black matrix pattern and 1/4λ polarizing film may not be required for the improved visibility of OLED devices. However, the photosensitivity of the positive-tone polyimide currently used is not high enough to give black PDL patterns which have thickness of 1.0 - 1.2 µm. So far to the best of our knowledge, thermally stable black PDL researches on OLED display have not been reported yet.

In this work, a negative-tone photoresist was investigated for the photolithographic patterning of black PDL of OLED, since the polymerization depth of UV light is deeper than that of positive-tone photosensitive polyimide. The components necessary for the black negative photoresist include photoinitiator, photosensitizer, binder polymer developable with aqueous alkaline solution, multifunctional monomer for crosslinking reaction, black millbase and polyimide [5] [6] to increase the thermal stability of patterned black PDL of OLED devices. The last component of the black negative photoresist is very important since the process temperature of black PDL reaches close to 300˚C including post-curing step after photopatterning. This is the reason why photosensitive polyimide has been used in the normal (not black) pixel define layer patterning. Another important part of the black negative photoresist for patterning black PDL of OLED is the complete solubility of all the components of negative photoresist in the common organic solvent in this case propyleneglycol monomethylether acetate (PGMEA). If this condition is not met, the resulting black PDL pattern will have saw-toothed deformation due to the aggregates made by incomplete solubility of

Figure 1. Cross-sectional view diagram of OLED panel.

the ingredients in the photoresist solution [7] [8] [9] . So extensive research was conducted on the synthesis of polyimides which have both high thermal stability and solubility in PGMEA common organic solvent and their application to the black photoresist formulation for photolithographic patterning of black PDL in OLED devices.

2. Experimental

2.1. Materials

All the reagents and solvents were purchased from commercial sources and used directly in the experiments without further purification. Abbreviations of compounds are as following: 4,4’-(hexafluoroisopropylidene) dipthalic anhydride (6FDA); 5-(2,5-dioxo tetrahydrofuryl)-3-methyl-3-cyclohexene-1,2-dicarboxylic anhydride (MCDA); 2,2’-bis(3-amino-4-hydroxy-phenyl)hexafluoropropane (AH6FP); 4-phenylethynylpthalic anhydride (PEPA); trimellitic anhydride (TMA); pthalic anhydride (PAn); dimethyl acetamide (DMAc); N-Methyl-2-pyrrolidone (NMP); propyleneglycol monomethylether acetate (PGMEA); and ethyl acetate (EtOAc).

2.2. Synthesis of Polyimides by Solution Polymerization

Dianhydride (6FDA, 14.9 mmol) and monoanhydride (PAn, 2 mmol) in 30 wt% NMP solution was added into two different diamine (4,4-ODA, 15 mmol and AH6FP, 15 mmol) 30 wt% NMP solutions separately at 0˚C and stirred for 1 hour. Then the two reaction mixture were bought up to 45˚C and stirred for 23 hours and finally at 130˚C for 4 hr for thermal imidization as shown in Figure 2. After cooling down the viscous reaction mixture was poured into excess amount of water and the precipitates were collected by centrifugation. The precipitates were redissolved in EtOAc and the organic layer was washed with brine twice. The organic layer was dried with anhydrous Na2SO4 and evaporated to dryness under vacuum to afford polyimides as red-orange powder (SPIO and SPIF).

2.3. Synthesis of Polyimides by Melt Polymerization

Dianhydride (6FDA or MCDA), diamine (AH6FP) and monoanhydride (PEPA or TMA) in powder form were well ground and mixed by using mortar. The powder mixture in a stainless container with metal cup was placed in the electric furnace and heated for 10 min at 240˚C under nitrogen atmosphere. After cooling down to room temperature, the resulting polyimides were collected and ground to fine powder as shown in Figure 3.

3. Result and Discussion

3.1. Polyimide Syntheses and Solubility in PGMEA Solvent

Usually solution polymerization of polyimides are carried out in two steps, that is, polyamic acid in the first step and second imidization step either by chemical

Figure 2. Synthesis of polyimides by solution polymerization.

Figure 3. Synthesis of polyimide by melt polymerization.

or thermal imidization. We modified the two-step solution polymerization as shown in Figure 2 without separating the polyamic acid intermediate.

The degree of imidization versus the time of thermal imidization curves are shown in Figure 4. It was found that after 30 min reaction at 130˚C the thermal imidization could reach to 97% imidization.

When the two polyimides (SPIO and SPIF as shown in Figure 2) were tested for solubility in PGMEA common solvent polyimide SPIF was found to be

Figure 4. Imidization degree vs. reaction time plot.

completely soluble in PGMEA, NMP and DMSO solvents while SPIO was not soluble in PGMEA but only soluble in NMP and DMAC solvents. Thus it was noted that combination of dianhydride and diamine monomer is very important to satisfy the solubility in PGMEA common solvent.

3.2. Synthesis and Properties of Polyimides by Melt Polymerization

As was noted in the solution polymerization session it took a long time to test the solubility of resulting polyimide samples in PGMEA common solvent. Therefore a melt polymerization of polyimides was conducted to save the reaction time. Two typical examples were shown in Figure 3.

In Table 1 are shown the relationship between the melt polymerization condition of polyimides and solubility in PGMEA, NMP and DMAC solvents. The chemical structures and melting points of dianhydrides, diamines and monoanhydrides are shown in Figure 5. As shown in Table 1(a), the combinations of dianhydrides and diamines which give solubility in PGMEA solvent in the melt polymerization of polyimides were found to be (Dianhydrides; 6FDA, MCDA) and (Diamines; AH6FP, BF6, TFDB), while the combinations of insolubility in PGMEA solvent (although soluble in such good solvents as DMAC and NMP) were (Dianhydrides; BTDA, ODPA) and (Diamines; 4,4’-ODA, BAD, BAS). The main reason for the insolubility of polyimides in PGMEA which is known to be a poor solvent is the formation of change transfer complex formed by inter-or intra-molecular interaction of dipole moments between imide linkages. The presence of trifluoromethyl groups in 6FDA, AH6FP, BF6, TFDB monomers or alicyclic structure in MCDA monomer can prevent the charge transfer complex formation by the steric hinderance mechanism thus promote solubility in

Table 1. Monomer combination, melt polymerization condition and solubility of resulting polyimides. (a) Effect of combination of monomers on solubility. (b) Effect of melt polymerization condition on solubility.

PGMEA solvent.

The effects of melt polymerization temperature and reaction time on the solubility of resulting polyimide are shown in Table 1(b). When the reaction temperature exceed 240ºC or reaction time over 10 min, the resulting polyimides exhibited insolubility or partial solubility (turbidity) in PGMEA solvent. This could be resulted from the crosslinking reaction between phenolic −OH groups with removal of water molecules.

Of the melt polymerized polyimides in Table 1 DAMP-4, DAMP-5, FTAP-1 and MCAP-1 samples were completely soluble in PGMEA solvent. Of these we chose the MCAP series polyimides in order to further investigate the effect of monoanhydrides on the molecular weights of resulting polyimides.

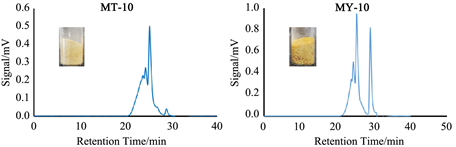

From Table 2 it is noted that the molecular weights (Mw) of MT-series polyimides are higher than those of MY-series polyimides. This may be explained by the comparison of melting temperature(Tm) of monoanhydrides used. Since TMA has about 12˚C higher Tm than PEPA, MT series polyimides can be more homogeneous during melt polymerization. As the MCDA and TMA do not react with each other until the temperature reach to 240˚C melt polymerization temperature, they may give narrow distribution of Mw in MT series compared to the

Table 2. Molecular weights of melt polymerized polyimides.

Figure 5. Structures, abbreviations and melting temperatures of monomers used in the melt polymerization of polyimides.

Mw of MY series polyimides. The typical GPC chromatograms of MT-10 and MY-10 are shown in Figure 6.

3.3. Photolithography and Thermal Stability of Pixel Define Layer Patterns

The black photoresist is composed of photoinitiator, photosensitizer, binder polymer, multifunctional monomer, black pigment dispersion in PGMEA solvent and polyimide as thermal stabilizer. The binder polymer SR-6300T (SMS Co., South Korea) was a commercial sample known as cresol novolac epoxyacrylate dissolved in PGMEA at 30 wt%. An acrylate type monomer, dipentaerythritol hexaacrylate (DPHA), was used as multifunctional monomer. The binder polymer and multifunctional monomer are the main component of the photoresist which function as the photo-patterning agents. However the thermal stability of the acrylate type compounds is not high enough (about 300˚C) to endure the photolithographic process and post-cure treatment. That is main reason why polyimide is required as thermal stabilizer in the black photoresist formulation.

Another important major component of black photoresist is black pigment. In this experiment a commercial lactam black (LT-1, 23 wt% in PGMEA obtained from SKC htm Co., Korea) was used. The black pigment LT-1 is in a finely dispersed state (average particle size; 50 nm) in PGMEA solvent. The compatibility of all other components of the black photoresist with the black pigment is very important, otherwise micro-coagulums may be formed which will give saw-toothed or wavy patterns in the black pixel define layer.

The photolithographic process was as following. The black photoresist was spin coated on the wafer (Si/SiO2 200 nm) with a stepwise speed of 300 rpm/5 sec, 500 rpm/5 sec, and 5000 rpm/50 sec. After soft bake at 120˚C for 100 sec, the dry black photoresist thin film was exposed to UV irradiation (120 mJ/cm2) through the photomask. After hard bake at 120 ºC for 100 sec, the black PDL thin film was developed with AZ-300 MIF developer (tetramethylammonium hydroxide 2 wt% in water, Bayer Co., Germany) for 120 sec followed by water rinsing and drying with N2 gun.

Of the polyimide thermal stabilizers in Table 1 and Table 2, six samples soluble in PGMEA solvent were used in the black photoresist formulation as shown in Table 3.

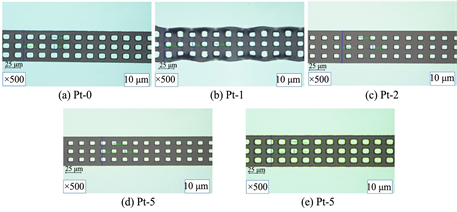

Black photoresist samples (Pt-3 and Pt-4) failed to give patterns in the black pixel define layer while other black photoresists exhibited fine PDL patterns. Typical PDL patterns are shown in Figure 7. Although all six polyimides used in the black photoresist were completely soluble in PGMEA solvent, there were differences in the diamine monomers in the DAMP-4 (BF6) and DAMP-5 (TFDB) polyimides as shown in Figure 5. The polyimides which gave good PDL pattern had AH6FP as diamine monomer. The phenol −OH group in AH6FP

Figure 6. GPC chromatograms and sample images of MT-10 and MY-10 polyimides.

Table 3. Formulation of black photoresist and stability of black PDL pattern.

monomer could provide the binder polymer with high acid value (120 mg KOH/g sample), thus, promoting development by reacting with basic TMAH aqueous solution, while the binder polymers with BF6 and TFDB as diamines could not be developed without acidic group.

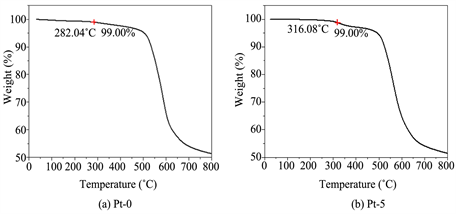

The effect of polyimides in the black photoresist on the thermal stability of the resulting PDL patterns was investigated by TGA analysis. The black PDL patterns obtained on the silicon wafer was scratched off by using sharp razor blade and then the 1 wt% loss temperatures were checked. As shown in Figure 8 the black photoresist (Pt-5) exhibited higher 1 wt% loss temperatures than Pt-0 without polyimide as thermal stabilizer.

4. Conclusion

In this work, a negative-tone photoresist was investigated for the photolithographic patterning of PDL with black color since the penetration depth of UV light is deeper than that of positive-tone photoresist containing photosensitive polyimide. The typical formulation of a negative tone photoresist for the patterning of black PDL of OLEDs included photoinitiator, photosensitizer, dispersant, binder polymer, multifunctional monomer (DPHA, dipentaerythritol hexaacrylate), black millbase and polyimide which were dissolved completely in the

Figure 7. The optical microscopic images of black PDL patterns obtained with (a) Pt-0, (b) Pt-1, (c) Pt-2, (d) Pt-5, (e) Pt-6 photoresists.

Figure 8. TGA Thermograms of black thin film layer of PDL patterns fabricated with photoresist (a) Pt-0 and (b) Pt-5.

common solvent, propyleneglycol monomethyletheracetate (PGMEA). It was found that polyimides melt polymerized with dianhydride monomers containing trifluoromethyl groups or alicyclic groups, and diamine monomers containing trifluoromethyl and phenolic −OH groups gave good patterns of pixel define layer in the photolithographic test. The black pixel defining layer patterns made with the polyimides as thermal stabilizer were found to have high thermal stability over 300˚C. We believe that this work can give direction to the design of new polyimides with high thermal stability for use in the photolithographic patterning of black PDL by precisely tuning the functional groups on the polyimide chain and the molecular weight.

Acknowledgements

This work was supported by the Technology Innovation Program of Industrial Strategic Technology Development Program (10063289, Development of High Temperature Negative tone Photosensitive Black Resin and Fabrication Process for Pol-less AMOLED Devices) funded by the Ministry of Trade, Industry & Energy (MOTIE, South Korea).

Cite this paper

Shi, G., Park, J.W. and Park, L.S. (2018) Black Photoresist for Patterning Pixel Define Layer of Organic Light Emitting Diode with Polyimide as Thermal Stabilizer. Materials Sciences and Applications, 9, 554-564. https://doi.org/10.4236/msa.2018.96040

References

- 1. Lee, J.K., Cho, S. and Kang, D.W. (2016) Analysis of Light Leakage between the Adjacent Pixels in a Color-Filter Stacked White OLED Display. Displays, 45, 6-13. https://doi.org/10.1016/j.displa.2016.09.001

- 2. Kim, M. and Jin, G.H. (2009) ITO/AlNdN/Al Contact Process for Active Matrix OLED Displays. Electronics Letters, 45, 421. https://doi.org/10.1049/el.2009.0037

- 3. Noda, M., Kobayashi, N., Katsuhara, M., Yumoto, A., Ushikura, S.I., Yasuda, R.I., Hirai, N., Yukawa, G., Yagi, I., Nomoto, K. and Urabe, K. (2010) 47.3: A Rollable AM-OLED Display Driven by OTFTs. SID 10 Digest, 41, 710-713.https://doi.org/10.1889/1.3500568

- 4. Liu, W., Jiang, C., Wang, D. and Li, Y.U.S. (2016) Organic Light-Emitting Diode (OLED) Display Panel, Pixel Define Layer (PDL) and Preparation Method Thereof. Patent 9373814 B2, 06. 21.

- 5. Liaw, D.-J., Wang, K.L., Huang, Y.C., Lee, K.R., Lai, J.Y. andHa, C.S. (2012) Advanced Polyimide Materials: Syntheses, Physical Properties and Applications. Progress in Polymer Science, 37, 907-974. https://doi.org/10.1016/j.progpolymsci.2012.02.005

- 6. Tamai, S. and Yamaguchi, A. (1996) Melt Processible Polyimides and Their Chemical Structures. Polymer, 37, 3683-3692.https://doi.org/10.1016/0032-3861(96)00178-4

- 7. Defranco, J.A., Schmidt, B.S., Lipson, M. and Malliaras, G.G. (2006) Photolithographic Patterning of Organic Electronic Materials. Organic Electronics, 7, 22-28.https://doi.org/10.1016/j.orgel.2005.10.002

- 8. Lee, J.B., Park, S., Heo, S.K., You, C.K., Min, H.K. and Kim, C.W. (2006) 2.22-Inch qVGA a-Si TFT-LCD Using a 2.5 um Fine-Patterning Technology by Wet Etch Process. Journal of Information Journal of Information Display, 7, 1-4.https://doi.org/10.1080/15980316.2006.9652004

- 9. Kim, H.R., Jung, J.W., Shin, M.S., Kim, M.E., Lee, Y.J. and Kim, J.H. (2007) Soft-Lithography for Preparing Patterned Liquid Crystal Orientations. Journal of Information Display, 8, 5-9. https://doi.org/10.1080/15980316.2007.9652026