Journal of Transportation Technologies

Vol. 3 No. 2 (2013) , Article ID: 30419 , 13 pages DOI:10.4236/jtts.2013.32015

Life Cycle Assessment of Creosote-Treated Wooden Railroad Crossties in the US with Comparisons to Concrete and Plastic Composite Railroad Crossties

1AquAeTer, Inc., Division of Sustainability, Centennial, USA

2AquAeTer, Inc., Division of Sustainability, Helena, USA

Email: cbolin@aquaeter.com, stephentsmith@wildblue.net

Copyright © 2013 Christopher A. Bolin, Stephen T. Smith. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received March 9, 2013; revised April 11, 2013; accepted April 17, 2013

Keywords: Creosote; Environmental Impact; Railroad Crossties; Life Cycle Assessment (LCA); Concrete; Plastic Composite

ABSTRACT

Creosote-treated wooden railroad crossties have been used for more than a century to support steel rails and to transfer load from the rails to the underlying ballast while keeping the rails at the correct gauge. As transportation engineers look for improved service life and environmental performance in railway systems, alternatives to the creosote-treated wooden crosstie are being considered. This paper compares the cradle-to-grave environmental life cycle assessment (LCA) results of creosote-treated wooden railroad crossties with the primary alternative products: concrete and plastic composite (P/C) crossties. This LCA includes a life cycle inventory (LCI) to catalogue the input and output data from crosstie manufacture, service life, and disposition, and a life cycle impact assessment (LCIA) to evaluate greenhouse gas (GHG) emissions, fossil fuel and water use, and emissions with the potential to cause acidification, smog, ecotoxicity, and eutrophication. Comparisons of the products are made at a functional unit of 1.61 kilometers (1.0 mile) of railroad track per year. This LCA finds that the manufacture, use, and disposition of creosote-treated wooden railroad crossties offers lower fossil fuel and water use and lesser environmental impacts than competing products manufactured of concrete and P/C.

1. Introduction

Railroads are a critical transportation element of the US economy, distributing large quantities of material goods and oftentimes in a more efficient manner than roadbased transportation [1]. This transportation efficiency is often measured by the equipment moving goods [2-4], but to understand the burdens associated with various modes of transportation, one must consider the system as a whole, including not only the equipment moving the goods, but the surface the equipment moves upon. The structural components that make up the railway line include the rail, rail tie-plate, crossties, supportive ballast, and subgrade [5]. Railroad crossties are the base members, to which steel rails are attached to transfer load from the rails to the underlying ballast. The ties also provide the critical function of keeping the rails at the correct gauge and alignment. Wooden crossties have been the backbone of this system for more than 150 years, a system that, in the US, has an estimated 273,700 track kilometers (170,000 miles) [6].

While non-durable wood products are susceptible to degradation when left untreated [7], wood preservative treatments can extend the useful life of a wood product by 20 to 40 times that of untreated wood [8] when used in weather-exposed or wet environments subject to microbial or insect attack.Wood preservation with coaltar creosote became commercially viable when a patent was taken out by John Bethell in 1838 [9]. Creosote “empty cell treatment” was introduced by Rueping in 1902 and refined in 1907 to a process in which a large cylinder is filled with compressed air, creosote is pumped in while maintaining air pressure, injection occurs under pressure,preservative is pumped out, and then a vacuum is applied at the end of the process so that air contained in wood cells will expel excess preservative. Lowry introduced in 1906 a quick vacuum at the end of the pressure process [9]. Today, most ties are treated with creosote using the empty cell Rueping process. Coal tar creosote treated wood products have a long history of proven performance in transportation systems [10].

Consumer and regulatory agency concern about environmental impacts resulting from the manufacture, use, and disposal of infrastructure products, such as coal-tar creosote treated crossties, understandably has resulted in increased scrutiny during selection of transportation construction products. Products such as creosote-treated wooden crossties are, in some cases, being replaced with concrete and plastic composite (P/C) crossties for various reasons, but at least partially based on perception rather than scientific or quantitative consideration of these concerns.

2. Goal and Scope

The goal of this study is to provide a comprehensive; scientifically-based; and fair, accurate, and quantifiable understanding of environmental burdens associated with the manufacture, use, and disposition of creosote-treated wooden crossties using primary data collected at US treating plants and secondary data from other sources.

The scope of this study includes investigation of cradle-to-grave life cycle environmental impacts for creosote-treated wooden railroad crossties in US Class 1 railroads using life cycle assessment (LCA) methodologies. The results of the creosote-treated crosstie LCA are compared to LCA findings for alternative products: concrete and P/C crossties. LCA is the preferred method for evaluating the environmental impacts of a product from cradle to grave, and determining the environmental benefits one product might offer over its alternative [11].

The LCA methodologies used in this study are consistent with the principles and guidance provided by the International Organization for Standardization (ISO) in standards ISO 14040 [12] and 14044 [13]. The study includes the four phases of an LCA: 1) Goal and scope definition; 2) Inventory analysis; 3) Impact assessment; and 4) Interpretation. The environmental impacts of creosote-treated, concrete, and P/C railroad ties are assessed throughout their life cycles, from the extraction of the raw materials through processing, transport, primary service life, reuse, and recycling or disposal of the product.

Crosstie alternatives are produced by many different manufacturers using differing materials and manufacturing processes. Therefore, a “typical product” has been estimated for both concrete and P/C crossties. The concrete and P/C typical products have approximately the same dimensions as, and generally are used as direct alternatives to, creosote-treated railroad ties. However, concrete ties have a different spacing requirement and cannot be interspersed with other types of ties. The LCAs for concrete and P/C ties do not include independent manufacturing inventory data (primary data). Consequently, a general comparison of LCIA impact indicators is done to understand how the creosote-treated crosstie and alternative product life cycles compare. Additional alternative product data collection and analysis are needed to fully detail the comparability of specific alternative products.

3. Life Cycle Inventory Analysis

The Railway Tie Association [14] estimates that North American railroads purchased 20,394,000 new wood ties in 2007. The creosote-treating industry reports that approximately 314 million liters (82.9 million gallons) or 345 million kilograms (760 million pounds) of creosote were used in the US in 2007 to treat 2.86 million cubic meters (101 million cubic feet) of wood, of which approximately 71% was produced for railroad applications, most of which was for creosote-treated crossties [15].

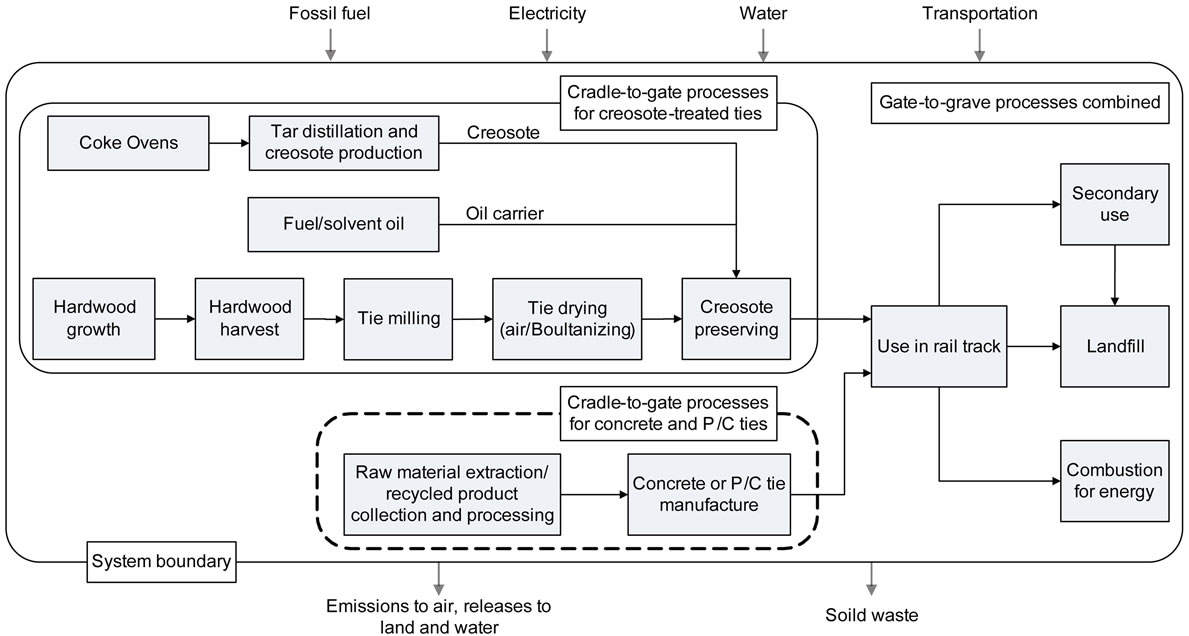

Primary data and information for the life cycle inventory (LCI) are obtained from US treaters of wooden railroad ties using creosote preservative. Secondary data are obtained from the scientific literature and from the US Life Cycle Inventory Database maintained by the National Renewable Energy Laboratory (NREL). LCI inputs and outputs for the creosote-treated wood tie are quantified per 28.3 cubic meters (1000 cubic feet (Mcf)). The cubic foot (cf) unit is a standard unit of measure for the US tie industry and is equivalent to 0.028 cubic meters (m3). Inventory data are converted to a functional unit of per 1.61 kilometers (1.0 mile) of Class 1 railroad per year of use, allowing assessment of the impacts of tie spacing and service life. The cradle-to-grave life cycle stages considered in this LCI are illustrated in Figure 1.

This life cycle assessment allocates manufacturing inputs on both volumetric and mass basis and outputs on a mass basis. In most cases life cycle process modules were downloaded from NREL. The NREL modules include allocations needed to determine applicable inputs and outputs associated with material acquisition and manufacturing processes. At disposition, some of the product leaves the system as thermal energy and is allocated as a credit to the use of fossil fuel.

3.1. Creosote-Treated Railroad Tie Inventory

This study builds on existing research for forest resources and adds the treating, service use, and disposition stages of creosote-treated wood railroad ties. Previous studies, such as research conducted by the Consortium for Research on Renewable Industrial Materials (CORRIM), have investigated the environmental impacts of wood products. CORRIM’s efforts build on a report is-

Figure 1. Life cycle stages of railroad ties.

sued under the auspices of the National Academy of Science regarding the energy consumption of renewable materials during production processes [16]. CORRIM’s recent efforts [17-19], have focused on an expanded list of environmental aspects necessary to bring wood products to market.

The main source of forest products LCI data used in this study is Oneil et al. [19]. Data include forestry practices applicable to hardwood products from the Northeast and North/Central U.S from the forest (cradle) to the mill (gate). Hardwood trees naturally regenerate and fertilizer usually is not applied, thus, the environmentally relevant inputs are limited to the fuel required to cut, trim, load, and transport logs to mills. Bergman and Bowe [20] completed a gate-to-gate LCI of hardwood lumber milling process inputs and outputs that is adapted in the inventory of this LCA to represent hardwood railroad tie production. Inputs and outputs include electricity and fuel requirements, transportation, water use, and particulate emissions. The data from Oneil et al. and Bergman and Bowe are allocated by volume for a “typical” tie measuring18 cm (7-in) high by 23 cm (9-in) wide by 2.6 m (8.5-ft) long.

Twenty-two (22) creosote treating plants in the U.S. provided primary data responses to a questionnaire covering operations in 2007. The total volume of creosotetreated ties reported in the surveys is approximately 2.0 million cubic meters (71,000 Mcf) of product, including approximately 1.7 million cubic meters (60,000 Mcf) of hardwood crossties. Vlosky [15] estimates US industry total creosote railroad tie treatment in 2007 at approximately 2.0 million cubic meters (71,000 Mcf). Gauntt [14] estimates that 20,394,000 new wood ties were purchased by North American railroads in 2007, or between 1.9 to 2.1 million cubic meters (67,000 to 75,000 Mcf) at an average volume of 0.093 to 0.11 cubic meters (3.3 to 3.7 cubic feet) per tie. Both estimates support the representation that all, or nearly all, creosote treatment in the US provided input to the primary data used in this study.

The LCI for creosote production considers both coke oven and tar distillation processes. Creosote preservative is produced to meet AWPA standards P1/P13 [21], P2 [22], or P3 [23]. Standard P2 creosote generally is used for crossties. A weighted average of creosote types from the survey data is used as the reference preservative for this LCA. The treaters surveyed as part of this LCA report a weighted average of creosote preservative use of 94% creosote (both P1/P13 and P2) and 6% petroleum oil.

AWPA [24]specifies creosote retention of 112 kg/m3 (7.0 pounds per cubic foot (pcf)) or refusal for oak and hickory crossties. Retention is based on gauge measurement, meaning that retention is the total weight of creosote injected divided by the total volume of wood treated. The average creosote use rate, as reported in surveys, is approximately 88 kg/m3 (5.5 pcf). The difference is consistent with the AWPA specifications because a large percentage of the total volume of wooden ties accepts less than specified amounts of preservative (“refusal”). Therefore, survey data are used in this study.

Outputs in the form of solid waste, waste water discharges, chemical releases from process equipment and stored product are primary data. Releases of creosote to air are reported under the Toxic Release Inventory (TRI) reporting program and include releases from the process equipment, such as tank vents and treating cylinders. Evaporative losses from the finished ties are estimated at 0.12 kg/m3 (7.5 pounds/Mcf) for the first 120 days following treatment [25]. Treatment process releases of creosote, used in the LCI, are summarized in Table 1.

Creosote-treated railroad ties are installed at 49.5 cm (19.5 inch) spacing, center-to-center, or at a frequency of 3249 ties per 1.61 km (1.0 mile). Service life is a function of quality and species of wood, quality and type of treatment, laying condition, use intensity, and environmental factors. Based on studies of US railways by Zarembski [26] and contact with industry sources, a 35-year average service life is assumed in this LCI for creosotetreated railroad ties, an estimate greater than the 15-year estimate in Japan [27], the 20 to 30-year estimate in Australia [28], and the 24 to 30-year estimate in Switzerland [29]. Extended service life by dual treatment with borate and creosote also is addressed through sensitivity analysis. Maintenance applications of preservative to an installed tie, such as ones containing borate, are considered rare and are not included in this LCA. The amount of steel, including tie plates, spikes, and rail anchors, is calculated and inventoried in the LCA. The system boundary does not include supportive ballast except for concrete tie products that require additional ballast material for stability. Only the ballast that is required in addition to that normally used for wood and P/C ties is considered.

Studies done by Becker et al. [30], Brooks [31], Burkhardt et al. [32], Chakraborty [33], Gallego et al. [34], Geimer [35], Gevao and Jones [36], and Kohler and Kunniger [37] have investigated the releases of “creosote” over time and the release mechanism (i.e., releases by volatilization or leaching).The term “creosote” describes the liquid used to treat wood ties, but is imprecise when applied to environmental releases to air, soil, or water. None of the creosote release studies provide individual chemical constituent information necessary as inputs in this LCI for determining impact indicators; thusrelease estimates were developed for this study. The molecular weights and mass fractions of the numerous chemical components of AWPA Standard P2 creosote are provided by Sparacino [38] and are used to estimate fractional amounts of chemical components released from ties at treatment and during time in service.

Creosote constituents are released in proportion to their pure vapor pressures (VPs) and initial concentrations. Constituent VPs range from approximately 4 kilopascal (KPa) to approximately 2 × 10−6 KPa (6 × 10−1 pounds-force per square inch absolute (psia) to 3 × 10−7 psia). Creosote constituents are sorted into four groups by VP (high, medium-high, medium, and low). For each group, assumptions are made regarding the amount of each constituent released and the fraction of the release emitted into the air, as shown in Table 2. These creosote loss factors are multiplied times the constituent mass in creosote and calculated as the amount released. The release times the air fraction value is the amount released to the air. Total releases of creosote are estimated to average approximately 1% per year with releases to air at approximately 0.1% per year of initial treatment mass.

According to the Railway Tie Association, approximately 17.1 million wood ties are removed from active and inactive track in the US per year. Following removal, the ties 1) are recycled to other treated wood uses, such as landscape materials (39%); 2) are beneficially used for energy recovery (56%); or 3) are disposed as waste in landfills (5%).

Table 1. Treating process outputs from creosote-treater surveys.

Table 2. Release of creosote constituents by vapor pressure.

Removed ties beneficially used as a fuel are modeled as fuel in a steam-electric power plant and the energy value is calculated assuming 20% moisture and considering the carbon content of the remaining wood, creosote, and carrier petroleum oil. Electricity production is based on 50% thermal efficiency. The amount of electricity produced from the tie fuel is entered as an electricity credit. All wood carbon emitted is inventoried as biogenic carbon dioxide. All creosote and petroleum oil preservative carbon emitted is inventoried as fossil carbon dioxide. Emissions from energy recovery are inventoried and assumed to occur with the use of advanced particulate controls. Credits, from recycling wood ties to energy following use, result in some LCI inputs being less than zero, and thus are environmentally beneficial when summed for the whole product life cycle, as shown in Table 3.

In contrast to an LCA done to evaluate GHG emissions from concrete and treated wood sleepers (crossties) by Crawford [28], this LCA accounts for anthropogenic GHG and biogenic GHG as neutral related to global warming. Crawford assumed all wood mass from the forestry product, not used as ties, was burned as waste and that at the end of service life, wood ties fully decayed. The carbon dioxide released from forestry product and ties was counted as a GHG, the same as fossil carbon dioxide, with no accounting for carbon uptake by tree growth and the assumption that no beneficial energy was produced either from forestry biomass or from used ties. This LCA better reflects actual North American practice and develops GHG conclusions that contradict those by Crawford.

Steel tie plates and other parts installed with ties are inventoried in the use stage by mass, assuming production in a blast furnace. Recycled steel is inventoried in the final fate stage both as a negative use offsetting the initial use and as the amount of electricity typically used in an electric arc “mini-mill” to melt and reform steel shapes. In this manner, as recycled steel approaches 100%, the minimum inputs required for steel are those to melt and shape steel in each use cycle. Primary steel manufacture, in a blast furnace, is based on inventory data from NREL. NREL database information assumes 85% of steel is recycled. New steel yield from recycled steel is 95%. Energy input to mini-mills, processing recycled steel, is assumed to be of 0.011 terajoule (TJ) per metric ton (1.33 kiloWatt hours per pound (kWh/lb) of steel) of grid electricity [39].

Landfill-disposed crossties are modeled as if decayed to a point where the primary phase of anaerobic degradation has occurred and 17% of the product’s carbon is released as carbon dioxide, 6% is released as methane, and 77% [40] remains in long-term storage in the landfill. Inputs and outputs related to landfill construction and closure are apportioned on a mass disposed basis [41].

Transportation-related inputs and outputs are quantified for each life cycle process. Distances and transport modes for preservative supply to treaters, inbound untreated ties, and outbound treated ties are based on treater survey weighted averages.

3.2. Concrete Railroad Ties Inventory

The “representative” concrete tie has a weight of 318 kg (700 pounds), and includes eight strands of 9.5 mm (3/8- in) pre-stressed steel cable. Concrete tie placement is assumed to be at 61 cm (24-in), on center. A survey of concrete tie manufacturers was not done for production inputs and outputs; therefore, some inputs and outputs may not be fully identified or quantified. Elastic fasteners and clips, constructed of steel, are included in the inventory. The maintenance frequency of concrete crossties includes clip replacement only once during the crosstie life. No carbonatization of concrete is accounted for in the inventory. This LCI does not account for polymer tie pads, pad replacements, or repairs to concrete tie seat areas, items that might add to indicator impacts.

The Railway Tie Association commissioned a study of concrete tie service life specifically for use in this LCA project [42]. The study concluded: “It appears that a reasonable estimate for concrete tie service life under North American railroad operating conditions is between 40 and 45 years.” However, the study noted that while concrete ties were installed by one railroad as early as the 1970s, current concrete ties are a relatively new product within the modern North American railroad system with the average age of in-service ties being approximately 13 years. Life variability is high with projected life from approximately 20 years (using Norfolk Southern data) to 41 years (Canadian National data). Premature concrete tie failures have been documented [43], further supporting a conservative service life estimate. Given the high variability and still unknown long-term performance, an assumption of 40 years is used in this LCI for average concrete tie life.

Concrete ties require additional ballast compared to wood or P/C tie systems. Only the additional ballast required for concrete ties is considered in this LCA. 23 cm (9 in) of additional ballast is assumed for the concrete tie model.

Concrete tie rail systems offer advantages to railroads in select situations. In particular, some, but not all, railroads use concrete ties for heavy-haul, higher-curvature track locations. The greater weight of the concrete ties is thought to reduce rail movement in comparison to the lighter wooden ties. Such special situations are outside the scope of this LCA.

When concrete ties are removed from service, it is assumed that a small fraction (5%) will be reused by railroads while most either will be crushed and reused as

Table 3. Creosote-treated, concrete, and P/C railroad tie cradle-to grave life cycle inventory summary (per tie).

aggregate (25%) or disposed in landfills (70%). The low fraction of recycled to aggregate reflects the difficulty and expense of grinding high-strength reinforced concrete. Steel from embedded fasteners and reinforcement from recycled ties is assumed to be recycled and inventoried in the same way as with creosote-treated ties.

Concrete railroad ties disposed in landfills have inputs and outputs associated with landfill construction and closure proportional to the mass of disposed ties. No releases or emissions are modeled from concrete ties once disposed in a landfill.

3.3. P/C Railroad Tie Inventory

P/C ties can be made of recycled plastics, generally polyethylene, but often include other materials such as steel fiber, steel reinforcing bar, shredded used tires, mineral filler, virgin plastic, or concrete. The modeled representative P/C tie is assumed to be 8% virgin HDPE plastic, 7% talc (mineral filler), and the balance a mixture of post-consumer recycled milk bottles, grocery bags, and tires [44]. Electric energy is required to process the mixture and extrude the P/C product. The spacing of the P/C product and the required steel used to fasten the P/C tie to the track are assumed the same as creosote-treated crossties.

While recycled plastic does not carry the inputs and outputs of virgin material, post-consumer plastic use requires collection and processing inputs [45]. Inputs and outputs included in the inventory are similar to those for thermoplastics recycling by Garrain et al. [46].

P/C ties have not yet developed enough history to accurately predict service life. This LCA assumes that P/C ties will provide an average service life of 40 years, similar to concrete ties. Also, the P/C tie market is not yet sufficiently mature to know how ties will be handled when removed from service. For this LCA it is assumed that following removal from railroad use, 5% of P/C ties will be reused by a railroad for another purpose, 20% will be recycled to the plastic reuse market, and 75% will be disposed in landfills. Steel, attached to P/C ties, is assumed to be recycled (75%) and is inventoried in the same way as for creosote-treated ties.

A summary of selected inventory inputs and outputs for creosote-treated, concrete, and P/C ties is provided in Table 3.

4. Life Cycle Impact Assessment

4.1. Selection of the Impact Indicators

The impact assessment phase of the LCA uses the LCI results to calculate impact indicators. The environmental impact indicators are considered at “mid-point” rather than at “end-point” in that, for example, the amount of greenhouse gas (GHG) emission in mass of carbon dioxide equivalent (CO2-eq) at mid-point is provided rather than estimating end-points of global temperature or sea level increases. The life cycle impact assessment is performed using USEPA’s Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts, Version 2002 ((TRACI [47] and [48]) to assess GHG, acidification, ecotoxicity, eutrophication, and smog impacts potentially resulting from life cycle air emissions. Other indicators of interest also are tracked, such as biogenic and anthropogenic contributions to net GHG emissions, fossil fuel use and water use.

4.2. Impact Indicators Considered but Not Presented

The TRACI model, a product of USEPA, and the USEtox model [49] a product of the Life Cycle Initiative (a joint program of the United Nations Environmental Program (UNEP) and the Society for Environmental Toxicology and Chemistry (SETAC)), offer several additional impact indicators that were considered during the development of the LCA, such as human health impacts and impacts to various impact indicators from releases to soil and water. The decision was made not to include these impact indicators because of limited and/or insufficientdata and concerns regarding misinterpretation. Thus, the life cycle inventory includes releases of chemicals associated with impacts (such as human health and land and water ecological impacts), but impact indicators for these categories are not calculated. Land use impacts are beyond the scope of this LCA.

5. Life Cycle Interpretation

5.1. Findings

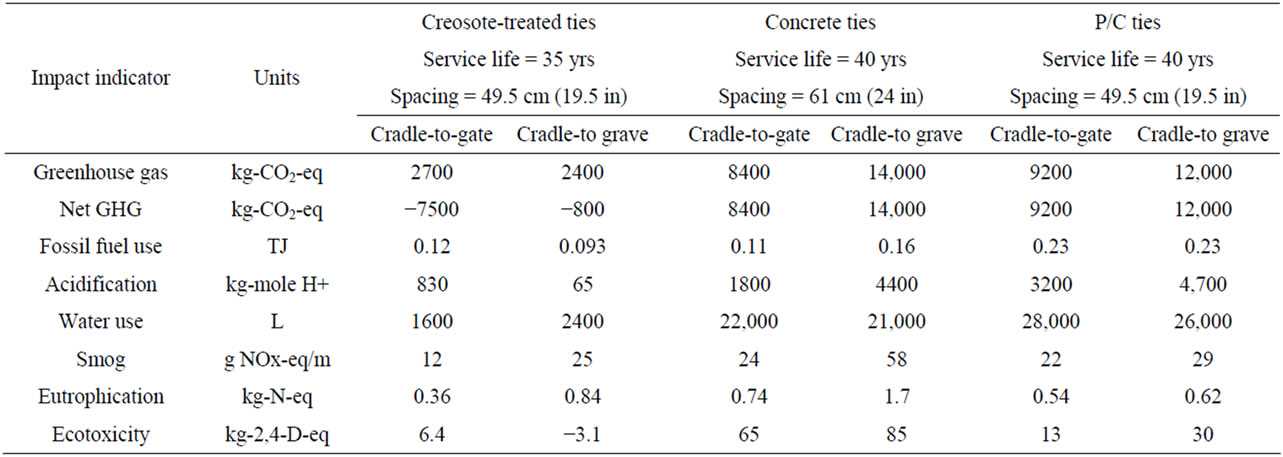

Impact indicator values are totaled at two stages for creosote-treated, concrete, and P/C crosstie products: 1) the new tie at the manufacturing facility after production, and 2) after service and final disposition. A summary of impact indicator values for all three crosstie products is provided in Table 4. Negative-value impacts are recognized as credits or beneficial to environmental conditions. Comparisons are made per year and per 1.61 km (1.0 mi) of railroad track to account for differences in service life expectancy and spacing.

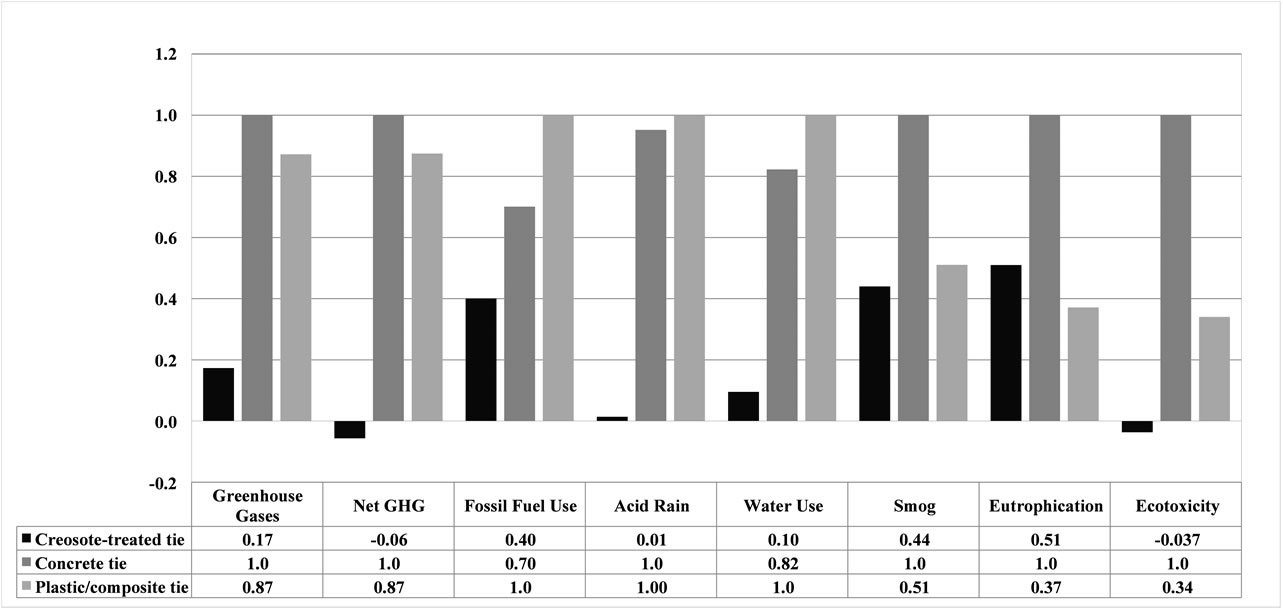

Impact indicator values are normalized to the product (creosote-treated tie, concrete tie, or P/C tie) having the highest cradle-to-grave value, allowing relative comparison of indicators between products on Figure 2. The product with the highest value at final disposition receives a value of one, and the other products are fractions of one.

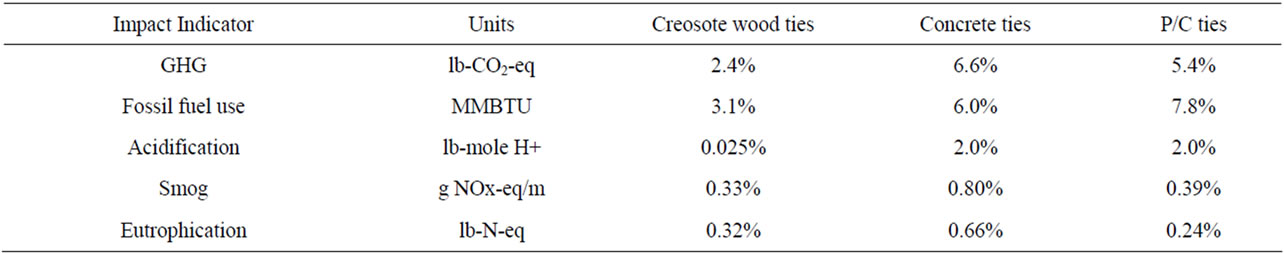

According to the Research and Innovative Technology Administration (RITA [50]), the Class 1 railroad total freight volume was approximately 2.58 trillion ton-

Table 4. Summary of impact indicator totals at life cycle stages for creosote, concrete, and P/C ties (per year of use and per 1.6 km (1mile) of railroad track).

Figure 2. Creosote-treated wood, concrete, and P/C ties normalized impact comparisons (normalized to maximum impact = 1).

kilometers (1.77 trillion ton-miles) in 2008. The annual impacts attributable to all ties in the US, if made of the same material, are compared as a percentage of the annual Class 1 freight related impacts in Table 5 (i.e., the impacts calculated for tie manufacture, use, and disposition of each tie material are compared to railroad freight impacts).

5.2. Data Quality Analyses

Data quality analyses per ISO 14044 [13] includes a gravity analysis, uncertainty analysis, and sensitivity analysis.

5.2.1. Gravity Analysis

A gravity analysis is done to identify the creosote-treated crosstie manufacture, use, and disposition processes most significant to the impact indicator values. This gravity analysis only considers creosote treated ties. Significant contributing processes to the gravity of each impact indicator are described below.

• Anthropogenic GHG emissions are most notably impacted by steel plates and spikes, but also by green tie production and tie treatment. GHG emissions are reduced or offset from steel recycling and for fossil energy offset by producing electricity from recycled used ties.

• Net GHG emissions demonstrate the environmental benefit of wood products that first remove carbon dioxide as the forestry product grows. The net result is

Table 5. National normalized cradle-to-grave impact per year for total miles of track ties in the US as a fraction of total class 1 RR freight transport impacts per RITA [50].

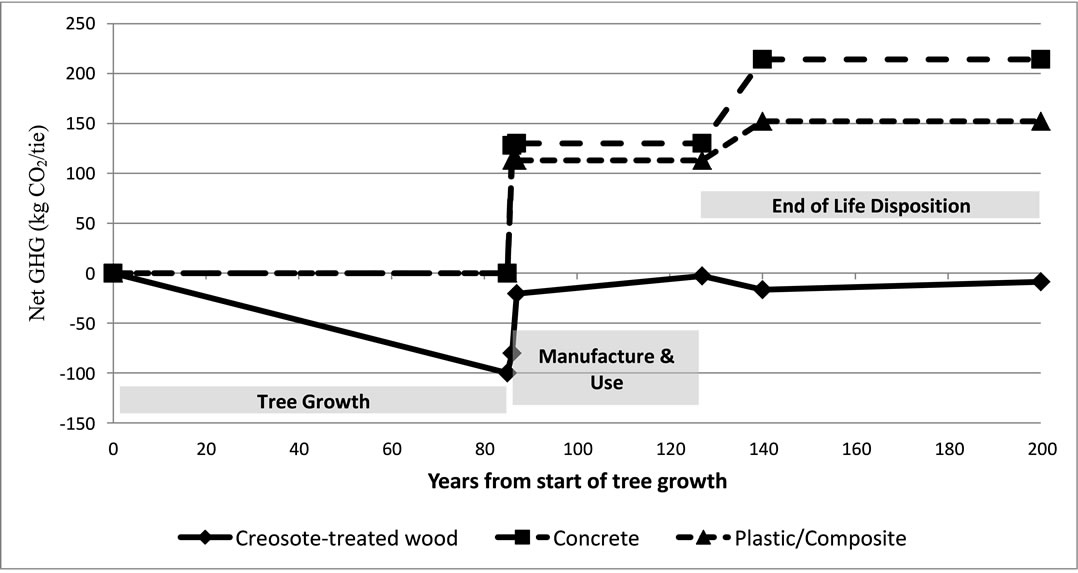

an overall reduction in GHG when using creosotetreated wood ties, whereas ties made of extracted materials only emit GHG in all stages. This difference between wood and products of other materials is clear in Figure 3.

• Fossil fuel use is most notably impacted by preservative manufacture and use, the manufacture of steel plates and spikes, and fossil fuel offsets from the energy recovery of used creosote-treated ties.

• Acidification is most notably impacted by the manufacture of steel plates and spikes, and credits from the offset of electricity from energy recovery. The credits received from the beneficial use of ties for energy recovery are large enough to result in an overall cradleto-grave impact of acidification near zero.

• Water use is most notably impacted by use at the treating facility and in the manufacture of steel plates and spikes.

• The potential to impact smog is most notably impacted by the manufacture of steel plates and spikes, creosote releases from ties in service, and transport of the ties throughout the life cycle; however, a credit also is recognized from steel recycling and the offset of electricity from energy recovery.

• Eutrophication is most notably impacted by the manufacture of steel plates and spikes and the combustion of used ties in the energy recovery stage. Emissions related to transportation also are significant to eutrophication. Eutrophication is reduced by steel recycling.

• Ecotoxicity impact is largely a result of the manufacture of steel plates, creosote releases from ties inservice, and combustion of used ties for energy recovery. The ecotoxicity impact indicator is reduced by steel recycling and the offset from the combustion of used ties for energy recovery, resulting in an overall credit for ecotoxicity.

• As more steel is recycled, lower fossil fuel use, water use, and eutrophication result, but with increases in acidification, and ecotoxicity. These changes occur as less energy is derived from primary sources, such as coal to fuel primary steel production, and more energy is derived from the electric grid for electric arc mills converting recycled steel.

5.2.2. Uncertainty Analysis

Areas of uncertainty identified in this LCA include:

• The creosote preservative producers did not provide detailed LCI input and output data for creosote production; therefore, industry experts provided estimates for the creosote manufacture model.

• Creosote release estimates, during treatment, storage, use, and disposal in landfills, are guided by research and assumptions. Creosote constituent releases are a function of siteand product-specific factors resulting in uncertainty.

• End-of-life disposition methods employed by railroads vary by operator, based on corporate policies, geographic locations, and economics.

• Landfill fate and release models are based on USEPA GHG emission inventory data [40] and modeled assumptions result in variability of impact indicator values, especially GHG. In this LCA, creosote-treated crossties are conservatively assumed to degrade to the same degree and at the same rate as round wood limbs disposed in a landfill.

• The comparative analysis phase of this LCA includes the assembly of LCIs for concrete and P/C railroad ties. The cradle-to-grave LCIs of concrete and P/C ties include data inputs that involve professional judgment. No survey of manufacturers of the concrete or P/C products was done.

5.2.3. Sensitivity Analysis

Sensitivity analysis was completed to determine the magnitude of changes to impact indicators resulting from assumptions and uncertainties differing from those identified in the LCI and the impact on LCA conclusions. The sensitivity of the creosote-treated railroad tie model was analyzed after variations in: preservative use (retention of preservative in the treated product), releases to environment, service life, post-use disposition, landfill decay percentages, and the addition of borate to creosote treatment as a dual-treatment application. The concrete tie model was investigated using sensitivity analysis and

Figure 3. GHG uptake and release by manufacture, use, and disposition of ties over time.

included variations in: post-use fate, service life, impact of rolling resistance, and ballast requirements. The P/C tie model was investigated using sensitivity analysis and included variations in: service life and post-use fate. Items deemed most notable from the sensitivity analysis are further discussed below.

Altering the estimated average service life (35 years) of creosote-treated railroad ties to 20 years results in notable increases to the impact indicators GHG, fossil fuel use, water use, smog, and eutrophication. In this scenario, more ties are recycled for energy recovery and indicators improve (net GHG, acidification, and ecotoxicity) because of additionalfossil fuel offsets. However, even with a shortened service life, many of the impact indicators, including GHG, net GHG, acidification, water use, and ecotoxicity, compare favorably to both alternatives.

Dual treatment with borate followed by creosote has been shown to increase the service life of ties [51], but at the cost of increasing the inputs and outputs of treatment. Addition of treatment with borate, before consideration of extended service life, has minimal impact on the indicators. Assuming a 10-year (30%) increase in service life because of dual-treatment, impact indicators decrease between 10% and 25% for GHG, fossil fuel use, smog, and eutrophication while increasing for other indicators. Changes result from fewer wood ties being used and recycled to energy. Comparisons with alternative products do not change. The use of borates in dual-treatment systems has given rise to railroads experimenting with reducing the amount of creosote used in dual-treated ties by as much as 30% to 40%. If experience proves that these reductions can be maintained without negatively impacting service life, improved treated wood tie performance, in most impact indicator categories, is expected.

Theoretical evaluation indicates that rail transport over concrete tie systems may result is lower fuel consumption than occurs with traditional wood tie track, because the concrete system is “stiffer”, thus resulting in less rolling resistance. Modeling indicates that up to 0.19 liter (0.05 gallons) of diesel fuel are saved per 1459 ton-kilometers (1000 ton-miles) of freight [52]. A sensitivity case assuming 10% of fuel saving is attributable to the use of concrete ties, found reductions to GHG (−11%), fossil fuel use (−25%), acidification (−35%), smog (−83%), and eutrophication (−100%). This does not include increased impacts due to increased wear and damage to the trains. Under this scenario, concrete offers lower impacts in comparison to creosote-treated wood for smog and eutrophication, but higher than wood for the other indicators.

A sensitivity test considers less than 10% of creosotetreated ties recycled for energy and over 50% landfilled. Shifting used ties from beneficial energy recovery to landfilling notably impacts indicators for GHG (4-times more) fossil fuel (2-times more) and smog (+55%). Net GHG, acid rain, and ecotoxicity impacts were increased from negative or near zero values to values similar to the alternative products.

5.3. Limitations

The life cycle inventory completed for both concrete and P/C ties was designed to be representative of a product category, and therefore by design, likely will not be accurate for a specific product brand. A survey of manufacturers of concrete and P/C railroad ties was not done; therefore, inputs such as fuel and electricity use, water use, and solid waste generation at the manufacturing facilities are estimated.

6. Conclusions and Recommendations

6.1. Conclusions

The use of creosote-treated railroad ties offers lower fossil fuel and water use and lower environmental impacts than similar products manufactured of concrete and P/C, except for the eutrophication impact indicator for P/C ties.

Compared to creosote-treated railroad ties, and using the assumptions of this LCA with the understanding that actual values can vary from the assumptions, the use of concrete railroad ties results in 1.8 times more fossil fuel use and 8.7 times more water use, and results in emissions with the potential to cause approximately 5.8 times more GHG, 68 times more acid rain, 2.3 times more smog, and 2.0 times more eutrophication.

Compared to creosote-treated railroad ties, the use of P/C ties results in 2.5 times more fossil fuel use and 11 times more water use, and results in emissions with the potential to cause 5.0 times more GHG, 72 times more acid rain, and 1.1 times more smog. Creosote railroad ties result in approximately 1.4 times more eutrophication impact than P/C railroad ties.

The life cycle of creosote-treated ties results in credits (or environmental benefits) for the net GHG and ecotoxicity impact indicators.

Reuse of wood ties for energy improves the environmental life cycle performance.

This study includes the comparison of creosote-treated railroad ties to concrete and P/C ties. The results conform with the ISO 14040 and ISO 14044 standards and are suitable for public disclosure. A detailed, peer-reviewed Procedures and Findings Report can be requested by contacting the TWC at www.treated-wood.org/contactus.html. This LCA covers one treated wood product in a series of LCAs commissioned by the Treated Wood Council (TWC). The series of treated wood product LCAs covers alkaline copper quaternary (ACQ)-treated lumber [53], borate-treated lumber [54], pentachlorophenol-treated utility poles [55], chromated copper arsenate (CCA)-treated marine pilings [56], and CCA-treated guard rail systems [57].

6.2. Recommendations

Recycling of ties to energy production should be supported and increased.The LCA shows clear benefits to the impact indicators considered, particularly fossil energy, GHG, acidification, and ecotoxicity with the use of used ties as an energy source and potential remains for increased reuse. The fuel offset gained by recycling creosote-treated ties for energy recovery is 20 times greater than energy recovery from landfill disposal. Furthermore, offsets result in a significant decrease in GHG emissions when ties are recycled for energy compared to a slight increase in GHG emissions when landfilled.

Each tie recycled for energy represents approximately 0.5% of the annual U.S. per capita GHG emissions and fossil fuel usage. Thus, approximately 200 ties recycled for energy will offset the GHG and fossil fuel impacts of one typical US resident. If all ties replaced annually in the US (approximately 20 million ties) are recycled for energy, their use would offset the GHG and fossil fuel use equivalent to nearly 100,000 residents.

Utilization of dual treatment of ties should be promoted and increased in high decay regions. A service life extension of 10 to 15 years is expected when using borate/ creosote dual treatment. The resulting impacts from the use of borate/creosote dual treatment are more than offset by the reduced impacts resulting from a longer service life. Wider application of dual treatment of ties in high decay regions will result in lower overall life cycle impacts.

Research evaluating the use of biodiesels as carriers of oil-borne preservatives, such as creosote and pentachlorophenol, should be continued. Data are needed to demonstrate both that biodiesel has lower impact indicators than fossil diesel, and that its use does not impact service life of treated products. If supported by these data, substitution of biodiesel for fossil oil may decrease the need for fossil oil in preservative.

Landfill disposal should be minimized. The treated wood industry and utilities should seek to minimize releases of methane resulting from disposal of wood in landfills in two ways: minimize disposal in landfills and if disposal is necessary, encourage disposal in landfills equipped with methane collection systems. Minimizing disposal is especiallybeneficial, because it reduces use of landfill capacity, reduces release of methane from landfills, and offsets fossil fuel use and GHG emissions with renewable biogenic fuel use.

Production facilities should continue to strive to reduce energy inputs through conservation and innovation, including sourcing materials from locations close to point of treatment and use. Also, the use of biomass as an alternate energy source can reduce some impact category values compared to the use of fossil fuel energy or electricity off the grid.

7. Acknowledgements

The authors wish to thank the TWC for their funding of this project. The TWC members and its Executive Director, Mr. Jeffrey Miller, have been integral in its completion. The authors and TWC thank the Railway Tie Association for additional studies conducted to support this LCA. We also thank the internal reviewers, James Clark, Craig McIntyre, and Maureen Puettmann, and the independent external reviewers, Mary Ann Curran, Paul Cooper, and Yurika Nishioka for their support, patience, and perseverance in seeing this project through to completion.

REFERENCES

- D. J. Forkenbrock, “Comparison of External Costs of Rail and Truck Freight Transportation,” Transportation Research Part A, Vol. 35, No. 4, 2001, pp. 321-337. doi:10.1016/S0965-8564(99)00061-0

- G. Gould and D. Niemeier, “Review of Regional Locomotive Emission Modeling and the Constraints Posed by Activity Data,” Transportation Research Record: Journal of the Transportation Research Board, Vol. 2117, 2009, pp. 24-32. doi:10.3141/2117-04

- C. Fracanha and A. Horvath, “Evaluation of Life-Cycle Air Emission Factors of Freight Transportation,” Environmental Science and Technology, Vol. 41, No. 20, 2007, pp. 7138-7144.

- E. Garshick, et al., “Lung Cancer in Railroad Workers Exposed to Diesel Exhaust,” Environmental Health Perspectives, Vol. 112, No. 15, 2004, pp. 1539-1543. doi:10.1289/ehp.7195

- P. Qiao, J. Davalos, and M. Zipfel, “Modeling and Optimal Design of Composite-Reinforced Wood Railroad Crossties,” Composite Structures, Vol. 41, No. 1, 1998, pp. 87-96. doi:10.1016/S0263-8223(98)00051-8

- R. Resor, A. Zarembski and P. Pradeep, “Estimation of Investment in Track and Structures Needed to Handle 129,844-kg (286,000-lb) Railcars on Short-Line Railroads,” Transportation Research Record: Journal of the Transportation Research Board, Vol. 1742, 2001, pp. 54-60. doi:10.3141/1742-07

- R. Ibach, “Wood Handbook-Wood as an Engineering Material. General Technical Report. FPL-GTR-113,” Forest Service, Forest Products Laboratory, Madison, 1999.

- J. Morrell, “Disposal of Treated Wood,” Proceedings for the Environmental Impacts of Preservative-Treated Wood Conference, Gainesville, 8-11 February 2004, pp. 196-209.

- C. C. Schnatterbeck, “Handbook on Wood Preservation,” American Wood Preservers’ Association, Baltimore, 1916.

- J. Bigelow, S. Lebow, C. Clausen, L. Greimann and T. Wipf, “Preservation Treatment for Wood Bridge Application,” Transportation Research Record: Journal of the Transportation Research Board, No. 2108, 2009, pp. 77-85. doi:10.3141/2108-09

- K. Andersson, M. Eide, U. Lundqvist and B. Mattsson, “The Feasibility of Including Sustainability in LCA for Product Development,” Journal of Cleaner Production, Vol. 6, No. 3-4, 1998, pp. 289-298. doi:10.1016/S0959-6526(98)00028-6

- International Organization for Standardization (ISO), “Environmental Management-Life Cycle AssessmentPrinciples and Framework,” Switzerland, 2006.

- International Organization for Standardization (ISO), “Environmental Management-Life Cycle AssessmentRequirements and Guidelines,” Switzerland, 2006.

- J. Gauntt, “Welcome to the Future and What Will They Think of Next?” Crossties, Vol. 89, No. 4, 2008, pp. 13-17.

- R. Vlosky, “Statistical Overview of the U.S. Wood Preserving Industry: 2007,” Louisiana State University Agricultural Center, Los Angeles, 2009.

- C. Boyd, et al., “Wood for Structural and Architectural Purposes. Committee on Renewable Resources for Industrial Resources: Panel II,” Wood and Fiber, Vol. 8, No. 1, 1976, pp. 3-72.

- L. Johnson, B. Lippke, J. Marshall and J. Comnick, “Forest Resources—Pacific Northwest and Southwest. CORRIM Phase I Final Report Module A. Life-Cycle Environmental Performance of Renewable Building Materials in the Context of Residential Building Construction,” Seattle, 2004.

- L. Johnson, B. Lippke, E. Oneil, J. Comnick and L. Mason, “Forest Resources—Inland West. CORRIM Phase II Report Module A. Environmental Performance Measures for Renewable Building Materials with Alternatives for Improved Performance,” Seattle, 2008.

- E. Oneil, et al., “Life-Cycle Impacts of Inland Northwest and Northeast/North Central Forest Resources,” Wood and Fiber Science, Vol. 42, 2010, pp. 29-51.

- R. Bergman and B. Bowe, “Environmental Impact of Producing Hardwood Lumber Using Life-Cycle Inventory,” Wood and Fiber Science, Vol. 40, No. 3, 2008, pp. 448-458.

- American Wood Protection Association, “Standard P1/ P13-09. Standard for Creosote Preservative,” In: 2010 Book of Standards, Birmingham, 2010, p. 109.

- American Wood Protection Association, “Standard P2-09. Standard for Creosote Solution,” In: 2010 Book of Standards, Birmingham, 2010, p. 110.

- American Wood Protection Association, “Standard P3-09. Standard for Creosote-Petroleum Solution,” In: 2010 Book of Standards, Birmingham, 2010, p. 111.

- American Wood Protection Association, “Standard U1-10 Use Category System: User Specification for Treated Wood,” In: 2010 AWPA Book of Standards, Birmingham, 2010, pp. 5-71.

- American Wood Preservers’ Institute, “Clean Air Act Title V Guidance Manual for Wood Preserving Facilities,” Fairfax, 1995.

- A. Zarembski, “Development of Comparative Crosstie Unit Costs and Values,” Crossties, Vol. 87, No. 6, 2007, pp. 17-18.

- M. Emoto, H. Takai, T. Tsujimura and H. Ueda, “Fundamental Investigation of LCA of Cross Tie,” Railway Technical Research Institute, Vol. 40, No. 4, 1999, pp. 210-213.

- R. Crawford, “Greenhouse Gas Emissions Embodied in Reinforced Cncrete and Timber Railway Sleepers,” Environmental Science & Technology, Vol. 43, No. 10, 2009, pp. 3885-3890.

- T. Kunniger and K. Richter, “Comparative Life Cycle Assessment of Swiss Railroad Sleepers, IRG/WP 98-50117,” Paper prepared for the 29th Annual Meeting, Maastricht, 1998.

- L. Becker, G. Matuschek, D. Lenoir and A. Kettrup, “Leaching Behavior of Wood Treated with Creosote,” Chemosphere, Vol. 42, No. 3, 2001, pp. 301-308. doi:10.1016/S0045-6535(00)00071-0

- K. Brooks, “Polycyclic Aromatic Hydrocarbon Migration from Creosote-Treated Railway Ties into Ballast and Adjacent Wetlands. Research Paper FLP-RP-617,” Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, 2004.

- M. Burkhardt, L. Rossi and M. Boller, “Diffuse Release of Environmental Hazards by Railways,” Desalination, Vol. 226, No. 1-3, 2008, pp. 106-113. doi:10.1016/j.desal.2007.02.102

- A. Chakraborty, “Investigation of the Loss of Creosote Components from Railroad Ties,” University of Toronto, Toronto, 2001.

- E. Gallego, F. Roca, J. Perales, X. Guardino and M. Berenguer, “VOCs and PAHs Emissions from CreosoteTreated Wood in a Field Storage Area,” Science of the Total Environment, Vol. 402, No. 1, 2008, pp. 130-138. doi:10.1016/j.scitotenv.2008.04.008

- R. Geimer, “Feasibility of Producing Reconstituted Railroad Ties on a Commercial Scale: Research Paper FPL 411,” United States Department of Agriculture Forest Service, Forest Products Laboratory, Madison, 1982.

- B. Gevao and K. Jones, “Kinetics and Potential Significance of Polycyclic Aromatic Hydrocarbon Desorption from Creosote-Treated Wood,” Environmental Science and Technology, Vol. 32, No. 5, 1998, pp. 640-646. doi:10.1021/es9706413

- M. Kohler and T. Kunninger, “Emission of Polycyclic Aromatic Hydrocarbon (PAH) from Creosoted Railroad Ties and Their Relevance for Life Cycle Assessment,” Springer, Vol. 61, No. 2, 2003, pp. 117-124.

- C. Sparacino, “Final Report—Preliminary Analysis for North American CTM Creosote P2,” Research Triangle Institute, Research Triangle Park, 1999.

- M. D. Fenton, “Mineral Commodity Profiles—Iron and Steel,” US Geologic Survey, US Department of Interior, Reston, 2005.

- USEPA, “Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2007: Report No: EPA 430-R-09-004,” Washington DC, 2009.

- J. Menard, et al., “Life Cycle Assessment of a Bio-Reactor and an Engineered Landfill for Municipal Solid Waste Treatment,” 2003. www.lcacenter.org/InLCA-LCM03/Menard-presentation.ppt

- A. Zarembski, “Assessment of Concrete Tie Life on US Freight Railroads,” Report Submitted to the Railway Tie Association, 2010.

- Crossties, “UP Makes Claim Against CXT Inc. for Failing Ties,” Crossties, Vol. 93, No. 1, 2012, p. 1.

- S. Morris, “Market Watch,” 2008. http://www.marketwatch.com/news/story/tieteck-llc-sells-over-one/story.aspx

- U. Arena, M. Mastellone and F. Perugini, “Life Cycle Assessment of a Plastic Packaging Recycling System,” International Journal of Life Cycle Assessment, Vol. 8, No. 2, 2003, pp. 92-98.

- D. Garrain, P. Martinez, R. Vidal and M. Belles, “LCA of Thermoplastics Recycling,” 2009. http://www.lcm2007.org/paper/168.pdf

- J. Bare, G. Norris, D. Pennington, and T. McKone, “TRACI—The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts,” Journal of Industrial Ecology, Vol. 6, No. 3-4, 2003, pp. 49-78.

- USEPA, “Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI),” 2009. http://www.epa.gov/nrml/std/traci/traci.html

- R. Rosenbaum, et al., “USEtox—The UNEP-SETAC Toxicity Model: Recommended Characterization Factors for Human Toxicity and Freshwater Ecotoxicity in Life Cycle Impact Assessment,” The international Journal of Life Cycle Assessment, Vol. 13, No. 7, 2008, pp. 532-546. doi:10.1007/s11367-008-0038-4

- Research and Innovative Technology Administration (RITA), Bureau of Transportation Statistics, 2010. http://www.bts.gov/publications/national_transportation_statistics/html/ table_01_46a.html

- M. G. Sanders and T. L. Amburgey, “Tie Dual Treatments with TimBor and Creosote or Copper Naphthenate —20 Years of Exposure in AWPA Hazard Zone 4,” Crossties, Vol. 90, No. 5, 2009, pp. 20-22.

- AREMA, “Section 2.1 Resistance to Movement,” In: AREMA Manual for Railway Engineering, American Railway Engineering and Maintenance-of-Way Association, Lanham, 1999.

- C. Bolin and S. Smith, “Life Cycle Assessment of ACQTreated Lumber with Comparison to Wood Plastic Composite Decking,” The Journal of Cleaner Production, Vol. 19, No. 6-7, 2011, pp. 620-629.

- C. A. Bolin and S. T. Smith, “Life Cycle Assessment of Borate-Treated Lumber with Comparison to Galvanized Steel Framing,” The Journal of Cleaner Production, Vol. 19, No. 6-7, 2011, pp. 630-639.

- C. Bolin and S. Smith, “Life Cycle Assessment of Pentachlorophenol-Treated Wooden Utility Poles with Comparesons to Steel and Concrete Utility Poles,” Renewable and Sustainable Energy Reviews, Vol. 15, No. 5, 2011, pp. 2475-2486.

- C. Bolin and S. Smith, “Life Cycle Assessment of CCATreated Wood Marine Piles in the US with Comparisons to Concrete, Galvanized Steel, and Plastic Marine Piles,” Journal of Marine Environmental Engineering, Vol. 9, No. 3, 2012, pp. 239-260.

- C. Bolin and S. Smith, “Life Cycle Assessment of CCATreated Wood Highway Guard Rail Posts in the US with Comparisons to Galvanized Steel Guard Rail Posts,” Journal of Transportation Technologies, Vol. 3, No. 1, 2013, pp. 58-67. doi:10.4236/jtts.2013.31007