Journal of Environmental Protection

Vol. 3 No. 7 (2012) , Article ID: 21115 , 5 pages DOI:10.4236/jep.2012.37070

Biofiltration of Nitrous Oxide Using Cow-Manure Based Compost as Medium Filter

![]()

Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Indonesia.

Email: nana@che.ui.ac.id

Received February 7th, 2012; revised March 6th, 2012; accepted April 9th, 2012

Keywords: Biofilter; Compost; Cow-manure; Nitrous oxide; Removal efficiency

ABSTRACT

Nitrous oxide (N2O) gas is a fourth contributor in the greenhouse effect after CO2, CH4, and water vapor. Although its concentration is relatively low, but very difficult to be decomposed in the atmosphere. A laboratory-scale biofilter was used to evaluate the effects of flow rate, medium depth, and water content of filter medium on the N2O removal efficiency and the growth of microorganisms in the compost. The biofilter was operated using cow-manure based compost medium with husk and coco peat as bulking agent. Research was carried out by batch flow system for 9 hours. The result indicates that the highest N2O removal efficiency is obtained under flow rate of 88 cm3/min with a depth of 50 cm and water content 50% (w/w) by 61%, and elimination capacity for 14,078 g/(m3·h) was achieved.

1. Introduction

Global warming will be followed climate change marked by increasing rainfall in some parts of the earth, while other parts have a prolonged dry season. This happens because there are changes in temperature and rainfall that occur gradually within a period of decades. One of the six types of gases that are classified as greenhouse gas in the UN Convention on Climate Change (United Nations Framework Convention on Climate Change—UNFCCC) is N2O gas. N2O gas is a fourth contributor in the greenhouse effect after CO2, CH4, and water vapor. Although the concentration is relatively low, but very difficult to decompose N2O in the atmosphere. N2O gas also has global warming potential index 310 times per unit weight is greater than CO2.

According to the Intergovernmental Panel on Climate Change (IPCC), in atmospheric N2O concentration increase of 46 ppb (17%) since 1750 and continues to increase [1]. Increasing is caused by N2O can be generated from natural processes and human activities. Naturally, N2O is produced from a large number of microbial activities in soil and water. Agricultural activities such as animal waste management and soil enrichment contributed 86% of the total emissions of N2O produced. Farm and industrial sectors such as the production of nylon, adipic acid, nitric acid and the burning of fuel in internal combustion engines also produce N2O.

Biofiltration has gained widespread support as an exhaust gas control technology that is economical to treat waste gas streams containing low concentrations of volatile organic and inorganic compounds [2]. Biofiltration involving immobilized microorganisms in the form of biofilms in porous media filter. Exhaust gas is transferred from the air flow into the biofilms that grow on the filter medium and will be degraded by microorganisms. The biofilter appears promising because it works by draining the contaminated air flow through a porous medium in which contaminants in the air flow are adsorbed by biofilms; these contaminants are oxidized to produce biomass, CO2, H2O, nitrate ( ), and sulfate (

), and sulfate ( ). In addition, the biofilter supports the growth of microorganisms present in the porous medium [3]; it has also been successfully used to eliminate odors and volatile organic compounds (VOC) such as benzene [4], styrene [5], phenol [6], and alkenes [7] from various industrial processes.

). In addition, the biofilter supports the growth of microorganisms present in the porous medium [3]; it has also been successfully used to eliminate odors and volatile organic compounds (VOC) such as benzene [4], styrene [5], phenol [6], and alkenes [7] from various industrial processes.

In biofiltration process, the success of the biodegradation process is totally determined by the activity of microbes in the filter medium. Therefore, the filter medium in the biofilter must be designed to provide a good environment for microbial growth and flow of gas through the filter medium. A number of factors need to be controlled so that the microbes can degrade and absorb exhaust gas efficiently. Temperature, water content of filter medium, pH, flow rate, nutrients, amount of pollutant content, and microbiology biofilter are a number of factors that affect biofiltration efficiency.

When compared with other filter media, compost not expensive, easily obtained, and contains a complex microbial community. Additional nutrients are also not required because compost have significant amount of organic nitrogen and other micronutrient [8]. Compost can be mixed with bulking agent to avoid high pressure drop, resistance and channeling as well as to increase endurance [9,10]. Biofiltration of NOX using compost filter medium capable of producing high reduction efficiency. Reference [11] investigated the concentrations of NO and O2, the column height, flow rate, the existence of an external carbon source on NO biofiltration using a mixture of the filter medium of compost and sawdust, and gain efficiency of NO reduction by 99%. In this research, a laboratory-scale biofilter was used to evaluate the effects of flow rate, medium depth, and water content of cowmanure based compost as filter medium on the N2O removal efficiency and the growth of microorganisms in the compost.

2. Materials and Methods

Biofilter equipment used in this research is made of acrylic material with a high dimensional column 120 cm, outside diameter 8 cm, and 7.35 cm inside diameter. Materials are selected in order to prevent leakage effectively as possible [11]. Meanwhile, piping and junctions in the biofilter system is made of stainless steel which has a minimum connection. Schematic diagram of biofilter used in this research is shown in Figure 1.

Filter medium used is compost. Compost is used comes

Figure 1. Biofilter column.

from the Green Lab, Sekolah Alam Indonesia. Compost consists of a mixture of cow-manure with coco peat and rice husks as bulking agent. Bulking agents are used to avoid high pressure drop, resistance and channeling. The process of drying and sifting filter medium made to get the filter medium with the appropriate moisture for the growth of microorganisms to degrade pollutants and produced compost with homogeneous particles.

Biofiltration experiment was conducted for 9 hours with continue flow system in order to evaluate the effects of flow rate, medium depth, and water content of filter medium on the N2O removal efficiency and the growth of microorganisms in the compost. Medium filter is one important factor affecting the performance of biofilter. Filter medium is a place for the growth of biofilms and microbial that will do the degradation of pollutants.

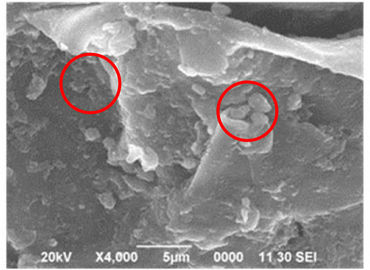

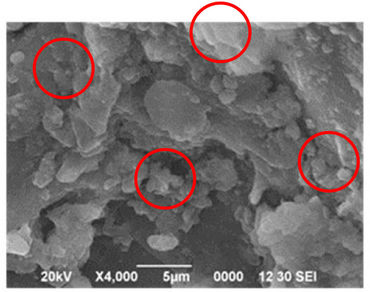

Biofilter performance test is carried out through analysis of N2O gas that comes out of filter medium with TCD gas chromatography (Shimadzu, Japan). Content of microbes in the compost before and after biofiltration was tested by Total Plate Count (TPC) method. Surface morphology of compost medium analyzed by using Scanning Electron Microscope (SEM) 4000× magnification, type JEOL JSM-6390 with 20 kV acc volts, wd 12 mm, spolsize 30th, and SEI signals. Prior to SEM, samples were first coated by using platinum for 30 seconds at 30 mA current.

3. Results and Discussion

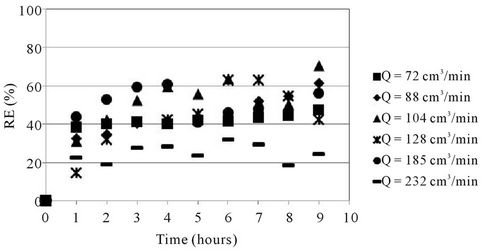

Figure 2 shows the N2O Removal Efficiency (RE) of biofiltration for each flow rate. The N2O RE tends to increase every hour, although this does not happen in 0 to 2 hours because at this time the N2O flowing in the medium has not homogenous and produced unsteady conditions. It can be seen that the highest RE obtained in the 9 hours of biofiltration is reached in 103 cm3/min gas flow rate with 70.1% N2O RE.

However, the selection of the optimal flow rate to produce the highest RE is not only based on the results obtained in the 9 hours but also through observation of the RE profile that can generate steady condition. Reference [12] states that the emission of pollutant gases that often fluctuates can cause damage to the biofilter microbial population and the overall performance. Therefore, the optimum N2O gas flow rate chosen in this experiment is 88 cm3/min with RE 61.3%.

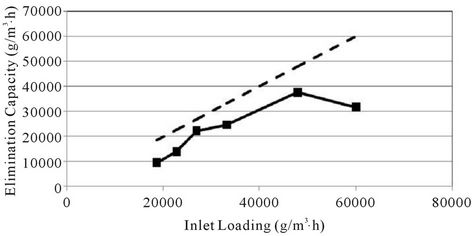

Elimination Capacity (EC) is an actual reduction capacity of the biofilter. Generally, EC value will be lower than the load and its value will be equal to the load when the removal efficiency of 100% obtained. Figure 3 shows that the EC is not equal to the load and its value is lower than the value of load. If the load value increased, a point will be reached where the rate of mass load will

Figure 2. N2O removal efficiency at various flow rate (h = 49.7 cm, m = 945 g, filter medium = dry compost).

Figure 3. Elimination capacity in various inlet loading.

exceed the overall capacity of the overall elimination and RE is lower than 100%. This point is called the critical load or critical EC. In studies with this flow rate variations, load value can’t be increased because the overall mass loads rate have exceeded the capacity of the overall elimination. Therefore, the RE obtained is lower than 100%.

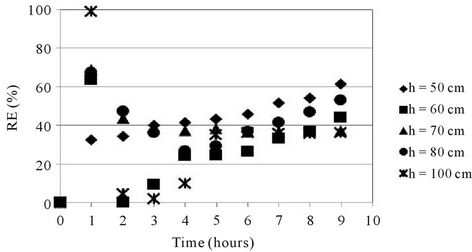

N2O RE of each filters medium depth shown in Figure 4. The previous research results stated that the position of the higher column can produce a better reduction performance [11]. On the other hand, increasing the depth of the filter medium has the potential to create compaction in medium at the bottom of the column which can lead to the high pressure drop. High pressure drop indicates the resistance of N2O gas which makes the gas can not be through the medium filter for degraded by microbes.

N2O RE at 50 cm depth is higher when compared with the RE at a higher depth. This can be explained by considering Figure 4, where the time required by N2O to be homogeneous in the biofilter column until it reaches steady state at 50 cm depth only 2 hours. Meanwhile, at a depth ≥ 60 cm the time required by N2O to be homogeneous is more than 4 hours. Therefore, in order to evaluate the N2O RE at medium depth ≥ 60 cm, may take longer observation due to the time of N2O gas to reach a stable state.

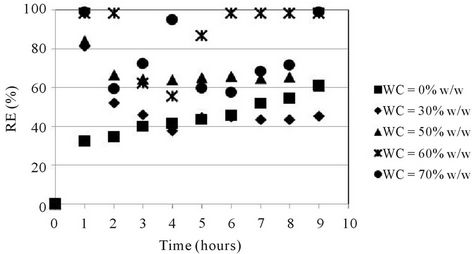

Figure 5 shows profile of the reduction efficiency in water content of filter medium variation up to 9 hours. Addition of water content, aims to increase the humidity

Figure 4. N2O removal efficiency at various depths (filter medium = dry compost).

Figure 5. N2O removal efficiency at various WC (h = 49.7 cm, m = 945 g, filter medium = wet compost).

of filter medium. Humidity is a critical factor in the effectiveness of biofilter because the microorganisms require water for metabolic activities. Humidity recommended for organic filter medium ranged between 40% - 60% (by weight) [13].

Higher humidity occur instability of N2O outlet concentration. RE in 60% and 70% humidity, reached up to 100% caused by N2O gas at outlet column was not detected by gas chromatography. This occurs because the addition of the water making too much water in filter medium. This will prevent the transfer of oxygen and hydrophobic pollutants in biofilms, the emergence of anaerobic zones in the filter medium, inhibits the reaction rate, the back pressure due to decrease in empty space volume [12].

Its shows that through the addition water will tend to increase the N2O RE, but if additional water is too much, then the efficiency will be reduced. Biofiltration operate most efficiently on water content (WC) of between 50% - 70% and temperatures between 15˚C and 35˚C [14]. In this research, the best RE obtained at water addition of 50% wt of compost.

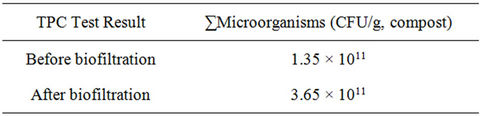

TPC is one of microbes’ calculation technique using nutrients (NA) as a medium for microorganisms that will be counted. The results of the TPC calculation will be represented in terms of Colony Forming Units (CFU) per gram of compost tested. In the TPC test results can be seen different numbers of bacteria before and after biofiltration visually. The calculation result of colonies number after biofiltration is more than prior colonies number. Increasing the number of microbes after 9 hours biofiltration can be seen in Table 1.

Increasing the number of microorganisms showed that microbes could survive and reproduce themselves during the process of biofiltration. In order to survive, microbes need food with balanced nutrition and a natural filter medium such as compost to provide nutrients to support the growth of microorganisms, while carbon and energy needed by the microorganisms can be derived from contaminant gases. Contaminant transferred from flow of air into the biofilms that grow on the filter medium and be degraded by microorganisms.

The transform of microorganisms population before and after biofiltration also be observed through the SEM (Scanning Electron Microscope) to see the morphology of compost. Figures 6 and 7 show the surface morphology of compost before and after 9 hours biofiltration

Figure 6. SEM test results on compost before biofiltration.

Figure 7. SEM test results on compost after biofiltration.

Table 1. TPC test results.

process. Based on the SEM results, can be seen the difference in the initial compost with compost that has been used for biofiltration. Compost before biofiltration contains less visible microorganisms than the compost after biofiltration.

4. Conclusion

The highest N2O removal efficiency 61% in biofiltration process using cow-manure based compost as medium filter, was obtained under 88 cm3/min flow rate, with a depth of 50 cm, and water content 50% (w/w). Microorganisms in compost could survive and reproduce themselves during 9 hours process of N2O biofiltration.

REFERENCES

- Intergovernmental Panel on Climate Change (IPCC), “Climate Change 2001: Impacts, Adaptation, and Vulnerability,” IPCC Third Assessment Report, 2001.

- C. Kennes and M. Veiga, “Conventional biofilters,” In: C. Kennes and M. Veiga, Eds., Bioreactors for Waste Gas Treatment, Kluwer Academic Publishers, Dordrecht, 2001, pp. 47-98.

- Y. h. Liu, et al., “Removal of Ternary VOCs in Air Streams at High Loads Using a Compost-Based Biofilter,” Dalian University of Technology, Dalian, 2004.

- K. Kardono and E. R. Allen, “Elimination of Benzene Using a Compost Biofilter,” 88th Annual AWMA Meeting & Exhibition, 1995.

- L. Lackey and T. Holt, “Not for the birds,” WEF Industrial Wastewater, Vol. 4, 1996, pp. 31-33.

- M. Zilli, A. Converti, A. Lodi, D. M. Borghi and G. Ferraiolo, “Phenol Removal from Waste Gases with a Biological Filter by Pseudomonas Putida,” Biotechnology and Bioengineering, Vol. 41, No. 7, 1993, pp. 693-699. doi:10.1002/bit.260410703

- E. Morgenroth, E. D. Schroeder, D. P. Y. Chang and K. M. Scow, “Nutrient Limitation in a Compost Biofilter Degrading Hexane,” Journal of the Air & Waste Management Association, Vol. 46, 1995, pp. 300-308.

- E. Pagans, X. Font and A. Sanchez, “Biofiltration for Ammonia Removal from Composting Exhaust Gases,” Chemical Engineering Journal, Vol. 11, No. 2-3, 2005, pp. 105-110. doi:10.1016/j.cej.2005.03.004

- Y. Liang, et al., “Long-Term Results of Ammonia Removal and Transformation by Biofiltration,” Journal of Hazardous Materials, Vol. 80, No. 1-3, 2000, pp. 259- 269. doi:10.1016/S0304-3894(00)00314-9

- R. E. Nicolai and K. A. Janni, “Biofilter Media Mixture Ratio of Wood Chips and Compost Treating Swine Odors,” Water Science and Technology, Vol. 44, No. 9, 2001, pp. 261-267.

- W.-F. Yang, et al., “The Effect of Selected Parameters on the Nitric Oxide Removal by Biofilter,” Journal of Hazardous Materials, Vol. 148, No. 3, 2007, pp. 653-659. doi:10.1016/j.jhazmat.2007.03.023

- Z. Shareefdeen and S. Ajay, “Biotechnology for Odor and Air Pollution Control,” Springer, Heidelberg, 2005.

- C. Van Lith, S. L. David and R. Marsh, “Design Criteria for Biofilters,” In: C. Van Lith, S. L. David and R. Marsh, Eds., Effluent Treatment and Waste Disposal, ClairTech, Utrecht, 1990, pp. 127-132.

- R. E. Nicolai and K. A. Janni, “Effect of Biofilter Retention Time on Emissions from Dairy, Swine, and Poultry Buildings,” 1999.