Journal of Power and Energy Engineering, 2014, 2, 381-387 Published Online April 2014 in SciRes. http://www.scirp.org/journal/jpee http://dx.doi.org/10.4236/jpee.2014.24051 How to cite this paper: Eslava, H., et al. (2014) Implementation of Machine-to-Machine Solutions to Improve Quality of Service for Electrical Energy Distribution Networks in Colombia. Journal of Power and Energy Engineering, 2, 381-387. http://dx.doi.org/10.4236/jpee.2014.24051 Implementation of Machine-to-Machine Solutions to Improve Quality of Service for Electrical Energy Distribution Networks in Colombia Hermes Eslava1, Luis Alejandro Rojas1, Ramón Pereira2 1Universidad Distrital, Bogotá, Colombia 2ITELCA, Bogotá, Colombia Email: hjeslavab@udistrital.edu.co Received N ovemb er 2013 Abstract In order to incorporate smart elements into distribution networks at ITELCA laboratories in Bo- gotá-Colombia, a Machine-to-M ach in e-based solution has been developed. This solution aids in the process of low-cost electrical fault location, which contributes to improving quality of service, par- ticularly by shortening interruption time spans in mid-voltage grids. The implementation makes use of a GENEKO modem that exploits its digital inputs together with a full coverage of certain re- quired auxiliary services so as to generate proper detection signals whenever failure currents oc- cur; which allows incorporating the latest failure detection technology into the system. Keywords Machine to Machine; Quality of Service; Distribution Grids; Ge neko; Electrical Energy 1. Introduction Demographic trends and industrial growth have prompted an increase in electrical energy demand and also have promoted the use of new technologies, which is accompanied by increased complexity in the type of solutions that are to be implemented in high-power electrical systems. In most cases, companies have made particular ef- forts trying to adopt standards and apply better practices. However, the increase in energy demand together with the particular financial and social conditions of customers have forced companies to operate under safety-limit conditions and also to reduce generation margins [1]. When facing various undesired situations (e.g. machines failing to start, transmission problems with complete boiler-pump-motor subsystems) that lead to deficient energy production, it is absolutely necessary to take ac- tions that allow identifying the point at which failure is occurring, thus guaranteeing better supply quality. Based on this premise and also in an attempt to assist failure-location processes in electrical systems, implementation of smart devices within distribution grids was proposed (supported by Itelca S.A.S) in order to develop a com- plete machine-to-machine solution for failure detection that also incorporates the latest available technology.  H. Eslava et al. 2. Ident ifying a Need As previously mentioned, various factors associated to both energy-supply companies and customers have yielded more complexities in terms of control and operation of electrical power systems. The main purpose of electrical energy distribution systems is to deliver energy from a distribution substation to the corresponding end users (clients). In this context, such systems are to be distributed over large geographic areas. In order to achieve electrical energy supply stability, power systems must be extremely reliable. However, occasional failure events and undesired faulty operation are almost unavoidable, leading to potential electricity interruptions in particular service areas. When failure actually occurs, its effects spread due to the joint operation of breakers and relays. In these situations, the work of an operator (at a control center) is to interpret the sys- tem’s protection counteractions and determine the precise failure location so that the most suitable decision is made in order to accomplish full system recovery. Based on the type of counteraction behavior of breakers and relays during the failure event, an operator must select the most reasonable failure location from a set of potential hypothetical causes, namely identifying a bro- ken element and determine the sub-set of elements that can be immediately recovered (back to normal opera- tion). However, reported cases suggest that operators may not be able to accomplish this task successfully in terms of precision and/or promptness due to the complexity involved and the psychological pressure during fail- ure events. In simple cases, when single failure causes primary protection devices to trigger, simple and direct decision- making is required. Conversely, when two or more failure events occur within a very short period of time, or when there is any sort of operation failure (equipment failure or improper human operation) in protection schemes, the number of potential failure location increases significantly [1]. 3. Distribution Grids, Electrical Failure Location and Machine-to-Machine Solutions in Colombia 3.1. Distribution Grids To date, electrical energy has been carried to potential consumption areas to serve the needs of residential and industrial clients by implementing transmission and generation substations as part of distribution grids. Along these grids, three particular voltage levels can be identified and associated to three types of sub-grid, namely de- livery voltage, medium voltage y and low voltage. Distribution activities involve the following [2]: Distribution grids operation in order to ensure that electrical energy reaches the premises of clients through distribution grids complying with proper supply quality standards. Providing users along the grid with electrical energy by promoting a rational use of resources and also gua- ranteeing specific quality of service. Maintenance of buildings and facilities in order to keep proper operation activities. Measurements of electrical balance and single-client consumption levels. Regarding this aspect, smart coun- ters and tele-management guarantee modernization. Planning and construction of new distribution facilities to meet new demand. Comply with all requirements in terms of regulations and information for official institutions. In addition to these activities, big distribution companies must cope with and be aware of the large social and commercial impact that is entailed in delivering adequate voltage levels (always available ready-to-use) . A number of factors such as intermediate loads, lateral branching, non-homogeneous conductors, system-to- load imbalance, cause an increase in complexity when locating failure points [3]. Most of the failure events oc- curring in urban or rural areas, either in transport grids or conventional generation systems, are associated to undergr ound-cabling equipment or aerial lines. Damage is normally caused by fauna, vegetation, human factors, atmospheric phenomena or meteorological events [4]. In this last category, and also considering electrical-energy system failure, it is worth looking at aspects like atmospheric behavior and the weather conditions of particular regions. Colombia is located in a tropical area (4.00 N, 72.00 W). Considering the main elements that contribute to weather characterization; namely atmospheric pressure, temperature, humidity, wind speed, wind direction, annual precipitation, sunshine and cloudiness; it can be ob- served that these features represent direct causes of failure for most electrical energy supply companies. Atmos-  H. Eslava et al. pheric phenomena such as fog, electrical storms, gales, mist and steam are also considered as weather-defining elements [5]. Colombia is located in an area of very high lightning activity. According to data reported by a company called Keraunos (a recognized lighting-monitoring and research institution in Latin America) Figure 1, in 2012, official figures reached 410 lightning events; which according to experts is just a small percentage of the actual number of cases that are never recorded [6]. Likewise, it has been observed that failure in energy distribution and transmission systems is commonly caused by lightning Table 1, accounting for almost 60% to 70% of failure events [7]. Some of the most common consequences include the following: Failure and permanent damage (burning) of distribution grid equipment. The number of distribution trans- formers that suffered this type of damage ranges from 600 to 2000 a year on average for all distribution companies in Colombia. This suggests that there is an estimate of over 15,000 events of this nature (burnt transformers), which represents damage costs of around 40 million dollars. Impacts on energy quality. Compensations associated to Quality of Energy (compliant with resolution CREG097/2008), represent costs of around $8000'000.000 (Colombian pesos) a year for distribution compa- nies. It is estimated that lightning accounts for 70% - 80% of these figures, particularly in areas of high lightning activity in the country. High risk to the life of workers that carry out construction, maintenance and/or operation activities in distri- bution grids, mainly in rural areas. Figure 1. Lightning activity in 2012 in Colombia. Table 1. Accidents and damage caused by lightning in Colombia January 2010-April 2013 Department % Occurrence Department % Occurrence Risaralda 1.46% Bogotá 3.41% Huila 1.46% Sucre 3.66% Santander 1.71% Córdoba 3.66% Caquetá 1.71% Cesar 3.66% Meta 1.95% Boyacá 3.66% Caldas 1.95% Cauca 5.61% Quindío 2.20% Bolívar 5.61% Atlántico 2.20% Nte. Santander 5.85% Tolima 2.44% Valle 6.10% Magdalena 2.44% Antioquia 34.39% Guajira 3.17% Otros 1.71%  H. Eslava et al. 3.2. Failure Detection At present, whenever there is a problem in power systems, analysis is carried out in two main stages: a) on-line analysis conducted by operators at the control center as soon as the failure event is observed in order to interpret what the situation is, and b) off-line analysis, either conducted by the same operators or by specific protection staff in order to assess the level of operation during the incident and so detect potential future problems (verifi- cation, adjustment, and recalibration if necessary). There is no doubt that the failure detection process entails high costs to be properly conducted (human re- sources, technical equipment and time). The problem is ever more complex when large portions of the distribu- tion grid are involved and therefore a large number of substations can be affected by weather conditions, as pre- viously observed in the figures of failure rates due to lightning in Colombia, particularly in rural areas. Never- theless, the same basic steps are to be followed in order to achieve precise results and so achieve suitable solu- tions [8], namely: 1) Gathering information This is the most sensible first step when attempting to locate any type of failure within a system. It always necessary to ask the questions like what type of technical documentation about the piece of equipment is availa- ble? How precise is normal equipment operation is supposed to be? Is there a record of any previous experience regarding similar situations? Any historical records for the piece of equipment in question must be checked. 2) Understanding faulty behaviour This implies an understanding of what the process actually involves, and also how it works and what part of it is failing to respond as expected. The following questions should be asked: how is the process supposed to occur? What element is not working as it should? What are the potential causes of the behavior observed? 3) Identifying the parameters to be assessed This step requires a clear understanding of the nature of the failure event and shows the component that is most likely to have been affected. The questions to be asked include: what is the input signal that controls the component? What is the expected output of the circuit in question? Is there a delay or change in sequence that can be verified? Parameters that are to be recorded should be identified in order to either confirm or discard sin- gle hypothesis about the real cause of the problem. 4) Identifying the problem source It is essential to have completed the three first steps successfully and also have support from an expert in electrical energy distribution grids. Components must be isolated and specific circuit parameters must be as- sessed. When facing complex failure behavior, it might be necessary to carry out group isolation to finally iden- tify which components actually suffered considerable damage (using the previously recorded data). 5) Component corrections/repa ir After identifying the potentially faulty component and establishing the damage based on the previously rec- orded data, the next step is to correct malfunction or repair the component. This may entail partial repair of the component or even complete component replacement. 6) Repair verification Once the previous step is finished, the operator must ensure that the piece of equipment in question operates as initially intended according to design purposes. A series of tests are to be carried out in order to verify proper operation and discard any additional malfunction. 7) Root Cause Analysis (RCA) This step usually represents a last stage before gathering all the associated information and formalizing the final documentation about the event. However, this step can be completed in parallel with the development of the other steps. 3.3. Machine to Machine—M2M From the previous process, and considering the implications of solution development, an automated process is proposed. The first steps will also be necessary, but, when compared to the complete process less time should be spent in order to accomplish the corresponding failure survey and finally determine the most suitable counterac- tion. At this particular point, machine-to-machine technology (M2M) plays an important role, and in the future this technology will support the development of smart grids through the use of the so called Internet of Things (IoT), whose deployment is expected to have a profound impact on the future of energy within our societies [9].  H. Eslava et al. M2M technology is a whole concept that involves communication among machines, allowing process auto- mation between mobile devices and machines (Mobile to Machine), and also between men and machines (Man to Machine). These machines range from very small electronic devices (e.g. communication/entertainment per- sonal equipment) to measurement/control equipment (e.g. sensors and smart meter or actuators); and also from smart electronic labels, micro-processors embedded in household appliances, cars or offices, to personal com- puters or complex servers located at large data processing centers. M2M assists communication between its own devices and information centers regardless of their location; this technology also facilitates communication with other types of devices and with people in various places through the use of personal communication devices instantly (in an organized fashion). Through M2M commu- nication, it is possible to offer a wide variety of services in the fields of telemetry and tele-control (e.g. vehicle- to-vehicle communication, remote monitoring of public utility consumption), telemedicine and tele-assistance, security services and corporate/domestic remote-control applications. Together with the development of internet-based connectivity as well as the development of smart energy sensing and energy measurement devices, there have been significant advances in unconventional renewable energy sources, particularly regarding solar energy, electrical grid operation controllers and storage batteries. This will allow better energy management in the near future in every city through the use of Smart Grids, A smart Grid is basically a system that integrates electricity transport and distribution with information technology, allowing real-time communication between customers, distribution devices, transporters and generators by using particular devices intended to guarantee more efficient, sustainable energy consumption [10]. As stated by Andrés Alonso Rivas (Manager of Energy Affairs and Water Resources at Codelco), provided the new technological advances regarding renewable energy, smart measurement devices, sensors, batteries, In- ternet and control systems, it should be possible to save and generate electricity at the very points of consump- tion; furthermore, the electricity excess might be sold back to electricity distribution companies, which will re- sult in more efficient management of energy within our cities. From the perspective of energy savings (at home, industries and corporations) smaller and more stable (constant) energy consumption should be possible during the day by using smart sensors for electrical-device tele-control trough the internet. One example associated to electrical energy generation can be observed in the progressive increase of photovoltaic panel efficiency, to- gether with a reduction in costs and recent advances in fuel cells with alternative technologies that allow elec- tricity generation at consumption points. Likewise, technological advances in the design of batteries should faci- litate continuous, economical electricity storage at consumption points; thus facilitating the creation of a new distribution grid or providing suitable charging outlets for near-future electric cars. This ultimately will make of every single household (office or industrial facilities) a potential distributed generation point within a smart electrical grid. The applications for companies are endless and should increase the number of potential distri- buted generation alternatives as well as overall energy-use efficiency. For these companies it will be possible to integrate and generate renewable sources by means of the co-generation strategies derived from their own pro- ductive processes. Thus, this co-generated energy can be fed back to charge the company’s own battery banks or it can be sold in large amounts to the main regional grid Likewise, the introduction of robots together with higher levels of automation should also result in an im- provement of security standards and production times, derived from a more efficient use of energy associated to the optimization of process tele-measurements and tele-control (e.g. by measuring and controlling the heat levels used in boilers when manufacturing particular products) [9]. 4. Design of a Machine-to-Machine Solution The solution proposed herein was supported by the broad experience of ITELCA S.A.S. regarding the import and commercialization of products associated to telecommunications systems as well as the development of in- tegrated ICT solutions. This Colombian company was founded in March 1987 and is currently certified by Bu- reau Veritas Quality International under standard ISO 9001 version 2008. The system was implemented a using proprietary design developed in order to provide coverage to rural areas whose lightning rates per year are significant; thus the system provides failure alerts for low-consumption areas where traditional solutions that use equipment such as reclosers offer no financial competitiveness. The system consists of.  H. Eslava et al. 4.1. Direct Current Feeding Equipement This equipment provides autonomous operation for customized periods of time according to the corresponding needs of each area. The equipment deals with rectification and conversion into adequate voltage levels. 4.2. Solar-Power Backup Resource Companies involved in development and management of renewable energy sources, locally and internationally, have promoted the use of renewable energy that satisfies energy-supply needs and avoids massive emissions of CO2 into the atmosphere (tons of CO2). Such is the case of Enel Group, which is world-class leading company capable of providing up to 8700 MW (already installed) by gathering various types of sources such as eolic, so- lar, hydro-electric, geo-thermal y biomass; involving at least 740 operational plants in 16 countries throughout Europe and America [11]. In Colombia, the relative participation of alternative energy sources can be found in Alta Guajira, where EPM (Empresas Públicas de Medellín) installed the very first Colombian wind farm, called Jepirachí, consisting of 15 air-based generators that feed 19.5 mega-watts into the National Interconnected System. In regions such as San- tanderes, the Eastern Plains and the Atlantic Coast, there are already various bio-ma ss -based generation projects. Potential solar-energy sources are to be explored in other areas like Magdalena, La Guajira, San Andrés y Pro- videncia; and according to UPME, there is an estimate of energy generation obtained from oceans that may reach 30 GW, exploiting 3000 Km of coastal zones [12]. 4.3. Geneko Router GWR-I industrial cellular router series” represents a group of industrial graded cellular routers specially de- signed for expansion of existing industrial networks, remote telemetry and data acquisition in harsh environ- ments. Low transmission delay and very high data rates offered by existing cellular networks completely eliminate the need for very complex installation of wired infrastructure in industrial environments. This router is a pure machine to machine connectivity solution. Easy to install, reliable and high performance router models from GWR-I industrial cellular router series introduce a completely new dimension into industrial networking area. Many useful features make GWR-I cellular routers a perfect solution for wide variety of industrial applications [13]: Dual SIM card support increases the reliability of the router and provides a solution for those applications where failure of one mobile network must not result in system downtime. The whole set of advanced WAN settings allow a user to specify desired parameters in order to meet the re- quirements of specific cellular network. GWR-I routers proved themselves to be reliable and high perfor- mance devices in so many countries around the world. VPN (GRE, IPsec and OpenVPN) tunnel support provides powerful options for network expansion and se- cure data transfer over the cellular network. With Serial-to -IP feature it is possible to connect, control and perform data acquisition from almost any de- vice with serial RS232 port. In addition to this feature, GWR-I industrial cellular router series implements Modbus RTU-to-Modbus TCP functionality designed to support expansion of Modbus SCADA networks over the cellular networks. Easy to use web interface, extended CLI (Command Line Interface), detailed log, SMS control feature, par- tial and full configuration Export/Import and remote management and monitoring software provide wide range of management functionalities. 5. Conclusions The system development presented herein allows electrical energy companies to increase their failure detection capacity with low-cost procedures, which permits using the system in rural areas where energy consumption le- vels hinder the use of traditional technologies. Additionally, the autonomous nature of the system and its easy- to-implement live-line characteristics guarantee a positive impact on improving quality-of-service indices for companies. In the mid- and long-term, various goals are to be accomplished, namely a reduction in the number of failure  H. Eslava et al. events associated to distribution transformers, an optimal implementation of the system for aerial grids, a com- prehensive inclusion of the real currents and the real energy levels that occur due to lightning in particular re- gions in order to improve the design and implementation of protection devices, better planning of maintenance activities according to impact, and future scheduling for modifications to existing line routes that includes risk assessment for future grids. In the long term, massive adoption of new concepts regarding energy supply assisted by Machine-to-machine solutions will continue, which should contribute to reducing potential problems associated to apparent lack of safety and reliability of electrical systems. Acknowledgements The authors would like to thank ITELCA S.A.S for its permanent support in developing the present system im- plementation. This company made it possible to materialize the proposed solution by offering experienced as- sistance (over 23 years of experience) in the practical issues that pertain to ICT-integrated telecommunication- systems equipment; also promoting innovative solutions and contributing to optimizing industrial development with economic growth. References [1] Mart ínez, E.V. (2010) Academia de Ingenieria de México. http ://academiadei ngenieriademexico.mx/archivos/coloquios/9/Diagnostico%20de%20Ubicacion%20de%20Fallas%20 en%20Sistemas%20Electricos%20de%20Potencia.pdf [2] Endesa, G. (2013) Endes a-Elect ricid ad-La red de Distribución. http://www.endesa.com/es/conoceendesa/lineasnegocio/Electricidad/Red_distribuci%C3%B3n [3] Short, T.A. (2004) Electric Power Distribution Handbook. 1 Edition, CRC Press. [4] Lehtonen, M. (2010) Electric Power Quality and Supply Reliability Conference. Fault Rates of Different Types of Me- dium Voltage Power Lines in Different Environments, Kuressaare. [5] Pabón, J. D., Zea, J., León, G. , Hurtado, G., Gonzál ez, O. C. an d Montealegre, J.E. (2001 ) La At mósfera, el Tiempo y el Clima. El Medio Ambiente en Colombia, Bogotá IDEAM, P. Leyva, 35-91. [6] Castañ o-Unimedios, L. (2013) Ciencia y Tecnología: Colombia Tendrá Norma para Predicción de Ra yos. http://www.unperiodico.unal.edu.co/dper/article/colombia-tendra-no r ma-para-p red iccion -de-rayos.html [7] Keraunos (2013) Keraunos -Innovación Tecnológica en P redicción de R ayo s. http://keraunos.co/ [8] Bech ard, P. (2013) Localización de Fallas Eléctr icas. PdMA Corporation. http://confiabilidad.net/articulos/localizacion-de-fallas-electricas / [9] Ri vas, A.A. (2012) Visiones de Telefónica-Innovaciones que Muestran el Valor de la Tecnología. http://visionesdetelefonica.cl/paper/4/esp/index.html [10] (2003) The United States Department of Energy, Grid 2030—A National Vision for Electricity’s Second 100 Years, Washington. [11] Endesa, G. (2013) End esa-El ectrici dad-Energías Renovables. http ://www.end esa.co m/es/con oceen desa/ lineasn egocio /Co generacio nyreno vables/ Energi asReno vables [12] Unidad de Planeación Minero Energética (2012) Decreto 255 de enero 28 de 2004. UPME. http://www.upme.gov.co/funciones.asp?Cap=1 [13] GeNeKO (2013) GWR -I Industrial Cellular Router Series. Geneko 2013. http://www.geneko.rs/en/products/m2m-products-and-solutions/gwr-i-cellular-ro uter -series-1.html

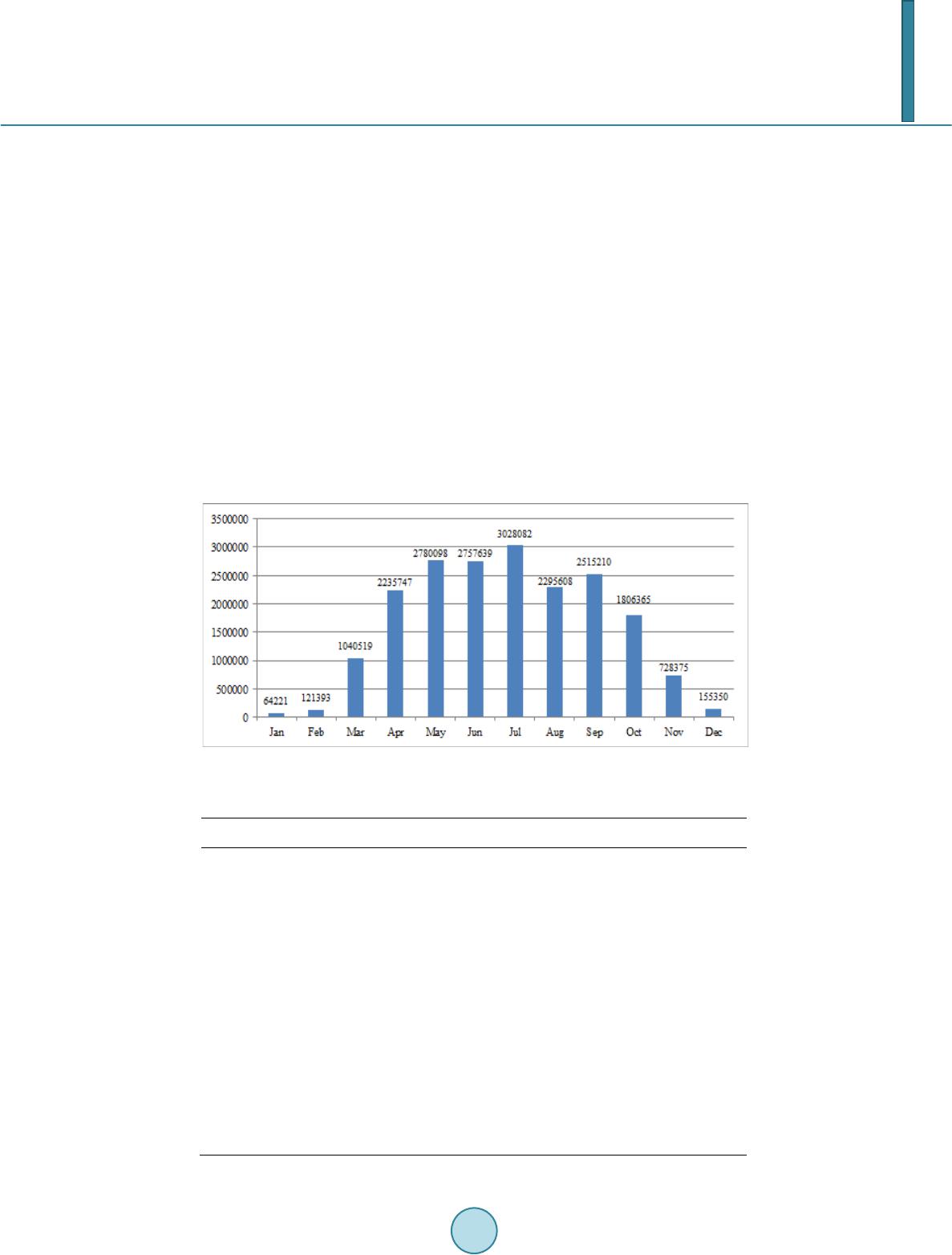

|