Journal of Power and Energy Engineering, 2014, 2, 470-476 Published Online April 2014 in SciRes. http://www.scirp.org/journal/j pee http://dx.doi.org/10.4236/jpee.2014.24063 How to cite this paper: Gao, F., et al. (2014) The Research and Development of Integrated Operation-Maintena nce Simula- tion Training System. Journal of Power and Energy Eng ineeri ng, 2, 470-476. http://dx.doi.org/10.4236/jpee.2014.24063 The Research and Development of Integrated Operation-Maintenance Simulation Training System Feng Gao1, Xiue Zhang2, Lianzheng Zhao3 1Beijing Kedong Electric Control Sy stem Co. Ltd., Beijing, China 2Datong Electric Power S eni or Technical School, Datong, China 3Jibe i Electric Po wer Training Cent er, Beijing, China Email: YL_100 00@sina.co m Received Sep temb er 20 13 Abstract With deep devel opmen t of stat e gri d’s system of "Th ree Se ts of Fiv e [1]", China is in urge nt need of establishin g an appropriate type of sim ulat ion sys tem to rapidly improve oper ati on e fficienc y and the level of m aint ainers, wh ich ai m at the integrated operati on of su bstation op erati on an d mai n- tenance servi ce. This ar ti c l e gives an in tr od u ctio n of a simulation traini ng system wh ich is de- signed for ope ration-skil ls training in electric al systems. By the comp o siti on of the multiple sub- jects and skill s training for operati ons staff , this sys tem can pr ovide hum an gu aran te e and int el- lectual support for the "Big-Centralized O verh al". Keywords Substation ; Ope ra tio n and Maintenance; Integration ; The Simulation Training 1. Introduction The State Grid Corporation of China Worker’s congress proposed: Building a modern company shall focus on the estab lish ment of manage me nt system. O ne of the most important components of the “Five integra tio n” is in- tegrated recondition, it deep ens the in tegra tio n revo lutio n and will build up a matrix production management system on aspects such as management model study, production process optimization, lea n production manage- ment and perfected standard syste m. The revolution of management system brings up an improved requirement of operation-maintena nc e (OM) [2] staff, t he traini n g of OM staff is the key to the success of integrated recondi- tion model [3]. Electrical power syste m si mu latio n research is firstly operated on grid simulatio n research, the power gri d yardman trainin g simulation syst em simulates the switc hing operation, malfu nc t ion, a nd accident process to train grid yardman. Afte r more and more transformer substation has been established, the tr a i ning demand is en- larged. The earl y transformer station simulation mechanism is based on real device, after the applic ation of computer techno l ogy especiall y virtual realit y technolog y, 3D virt ual device and p ur e di gital sub statio n has ex-  F. Gao et al. perienced a rapid development. The integrated sys tem of digital -physical simulation device, central control sta- tion and s ubstatio n has beco me the mainstream product. With the adjustme nt of the substatio n running management mode, the training s i mulatio n sys t em which is suitable for operational inte gratio n mode is still blank. As a re sult, the current train in g simulation syste m ca n’t satisfy the training needs of operational skills of talent already. Therefore, developing a set of electric power, comprehensive Simulation Trai ning Syst em which is aimed at training of operation positions, and that will ef- fectively improve the overall level of the trainin g, the teaching of overhaul , trainin g of appraisal of techniques and ways of assess me nts has vital meanings. In this paper, based on the research of the exist ing Simul atio n T raining System, the autho r d eveloped and succe ss fu lly impl eme nted oper ational power mechanic school integration Simulatio n T raining S yste m of the Dato ng Se ni or Electrical Engineering School and Jibei Power training center. The SIMULATION TRAINING SYSTE M concludes grid s , substations, the p aper int r oduc e d t he syst em’s the f unctio n of each part of the train- ing methods, and ho w to realize an organic combinatio n of implementation. Sys tem can not only realize the production unit operation personnel p atr ol, accident treatment and dail y operation, abnormal joint a nti-accident exercises tra ining of the power gr id and the substation simulatio n sys t em, b ut can also re alize sub sta t i o n eq ui p- ment ’s routine C and D level mainte nance and routi ne test of visual experience [4]. Thi s paper intr o duces the general structur e of the Simul atio n Tr aining System, and it s key technology in the process of system implemen- tation, applic ations of the system are introduc e d in the last p art of the paper. 2. General Structure of the System The general construct of SIMULATION TRAINING SYSTE M is sh owed in Figure 1. The Simulatio n T raining System conclud es grid simulatio n, transformer station simulation, disp atc h automatic system, C and D level regula r recondition simulation, experimental transformer substatio n regular simula tion. Send orders to trainee thro ugh teaching syst em to perform the cooperation of different parts of simulation module. T he function of the Simulation T r aining S yst em is as follo w: 1) Grid simulation: tra nsien t state, metaphase, long pr ocess integrated simu lation method, performing Real-time calculation of power gri d, express power system dynamic behavior accurately. Use Power flow cal- culation through simulation op er atio n support system, requiring d ata distrib u tion for comprehensive Simulation Training System, to guarantee the syste m operation condition and the c onsistency of the d ata. 2) Substation simula tio n, v is ualization, modular thre e -dimensional simulation technology was adopted to realize the substation in the primary and secondar y equipment of 3D scenes, virtual equip ment perform the right action according to the operation support system, at the same time, stud ents can stay in 3d patrol system to carry out patrol and operations on the primary and secondary eq uipme nt. 3) Dispatch automation simulatio n syst em: to power dispatch system as the prototype, the ma i n simulation monitori ng func tio n of SCADA, man -ma chine i nterface and operation process. Figure 1. Operational integration simulation training system’s overall structure.  F. Gao et al. 4) Substation integrated auto matic simulatio n system: the main simulatio n functio n of monitorin g and control system, man-machi ne inte rfac e a nd the operation pro c e ss, provide student s with a virtual working environment. 5) The conve nt i onal sub statio n simulatio n of C and D level maintenanc e: repair work is based on the substa- tion running si mulatio n scenario, to development a better simulation e nviro n me nt for c onventional sub statio n maint e nance trai ning. Operators can finish all kinds of tasks in this substat io n ro ut ine maintenance scenario. 6) The routi ne te st transformer substation simulation: through the e stablis h ment of the visualizatio n of routi ne test transformer substat io n simulatio n scenarios, the s ys t em let the trainees practice the ba sic k nowledge of sub- station routine test, test instrument operation, rout ine tes t work proc esse s and o t he r job tra ining, realize the whole dynamic simulation tra i ning process of routine te st for tr ained p erso nne l. 7) The faculty syste m: to realize a unified control to run all of the simulation s yst em on the support platform, teachers send the s yst em state through data s ys t em, state data simulatio n sys tem auto matic all y performs the data distribution mana geme nt ser vices to all par ts of the sys t em. On the basis of the simulation operation support syste m, the interac tion between each part of the simulatio n module, const ruct the integrat io n tra ining simulatio n syst em together. After the accident and abnor mal in simu- lation grid, substation equipme nt will correctly response , grid act correspond i ngly to change s in trends and to run other simula tio n module, the module wi ll co mplete actio n message alarm information, alarm signal, protec- tion and automatic devi c e acc ording to the pro tectio n configur a t i on, co mbined with the conventio nal mainten- ance test. 3. Key Techniques of the System 3.1. Operation Support Platform Ba se d on High Level Architecture (HLA) [5] Refer to the inter natio nal standard IEEE1516 standard series, perform the furthe r research of simulation applica- tion mana geme nt modeling in distributed, interactive power simulation operation support platform ’s si mulatio n component mana geme nt , statement management, ti me management and data distribution management technol- ogy, bui l d si mulatio n applica t ion support plug and pl ay, which has the functio n of time c olla bo ra tive simulatio n operation support platform. As shown in Figure 2, the oper a t i ng support environment is connected through communication soft standa rd interface to the simulation applicatio n. As long as it is based on HLA simulatio n applic ation standard interface, it can realize plug and play. Opera ting support environment is the realization of a high level architecture, it fully Figure 2. Operation support platform structure.  F. Gao et al. follows t he hi gh-leve l architec ture specification, to ensure the operation support environment to realize the func- tion through t he standard izatio n of technical specifications has nothi ng to do with specific application system, which concludes the characteristics of generali ty, op e nness and easy extension, and realizes the simulation of different types, di fferent time advance mechanism interoper abilit y between applications. Solving the reusabilit y and interop er ab ilit y of simulat ion app licatio n from the architecture, make it easy to the inte gr a t i on of new simu- lation system, management and reconstruc t i on, t he ideal is the coordination of complex simulation syst em sup- port environment. SIMULATION TRAINING SYST E M is a system contain s a variety of different complex simulatio n, si mula- tion applicatio n s ys tem requires a variety of simulation ap p lica tion work toge ther . In t he aspect of syst em con- struction, a syste m of flexible s truct ur e is needed, support system, in accordance with the unif ied planning and step-by-step implementation co ntinuall y develops and expands. The operation supports environment based on high level architecture is a good way to meet the needs of the integration of operations simulation system, laid a solid foundation for the success of the system deve l opme nt . 3.2. Operational Integrated Grid Mod eling Technology [6] System USES the international and domestic standards (CIM -XML, E l anguage, CIM-E, SVG graphic format, the grap h G format) to realize synchr onizations with external syst em model and data interface, in accordance with the trai ning simulatio n model and ap plic ation req uire ments of data integration, to perform the model’s ca- libration, cut t ing, stitch ing, equivalence, split, release, and othe r func ti ons. At the sa me time , providing visuali- zation and a model of hierarchical modeling tools, to ac hieve rap id modeling of power grid model. The system provides visual a nd componentized secondary device modeling tools, impleme nts secondary equipment (equi p- ment , circuit) of modular mod eling based on grap h model, establishes a fo undation fo r the u ni ficatio n of the secondary equipment and detaile d si mulatio n model. Operational integration training si mulatio n ur gently needs to provide a new typ e of secondary equipment model building technology, on one ha nd it can accurately describe the detail of the secondary equipment‘s physical properties of mecha ni sm, on the other hand, it can satisf y the practical require men ts of rapid deploy- ment . Based on the definitio n of IEC61850 standard, the secondary equipment model consists of logical node. As sh own in Figure 3, logical node is according to the basic unit of secondary equipme nt function definition module, logical node contains the corresponding attributes and functions, which can reflect the status of second- ary equipment, par ameter, setting value , interface and uni t connection topology relation, et c. 3.3. Modular Three-Dimensional Modeling Technology 3D modeling system uses a visualization, modularizatio n and gallery module integration modeling tec hno l ogy, usin g the perso nne l compo nent generator of 3D modeling to edit the 3D model of ori ginal equip ment, and de- rived for the thr e e dimensional components can be assemble d from the three -dimensional equipme nt after edit- ing. Component asse mb le r derived by using the compo nent generator of three dimensional components, is con- venient to asse mble equipment components which can be ran dire ctly by primary a nd s econdary simulation of Figure 3. Secondary device simulation model structure.  F. Gao et al. 3D program. Scene assemblers assembly equipment for 3D simulatio n traini ng scenario throug h visual ed it mode component, all kind s of equipme nt c ompo nent s can be qui c kly a ssembled for the power of 3D virtual scene, the visualization of the interface assembly can be fully realized by the assembly proce ss, we o nly need simple mouse operation. Scene assemblers provide a friendly environment, through the mouse drag eq ui pment, components can easily move to the r ight place, to facilitate t he ob servation scene, realized the functio n of com- pre he ns ive roaming observation, the scene of assembly process can be viewed from various angl es to ens ur e the correct asse mbl y of the scene. 3.4. Interactive 3D Engine Technology Base d on Open GL Ope nGL 3D graphics based on cross-platform language, develop a se t of 3D grap hi c s support engi ne , which provides a framework based on Ope nGL’s object-oriented technology, realizes the key techniques and algo- rithms of 3D engine efficiency and performance, encapsulated the realistic graphics, 3D scene manage ment, sound manage ment, colli sion detectio n, object interaction and real time maintenance funct ion, developed a 3D scene interface for a quick and e fficie nt develo pment, the engi ne considered the chara cteristics of the po wer system. To organi z e t he characteristic of scenario with the electrical connection in the scene tree, developers onl y need to use less code to set the sc ene fo r each node of the tree a nd a c hi eve efficie nt r endering 3D scene. 3D engine impl ements the 3D geograp hi c information system data and data schedulin g, in view of the mas- sive t hr e e -dimensional geographi c information data, using the rendering suc h as tiles segmentatio n and dyna mic scheduling strateg y, solvi ng the syst em operation performance degradation caused by the massive terr ain data. 3D engine i mplements the sa t ellite remote sensing image and the fus i on of 3D terrain d ata to improve the sense of reality of the system. 3.5. Substation Maintenance Simulation and Experiment Based on the Technology of Direct X Gaming Direct X is a kind of applicati on program interface, it allows higher exe cution efficie ncy fo r Windows platform game program and str engt hen the 3D grap hi c s and sound effects. DirectX is made up by many compo nents: Di- rec tS ound: provides voice mixing and pla yback of hardware and software; Direct3D: a 3 d graphics package which provides an advanced Retained Mode (Retained Mode) interface, this enables the user to ac hi eve a com- plete 3D graphics system. It also co nt a ins a low-level Immediate Mode interface, allows application programs to gain co mplete control over the r e ndering p ipe line. Based on the technology of Direct X gamin g, substation maint enanc e and test the simulatio n from the inter- face style, operation mode are similar to common real-time strategy game , trainees in substatio n virtual scene, select tools and several instruments to finish the maintenance and testing task s. The use and mai nt enanc e of a variety of tools, instrume nts, experimental steps and the process are exactly the sa me wit h their actual characte- ristics. Authenticity, target, high a ntagonism, task, help and evaluati on, makes t he substatio n mai nt ena nc e and test the k nowled ge more easily. 3.6. Operational Integration Technology of Remote Simulation Training Operational integration simulatio n trainin g of each subsys tem can run smoothly in the o nl ine electric power en- terp r ise s, remote training around the classr o om is distribut ed in the training center, the classroom is equipped with each training, student pla tfor m, switches and network equi pment, using a VPN network technology can realize a smooth connection between faculty and st ud ents platform, perfectly meet the training needs (Figure 4). Operational integration Simulatio n T ra ining S yst em has the n et wor k buffer server, realizing the si mula tion timing intelligent backtracking tech ni que a nd the a uto matic synchro ni z ation of simulatio n applic ation in remote simulation system. Durin g the broken network auto matic reconnection of the training system, the simulation system can adj ust the clock rate of intelligent simulation model, with history simulation e ve nt and state, to real- ize the stable synchro nizatio n of monitor ing center, substat i on and power grid simulatio n applica tion in complex netwo rk e nvi r on me nt . Operational integration simulation trai ning realized remote network oriented training simulation applicatio n mode. The remote user can log into the Si mulation T rainin g System, the automaticly download, install, and star t the remote training s i mulatio n system.  F. Gao et al. 4. Applic at ion of the System Compr e hensi ve operation-mainte nances Simulatio n Tra ini ng System has realized t he integratio n of power grid, substa ti o ns, dispatching automatio n, conventiona l C, D level mainte na nc e a nd routine test joi nt si mula tion, trai ning normal operation skills for related production personne l , abnormal and accident treatment skills, the re- lated pe r s o nnel of the C, D level maintenance and ro ut ine te st. The system has been put into use in Datong Se- nior Electrical Engi ne e ring School and Jibei Power train i ng center, the sys t em overall structure is shown in Figure 5. Figure 4. Remote training operations integration. Figure 5. Integrated training simulation system overall struc- ture.  F. Gao et al. Dato ng Senio r Electrical Engineering School using this system for 8 pe riod, about 240 times of training for substation operations. Stud ent s gener ally p raised the val ue of this system, especially in the s ubstation mainten- ance part, filled the gaps in simulatio n training. The gami ng interface operation is vivid, simple, practical, and the simulation system trained the trainees ho w to execute the primary and secondary transformer substatio n’s C and D level maintenance , improved the ir professional skills. 5. Conclusion Simulation Traini ng System is a set of joint operations integration Simulation Tr aining Syst ems, add high le ve l architecture, virtual r ealit y technol ogy, the t e chnol og y of Direct X, substation C, D level mai nt e nance a nd rou- tine test, on the b a sis of the or i gina l grid, substatio n simulation, so lves the problem of lacking maintenance, build an actual integrated operation manage ment mode for the first time . The whole process of the digital simu- lation of the environment and the whole scene, covers the r elevant operational integration production operation per s o nnel’s training, examina tion, app raisal and j oint anti-accident exercises and othe r functions, which can ef- fectively improve grid operati onal integratio n professional skills to improve production efficiency, shor t en the trai ning cycle, improve the qu alit y of training, and fo s ter a sta ff team which meets t he needs of “overhaul” sys- tem, rich professional knowledge, operation skill skilled hi gh -qua lit y in a relatively sho rt period of time, ensur- ing the safety of power grid stabilit y, economic efficient operation, well prepared for a grid production man- age me nt mode under o ve rhaul system, to meet China’s “over ha ul ” power grid ’s needs in the f uture . References [1] Zhang, Q. After the “Big Five” Three Reforms How to Deepen the Staff Skill Training Work. Science and Technology Innovation and Application, 30. [2] Ch en, X.Z. and Hao, Y.C. (2011) Overhaul Organization Integration of Operational Personnel Training Research. Electric Power Education in China, 9. [3] Gu o, W. (2013) Substation Operations Integration Scheme and the Existing Problems and Solutions. Computer Engi- neering Application Technology, 2. [4] Xu, Y.Y. (2012) Substation Operational Scheme Are Discussed. China Power Ed ucati on, 33. [5] Yang, X.H., Lin, C., Kingdoms Equality (2009) Based on High Level Architecture Integrated Simulation Platform of Power System. Power Grid Technology, 11, 98-103. [6] Bai, A.M., Xu, Z.Q. and Tan, L. (2012) Grid Control Integration of Research and Application of Simulation Training System Development Strategy. Qinghai Electric Power, 1.

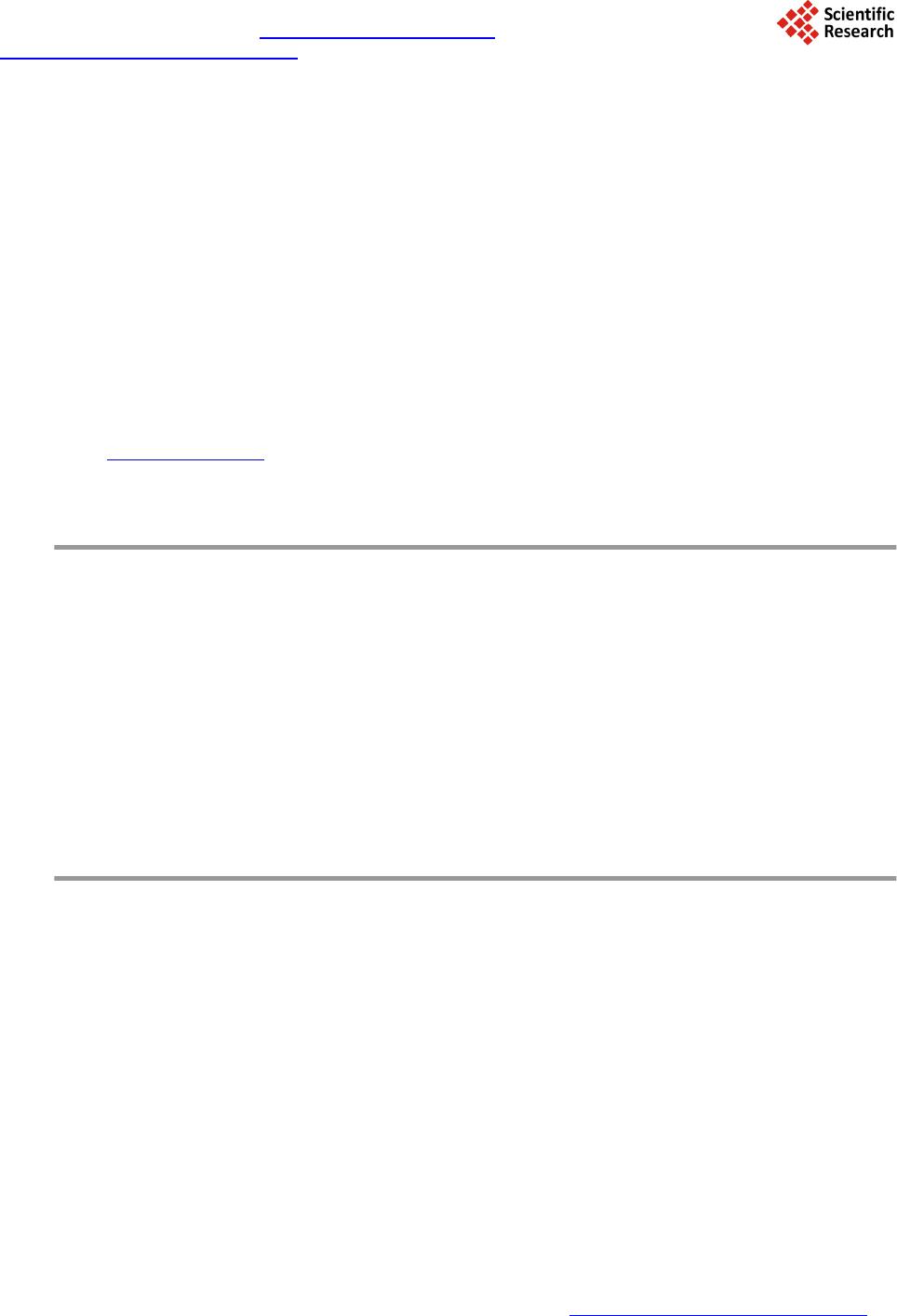

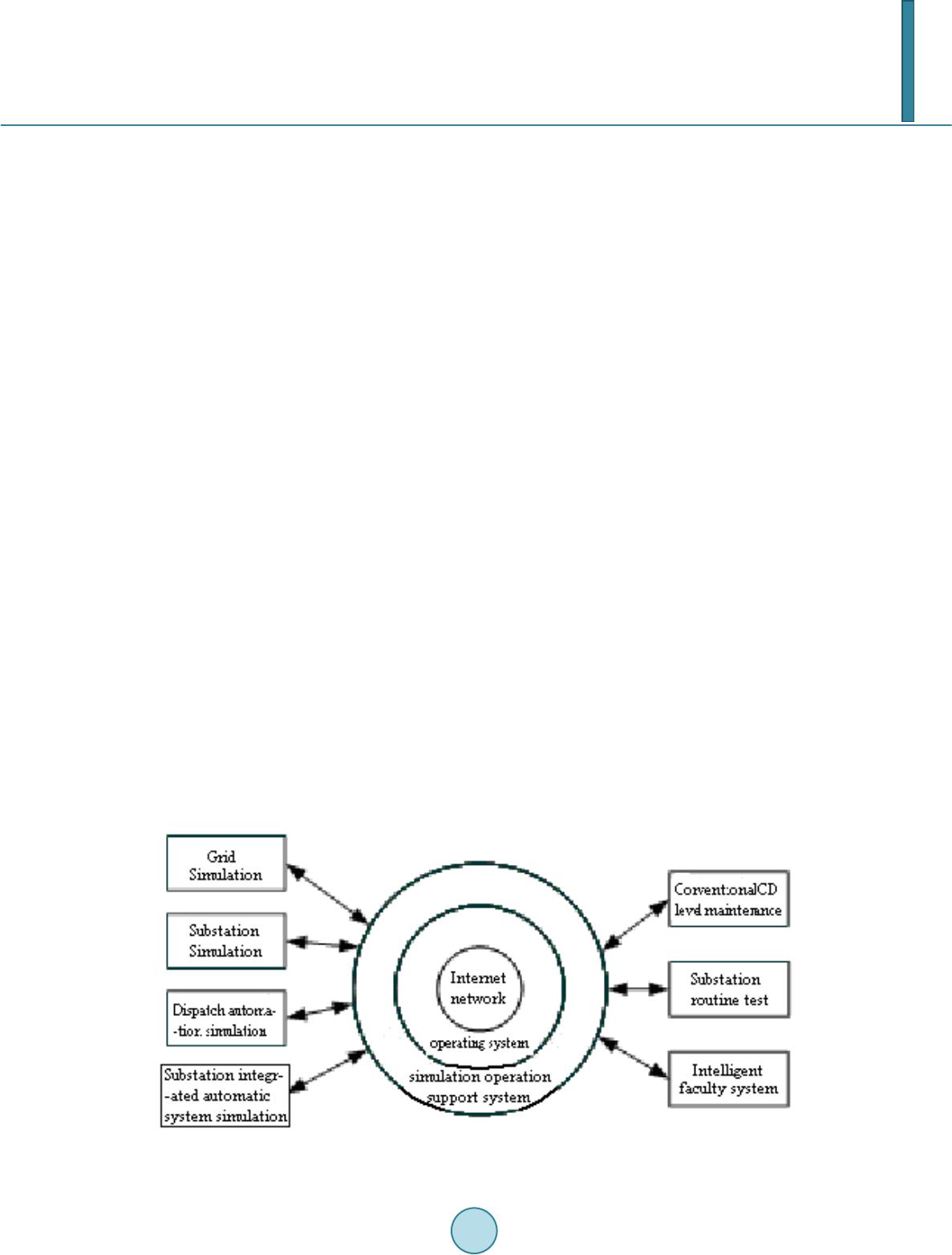

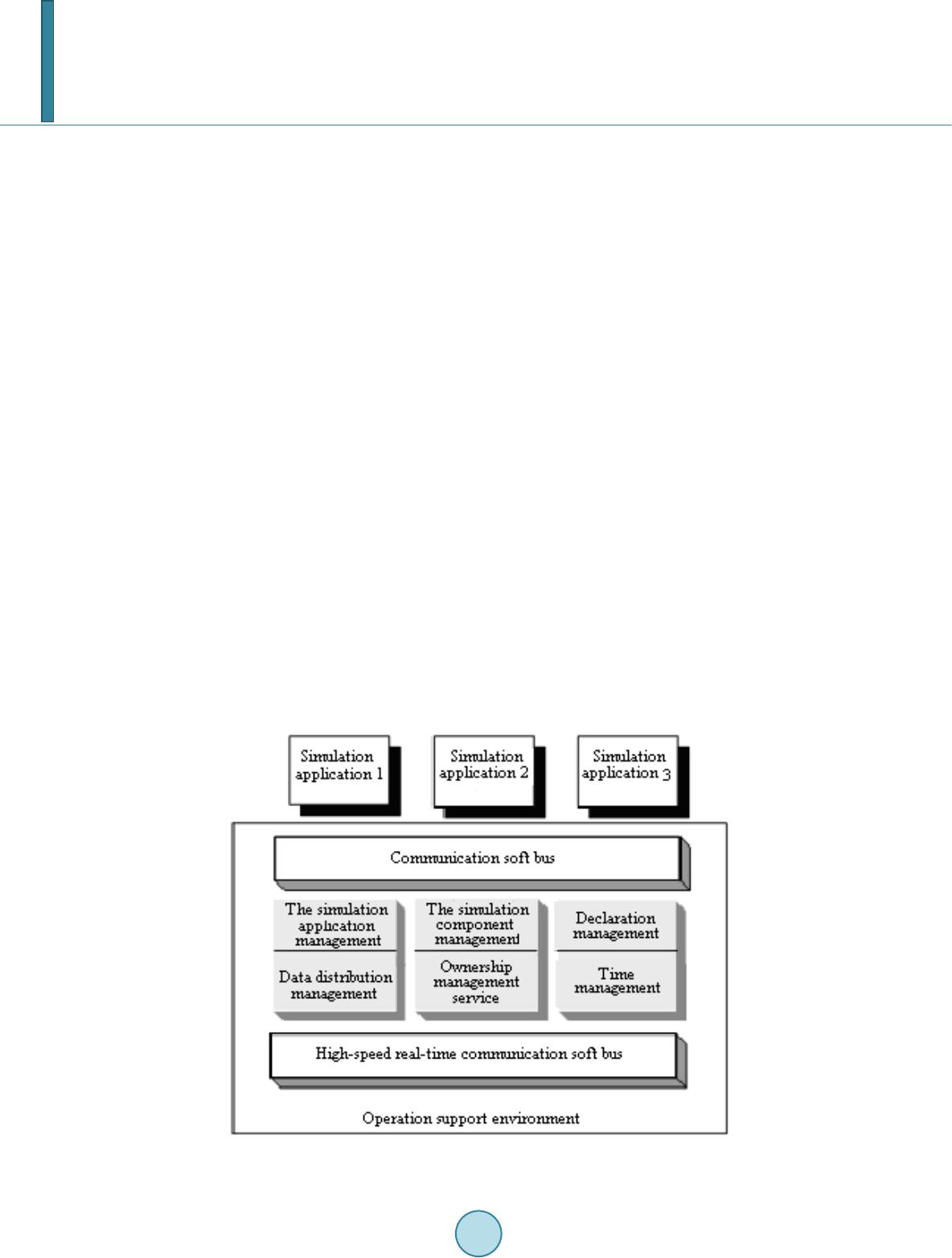

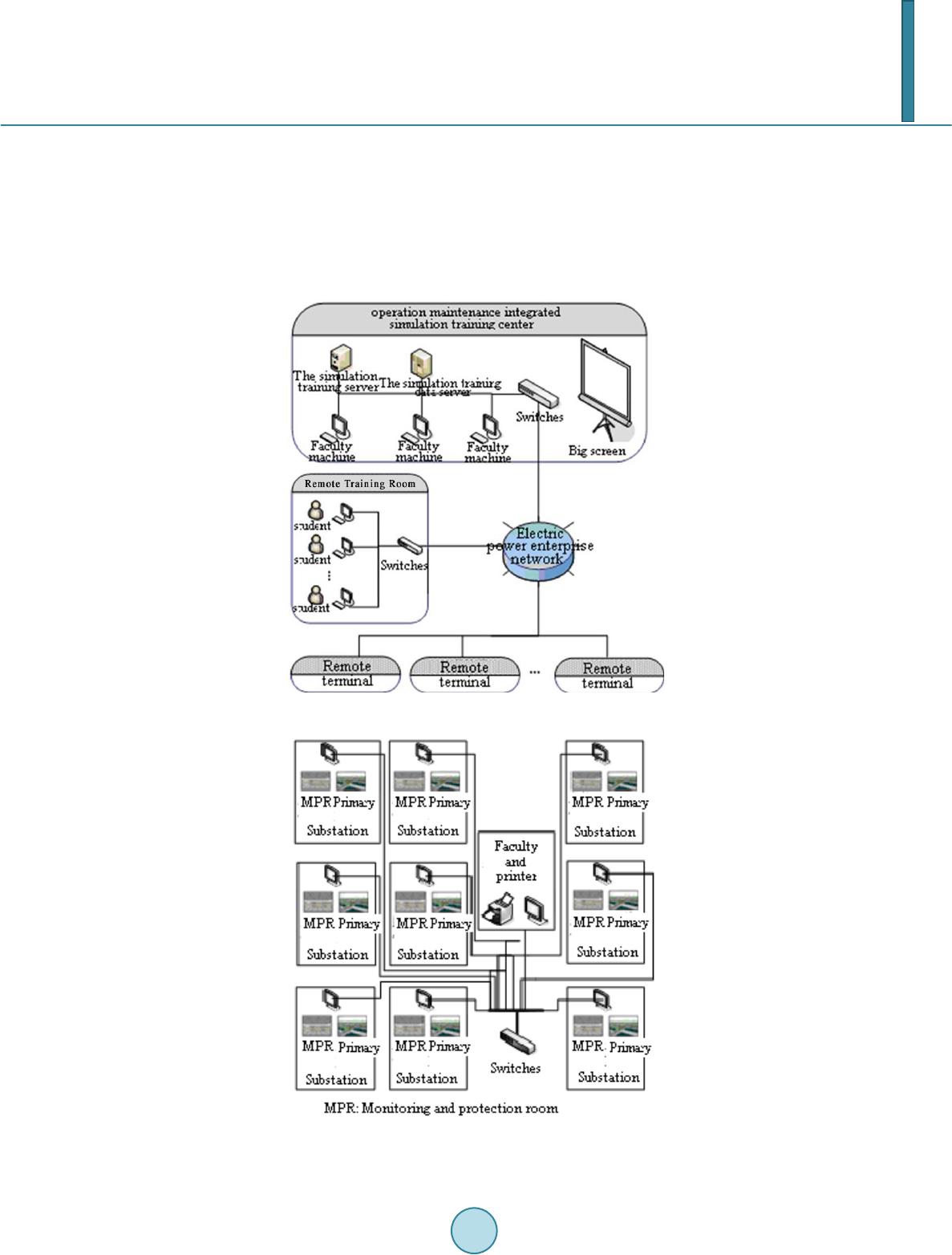

|