Natural Resources

Vol. 3 No. 4 (2012) , Article ID: 26261 , 10 pages DOI:10.4236/nr.2012.34026

Flax Retting Wastewater Part 1: Anaerobic Treatment by Using UASB Reactor

![]()

Chemical Engineering & Pilot Plant Department, Engineering Division, National Research Center, Cairo, Egypt.

Email: randa.osman@yahoo.com

Received August 16th, 2012; revised September 19th, 2012; accepted October 3rd, 2012

Keywords: UASB; Flax Retting Wastewater; COD Loading Rate; COD and BOD Reduction

ABSTRACT

The performance of UASB (Up-flow Anaerobic Sludge Blanket) reactor was investigated in the present study for treatment of flax retting wastewater. Batch and continuous experiments on a pilot scale were designed. The initial seed for granules (bacteria acclimation) formed earlier was from municipal sewage treatment plant with VSS of 18 - 20 g/L. Batch experiments proved that the sludge retention time (SRT) was 77 days. Under steady state conditions, continuous experiments were conducted at organic loading rates (OLRs) in the range of 1.2 to 8.6 kg CODs m–3·d–1, where the hydraulic retention time (HRT) decreased from 72 to 12 hrs. The results proved that the UASB technology provides good COD removal efficiency from 64.5% to 90.5% as COD loading rate decreased and good biogas production at proper food: micro-organism (F:M) ratios.

1. Introduction

Anaerobic treatment is now becoming a popular and an established process in wastewater treatment practice since 1980’s, because of its effectiveness in treating low and high strength wastewater and because of its economic advantages [1].

The upflow anaerobic sludge blanket (UASB) reactor seems to be the most promising for wastewater treatment. UASB reactor was used in the late of seventies for treating wastewater from sugar refining, breweries and beverage industry, distilleries and fermentation industry, food industry and pulp and paper industry [2].

The process is performed in one reactor; no support medium is required for attachment of the biomass which decreases the capital cost and minimizes the possibility of plugging. The energy requirement is also small because there is no mechanical mixing within the reactor, no recirculation of sludge and effluent. Gentle recirculation of effluent is required to dilute too strong wastes and to ensure proper hydraulic conditions within the reactor. Other advantages of the UASB reactor are related to the properties of anaerobic granules [3,4]. Microbial granulation involves different trophic bacterial groups, and physico-chemical and microbiological interactions [5]. Sludge granules are dense, multi-species, microbial communities, and none of the individual species in the granular ecosystem is capable of degrading complex organic wastes [6,7].

In water-retting, a variety of anaerobic bacteria is present and is considered as the primary agents responsible for fiber release. Several species of bacteria have been identified and investigated during retting process, of which spore-forming Clostridium spp. have been shown to contribute considerably to pectin-degrading activity and, therefore, retting. It is suspected that sources for retting bacteria are adhering soil particles, stem dust, air, and water. Bacterial floras are generally similar in various investigations [8,9]. Despite the broad knowledge and practical experience that have been accumulated in previous years [1], there are still certain aspects of flax retting wastewater which require further research.

In Tanta factory for Flax and Oil production, El-Gharbia Governorate, Egypt, the flax fiber is bound to outside of the woody stem then it is impregnated in water at open or closed rooms. The flax is retted with mesophilic temperature 37˚C for 7 - 10 days till pH reaches 4.5 where fibers are separated from the woody materials by natural degradation. The retting wastewater is discharged without any treatment to main agricultural drain.

The objective of the present work is to treat the retting wastewater resulted from the retting processes of flax in the company by using UASB reactor system, where treated water will be reused. Determination of the optimum COD loading rates, the optimum hydraulic retention time, the removal efficiencies of COD, BOD, volatile matters. The amounts of biogas produced with different COD loading rates are investigated in the present paper.

2. Materials and Methods

2.1. Experimental Set-up

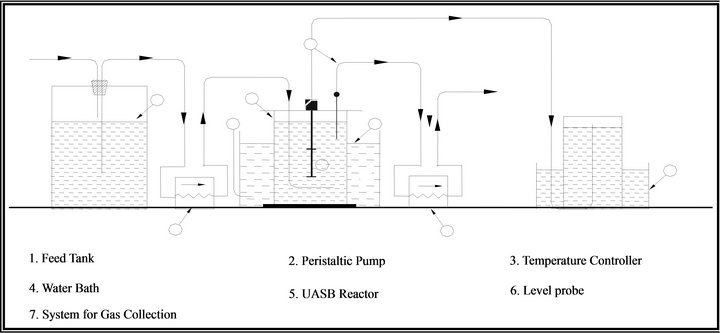

A laboratory-scale anaerobic sludge blanket bioreactor (UASB) was used. The experimental set up system is presented in Figure 1 which consists of: 1) Glass reactor of about 14 L volume, 45 cm height and 20 cm internal diameter. The reactor is embedded in a water bath and is maintained at constant mesophilic temperature (37˚C); 2) Two similar peristaltic pumps, one of them is used for introducing the feed into the reactor, hence acting as nutrient pump, while the other is used for discharging of the treated wastewater from the reactor, thus acting as harvest pump. The harvest pump operates automatically to maintain the liquid level in the reactor near to the required value; 3) Level controlling system is used to adjust the level of the liquid in the reactor at the required value and 4) A temperature controlling system is used to maintain the operating temperature of the water bath at the required level.

2.2. Wastewater Characteristics

Grap and composite samples were collected once per month for four months from open and closed retting rooms in Tanta Company to characterize the maximum pollution limits of retting effluents wastewater. The analyzed parameters were total chemical oxygen demand (COD), soluble chemical oxygen demand (COD)s, biological oxygen demand (BOD), total suspended solids (SS), phosphorus (PO4), ammonia (NH3), hydrogen sulphide (H2S), oil and grease and pH.

For all experiments the influent and effluent wastewater were characterized. Analysis of the bed was performed as TS and VS, and TSS and TVSS at the end of every experiment. The gas volume was monitored by water displacement method.

The samples were kept in a refrigerator at 4˚C to avoid pre-digestion, but later, they were fed at room temperature. All samples were analyzed according to standard methods [10].

2.3. Experimental Schedule

The experiments comprised of three parts; the first part was concerned with the preparation of seeding sludge, the second part was related to batch experiments and the third part was dedicated with the studying of steady state continuous experiments at different hydraulic retention times and COD loading rates.

3. Results and Discussions

3.1. Wastewater Characterization

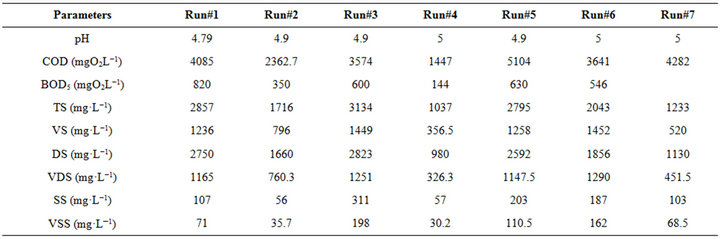

Grap and composite samples of retting wastewater were characterized and summarized in Table 1 for open and closed retting rooms. It is remarkable that the wastewater is characterized by high pollution loads of COD, BOD and SS when compared with the allowable limits to be discharged into drain according to the Egyptian law (Law 48/1982 Decree 66, modified by decree 402/2009).

3.2. Preparation of Seed Sludge

The inoculum was flocculent active sludge obtained from local municipal sewage wastewater treatment plant (Zenin station).

Figure 1. Pilot-scale UASB bioreactor.

Table 1. Characteristics of retting wastewater in grap and composite samples.

The seeding inoculum from local municipal sewage treatment plant was screened through a 0.6-mm sieve to remove the big debris and fibers before seeding. The characteristics of inoculum are summarized in Table 2, the reactor was seeded with 3.25 L of this inoculum. After that, the reactor was filled with the diluted retting wastewater, and then allowed to stand for 7 days as initial acclimation before start-up. The initial concentration of the biomass inside the bioreactor was in the range of 18 - 20 g volatile suspended solids (VSS)/L.

3.3. Characteristics of Influents Used During Start-up, Acclimatization and Operation Studies

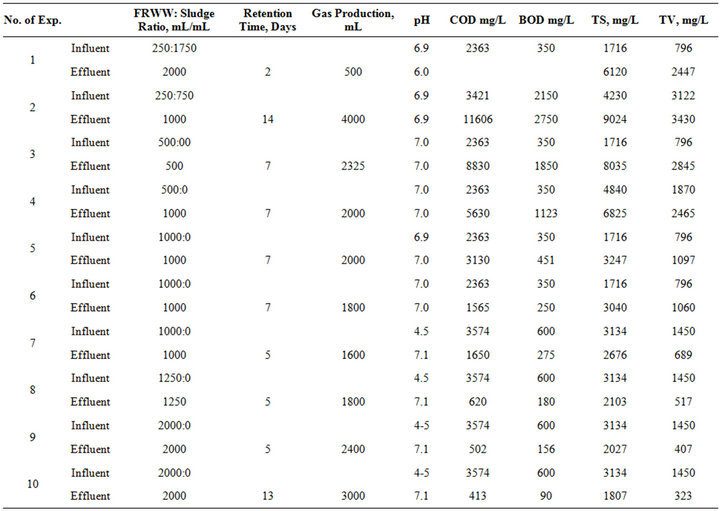

The influent retting wastewater characterization used in the acclimatization and in batch and continuous treatment experiments are presented in Table 3.

The characteristics of retting wastewater were fluctuated considerably according to the retting feed stocks, and operating process conditions and failures in retting systems.

3.4. Acclimatization and Batch Experiments

UASB reactor of 12 liters operating volume was used. Ten experiments were investigated. The effect of FRWW volume (flax retting wastewater) to seed sludge volume ratio with different retention time was studied. The analyzed parameters were pH, COD, BOD, TS and VS.

Table 2. Characteristics of seeding inoculum.

Biogas was collected and measured for all experiments. Also during the acclimatization period the pH was kept constant (6 - 7) as reported in literature [11,12] where the alkalinity plays an important role in minimizing over loading effects. The pH of the retting wastewater used was neutralized by using calcium oxide (CaO).

The operating conditions and the results are presented in Table 4 and described as follows:

• In the first experiment: 0.250 liters of flax retting wastewater and 1.75 liters of sewage sludge wastewater were used, so the total volume was 2 liters, the rest volume of this reactor was fluid of previous molasses wastewater treated under anaerobic conditions one year ago. The temperature was adjusted by using water bath at a temperature of 37˚C. After retention time of two days, it was noticed that the amount of biogas produced from the reactor was about 500 mL. This indicates the response of wastewater to anaerobic treatment.

• In the second experiment: the UASB reactor was fed with about 0.250 liters of flax retting wastewater

Table 3. Characteristics of influents used during start-up, acclimatization, batch and continuous operations study.

Table 4. Stages and anaerobic conditions of the sludge activation and results of analyses.

and 0.75 liters of sewage sludge wastewater (total volume of the inlet feed was 1 liter). After 14 days retention time, the gas produced was 4000 mL but the pollution load in effluent was higher than the influent due to using of flax retting wastewater, sewage sludge wastewater and the presence of fluids for previous anaerobic treatment.

• In the third and fourth experiments: the UASB reactor was fed with about 0.500 liters of flax retting wastewater only without the addition of sludge. After 7 days retention time, it was found that the gas produced was nearly 2.0 liter, which means that the bacteria in the reactor were capable to reduce the retting wastewater loads, and the reduction of pollution loads after treatment was started but their values did not record as it were slightly higher than the influent values. As proved in experiments three and four, the anaerobic bacteria decrease the retting wastewater pollution loads, so six batch experiments (5 - 10) were carried out to investigate the effect of retention time and the influent flow rate of retting wastewater on reducing pollution loads.

• In experiments (5 and 6): the UASB reactor was fed with about 1 liter of of flax retting wastewater only without the addition of sludge as in experiments (3 and 4). The pH was adjusted at 7. After 7 days retention time, it was found that the gas produced was about 2.0 liter. From experiments No. 3 to 6, we observed that the reactor ended in the start up period and reached the steady state conditions as proved from the constant volume of gas production and the stability in reducetion of the pollutants load.

• In experiments (7 - 9): the UASB reactor was fed with about 1, 1.25 and 2 liters of flax retting wastewater as it is (without pH adjustment), at constant retention time of 5 days, the gas production ranged from 1.6 to 2.4 L.

• In experiment (10): as retention time was 13 days, the gas production found to be 3 L.

So from experiments 7 to 10 as presented in Table 5, it is clear that the system became steady and the COD, BOD and TV removal percentages were in the ranges of (53.83% - 88.44%), (54.2% - 85%) and (52.5% - 77.8%) respectively.

The most significant results of the various experiments listed above are drawn below.

Figure 2 shows the variation of total volatile solids in effluent stream during the start up of the UASB reactor and the acclimatization of bacteria. It is remarkable that the acclimatization period was achieved after 42 days and the start up period was achieved after 70 - 77 days.

Figure 3 shows the volume of the biogas produced during the start up of the UASB and the acclimatization of bacteria. It is remarkable that the biogas production starts to increase after 42 days.

3.5. Continuous Operation

At the end of the batch experiments the anaerobic bacteria become active and the UASB reactor reached the steady state, so continuous experiments were investigated for three months, where the feed was introduced continuously at the bottom of the reactor in the central lower part of the bed by using a peristaltic pump acting as nutrient pump. The effluent overflowed from the top of the reactor into effluent collector so the liquid in the reactor remained at constant level. The biogas generated flows continuously through the gas line fixed in the head of the reactor, and then collected in the measuring jar. The temperature was maintained during all experiments at 37˚C. The reactor was maintained at strict anaerobic conditions and the performance of the reactor was continuously monitored. Hydraulic retention time remained constant during each stage until reaching the steady-state. The attainment of the steady state was verified after an initial period (three times the hydraulic retention time) by checking whether the constant effluent characteristic values were the mean of the last measurements in each stage.

The studied parameters were 1) the effect of hydraulic retention time on COD loading rate and on COD removal percentage; 2) the effect of COD loading rate on COD and BOD removal; 3) the effect of COD loading rate on gas production rate; 4) the effect of COD loading rate on bed characteristics; and 5) the effect of food to microorganism ratio on the removal efficiency of COD.

3.5.1. Effect of Hydraulic Retention Time on COD Loading Rate and on Treatment Efficiency

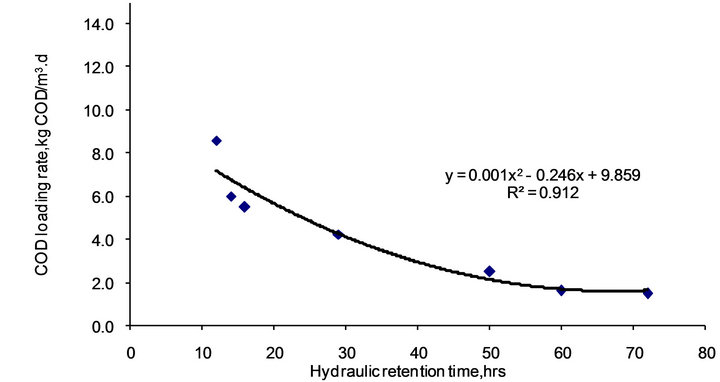

The initial COD concentration was kept constant at 3574 mg/L, while the hydraulic retention time HRT reduced step wise from 72 hr to 12 hr over seven steps.

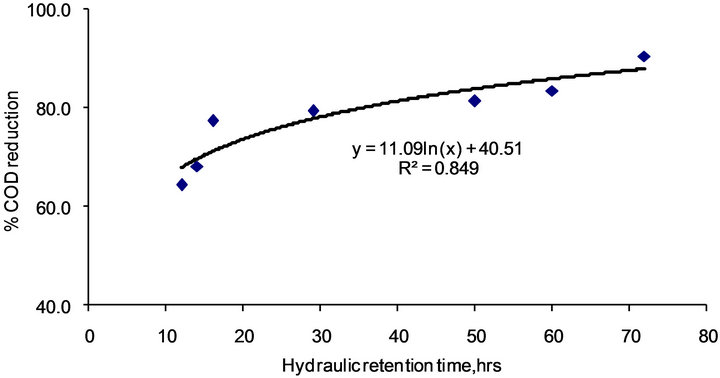

From Figures 4 and 5 the efficiency of substrate removal is a function of the hydraulic retention time and concomitant with the organic loading rate as reported in literature [13].

3.5.2. Effect of COD Loading Rate on Treatment Efficiency

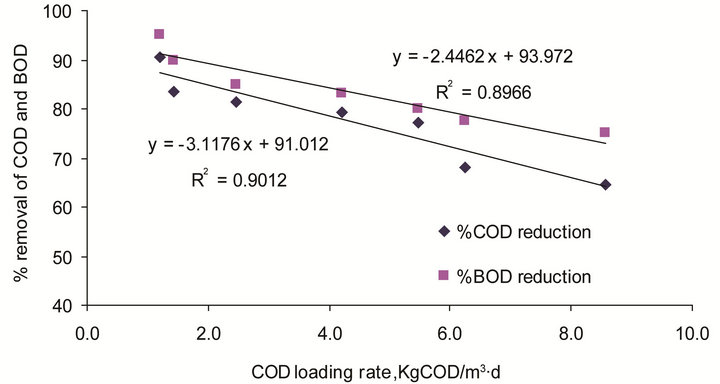

The COD and BOD removal efficiencies at different loading rate were studied and presented in Figure 6. The maximum COD removal efficiency was 90% when the reactor was operated at COD loading rate of 1.2 kg COD/ m3·d. Whereas the COD removal efficiency did not exceed 65% as COD loading rate increased to 9 kg COD/ m3·d. These results are in good agreement with Jun Liu et al. [14] who treated flax retting wastewater. They proved that the COD removal efficiency was 92% at OLR 4 kg COD/m3·d and the COD removal efficiency was 76% at ORL 14 kg COD/m3·d.

Under similar operating conditions the BOD removal efficiency was higher than 75% for all COD loading rate during experimental work as shown in Figure 6, and the maximum BOD removal efficiency was 95% when the reactor was operated at COD loading rate of 1.2 kg COD/ m3·d.

It is noticeable that the COD and BOD removal efficiencies were considered linear to COD loading rate as illustrated by the scatter plot in Figure 6. The R2 are 0.9 and 0.91 for COD and BOD removal, respectively. Figure 6 shows close relation between the COD loading rate and COD, BOD removal. Also, from the regression equation the COD loading rate could be predicted from

Table 5. Effect of hydraulic retention time and organic loads on reduction of pollutants and gas production under batch treatment.

Figure 2. Total volatile solids in the effluent stream through start-up of the system and acclimatization of the bacterial flora.

Figure 3. Volume of gas produced during start-up of the system and acclimatization of the bacterial flora.

Figure 4. Effect of hydraulic retention time on COD loading rate.

Figure 5. Effect of hydraulic retention time on % COD reduction.

Figure 6. Effect of COD loading rate on the treatment.

the percent of COD or BOD removal or vice versa.

3.5.3. Effect of COD Loading Rate on Gas Production Rate

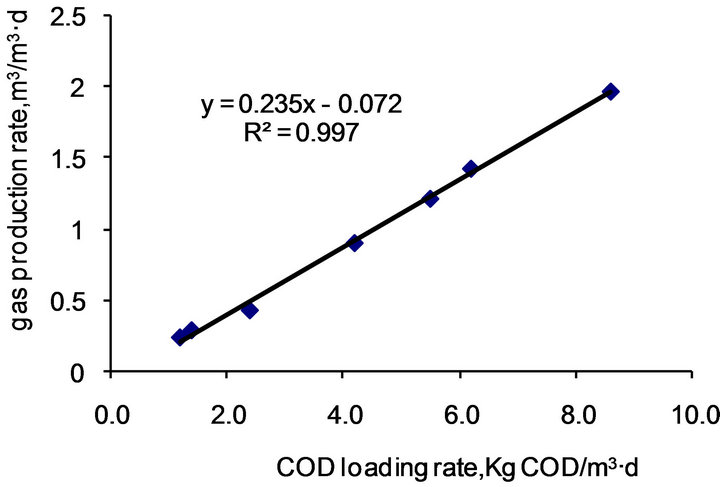

The gas production rate increased with increasing of the COD loading rate (1.2 to 8.6 kg COD/m3·d) as shown in Figure 7. The increase in gas production rate by increasing the COD loading rate is mainly due to the increase in the active organic matter available for digestion per unit time.

3.5.4. Effect of COD Loading Rate on Bed Characteristics

The bio-solids inside the UASB reactor can be either in granular or flocculent form. Granulation of biosolids is indicative of successful start-up of the process. The granular form of the sludge offers various engineering advantages over the flocculent form, such as, the high solid retention time due to its excellent settling property, providing maximum microorganisms to space ratio, and application of higher loading rates as compared to UASB

Figure 7. Effect of COD loading rate on gas production rate.

reactor with flocculent sludge. Hence, characteristics of the sludge developed are of vital importance for maximizing advantages of this reactor, and affecting the process economy.

Although, granule properties depend on the wastewater type, in order to exercise a better control on the sludge granulation for favorable wastewaters, it is necessary to understand how operating conditions influence the sludge characteristics. So far, little emphasis has been given on the characteristics of the sludge developed under different COD loading rates. In the present work, an attempt is made to evaluate the effects of COD loading rates applied on characteristics of the sludge developed in the UASB reactor. The favorable range of loading conditions is assessed to develop sludge with good characteristics, and hence, to obtain maximum chemical oxygen demand (COD) removal efficiency. The sludge properties tested under different loading rates are volatile suspended solids (VSS) and total suspended solids (TSS).

During the study, the sludge bed (VSS) concentration increased from the initial value of 19 g/L (1.9%) to 33 g/L (3.3%) by increasing the COD loading rate from 1.2 to 8.6 kg COD /m3·day; Figure 8 illustrates the obtained results for the sludge properties tested under different COD loading rates, where at steady state the bed concentration increased with increasing of the COD loading rate.

3.5.5. The Effect of Food to Microorganisms (F/M) Ratio on the Efficiency of COD Removal

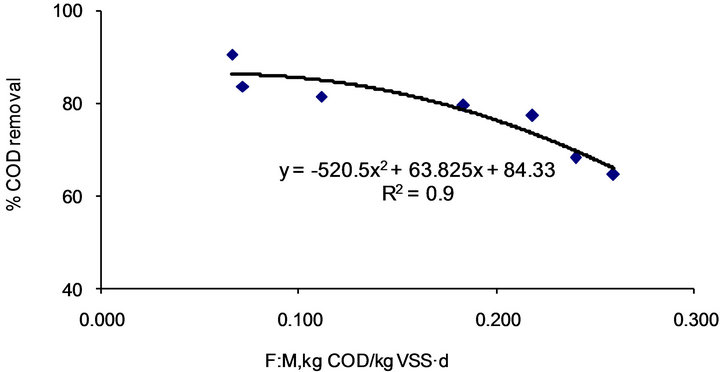

The F:M ratio can be used as a parameter for treatment performance evaluation of UASB reactor. For flax retting wastewater, excellent COD reduction and biogas production were achievable at the F:M ratio of 0.3 kg COD/kg VSS/d (more than 60% of feed COD was removed and 1.96 m3/m3·d. of biogas was produced).

Figure 9 illustrates that the removal of COD from wastewater was at all F/M ratio as in the range of study (re-duction of COD) moderate and decreased gradually, because operation occurred at F/M ratio, which obeys the declined curve due to over loading, and at F/M higher than 0.3 (COD loading rate > 9 kg/m3·d) a sharp decrease in efficiency was noticed as illustrated in Figure 9. Thus at F/M > 0.3 the biomass is not sufficient for reduction of COD.

4. Conclusion

Anaerobic treatment of flax retting wastewater in UASB reactor was successfully achieved at HRT 16 hours and a

Figure 8. Effect of COD loading rate on bed characteristics.

Figure 9. The effect of food to microorganisms (F/M) ratio on the efficiency of COD removal.

loading rate of 6 kg CODs m–3·d–1. Due to high sludge concentrations (18 - 21 g VSS/L.) a long SRT of 77 days was achieved. The effluent of the UASB reactor needs further treatment to remove the remaining 10% of COD and the 25% of BOD.

5. Acknowledgements

The authors are grateful to Tanta factory for Flax and Oil production (El-Gharbia Governorate-Egypt) for the financial assistance.

REFERENCES

- A. Pala, Ö. Bölükbaş, “Evaluation of Kinetic Parameters for Biological CNP Removal from a Municipal Wastewater through Batch Tests,” Process Biochemistry, Vol. 40, No. 2, 2005, pp. 629-635. doi:10.1016/j.procbio.2004.01.060

- G. Lettinga, J. Field, J. van Lier , G. Zeeman and L. W. Huishoff Pol, “Advanced Anaerobic Wastewater Treatment in the Near Future,” Water Science and Technology, Vol. 35, No. 10, 1997, pp. 5-12. doi:10.1016/S0273-1223(97)00222-9

- L. W. Hulshoff Pol, S. I. de Castro Lopes, G. Lettinga and P. N. L. Lens, “Anaerobic Sludge Granulation,” Water Research, Vol. 38, No. 6, 2004, pp. 1376-1389. doi:10.1016/j.watres.2003.12.002

- R. M. Osman, “Anaerobic Fermentation of Vinasse,” Ph.D. Thesis, Cairo University, Giza, 2005.

- H. Q. Yu, J. H. Tay and H. H. P. Fang, “The Roles of Calcium in Sludge Granulation during UASB Reactor Startup,” Water Research, Vol. 35, No. 4, 2001, pp. 1052-1060. doi:10.1016/S0043-1354(00)00345-6

- Y. Liu, H.-L. Xu, S.-F. Yang and J.-H. Tay, “Mechanisms and Models for Anaerobic Granulation in Upflow Anaerobic Sludge Blanket Reactor,” Water Research, Vol. 37, No. 3, 2003, pp. 661-673. doi:10.1016/S0043-1354(02)00351-2

- E. Şentürk, M. İnce and G. O. Engin, “Kinetic Evaluation and Performance of a Mesophilic Anaerobic Contact Reactor Treating Medium-Strength Food-Processing Wastewater,” Bioresource Technology, Vol. 101, No. 11, 2010, pp. 3970-3977. doi:10.1016/j.biortech.2010.01.034

- H. S. S. Sharma and C. F. Van Sumere, “The Biology and Processing of Flax,” M Publicationst, Belfast, 1992.

- H. Sharma and C. Van Sumere, “Enzyme Treatment of Flax,” Genetic Engineering and Biotechnology, Vol. 12, 1992, pp. 19-23.

- American Public Health Association, American Water Works Association and Water Pollution Control Federation, “Standard Methods for the Examination of Water and Wastewater,” 20th Edition, American Public Health Association, Washington DC, 2005.

- S. J. B. Duff and K. J. Kennedy, “Effect of Hydraulic and Organic Overloading on Thermophilic Down Flow Stationary Fixed Film (DSFF) Reactor,” Biotechnology Letters, Vol. 4, No. 12, 1982, pp. 815-520. doi:10.1007/BF00131159

- A. G. Lane, “Laboratory Scale Anaerobic Digestion of Fruit and Vegetable Solid Waste,” Biomass, Vol. 5, No. 4, 1984, pp. 245-259. doi:10.1016/0144-4565(84)90072-6

- M. Perez, L. I. Romero and D. Sales, “Organic Matter Degradation Kinetics in an Anaerobic Thermophilic Fluidized Bed Bioreactor,” Anaerobe, Vol. 7, No. 1, 2001, pp. 25-35. doi:10.1006/anae.2000.0362

- J. Liu, M. Ukata, H. Nakanishi, T. Imai and M. Fukagawa, “Estimation of Optimum Operating Parameters of UASB Reactor Treating Flax Retting Wastewater by Kinetic Model,” Hydraulic, Coastal and Environmental Engineering, No.521/II-32,249-255, 8, 1995.