Open Journal of Marine Science

Vol.07 No.02(2017), Article ID:75595,8 pages

10.4236/ojms.2017.72020

Uncertainty Modeling for Oil Tankers and Operational Guidance

Waheed Sami Abu Shanab

Faculty of Maritime Studies, King Abdul-Aziz University, Jeddah, Saudi Arabia

Copyright © 2017 by author and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: January 15, 2017; Accepted: April 21, 2017; Published: April 24, 2017

ABSTRACT

Technology evolution has been a driving factor in the oil tanker industry. The technology breakthroughs and historical data served as the main factor of evolution in the industry. Nowadays the oil tankers have been modified and optimized according to the requirements of the cargo and the area in which they are supposed to operate. This paper reviews some technological developments in the tanker industry and driving factors behind them. The issues of environmental pollution, failure prediction, and efficient operations are also discussed in mathematical terms.

Keywords:

Oil Tanker Operation, Oil Tanker Design, Electric Ships, Oil Tanker Safety

1. Introduction

Shipping always has been of extreme interest for the mankind. The primary objective of this extreme interest was the urge for survival, expansion and exploration [1] . Throughout the history of humanity, the empires and promising economies are depended on these and maritime transportation. A reliable marine transportation not only gave an extra edge in case of conflict but also provided reliable means of communication and cooperation regarding the trade and commerce [2] . Gradually, with the evolution of technology and scientific development, shipping also undergoes large development. The technology breaks through such as the introduction of sail, diesel engine, steam, and steel.

Today, the shipping industry is one of the most complex and fragile organisms. The production is influenced by several business factors like supply and demand principles. Political interests like conflicts and economy also impact on the shipping industry [1] . The sensitive oil prices also change operations of the transportation industry [1] . The ship owners, designers, sailors, and other related management staff are faced with a number of challenges of surviving under the increasing globalization and increased uncertainty in global economic markets [2] .

For this reason, when looking from the technical point of view, the Naval professionals of today’s world are not only responsible for designing, delivering and operating the ships at superior markets [3] . The principles of holism are imaged in the holistic Ship Design and Operations [2] . The designs of the ships and tankers keep on demanding the Multiple-Objective Optimization. The best solutions are required to meet the requirements of the customers and users of the tankers. In this paper, holistic review of technologies and standards used for the design and operation of boats are analyzed in a concise manner [1] .

2. Modern Tanker: Design Aspects and Operations

The oil tankers of the 21st century are developed from the evolutionary process in the technology. The market of tankers nowadays consists of number of people having small ships. Most of the tanker owners in today’s market are independent, and they are not owners of the cargo. These businesses are mostly providing their services to different corporations [4] . The capacities of the new tankers vary from 5000 to more than 350,000 DWT tons. The size of tankers is dependent on the nature of a cargo and the regulations which are supposed to be encountered by the tankers [5] . The most common types of tankers are:

1) Handymax tankers: These tankers have the capacity of less than 5000 tons and used to carry several trades and fluids [4] .

2) Panamax Tankers: These tankers are known to be the biggest ships that can pass through the Panama Canal. The weight range of these tankers is from 5000 to 7000 tons [1] . A typical 6000-ton Panamax ship has the following dimensions.

3) AFRAMAX tankers: Their dead weight ranges between 80,000 and 120,000 DWT tons. Their breadth is greater than 32.31 m. The name for this type of tankers is based on Average Freight Rate Assessment (AFRA) [1] . These are used in the North China Sea, Black Sea, Caribbean Sea, and Mediterranean Sea [5] .

4) Suezmax tankers: These ships are considered as the biggest ships than can pass through Suez Canal at their full load conditions [1] . The deadweight range from 120,000 to 200,000 DWT tons. The common dimensions are ,

,

, and

, and .

.

5) Very Large Crude Carriers (VLCC): They are not able to pass through various canals and positions. The DWT ranges from 200,000 to 3,500,000, it has dimensions as follows ,

,  , and

, and  [4] .

[4] .

3. Tanker Design Aspects and Optimization

Formal Safety Assessment (FSA): Hazard Identification

The present regulatory system used in the shipping industry is reactive. The governing principles were outlined after some disasters. For this need, the historical data must be available to the designers to identify the risk factors [4] . The Figure 1 represents the AFRAMAX tankers:

The risk factors are identified by two facts. The historical data is analyzed by the designers, and the hazards are determined by a meeting of experts [4] . The risks defined in these meetings are prioritized [8] . The first stage is complicated by analyzing the databases. After the completion of the first stage, the second step involves:

1) Loading and unloading operations. The cleaning of a tank and crude oil washing.

2) Ship-to-ship transfer in an open sea.

3) The activities conducted by the coastal and restricted waters.

4) The tasks for the maintenance.

The risk operations of Risk Control Options in FSA are developed by following steps.

1) Focusing on the risk factors need control.

2) Identification of RCO’s.

3) Evaluating RCO’s in reducing risk factors.

4) Grouping the RCO’s into regulatory options.

In standard terms, the RCO’s should be targeted one or more following factors as shown in Figure 2:

1) Reducing the frequency or occurrence of the failures supposed to happen on the tankers.

2) Evaluating the effects of failures.

3) The identification of the factors in which failure might occur.

4) Identification and managing of the results for the accidents.

Figure 1. Historical data for AFRAMAX tankers [4] .

4. Holistic Approach for Designing and Safety

The geometric modeling for the oil tankers is done in the Friendship System as the fundamental driver behind hull form development, the variation of parameters and optimization according to operational requirements. The lightship weight of the tanker is computed in the simulations. The machining and attached weight are estimated using different empirical methods known as Watson and Gilfillan formulas [4] Figure 3. The main engine selected for this study is

Figure 2. RCO procedure for the tankers [4] .

Figure 3. Flowchart for the optimization [4] .

known as MAN B&W marine engine. The oil consumption for this engine is 15,000 nautical miles.

Required Freight Rate (RFR), Sensitivity

The RFR is known as one of the most important performance indicators for calculating the operational efficiency and competitiveness of the tanker in the market (Figure 4). The primary objective of this exercise is to design cost-effec- tive ship operating efficiently [5] . It is assumed that larger ships have the positive relationship between RFR and stronger correlation to the tank capacity [4] .

Reliability Formulation

Reliability methods and techniques can be used to estimate basic safety, structural strength components, and load effect, which are considered as random variables. The structural capacity and the demand of the users are related to each other in mathematical equations. The limit state function and the requirements are related by the following equation:

= Random ultimate hull rider.

= Random ultimate hull rider.

RIF = Random variable strength index.

The above equation is used to apply reliability limits and the state equation, to failure modes. The above equation is to be applied to only one failure mode. The

Figure 4. Sensitivity analysis for selected engine [4] .

elementary loading condition to be applied to the above equation is known Full Load Condition (FL) [4] . In the case of a damaged ship, distinguishing is made between the intact and damaged section of the ship.

Ultimate Vertical Bending Moment

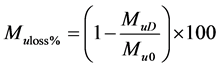

This minute, for the most part between versatile and the plastic moment, is the entirety of the contribution of longitudinally compelling components, i.e. the total of the first snapshots of the twisting worries around the flat impartial tomahawks. An absolute bowing minute limit figuring for in place ship is performed by utilizing Progressive Collapse Analysis (PCA) and it peruses 8246 MNm [6] . The irregular loss of an absolute twisting limit of harmed ship (Muloss%) is communicated as the rate of a definite structure support bowing snapshot of the harmed send (MuD) regarding an ultimate body brace bowing snapshot of the in place deliver (Mu0) as:

5. All Electric Ship (AES), Concept and Systems Overview

To address the pollution concerns and efficient operations of the ships AES is the dominant solution for the tanker. The fuel selected for the operation was LNG, and it can also operate on renewable or alternate energy such as lithium batteries [7] . The All-Electric Ship (AES) concept is developed using lithium cells and generators. The concept can be used to operate cruise ships, ferries, and small tankers. The concept is useful for the dynamic positioning, and it boosts the power transmission for large load range. A diesel power plant can also play an important role in facilitating this concept [6] . The advantages of using the electrical systems in place of conventional mechanical systems are as follows:

1) The weight is significantly decreased; the payload can be increased due to this fact [8] .

2) The concept can offer several hybridization options which can transfer loads from key generators with the use of renewable energy [8] .

3) The fuel efficiency can increase dramatically [8] .

4) Less space for an engine which can increase the space on the board [8] .

5) It can result in quick response time [8] .

6) Increased power redundancy; the ship can operate on just two generators [8] .

7) Flexible operating profile [8] .

8) Increased innovations in the future as the engines which are placed near the deck can be replaced easily. This development in the technology can improve the logistics, management and maintenance policy for tankers.

The disadvantages of such systems are:

1) The initial building cost for the tankers can be increased significantly; the proper engine leasing programs can reduce such costs.

2) The operating efficiency of an electrical generator is lower as compared to the efficiency of mechanical energy.

Figure 5. Azipod configuration [6] .

3) Increased complexity for the staff.

The primary electrical factor to be considered is known as propulsion load.

Propulsion load

Figure 5 represents the electrical power requires the propulsion load to the certain electric motors. The required electrical power to move the engine to attain the speeds of 15 knots is about 13,900 kW. The 5% margin is deduced, the power required for propulsion is estimated to be about 13,292 kW, 6466 kW for each of the propeller [6] . The Azipods are suitable devices to produce 6646 kW at the 100 RPM.

6. Conclusion

Ships and tankers are considered as the backbone of the international trade and economic development of the world. The safety regulations for the tankers are developed on the basis of historical accidents and risk factors identified by the experts. The technological evolution served as a crucial factor in the development of the maritime technology. Types of the tankers are dependent on the payload and the area of operation they are supposed to cover. Nowadays, ship designers and operators are faced with numerous challenges due to the changing industry and market dynamics. The political factors of the region they are operating in also affect the efficiency of the tanker operations. Recent technological development in the industry is the concept of using electrical energy in place of mechanical power in the tankers. However, this method has its respective merits and demerits.

Cite this paper

Shanab, W.S.A. (2017) Uncertainty Modeling for Oil Tankers and Operational Guidance. Open Journal of Marine Science, 7, 281-288. https://doi.org/10.4236/ojms.2017.72020

References

- 1. Oka, S., Zubair Muis Alie, M., Takemura, K., Iijima, K. and Fujikubo, M. (2012) Residual Hull Girder Strength of Asymmetrically Damaged Ships. Journal of the Japan Society of Naval Architects and Ocean Engineers, 16, 131-140.

https://doi.org/10.2534/jjasnaoe.16.131 - 2. Parunov, J. and Guedes Soares, C. (2008) Effects of Common Structural Rules on Hull-Girder Reliability of an Aframax Oil Tanker. Reliability Engineering & System Safety, 93, 1317-1327.

https://doi.org/10.1016/j.ress.2007.07.011 - 3. Caldwell, J., Kim, D., Park, D., Kim, H., Mansour, A. and Paik, J. (2013) Modified Paik-Mansour Formula for Ultimate Strength Calculations of Ship Hulls. Ships and Offshore Structures, 8, 245-260.

https://doi.org/10.1080/17445302.2012.676247 - 4. Paik, J., Kim, H., Mohd, M. and Kim, D. (2013) Comparison of Residual Strength-Grounding Damage Index Diagrams for Tankers Produced by the ALPS/HULL ISFEM and Design Formula Method. International Journal of Naval Architecture and Ocean Engineering, 5, 47-61.

https://doi.org/10.2478/IJNAOE-2013-0117 - 5. Luís, R., Teixeira, A. and Guedes Soares, C. (2009) Longitudinal Strength Reliability of a Tanker Hull Accidentally Grounded. Structural Safety, 31, 224-233.

https://doi.org/10.1016/j.strusafe.2008.06.005 - 6. Hussein, A. and Soares, C. (2009) Reliability and Residual Strength of Double Hull Tankers Designed according to the New IACS Common Structural Rules. Ocean Engineering, 36, 1446-1459.

https://doi.org/10.1016/j.oceaneng.2009.04.006 - 7. Qi, E. and Cui, W. (2006) Analytical Method for Ultimate Strength Calculations of Intact and Damaged Ship Hulls. Ships and Offshore Structures, 1, 153-163.

https://doi.org/10.1533/saos.2006.0121 - 8. Teixeira, A. and Soares, C. (2000) Structural Reliability of Two Bulk Carrier Designs. Marine Structures, 13, 107-128.

https://doi.org/10.1016/S0951-8339(00)00004-6