Journal of Surface Engineered Materials and Advanced Technology

Vol.04 No.04(2014), Article ID:47892,9 pages

10.4236/jsemat.2014.44025

Synthesis and Characterization of Polysulfone Hydrogels

Francis N. Muya, Lisebo Phelane, Priscilla G. L. Baker*, Emmanuel I. Iwuoha

SensorLab, Department of Chemistry, University of the Western Cape, Bellville, South Africa

Email: *Pbaker@uwc.ac.za

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 21 April 2014; revised 20 May 2014; accepted 19 June 2014

ABSTRACT

Polysulfone (PSF) membranes are frequently used in ultrafiltration, due to their chemical and structural stability and mechanical robustness. Despite these advantages, successful utilization of this membrane technology has been greatly limited by the susceptibility of these membranes to fouling, due to their hydrophobic nature. Here we report on the synthesis and characterisation of hydrophilic PSF membrane materials prepared by incorporation of polyvinyl alcohol, through chemical crosslinking to produce mechanically and chemically stable PSF hydrogels. The hydrogel composition was controlled at three different ratios to evaluate the effect of the PSF contribution i.e. 25:75, 50:50 and 75:25. PSF hydrogels were characterized using high resolution scanning electron microscopy (HR-SEM), cyclic voltammetry (CV), and drop shape analysis techniques. The polysulfone hydrogels formed showed a decrease in contact angle by 50% for all hydrogels regardless of their polysulfone contribution, confirming an improvement in hydrophilic nature. The electron diffusion and ionic transport properties of the hydrogels as immobilised thin films in aqueous solutions, were evaluated using cyclic voltammetry.

Keywords:

Hydrogels, Polysulfone, Polyvinyl Alcohol, Scanning Electron, Microscopy, Atomic Force Microscopy, Contact Angle

1. Introduction

Polysulfone has been used over the last decade as the main component in membrane processes and synthesis due to its excellent properties; such as high tensile strength, durability under heat, pressure resistance, mechanical robustness and chemical stability [1] - [8] . Polysulfone membranes find wide application in wastewater treatment, especially in ultrafiltration and nanofiltration processes [9] - [15] . Unfortunately these membranes are mostly hydrophobic by nature and therefore highly vulnerable to fouling due to chemosorptive mechanisms. Fouling increases operation and maintenance cost by deteriorating membrane performance and shortens membrane lifespan. Strategies employed to reduce hydrophobicity of PSF materials include incorporating redox centres (i.e. metal nanoparticles, metal oxides) or coating the hydrophobic material with hydrophilic hydrogels [16] - [22] . This paper focuses on crosslinking PSF with a hydrophilic polymer to produce a hydrophilic hydrogel free from metal nanoparticles, since metal nanoparticle leaching and associated environmental and health risks are a topical present day concern [23] . Crosslinking of natural and artificial polymers is achieved through the reaction of their functional groups like (OH, COOH and NH2) [23] . There are a variety of strategies reported within the literature to produce chemically crosslinked permanent hydrogels [23] .

2. Materials

PVA of 89,000 - 98,000 molecular weights (10001444119) and polysulfone (MW = 35.000, 0.2%w/v in CH3Cl3), gluteraldehyde (GA) or pentane 1, 5 dial solutions Grade I, (1001381318) and N,N-dimethyl acetamide (DMAc) of a molecular formula C4H9NO, (100990279) were sourced from Sigma Aldrich (South Africa).These products were used as received from the supplier without any modification and stored at room temperature, except for gluteraldehyde, which was stored in the freezer at −25˚C. HCl (32%, 508098) was supplied by Seabreeze (South Africa).

3. Experimental Methods

・ Synthesis of polysulfone hydrogel material

Polysulfone was prepared by dissolving 0.4214 g of polysulfone in 50 ml N, N-dimethyl acetamide to give a final concentration of 0.05 mole/L. The reaction mixture was sonicated in a water bath until a clear homogenous casting suspension was obtained. Freestanding films were cast by swirling the solution in a glass beaker in the presence of 0.5 M H2SO4 to obtain a homogenous film. The film was then rinsed with deionised water and dried overnight.

Polysulfone hydrogels were synthesised by reflux at controlled temperature of 75˚C. 5 mL of 0.05 M polysulfone solution was transferred into a round bottom flask. The solution was stirred using a magnetic stirrer at 200 revolutions per minutes (rpm) whilst adding 2.6 g of polyvinyl alcohol (PVA) powder. 1 mL of 2 M HCl catalyst was added and 1 mL glutaraldehyde crosslinker solutions were added to the reaction mixture. The reaction was stopped after 3 hrs. The mixture was stored at room temperature for 10 days in order for the cross- linking to reach completion.

A mechanism for the crosslinking based on first principles [24] , was supported with evidence from FTIR and H1 NMR spectroscopy (Figure 1).

・ Preparation of polysulfone and polysulfone hydrogel films

The polysulfone and hydrogel solutions were drop coated onto screen printed carbon electrodes (SPCE)for SEM and AFM analysis. Thin films were prepared by drop coating 10 μL aliquots and allowing them to dry overnight at room temperature. Each sample was coated with gold for viewing. Freestanding membrane films were prepared by casting the polysulfone solutions in the presence of 0.5 M H2SO4 and leaving it to dry. Using the Sessile drop method, the angle formed by a droplet of water with the surface of the membrane was measured using KRUSS drop shape analyser (Advanced Laboratory Solutions, South Africa). Four measurements were done for each material and the mean contact angle and standard deviation results were reported.

3.1. Characterization of the Hydrogels

・ Spectroscopic characterization (FTIR)

A small portion of the hydrogel was placed between two filter papers and a physical force was applied to dry it. The hydrogel was then dried at room temperature for 24 hours and compressed as a KBr disk. The disk was prepared by grinding approximately 1% mixture of a solid sample in KBr using a hydraulic press [24] . FTIR studies were performed on PSF, PVA and PSF/hydrogels. FTIR spectra of the PSF/hydrogels confirmed cross- linking of the two polymers by the absence C-O-C which was involved in crosslinking (Figures 2(a)-(c)). This indicates that the ether oxygen was the site of crosslinking, with a band C-H at 3125 C∙m−1, C=C at 1800 C∙m−1,

Figure 1. Proposed mechanism of PSF hydrogels formation.

SO2 at 1300 C∙m−1 and C-C at 1100 C∙m−1 (Table 1). The absence of OH groups from PVA was interpreted as evidence of its involvement in crosslinking (Figure 2(a)). Intermediate primary carbocations are more reactive than secondary and tertiary carbocation [24] . Sulphur is more electron negative compare to carbon and exerts an electron withdrawing effect. However both oxygen in ether and sulphone experience a dipole moment. Reaction of carbocation with sulphone oxygen will result in instability of the structure. Therefore, the carbocation would preferentially attack the ether oxygen. FTIR spectral analysis supports the proposed crosslinking mechanism.

3.2. Macroscopic Characterization

・ Scanning Electron Microscopy (SEM)

Zeiss Auriga, high resolution (fegsem) field emission gun scanning electron microscope was used to measure morphology of thin film samples. SEM images show differences in membranes morphology and porosity for PSF and the synthesised hydrogels. Unmodified PSF shows spherical shape with large pore size distribution and uniform morphology. The incorporation of the PVA though chemical crosslinking was visible as clusters of much smaller particles distributed onto the PSF template. The morphology was observed to be governed by the dominant polymer concentration. PSF/hydrogel materials were of nanometer size distribution and the homogeneous incorporation of the PVA morphological into the PSF template was interpreted as confirmation of crosslinking of the two polymers to produce completely new hydrogel materials. Bulk polymer was seen to aggregate in large

Figure 2. FTIR Spectrum of (a) PVA, (b) PSF and (c) PSF-PVA Hydrogel 50:50 are shown here.

Table 1. FTIR stretching frequencies for functional groups in PSF and modified PSF membranes.

particles in the form of large globules. This was due to an increase in chain interaction compared to its stabilized particles in which the polymeric surfactant chains act as a limiting factor for such an interaction. Charging of the material at the surface by incident electrons was observed as lighter in colour spots in SEM images. Unmodified PSF was observed to have a spherical shape without any colour distribution compared to hydrogel materials (Figures 3(a)-(d)). The hydrogels displayed a higher tendency to surface charging by incident electrons irrespective of composition. The changing in surface morphology as a results of compositional change, confirmed the incorporation of a conducting polymer into the polymer matrix to produce a homogeneous hydrogel.

3.3. Atomic Force Microscopy (AFM)

Atomic force microscopy has been used to characterise the surface roughness which is regarded as one of the most important surface properties that plays a significant role in membrane permeability and fouling behaviour [24] - [26] . Roughness parameters such as the average roughness (Ra) and root mean square roughness (Rrms), was automatically calculated by Nano Surf® software and provided information regarding hydrophilicity of the membrane materials [29] . Several AFM images (500 × 500 nm) of different parts of the same membrane were analyzed and mean values of each roughness parameter are reported (Figure 4). The roughness parameters of unmodified PSF was observed to be lower than hydrogels with 75:25 hydrogel measuring the highest Rrmx. Surface roughness could be associated with hydrophilicity of material. The more rough the surface the more hydrophilic it becomes [24] - [30] . However the improvement in roughness appeared to be independent of polymer ratio, but as a direct consequence of crosslinking (STD = 6.8%, n = 3) (Figure 5).

3.4. Optical Characterisation Contact Angle

Drop shape analysis (DSA25, Kruss) was used as analytical tool to confirm the hydrophobic nature of the membrane by measuring the angle formed between the film of a membrane and a drop of water [31] .

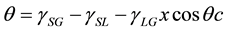

(1)

(1)

where γSG is an interfacial tention between the solid and gas, γSL is an interfacial tension between solid and liquid and γLG is an Interfacial tention between liquid and gas.

Membranes are defined as hydrophobic once its contact angle is greater than 90˚ and hydrophilic when it’s less than 90˚ (Figure 6). The contact angle measurements confirmed that, hydrogels were more hydrophilic as indicated by a decrease in the contact angle with water. The contact angle of the unmodified polysulfone was measured as 103˚ and upon crosslinking the contact angle decreased by 50% for all three hydrogel composites (Figure 7). Introducing an electrochemically conductive polymer such as PVA into PSF polymer matrix imparts its advantageous properties onto the resulting membrane and enhances hydrophilic characteristics of the membrane with a contact angle equal or much better than that achieved by metal nanoparticles modification [32] -[35] .

・ Electrochemical characterization

Electrochemical characterization techniques allow us to understand PVA, PSF and PSF hydrogel redox

Figure 3. SEM of (a) polysulfoneand (b) PSF-PVA hydrogel (50:50) (c) PSF-PVA hydrogel (75:25) and (d) PSF-PVA hydrogel (25:75).

Figure 4. (a) AFM image of PSF (b) AFM image of PSF-PVA (50:50); (c) AFM image of PSF-PVA (75:25).

Figure 5. Surface roughness of PSF and PSF hydrogels.

Figure 6. The wetting behaviour of a liquid droplet on rough solid surface by Young’s mode.

Figure 7. Contact angle distribution for hydrogel materials.

behaviour based on the diffusion of electrons in solution toward the surface of the modified electrode. Polysulfone hydrogel thin films were prepared by drop coating 10 μL aliquot of the hydrogel solution onto a glassy carbon electrode (GCE) and dried overnight before analysis. Cyclic voltammetry (CV) was performed by cycling the potential range between −200 and +1200 mV in 2 mL of 2 M HCl, at scan rates from 10 to 300 m∙Vs−1. The effect of PSF contribution within the formed hydrogel (i.e. 25:75, 50:50 and 75:25) was evaluated electrochemically in terms of its diffusional properties. The redox peaks a, a’ and b, b’ observed for the hydrogels were similar to the electrochemical performance observed in PVA. No additional peaks were observed due to the presence of polysulfone. However an increased peak separation was ascribed to the presence of polysulfone. All results reported for the hydrogel systems were based on the performance of the redox couple a/a’ which was identified as the rate determining step (Figure 8). Cyclic voltammogram showed a redox peak resulting from electron delocalization and the growth of a semi conducting polysulfone film on the electrode as the scan rates increased. The separation of oxidation and reduction current showed a near square shaped voltammogram indicative of the capacitive nature of polysulfone. To date, not much has been reported on polysulfone electrochemistry. However from organic chemistry considerations, the redox peaks observed (Figure 8) were ascribed to the delocalisation of the double bonds.

A trend was observed between characterization techniques (Table 2). Drop shape analysis showed a decrease in contact angle upon crosslinking and AFM measured an increase in roughness upon modification. Electrochemical characterization reported an increase in diffusion coefficient, following Randles Sevcik treatment of peak current as a function of scan rate. High surface roughness was linked to improved hydrophilicity and was also shown to agree with improved electron mobility within the polymer matrix. Hence a more hydrophilic interface was linked to the improved conductivity for the hydrogels. Crosslinking PSF with PVA reduced the hydrophobic nature of PSF as evidenced by surface features such as shape and surface roughness. Crosslinking PSF and PVA also improved electron transfer properties.

4. Conclusion

In this paper we have reported on the synthesis of polysulfone hydrogel materials produced by introducing a conductive hydrophilic polymer (PVA), into the polysulfone (PSF) matrix using gluteraldehyde as crosslinker. The SEM images show differences in membrane morphology and structure for PSF hydrogels as compared to clearly separated spherical shapes observed in unmodified PSF. The incorporation of the PVA through chemical crosslinking was visible as clusters of much smaller particles distributed onto the PSF template. The morphology was observed to be governed by the dominant polymer concentration. SEM revealed that the hydrogel materials were of nanometer size distribution (<1 µm) and the homogeneous incorporation of the PVA resulted in fine cluster formation templated by spherical PSF morphology. Atomic force microscopy confirmed the increased surface roughness of hydrogels (>200 nm) as compared to PSF (<200 nm). Surface area (Sa) and surface

Figure 8. Cyclic voltammetry of polysulfone hydrogel (50:50 shown here) on glassy carbon electrode as a function of increased scan rates.

Table 2. Summary of three hydrogels performance.

roughness (Ra) values showed a significant increase associated with PVA/PSF crosslinking. Polysulfone on its own showed a Ra value of 155.5 nm, and PSF contribution 75:25 shows a Ra value of 769.8 nm, 50:50 Ra value 595.6 nm and 25:75 the value of 791.4 nm. Hydrophobicity of native PSF was reduced by 50% by crosslinking PSF with PVA, using contact angle measurement as indicating parameter.

Acknowledgements

We would like to acknowledge the financial assistance of National Research Foundation (NRF), Water Research Commission (WRC) and University of the Western Cape (UWC) in South Africa.

References

- Al-Rabiah, A.A. (1999) Membrane Technology for Hydrogen Separation in Ethylene Plants. Chemical Engineering Science, 54, 943-950.

- Shen, Y., Zhao, W., Xiao, K. and Huang, X. (2010) A Systematic Insight into Fouling Propensity of Soluble Microbial Products in Membrane Bioreactors Based on Hydrophobic Interaction and Size Exclusion. Journal of Membrane Science, 346, 187-193. http://dx.doi.org/10.1016/j.memsci.2009.09.040

- Shon, H.K., Vigneswaran, S., Kim, I.S., Cho, J. and Ngo, H.H. (2006) Fouling of Ultrafiltration Membrane by Effluent Organic Matter: A Detailed Characterization Using Different Organic Fractions in Wastewater. Journal of Membrane Science, 278, 232-238. http://dx.doi.org/10.1016/j.memsci.2005.11.006

- Lee, J., Ahn, W.-Y. and Lee, C.-H. (2001) Comparison of the Filtration Characteristics between Attached and Suspended Growth Microorganisms in Submerged Membrane Bioreactor. Water Research, 35, 2435-2445. http://dx.doi.org/10.1016/S0043-1354(00)00524-8

- Hua, H., Li, N., Wu, L., Zhong, H., Wu, G., Yuan, Z., Lin, X. and Tang, L. (2008) Anti-Fouling Ultrafiltration Membrane Prepared from Polysulfone-Graft-Methyl Acrylate Copolymers by UV-Induced Grafting Method. Journal of Environmental Sciences, 20, 565-570. http://dx.doi.org/10.1016/S1001-0742(08)62095-1

- Richards, H.L., Baker, P.G.L. and Iwuoha, E. (2012) Metal Nanoparticle Modified Polysulfone Membranes for Use in Waste Water Treatment: A Critical Review. Journal of Surface Engineered Materials and Advanced Technology, 2, 183-193.

- Herzberg, M., Berry, D. and Raskin, L. (2010) Impact of Microfiltration Treatment of Secondary Wastewater Effluent on Biofouling of Reverse Osmosis Membranes. Water Research, 44, 167-176. http://dx.doi.org/10.1016/j.watres.2009.09.022

- Yang, Y., Zhang, H.X., Wang, P., Zheng, Q.Z. and Li, J. (2007) The Influence of Nano-Sized TiO2 Fillers on the Morphologies and Properties of PSF UF Membrane. Journal of Membrane Science, 288, 231-238. http://dx.doi.org/10.1016/j.memsci.2006.11.019

- Maximous, N., Nakhla, G., Wan, W. and Wong, K. (2009) Preparation, Characterization and Performance of Al2O3/ PES Membrane for Wastewater Filtration. Journal of Membrane Science, 341, 67-75. http://dx.doi.org/10.1016/j.memsci.2009.05.040

- Wu, Z.G., Munoz, M. and Montero, O. (2009) The Synthesis of Nickel Nanoparticles by Hydrazine Reduction. Advanced Powder Technology, 21, 165-168. http://dx.doi.org/10.1016/j.apt.2009.10.012

- Guo, F., Zheng, H., Yang, Z. and Qian, Y. (2002) Synthesis of Cobalt Nanoparticles in Ethanol Hydrazine Alkaline System (EHAS) at Room Temperature. Materials Letters, 56, 906-909. http://dx.doi.org/10.1016/S0167-577X(02)00635-3

- Zodrow, K., Brunet, L., Mahendra, S., Li, D., Zhang, A., Li, Q. and Alvarez, P.J.J. (2009) Polysulfone Ultrafiltration Membranes Impregnated with Silver Nanoparticles Show Improved Biofouling Resistance and Virus Removal. Water Research, 43, 715-723. http://dx.doi.org/10.1016/j.watres.2008.11.014

- Schacht, E.H. (2004) Polymer Chemistry and Hydrogel System. Journal of Physics: Conference Series, 3, 22.

- Hsu, S.C. and Williams, T.J. (1982) Evaluation of Factors Affection the Membrane Filters Technique for Testing Drinking Water. Applied and Environmental Microbiology, 44, 453-460.

- Naim, R., Ismael, A.F., Saidi, H. and Saion, E. (2004) Development of Sulfonated Polysulfone Membranes as Material for Proton Exchange Membrane. Proceedings of Regional Symposium on Membrane Science and Technology, Johor Bharu, 21-25 April 2004, ID Code: 1037.

- Taurozzi, J.S., Arul, H., Bosak, V.Z., Burban, A.F., Voice, T.C., Bruening, M.L. and Tarabara, V.V. (2008) Effect of Filler Incorporation Route on the Properties of Polysulfone Silver Nanocomposite Membranes of Different Porosities. Journal of Membrane Science, 325, 58-68. http://dx.doi.org/10.1016/j.memsci.2008.07.010

- Ficai, D.M., Ficai, A., Voicu, G., Vasile, B.S., Guran, C. and Andronescu, E. (2010) Polysulfone Based Membranes with Desired Pores Characteristics. Materiale Plastice, 47, 24-27.

- Pretorius, J. (2013) Encyclopaedia of Life Support Systems, Future Challenges of Providing High Quality Water― Volume II. International Protocols Regarding Global Climate Change and the Impact of Water Resource. http://www.eolss.net/sample-chapters/c07/e2-25-02-05.pdf

- Aroon, M.A., Ismail, A.F., Montazer-Rahmati, M.M. and Matsuura, T. (2010) Morphology and Permeation Properties of Polysulfone Membranes for Gas Separation: Effects of Non-Solvent Additives and Co-Solvent. Separation and Purification Technology, 72, 194-202. http://dx.doi.org/10.1016/j.seppur.2010.02.009

- Savage, N. and Diallo, M.S. (2005) Nanomaterials and Water Purification: Opportunities and Challenges. Journal of Nanoparticle Research, 7, 331-342.

- Kim, K.S., Lee, K.H., Cho, K. and Park, C.E. (2002) Surface Modification of Polysulfone Ultrafiltration Membrane by Oxygen Plasma Treatment. Journal of Membrane Science, 199, 135-145. http://dx.doi.org/10.1016/S0376-7388(01)00686-X

- Syed, K.H., Al-Assaf, S. and Phillips, G.O. (2011) Hydrogels: Methods of Preparation, Characterisation and Applications. International Standard Book Number (ISBN) 978-953-307-268-5. Intech, Croatia.

- Miller, J.D., Veeramasuneni, S., Drelich, J., Yalamanchili, M.R. and Yamauchi, G. (1996) Effect of Roughness as Determined by Atomic Force Microscopy on the Wetting Properties of PTFE Thin Films. Polymer Engineering and Science, 36, 1849-1855. http://dx.doi.org/10.1002/pen.10580

- Hart, H. (1976) Organic Chemistry. A Short Course. 6th Edition, Houghton Mifflin, Dallas.

- Bowen, W.R., Hilal, N., Lovitt, R.W. and Williams, P.M. (1996) Visualisation of an Ultrafiltration Membrane by Non-Contact Atomic Force Microscopy at Single Pore Resolution. Journal of Membrane Science, 110, 229-232. http://dx.doi.org/10.1016/0376-7388(95)00262-6

- Bottino, A., Capanneli, G., Grosso, A., Monticelli, O., Cavalleri, O., Rolandi, R. and Soria, R. (1994) Surface Characterization of Ceramic Membranes by Atomic Force Microscopy. Journal of Membrane Science, 95, 289-296. http://dx.doi.org/10.1016/0376-7388(94)00132-4

- Bowen, W.R., Mohammad, A.W. and Hilal, N. (1997) Characterization of Nanofiltration Membrane for Predictive Purpose―Use of Salts, Uncharged Solutes and Atomic Force Microscopy. Journal of Membrane Science, 126, 91-105. http://dx.doi.org/10.1016/S0376-7388(96)00276-1

- Khulbe, K.C., Kruczek, B., Chowdhury, G., Gagne, S. and Matsuura, T. (1996) Surface Morphology of Homogeneous and Asymmetric Membranes Made from Poly(phenylene oxide) by Tapping Mode Atomic Force Microscope. Journal of Applied Polymer Science, 59, 1151-1158. http://dx.doi.org/10.1002/(SICI)1097-4628(19960214)59:7<1151::AID-APP12>3.0.CO;2-8

- Khulbe, K.C., Kruczek, B., Chowdhury, G., Gange, S., Matsuura, T. and Verma, S.P. (1996) Characterization of Membranes Prepared from PPO by Raman Scattering and Atomic Force Microscopy. Journal of Membrane Science, 111, 57-70. http://dx.doi.org/10.1016/0376-7388(95)00276-6

- Singh, S., Khulbe, K.C., Matsuura, T. and Ramamurthy, P. (1998) Membrane Characterization by Solute Transport and Atomic Force Microscopy. Journal of Membrane Science, 142, 111-127. http://dx.doi.org/10.1016/S0376-7388(97)00329-3

- Yuan, Y. and Randall Lee, T. (2013) Contact Angle and Wetting Properties. Surface Sciences, 51, 3-34.

- Phelane, L., Muya, F.N., Richards, H.L., Baker, P.G.L. and Iwuoha, E.I. (2014) Polysulfone Nanocomposite Membranes with Improved Hydrophilicity. Electrochimica Acta, 128, 326-335. http://dx.doi.org/10.1016/j.electacta.2013.11.156

- Anandao, P., Fumie Sato, L., Weibeck, H. and Valenzuela-Diaz, F.R. (2010) Montmorillonite as a Component of Polysulfone Nanocomposite Membranes. Applied Clay Science, 48, 127-132.

- Peng, F., Huang, X., Jawor, A. and Hoek, E.M.V. (2010) Transport, Structural and Interfacial Properties of Poly(vinyl alcohol)-Polysulfone Composite Nanofiltration Memebranes. Journal of Membrane Science, 353, 169-176. http://dx.doi.org/10.1016/j.memsci.2010.02.044

- El-Aassar, A.-H.M. (2012) Polysulfone-Polyvinyl Alcohol Thin Film Nano-Composite Membranes: Synthesis, Characterisation and Application for Desalination of Saline Groundwater. Journal of Applied Science Research, 8, 3811- 3822.

NOTES

*Corresponding author.