Food and Nutrition Sciences

Vol.5 No.3(2014), Article ID:42254,9 pages DOI:10.4236/fns.2014.53034

Morphometric, Physicochemical, Thermal, and Rheological Properties of Rice (Oryza sativa L.) Cultivars Indica × Japonica

Centro de Desarrollo de Productos Bióticos del IPN, Yautepec, México.

Email: *msanchezri@ipn.mx

Received August 8th, 2013; revised September 8th, 2013; accepted September 15th, 2013

ABSTRACT

The anther culture technical was applied to produce haploid lines of rice (Oryza sativa L.). The hybrids (K/ A92VM061, K/A92VM067, K/A92VM0611, K/A92VM719, K/A92VM720 and K/A92VM721) were obtained in order to generate new varieties from Indica and Japonica cultivars. Morphometric parameters of the grains were evaluated by image analysis. Flours were prepared from the whole rice grains and physicochemical, thermal and rheological properties, X-ray diffraction pattern and evaluation of color using the CIELAB system were assessed. The hybrids lines showed long (061, 611, 721), medium (719 and 720) and short (067) grains. The rice samples presented lipids (2.6% - 3.2%), protein (11% - 15%), total dietary fiber (8.4% - 10.2%), total starch (65% - 74%) and apparent amylose (5% - 32%) contents. Gelatinization temperature (Tp) was found in the range of 66.1˚C - 79.4˚C with enthalpy (ΔH) value between 3.4 - 8.1 J/g. The retrogradation parameters (temperature and ΔH) were lower than those for gelatinization in all samples. The rice samples presented A-type X-ray diffraction pattern. Rice pastes showed a non-Newtonian behavior and the brightness (L*) characterize the color of the samples. Hybrid rice grains presented morphometric properties more similar to Japonica than Indica variety. Rice hybrid had higher protein content than Indica variety. Apparent amylose, viscosity and gelatinization temperature varied significantly among hybrids and varieties.

Keywords:Brown Rice; Hybrid Grains; Morphometric Parameters; Gelatinization Temperature; Flow Behavior; Pasting Viscosity

1. Introduction

In traditional plant breeding to produce homozygous lines, more than six generations for a particular trait are necessary [1]. However, anther culture allows rapid production of homogenizing alleles by haploids producing in one generation, then the breeding cycle is speeds up [2,3]. In rice (Oryza sativa L.) thousands of cultivars vary greatly in their attributes, including cooking, eating, and product-making quality [4-6]; therefore, new cultivars are being developed to cover the new consumer preferences [7]. In this sense, we launched the question: rice obtained by anther culture presents different functionality? In the world, rice grain is one of the most important foodstuffs [8,9] and rice flour has been increasingly used as a novel food like tortillas, processed meat, puddings, salad dressing and gluten free bread, because of its unique functional properties such as being hypoallergenic, colorless and bland [10]. Rice is mainly used as milled or white rice produced by removing the hull and bran layers of the rough rice kernel (paddy) in the dehulling and milling processes, respectively [11]. However, consumption of brown rice (hulled rice) is increasing in recent years, due to the increased awareness about its health benefits and good nutritional properties due higher amounts of proteins and minerals than white rice [9,12]. Whole rice grain is composed of bran (6% - 7% by weight), endosperm (≈90%) and embryo (2% - 3%) [11]. Particularly rice bran constituents are proteins (11.3% - 14.9%), lipids as spherosomes (12% - 18% fat), dietary fiber, essentials minerals, vitamins and phytochemicals: such a wide range of antioxidant phenolic compounds and gamino butyric acid (GABA) [8,12-14]. Starch is mostly in the endosperm of rice grain [15], and constitutes ~90% of milled rice on a dry weight basis (dwb); much of the starch functionality depends on two major components, amylose and amylopectin [16]. Rice starch mainly differs in amylose content; amylose molecule determines the grain’s gelatinization temperature, pasting behaviour and viscoelastic properties [17], and has been an important component to be considered in quality breeding of rice [18,19]. Amylose content in Indica rice variety (more than 27%) [20] is usually used for manufacturing rice noodles, while Japonica rice (14% - 18%) may be mixed partially to adjust the noodle texture [21,22]. The biodiversity of rice is important because it allows isolation of rice starches with different functionalities [6,19] or its use in different foods. Amylose content, gelatinization temperature and grain length have been used as quality indicators to introduce new rice varieties and the color of rice is an important sensory parameter [23].

The aim was analyzed by the morphometry of the grains and characterized by the physicochemical, thermal and rheological properties of the brown flours of two Indica and Japonica varieties and six haploid lines generated from these by anther culture method.

2. Materials and Methods

2.1. Materials

Paddy rice grains of Indica and Japonica cultivars as well as hybrids, crossbreeding between these varieties (i.e. K/A92VM061, K/A92VM067, K/A92VM0611, K/ A92VM719, K/A92VM720 and K/A92VM721) from anthers culture were provided by the Instituto Nacional de Investigaciones Forestales, Agricolas y Pecuarias (INIFAP) in Zacatepec, Morelos, Mexico.

2.2. Morphometric Characteristics of the Grains

The morphometric parameters (length, width, thickness, and elliptic factor) of the grains were measured by method of Davis [24] and Lira [25]. Pictures of 125 grains were captured with a stereoscopic microscope (Nikon, model SMZ1500, Japan) thereafter edited with Corel Photo Paint program (Corel Draw Corporation, USA) VII.5 and analyzed digitally with Sigma Scan Pro program (SPSS Inc) V5.0.

2.3. Rice Hybrid and Variety Flours

Samples of 500 g of paddy rice grains were dehulled by friction for removing the glumes. The whole grains were milled by 10 minutes in a conventional machine (Sumbeam) and then ground to pass through a 100-mesh sieve. The resulting brown rice flours were stored in hermetic glass containers at room temperature.

2.4. Proximal Chemical Analysis

The brown rice flours were analyzing in crude protein by official method of AOAC [26] and a conversion factor of 5.85 was used to calculate protein from nitrogen amount. The moisture, ash, and crude fat (or lipids) content were determined according to AACC [27]. Dietary fiber (DF) by AOAC method [28], and carbohydrate content was determined by difference. Iodine colorimetry method was used to determine apparent amylose [29], and total starch by Goñi’s method [30]. All chemical analyses were reported as the means of three replicates.

2.5. Color Parameters (L*, a* and b*)

Universal colorimeter (Milton Roy, mod. Color Mate) with color analyzer consisting of ilumination/D65 (medium daylight) and 10˚ (field of view), was used. The chroma meter was first calibrated with a white tile. The color was measured at least in four fold on the flours placed in a clear petri dish and covered with a white plate. The color was measured in CIE 1976 L*, a*, b* color space [31]. L* is a measure of the brightness from black (0) to white (100); a* parameter describes red-green color with positive a*-values indicating redness and negative a*-values indicating greenness; b* parameter describes yellow-blue color with positive b*-values indicating yellowness and negative b*-values indicating blueness [32].

2.6. Thermal Properties

Gelatinization properties were measured with a differential scanning calorimeter (DSC) (TA Instruments, model 2010, New Castle, DE USA) by the method proposed by Paredes-Lopez et al. [33]. Rice flour (2 mg, db) was weighed accurately into an aluminum DSC pan and moistened with 7 µL of desionized water with a microsyringe. The pan was hermetically sealed and allowed to stand for 1 h at room temperature and later heated from 20˚C to 130˚C at a rate of 10˚C/min. In all of the experiments, an empty pan was used as reference. After scanning, the gelatinized samples were stored at 4˚C for 7 days and rescanned under the same conditions as in the gelatinization measurement. The thermal properties: onset (To)peak (Tp), conclusion (Tc) temperatures and enthalpies (ΔHg) of gelatinization and retrogradation were recorded and calculated from the analysis of the software (TA Instruments OS/2 version 2.1). The thermal properties were measured at least in duplicate.

2.7. X-Ray Diffraction Patterns

Monochromatic Cu-Kα radiation (wavelength 1.542 Ă) was produced by an X-ray powder diffractometer (Bruker advances D8). The rice flour powders (20 mg db) were packed tightly in a rectangular aluminum cell (20 × 20 mm, thickness 0.15 cm). The brown rice flours were exposed to the X-ray beam with the X-ray generator running at 35 KV and 30 mA. The scanning regions of the diffraction angle 2θ were 3˚ - 37˚, which covers all the significant diffraction peaks of starch crystallites. The other operation conditions were as follows: step interval 0.05˚ and scan rate of 60 s/˚min. Duplicate measurements were made at ambient temperature.

2.8. Pasting and Rheological Measurements

Rice flours were mixing with distilled water (10% w/v, d.b.) and the dispersions were measurements in a rheometer (AR 1000 TA Instruments, New Castle DE USA). Acrylic parallel plate geometry (60 mm diameter) and gap 1000 µm were used. Mineral oil was adding around the perimeter of the geometry to protect the sample to minimize the moisture loss due to evaporation during the test. Three replicates were analyzed. The machine was programmed in-sequence steps with a program of temperature starting at 25˚C and heating to 90˚C (holding at this temperature during 10 min to gelatinize), then cooling to 25˚C and holding for 10 min at this temperature (25˚C). The rate of heating and cooling was 2.5˚C/min. Firstly, the pasting properties were measurement by paste viscosity profiles, and maximum, minimum and final viscosities, breakdown and consistency were read automatically from these profiles. Immediately after the completion of the pasting program, next program step measured the flow behavior properties at 25˚C. In this case, the viscosity was measured increasing shear rate down to 0.06 s−1 to 300 s−1 followed by a decreasing shear rate down to 0.06 s−1. Only second cycles (ascendant-descendant) are reported. In order to describe the variation in the rheological properties of brown flours dispersions under steady shear, the data obtained were fitted to the well-known power law model Eq. (A.1):

. (1)

. (1)

where h is the viscosity, K is consistency index (Pa∙sn), and “n” is the flow behavior index (dimensionless).

2.9. Statistical Analysis

Comparison of means was performed by one way analysis of variance (ANOVA) followed by Tukey’s method, least significant differences were computed at P < 0.05.

3. Results and Discussion

3.1. Physic Properties of the Rice Grains

The morphometric characteristics of the grains from Indica and Japonica varieties and six hybrid lines from these are summarizes (Table 1).

All morphometric parameters differed significantly (α = 0.05) between the two rice varieties. Grains of the variety Indica had higher area (mm2), perimeter (mm) and length (mm) in comparison with Japonica. Indica was an extra-long grain cultivar with slender shape; meanwhile Japonica was a long grain cultivar with bold shape. Values of area, perimeter, length and width of hybrid line grains ranged between 21.29 - 11.92 mm2, 19.75 - 14.03 mm, 7.18 - 5.01 mm, and 4.07 - 2.53 mm, respectively. Hybrid lines 061, 611 and 721 were long grain cultivars and 067, 719 and 720 were short and medium grains types, respectively. In general, area, perimeter and length of hybrid rice were lower or similar to Japonica but not close to Indica, indicating major influence of the former parent. In relation to the width of the grains, hybrid lines 061, 611 and 721 had higher values than their parents, and the 067, 719 and 720 showed values between 2.53 and 2.93 mm; this is a parameter that should be considered to introduce new rice lines. Indica and japonica

Data are means of 120 replicates ± standard deviations. Different letters in the same column indicate statistical differences significances (*P < 0.05). ND: undetermined.

varieties are two different varietal groups that have morphological and physiological variances despite of being grown in the same geographic area [34]. Quantitative trait locus (QTL)-mapping experiments confirmed that seed size and shape of the seeds are under polygenic control in rice, enabling breeders to obtain different combination of alleles conferring particular grain sizes and shapes to satisfy varied quality necessities of the rice market [35].

3.2. Brown Rice Color Evaluation

The Color parameters (L*, C* and h*) of brown rice flours are shown in Table2 Indica and Japonica varieties were not statistically different for lightness (L*), but the hybrids 611 and 719 had similar L* values than varieties, and the other hybrids showed lower L* values.

The color parameters redness (a*), yellowness (b*) and chromaticity (C) were higher for Japonica than Indica; the hybrid 061 had a* value similar to Japonica and the 719 to Indica; another hybrid line showed values of a* between both varieties. However, all hybrids presented b* values higher than Indica and more similar to Japonica variety. The hue angle (h*) and chromaticity (C*) values presented slight variation between varieties and hybrids, ranged between 82 and 85 and 6 and 8, respectively. The C* and h* parameters were slight affected by the combination of the two varieties to produce new rice lines. Color parameters of brown rice were positively correlated with total phenolic and flavonoid content [36].

On the other hand, the degree of milling (DOM) also has influence on the color parameters. It had been reported that milled brown rice to obtain rice with various DOM (0% to 25%), redness (a*) and yellowness (b*) decreased until a DOM of 15% [23]; nevertheless, in our study all grains were only dehulled. In this case, the numerical differences of color parameters were slight due to that brown rice flours instead of rice grains were used, and the flour is a mixture of bran (pigmented fraction) and endosperm (light fraction), giving as result a dilution effect on the measured color parameters [23].

3.3. Chemical Composition

Proximate analysis of milled brown rice grains is shown in Table3 Moisture content of the varieties and hybrids was similar, the drying conditions such as temperature and relative humidity of the grains are important, indicating that the rice grains were treated under the same conditions. Similar pattern was found for ash content, because no difference (a = 0.05) was found in the brown rice flours (Table 3). The lipid content in the Indica and Japonica was similar and slight variation was recorded in the hybrid lines.

L* (Brightness); a* (redness); b* (yellowness); h* (hue angle); C* = Chromaticity. Data are means ± standard deviations, n = 3. Different letters in the same column indicate statistical differences significances * P < 0.05.

Table 3. Chemical composition of brown rice flours (%).

All data are mean ± standard deviations, n = 3; Means in the same column followed by the same lowercase superscript letters are not different (*P > 0.05) ó (*P = 0.05). ND: not determined. *N × 5.95. **By difference.

The lipid content in brown rice was higher than those determined in Mexican rice cultivars (0.47% - 1.22%) [5] and rice varieties harvested in California and Arkansas (between 0.23% and 0.74%) [4]. The lower lipid content determined in those studies is due to that rice was polished and important amount of lipids was removed. The flour of the Japonica variety had the highest protein content and the Indica the lowest one with respect to the hybrid lines (Table 3).

In general, the protein content of hybrid lines was between those determined in Japonica and Indica varieties, except the hybrid 721 that content was similar to the Indica flour. The protein content of the eight varieties studied was higher than those determined in USA (5.4% to 8.5%) [4] and Mexican rice cultivars (7.0% - 11.0%) [5]. The protein content influences the texture of cooked rice due to that high protein content in the grain produced reduced stickiness after cooking and vice versa [37]. Cooking of the rice grain produced starch gelatinization and this polymer interacted with the protein oryzenin to form reversible adsorption, influencing the stickiness of cooked rice [38]. Brown rice is considered more nutritious than milled rice because it contains bran and embryo that are rich in fibres and vitamins [39]. More recently, was found that rice bran may suppress colon carcinogenesis in rats and it can be a novel dietary supplement for chemoprevention of colon cancer [40].

The brown flour of Japonica had higher dietary fiber (DF) content than its Indica counterpart. Four hybrid lines presented similar DF content than Japonica flour and one hybrid (719) was similar to Indica variety. The hybrid 061 had the highest DF amount. DF is important due to the beneficial effects to the health related with its consumption and the consumption of whole grains is an actual tendency in healthy nutrition. Rice grain is characterized by the high starch content that is quantified in the total carbohydrates and in the culinary characteristics, starch is important due to the that supply at the cooked rice, as well as the nutritional importance of this polysaccharide. Apparent amylose of the parent rice was 24.6% for Indica and 17.6% for Japonica. In general, the hybrid lines presented lower amylose content than the varieties, except the hybrid 720 that showed the highest amylose content. All rice hybrids had lower amylose content than Mexican cultivars (24.3% to 30.4%) [5].

The biotechnological procedure to obtain these hybrid lines can be responsible of the variation in the amylose content. In rice grains, was reported the amylose content varied with the climatic and soil conditions during grain development [4,41,42]. In the same sense, a wide range of amylose content (between 6.0% and 35.7%) was determined in starch of Chinese rice varieties [43], Indian rice cultivars (between 4.1% and 16.4%) [44] and USA rice varieties (13% and 21%) [4].

3.4. X-Ray Diffraction Patterns

The X-ray diffraction patterns of varieties and hybrid lines are shown (Figure 1). A characteristic A-type Xray diffraction pattern is present in all rice samples analyzed. The X-ray diffraction pattern showed main reflections at 2q = 15.0˚, 17.3˚, 18.0˚ and 23.0˚, similar results were found by Lamberts et al. [45] using two varieties of Indica. The crystalline arrange of double helices of amylopectin can be important in the gelatinization and retrogradation properties of starch present in food crops.

3.5. Thermal Properties

Gelatinization and retrogradation characteristics of the rice cultivars are shown (Table 4). Variation (approximately 7˚C) in the gelatinization temperatures (onset, peak and conclusion temperatures) was found between rice varieties, but the enthalpy of gelatinization was similar. Indica cultivar presented higher gelatinization temperatures than its Japonica counterpart. Four rice hybrids had temperatures of gelatinization higher that Indica variety, a hybrid (720) presented lower temperatures than Japonica and the hybrid 721 had similar temperature than this variety.

The gelatinization parameters are important to breeders who select lines with specific starch physicochemical characteristics, and to food processors that select rice cultivars with desired properties for food applications.

Figure 1. Diffraction patterns of brown rice flours. Varieties (Indica and Japonica) and hybrids (721, 720, 719, 611, 067, and 061).

Table 4. Gelatinization and retrogradation properties of brown rice flour measurement by differential scanning calorimetry.

**: stored at 4˚C for 7 days. All data are means ± standard deviations, n = 3. Different letters in the same column indicate statistical differences significances (*P < 0.05). To = Onset of gelatinization; Tp = Peak temperature; Tc = Conclusion temperature; ΔH = Enthalpy (values are based on the dry weight of starch).

Milled rice flour of different Mexican cultivars had temperatures of gelatinization between 60.6˚C and 81.5˚C, with enthalpy values of 7.7 and 11.9 J/g [5]. Studies with various rice presented mean gelatinization temperatures (onset, peak and conclusion) of 66.8˚C, 72.4˚C and 78.8˚C, respectively, with a mean enthalpy of gelatinization of 8.0 J/g [46]. Rice cultivars from California and Arkansas, had gelatinization temperatures which ranged between 64.5˚C and 70.3˚C for onset temperature, and between 72.5˚C and 75.3˚C for peak temperature.

The gelatinization parameters are influenced by amylopectin structure (chain length distribution), which can be varying by cultivar, location and crop year [4,44]. Retrogradation temperatures were lower than those assessed in the gelatinization test (Table 4) due to that during storage small and/or imperfect crystals that are formed, which are disorganize at low temperatures. Rice varieties had similar temperatures and enthalpy values of this phase transition. Slight variation was recorded in the temperatures of retrogradation for different hybrids, except the hybrids 720 and 721 that presented the lowest temperatures. The enthalpy values associated with this phenomenon for different lines of hybrids ranged between 0.53 to 0.91 J/g showing similar values in the six hybrid lines and only two hybrids (719 and 721) had the highest enthalpy value. The enthalpy value is a parameter that gives information on the level at which starch components are organized during storage; therefore, when enthalpy are low, the reorganization of starch components are produced in small amounts. Retrogradation enthalpy for different rice cultivars ranged between 2.6 and 7.7 J/g, that were higher to those determined here, due to that polished rice was used [5]. A wide range of enthalpy of retrogradation (between 0.1 and 5.0 J/g) was reported in 236 non-waxy rice accessions [46].

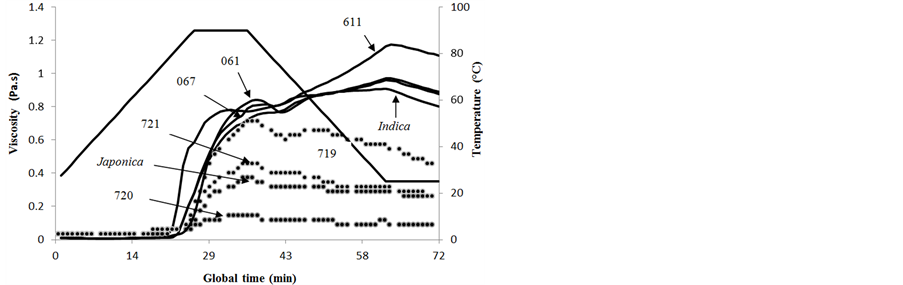

3.6. Pasting Properties

The pasting profiles of varieties and hybrid rice lines are presented (Figure 2).

Figure 2. Pasting properties of brown rice flour measured with a rheometer. Varieties (Indica and Japonica) and hybrids (721, 720, 719, 611, 067, and 061).

Pasting profiles of waxy hybrid lines (611, 067 and 061) and Indica variety had the highest values of maximum, final viscosity and consistency than the other variety and hybrid lines. It has been reported that waxy rice starches had higher swelling volume, resulting in higher viscosity than other rice [47]. Japonica variety paste exhibited a significantly lower viscosity than Indica, but the hybrid 720, showed the lowest profile values. Differences in the viscosity profile have been attributed to the characteristics of the starch granules (amylose/amylopectin ratio, chain length distribution of amylopectin) contained in the brown rice flours dispersions. The pasting peak temperature reflects the beginning of granule distortion of disruption after the granule structure can no longer support continued swelling [48]. Among the waxy brown flours hybrids (061 and 067) the peak viscosity were similar with Indica variety, but there were significant differences between non-waxy brown rice flours (720, 721 and 719 hybrid lines).

During cooking, the hybrid 719 showed higher peak viscosity than the hybrids 720 and 721 and Japonica variety; in this stage, the swollen granules brush each other and some of them, mainly the fragile granules, lose their structural rigidity and form homogenous mass (pasting) and a result, the viscosity decreases. During holding stage, only the hybrid 720 (high amylose content) kept the same viscosity profile during heating and cooling. During cooling, the waxy brown rice pastes showed a slight increase in viscosity values than non-waxy flours; particularly, the viscograms of hybrids 719 and 721 and Japonica variety. In rice non-waxy brown flour, the values of final viscosity and consistency decreased not significantly, only in waxy rice flour paste (611), breakdown viscosity was increased, attributable an increased rate of starch granule rupturing during processing in the rheometer [49].

The final viscosity is related to the quality of cooked rice when was cooled [50]. The pasting behavior and the rheological properties are also influenced by the presence of minor components (protein, phosphorus and lipid content), by organization of starch components in amorphous and crystalline zones, and also by the size, structure, distribution and water binding capacity of the starch granules [12].

3.7. Rheological Behavior

The curves shear-rate vs shear-stress (data no show) of the gelled pastes at 25˚C from rice brown flours showed a non-Newtonian pattern, indicating that cooked rice gelled pastes have pseudoplastic behavior following the power law model. The flow behavior properties: consistency index (K) and flow behavior index (n) are shown in Table5 The K value indicates the apparent viscosity when shear rate is 1 s−1 and “n” is the parameter that indicates the easiness of flow [49], and is controlled by the translational motion of the macromolecules [51].

For Chinese rice flour dispersion, power law model was found to be suitable [51]. The gelled paste of rice waxy brown flour differed from the non-waxy brown flours; it appeared that the waxy brown flours produced gelled pastes which were more viscous than gelled pastes of rice with more amylose content. While “n” and K values were similar between waxy rice flours, values of the non-waxy rice flours were significantly different.

The maximum K values obtained were found in waxy hybrid lines and Indica variety of rice, thus the viscosity

Table 5 . Flow behavior (n) and consistency index (K) in the power law of the pastes of brown rice flour.

of waxy gelled paste was higher than those with higher amylose content. Rice with higher amylose content (hybrid 720) showed lower viscosity compared with Japonica; it means that the viscosity of this gelled paste that had been gelatinized is related with the structure of amylopectin, became be more fragile by stirring and resulting in the decreased of viscosity [50]. The gelled pastes from non-waxy rice dispersions showed low magnitudes of the K in the range of 0.21 - 0.61 Pa and were highly shearthinning fluids with low magnitudes of yield stresses (data no show). “n” values observed in the power law model were in the range of 0.36 - 0.39 for waxy rice dispersions and 0.42 - 0.73 for non-waxy dispersions. The hybrid 721 and Japonica variety had similar “n” but the hybrid 719 (classified as intermediate in amylose content) had higher value of “n”. From these parameters, it is clear that the flow behavior properties of the gelled pastes from non-waxy rice had higher fluidity than waxy rice samples.

4. Conclusion

The rice grains varied in size as well as in their physicochemical properties. Hybrid samples had higher protein content than Indica variety but lower than Japonica variety. The ash, fat and dietary fiber content did not differ significantly between hybrid lines or varieties of rice. All hybrids had lower total carbohydrate content than Indica variety, but higher than Japonica cultivar. Significant differences were detected in apparent amylose content between the hybrids and varieties. Rheological measurement revealed that the viscosity value depended on the hybrid line and variety of rice. This study contributes to understanding the wide genetic diversity among different rice cultivars.

Acknowledgements

We appreciate the financial support from SIP-IPN, COFAA-IPN and EDI-IPN. One of the authors (LEMM) also acknowledges the scholarship from CONACYT-México.

REFERENCES

- F. K. Rimberia, H. Sungagawa, N. Urasaki, Y. Ishimine and S. Adaniya, “Embryo Induction via Anther Culture in Papaya and Sex Analysis of the Derived Plantlets,” Science Horticulture, Vol. 103, No. 2, 2005, pp. 199-208. http://dx.doi.org/10.1016/j.scienta.2004.04.013

- V. C. Lapitan, E. D. Redoña, T. Abe and D. S. Brar, “Molecular Characterization and Agronomic Performance of DH Lines from the F1 of Indica and Japonica Cultivars of Rice (Oryza sativa L.),” Field Crops Research, Vol. 112, No. 2-3, 2009, pp. 222-228. http://dx.doi.org/10.1016/j.fcr.2009.03.008

- J. Li, Y. Wang, L. Lin, L. Zhou, N. Luo, Q. Deng, J. Xian, Ch. Hou and Y. Qiu, “Embryogenesis and Plant Regeneration from Anther Culture in Loquat (Eriobotrya japonica L.),” Scientia Horticulturae, Vol. 115, No. 4, 2008, pp. 329-336. http://dx.doi.org/10.1016/j.scienta.2007.10.007

- D. K. Cameron, Y.-J. Wang and K. A. Moldenhauer, “Comparision of Physical and Chemical Properties of Medium Grain Rice Cultivars Grown in California and Arkansas,” Journal of Food Science, Vol. 73, No. 2, 2008, pp. C72-C78. http://dx.doi.org/10.1111/j.1750-3841.2007.00631.x

- C. E. Chávez-Murillo, Y.-J. Wang, A. G. QuinteroGutiérrez and L. A. Bello-Pérez, “Physicochemical, Textural, and Nutritional Characterization of Mexican Rice Cultivars,” Cereal Chemistry, Vol. 88, No. 3, 2011, pp. 245-252. http://dx.doi.org/10.1094/CCHEM-10-10-0146

- G. E. Vandeputte and J. A. Delcour, “From Sucrose to Starch Granule to Starch Physical Behaviour a Focus on Rice Starch,” Carbohydrate Polymers, Vol. 58, No. 3, 2004, pp. 245-266. http://dx.doi.org/10.1016/j.carbpol.2004.06.003

- L. Iturriga, B. Lopez and M. Añon, “Thermal and Physicochemical Characterization of Seven Argentine Rice Flours and Starches,” Food Research International, Vol. 37, No. 5, 2004, pp. 439-447. http://dx.doi.org/10.1016/j.foodres.2003.12.005

- L.-J. Zhu, Q.-Q. Liu, Y. Sang, M.-H. Gu and Y.-C. Shi, “Underlying Reasons for Waxy Rice Flours Having Different Pasting Properties,” Food Chemistry, Vol. 120, No. 1, 2010, pp. 94-100. http://dx.doi.org/10.1016/j.foodchem.2009.09.076

- F. Tan, W. Dai and K. Hsu, “Changes in Gelatinization and Rheological Characteristics of Japonica Rice Starch Induced by Pressure/Heat Combinations,” Journal of Cereal Science, Vol. 49, No. 2, 2009, pp. 285-289. http://dx.doi.org/10.1016/j.jcs.2008.11.006

- Y. Wu, Z. Chen, X. Li and Z. Wang, “Retrogradation Properties of High Amylose Rice Flour and Rice Starch by Physical Modification,” Food Science and Technology, Vol. 43, No. 3, 2010, pp. 492-497.

- J. Liang, Z. Li, K. Tsuji, K. Nakano, M. J. R. Nout and R. J. Hamer, “Milling Characteristics and Distribution of Phytic Acid and Zinc in Long-, Mediumand Short-Grain Rice,” Journal of Cereal Science, Vol. 48, No. 1, 2008, pp. 83-91. http://dx.doi.org/10.1016/j.jcs.2007.08.003

- B. H. Mohan, N. G. Malleshi and T. Koseki, “PhysicChemical Characteristics and Non-Starch Polysaccharide Contents of Indica and Japonica Brown Rice and Their Malts,” Food Science and Technology, Vol. 43, No. 5, 2010, pp. 784-791.

- B. Min, A. M. McClung and M.-H. Chen, “Phytochemicals and Antioxidant Capacities in Rice Brans of Different Color,” Journal of Food Science, Vol. 76, No. 1, 2011, pp. 117-126. http://dx.doi.org/10.1111/j.1750-3841.2010.01929.x

- P. Wanyo, C. Chommawang and S. Siriamornpun, “Substitution of Wheat Flour with Rice Flour and Rice Bran in Flake Products: Effects on Chemical, Physical and Antioxidant Properties,” World Applied Sciences Journal, Vol. 7, No. 1, 2009, pp. 49-56.

- A. A. Perdon, T. J. Siebenmorgen, A. Mauromoustakos, V. K. Griffin and E. R. Johnson, “Degree of Milling Effects on Rice Pasting Properties,” Cereal Chemistry, Vol. 78, No. 2, 2001, pp. 205-209. http://dx.doi.org/10.1094/CCHEM.2001.78.2.205

- J. Patindol and Y.-J. Wang, “Fine Structures of Starches from Long-Grain Rice Cultivars with Different Functionality,” Cereal Chemistry, Vol. 79, No. 3, 2002, pp. 465- 469. http://dx.doi.org/10.1094/CCHEM.2002.79.3.465

- K. A. C. Tavares, E. Zanatta, D. Zavareze, E. Helbig and G. A. R. Diaz, “The Effects of Acid and Oxidative Modification on the Expansion Properties of Rice Flours with Varying Levels of Amylose,” Food Science and Technology, Vol. 43, No. 8, 2010, pp. 1213-1219.

- Y.-L. Zhang, M.-H. Xu, Y.-W. Zeng, C.-X. Yao and S.-N. Chen, “Relationship between the First Base of the Donor Splice Site of Waxy Gene Intron 1 and Amylose Content in Yunnan Indigenous Rice Varieties,” Rice Science, Vol. 14, No. 3, 2007, pp. 189-194. http://dx.doi.org/10.1016/S1672-6308(07)60026-2

- K. R. Bhattacharya, “Physicochemical Basis of Eating Quality of Rice,” Cereal Food World, Vol. 54, No. 1, 2009, pp. 18-28.

- R. B. Latha, K. K. Bhat and S. Bhattacharya, “Rheological Behaviour of Steamed Rice Flour Dispersions,” Journal of Food Engineering, Vol. 51, No. 2, 2002, pp. 125-129. http://dx.doi.org/10.1016/S0260-8774(01)00048-6

- Z.-H. Lu, T. Sasaki, Y.-Y. Li, T. Yoshihashi, L.-T. Li and K. Kohyama, “Effect of Amylose Content and Rice Type on Dynamic Viscoelasticity of a Composite Rice Starch Gel,” Food Hydrocolloids, Vol. 23, No. 7, 2009, pp. 1712-1719. http://dx.doi.org/10.1016/j.foodhyd.2009.01.009

- M. Huang, J. F. Kennedy, B. Li, X. Xu and B. J. Xie, “Characters of Rice Starch Gel Modified by Gellan, Carrageenan, and Glucomannan: A Texture Profile Analysis Study,” Carbohydrate Polymers, Vol. 69, No. 3, 2007, pp. 411-418. http://dx.doi.org/10.1016/j.carbpol.2006.12.025

- L. Lamberts, E. De Bie, G. E. Vandeputte, W. S. Veraverbeke, V. Derycke, W. De Man and J. A. Delcour, “Effect of Milling on Color and Nutritional Properties of Rice,” Food Chemistry, Vol. 100, No. 4, 2007, pp. 1496- 1503. http://dx.doi.org/10.1016/j.foodchem.2005.11.042

- E. R. Davis, “Image Processing for the Food Industry,” Series in Machine Perception and Artificial Intelligence, Vol. 37, World Scientific Publishing Co. Pte. Ltd., Singapore, 2000.

- C. Lira, “Introducción al Tratamiento Digital de Imágenes,” IPN-UNAM-FCE, México, 2002.

- AOAC, “Official Methods of Analysis of the Association of Official Analytical Chemists,” 14th Edition, Association of Official Analytical Chemists Inc., Arlington, 1984.

- AACC International, “Approved Methods of Analysis,” 10th Edition, Vol. II. Method 44-15A, 46-19 and 61-02. AACC International, St. Paul, 2000.

- AOAC, “Official Methods of Analysis of Official Analytical Chemists,” Association of Official Analytical Chemists, Washington DC, 1999.

- B. O. Juliano, C. M. Perez, A. B. Blakeney, T. Castillo, N. Kogeree, B. Laignelet, E. T. Lapis, V. V. S. Murty, C. M. Paule and B. D. Webb, “International Cooperative Testing on the Amylose Content of Milled Rice,” Starch, Vol. 33, No. 5, 1981, pp. 157-162. http://dx.doi.org/10.1002/star.19810330504

- I. Goñi, A. García-Alonso and F. Saura-Calixto, “A Starch Hydrolysis Procedure to Estimate Glycemic Index,” Nutrition Research, Vol. 17, No. 3, 1997, pp. 427-437. http://dx.doi.org/10.1016/S0271-5317(97)00010-9

- G. R. McGuire, “Reporting of Objective Color Measurements,” HortSciencie, Vol. 27, No. 12, 1992, pp. 1254- 1255.

- H. Good, “Measurement of Color in Cereal Products,” Cereal Foods World, Vol. 47, No. 1, 2002, pp. 5-6.

- O. Paredes-López, L. A. Bello-Pérez and M. G. López, “Amylopectin: Structural Gelatinization and Retrogradation Studies,” Food Chemistry, Vol. 50, No. 3, 1994, pp. 411-418.

- M. J. Kovach, M. T. Sweeney and S. R. McCouch, “New Insights into the History of Rice Domestication,” Trends in Genetics, Vol. 23, No. 11, 2007, pp. 578-587. http://dx.doi.org/10.1016/j.tig.2007.08.012

- M. A. Fitzgerald, S. R. McCouch and R. D. Hall, “Not Just a Grain of Rice: The Quest for Quality,” Trends in Plant Science, Vol. 14, No. 3, 2009, pp. 133-139. http://dx.doi.org/10.1016/j.tplants.2008.12.004

- L. Jin, P. Xiao, Y. Lu, Y. Shao, Y. Shen and J. Bao, “Quantitative Trait Loci for Brown Rice Color, Phenolics, Flavonoid Contents, and Antioxidant Capacity in Rice Grain,” Cereal Chemistry, Vol. 86, No. 6, 2009, pp. 609- 615. http://dx.doi.org/10.1094/CCHEM-86-6-0609

- E. Primo, A. Casas, S. Barber and B. C. Barber, “Factores de Calidad del Arroz. VI. Influencia de las Proteínas Sobre la Calidad de Cocción. Proteínas en la Capa Externa,” Revista de Agroquímicos Tecnología de Alimentos, Vol. 2, No. 1, 1962, p. 135.

- J. Chrastil, “Changes of Oryzenin and Starch during Preharvest Maturation of Rice Grains,” Journal Agricultural and Food Chemistry, Vol. 41, No. 12, 1993, pp. 2242- 2244. http://dx.doi.org/10.1021/jf00036a003

- Y. Maramatsu, A. Tagawa, E. Sakaguchi and T. Kasai, “Water Absorption Characteristics and Volume Changes of Milled and Brown Rice during Soaking,” Cereal Chemistry, Vol. 83, No. 6, 2006, pp. 624-631. http://dx.doi.org/10.1094/CC-83-0624

- S.-C. Li, T.-C. Chou and C.-K. Shih, “Effects of Brown Rice, Rice Brand and Polished Rice on Colon Carcinogenesis in Rats,” Food Research International, Vol. 44, No. 1, 2011, pp. 209-216. http://dx.doi.org/10.1016/j.foodres.2010.10.034

- B. O. Juliano, G. M. Bautista, J. C. Lugay and A. C. Reyes, “Studies on the Physicochemical Properties of Rice,” Journal of Agricultural and Food Chemistry, Vol. 12, No. 2, 1964, pp. 131-138. http://dx.doi.org/10.1021/jf60132a010

- Y. Sano, M. Maekawa and H. Kikuchi, “Temperature Effects on the Wx Protein Level and Amylose Content in the Endosperm of Rice,” Journal of Heredity, Vol. 76, No. 3, 1985, pp. 221-222.

- S. Yu, Y. Ma and D.-W. Sun, “Impact of Amylase Content on Starch Retrogradation and Texture of Cooked Milled Rice during Storage,” Journal of Cereal Science, Vol. 50, No. 2, 2009, pp. 139-144. http://dx.doi.org/10.1016/j.jcs.2009.04.003

- N. Singh, L. Kaur, S. K. Sandhu, J. Kaur and K. Nishinari, “Relationships between Physicochemical, Morphological, Thermal, Rheological Properties of Rice Starches,” Food Hydrocolloids, Vol. 20, No. 4, 2006, pp. 532-542. http://dx.doi.org/10.1016/j.foodhyd.2005.05.003

- L. Lamberts, S. V. Gomand, V. Deycke and J. A. Delcour, “Presence of Amylose Crystallites in Parboiled Rice,” Journal of Agricultural and Food Chemistry, Vol. 57, No. 8, 2009, pp. 3210-3216. http://dx.doi.org/10.1021/jf803385m

- J. Bao, Y. Shen and L. Jin, “Determination of Thermal and Retrogradation Properties of Rice Starch Using NearInfrared Spectroscopy,” Journal of Cereal Science, Vol. 46, No. 1, 2007, pp. 75-81. http://dx.doi.org/10.1016/j.jcs.2006.12.002

- Y. Li, Ch. F. Shoemaker, J. Ma, K. J. Moon and F. Zhong, “Structure-Viscosity Relationships for Starches from Different Rice Varieties during Heating,” Food Chemistry, Vol. 106, No. 3, 2008, pp. 1105-1112. http://dx.doi.org/10.1016/j.foodchem.2007.07.039

- F. Zhong, Y. Li, A. M. Ibáñez, M. O. Hun, S. K. McKenzie and C. Shoemaker, “The Effect of Rice Variety and Starch Isolation Method on the Pasting and Rheological Properties of Rice Starch Pastes,” Food Hydrocolloids, Vol. 23, No. 2, 2009, pp. 406-414. http://dx.doi.org/10.1016/j.foodhyd.2008.02.003

- G. Baxter, Ch. Blanchard and J. Zhao, “Effects of Prolamin on the Textural and Pasting Properties of Rice Flour and Starch,” Journal of Cereal Science, Vol. 40, No. 3, 2004, pp. 205-211. http://dx.doi.org/10.1016/j.jcs.2004.07.004

- K. Ohishi, M. Kasai, A. Shimada and K. Hatae, “Effects of Acetic Acid on the Rice Gelatinization and Pasting Properties of Rice Starch during Cooking,” Food Research International, Vol. 40, No. 2, 2007, pp. 224-231. http://dx.doi.org/10.1016/j.foodres.2006.10.005

- S. Y. Chun and B. Yoo, “Rheological Behavior of Cooked Rice Flour Dispersions in Steady and Dynamic Shear,” Journal and Food Engineering, Vol. 65, No. 2, 2004, pp. 363-370. http://dx.doi.org/10.1016/j.jfoodeng.2004.01.035

NOTES

*Corresponding author.