Journal of Environmental Protection, 2014, 5, 9-16 Published Online January 2014 (http://www.scirp.org/journal/jep) http://dx.doi.org/10.4236/jep.2014.51002 Review: Cu rrent Stat u s of Recycling of W aste Printed Circuit Boards in India Rashmi Kumar1*, Dahyalal. J. Shah2 1Chemical E ngineer ing, D. J. Sanghvi College of Engineering, Mumbai, India; 2Mukesh Patel School of Technolo gy Management & Engineering, NMIMS University, Mumbai, Ind ia. Email: *rashmikumar_djs@yahoo.co.in Received November 10th, 2013; revised December 8th, 2013; accepted January 6th, 2014 Copyright © 2014 Rash mi Kumar , Dah yalal. J. Shah. This i s an open access art icle d ist rib u ted under t he Cr eative Co mmons Attr ibu- tion License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. In accordance of the Creative Commons Attribution License all Copyrights © 2014 are reserved for SCIRP and the owner of the intellectual property Rashmi Kumar, Dahyalal. J. Shah. All Copyright © 2014 are guarded by law and by SCIRP as a guardian. ABSTRACT Printed Circuit Boards (PCBs) are an integral part of any electronic equipment. The growth of e-waste as end- of-life electronic equipments at an exponential rate is producing large quantities of discarded PCBs. In India, current recycling and processing of PCBs is managed almost entirely by the i nformal sector or the unskilled la- bor (95%). The crude recycling activities cause irreversible health and environmental hazards and the loss of valuable materials due to the poor recovery of base and precious metals. With the disclosures of the recycling being done by unskilled labor, alternative recycling strategies are being sought with the aim of higher recovery of materials in an environment friendly manner. There is an urgent need to establish effective and efficient me- thods for recycling the metals presented in the w aste PCB s. In this st udy, the existing methods practiced for re- cycling of waste P C Bs in India and the management strateg ies for handling them are assessed. KEYWORDS Printed Circuit Boards; India; E-W aste; Informal Recycling 1. Introduction Growth rate of discarded electronic waste is high in India since it has emerged as a giant hub for Information Technology. There is a rapid modernization of life style. Printed Circ uit Boards (PCBs) are an integral part of an y electronic equipment. They act as a base and provide electrical connections to all mounted components pre- sented in any electronic equipment. With the rapid growth of electronic goods combined with rapid rate of obsolescence, e-waste is the fastest growing waste pro- ducing large quantities of waste printed circuit boards. Concerns about waste PCBs began to mount after inves- tigations by several environmental groups such as Basel Action Network (BAN), the Silicon Valley Toxicity Coalition (SVTC), Greenpeace and Toxics Links. It re- vealed that e-waste is being illegally brought into India and other developing countries by misleadingly labeling it as metal scrap or second hand computers. Absence of any specific law regulating e-wa ste till 2012, the lax en- vironmental standards and cheap labor have made India an attractive site for recycling. In India, it is believed that almost 40% of obsolete electronic products are unused at homes or in warehouses as people are unaware as what to do with the m and t here is a lack of systematic mechanism for their disposal. Re- cycling and processing of the waste PCBs in e-waste is managed almost entirely by informal sector and is purely market driven. It is a source of livelihood for unorga- nized recyclers. Very crude methods which are used cause occupational and environmental hazards and the loss of valuable materials due to the poor recovery of base and precious metals. These methods cause irreversi- ble health and environmental hazards. In this study, the existing methods practiced for recy- cling and the management s trategies of handli ng the hu ge quantities of waste PCBs in India are assessed. It gives a review of current status of informal recycling and the emerging tr e nds o f fo r ma l r ec ycl i ng d ue to the awareness OPEN ACCESS JEP  Review: Current Status of Recycling of Waste Printed Circuit Boards in India by NGOs like Greenpeace, Toxics Link, etc. 2. Technology Options for Recovery of Metals from PCBs PCB s in e-waste are complex mixtures of metals, ceram- ics and organics. For the determination of composition the Printed Circuit boards the comminution fines wet anal ysis is not o nly ver y dep endent o n the diges tion co n- ditions, determination of absolute assays of all constitu- ents will also require comparison of data from more than one digestion condition. The effect of digestion proce- dure o n the fi nal assays in wet spectroscopic analyses has been assessed by Ogunniyi, et al. [1]. Recovery of pre- cious metals as gold, silver, platinum, palladium and base metals as copper, nickel, aluminum, zinc, tin, iron, etc. is the main driving force for the recycling of PCBs. The heterogeneous composition of the PCBs poses problems for se parati on of the var ious co nstitue nts. Table 1 shows the weight and price of the various metallic components in PCB s [2]. Technologies to retrieve metals from the waste PCBs without harming the environment are required. Success- ful recycling of PCBs depends on the efficient and eco- nomical technology for recovering the valuable metals from PCBs which account for more than 80% of the in- trinsi c value, thoug h weight of t hese is less tha n 1%. Re- trieving of metals can be done either by pyrometallurgic- al or hydrometallurgical process in combination with mechanical pretreatment. PCBs recycling process usually includes three stages: pretreatment, separation/concen- tration, and mechanical /chemical refining [3]. For efficient liberation and separation of metallic components from non-metallic components as plastics and ceramics, the PCBs are first to be crushed. Grinding is followed by material separation based on physical properties as magnetic, electrostatic properties, density, visual or other characteristics. A series of permanent magnets may be used to remove ferrous metals as iron Table 1 . M arket val ue of th e metal re covered fr om 100 0 Kg of PCBs (Chate r jee and Kumar , 2009) [2]. Reco v ered metal Weight Approximate c os t (in US$) Gol d 279.93 g 6115 (@ 68 5.00 pe r 31 g) Precious metals (Pt, Pd, In) 93.31 g 3852 (@128 4.00 per 31 0 g) Copper 190.512 Kg 1470 (@3.50 per 453.59 g) Alumi nium 145.152 Kg 448.00 (@ 1.28 p er 453.5 9 g) Le ad and Ti n 30.844 Kg 144.16 (@2.1 2 p er 453. 59) Silver 450 g 213.15 (@14.70 per 31 g) N. B. Data gene rated on avera ge rec overy of one t on of p opulat ed P CBs and value is taken from the prevailing rate at that point of time. These are only to give a per ception of valu e from the metal recove ry from e-waste. and nickel from non ferrous materials. Eddy current se- parators can separate non-ferrous metals as copper and aluminum. Further separation of the precious and base metals can be done by hydrometallurgical or pyrometal- lurgical treatment. The main steps in hydrometallurgical processing con- sist of leaching which is selective separation of metals from solid mi xtures b y disso lving i n an acid or a re agent to form metallic salts or leachates and then metal recov- ery from the leachates by methods such as precipitation, solvent extraction, adsorption, ion-exchange, and ce- mentation. In hydrometallurgy, solvent extraction is a well established technology in processing of nuclear ma- terials and in mineral processing of metals like copper, nickel, zinc, cobalt, gold and silver on a commercial scale and can be extended to retrieve metals from PCBs. Par k and Fr ay [4,5 ] have r eporte d a promising method to separate the metals in PCBs using solvent extraction. In pyrometallurgy processing, the PCBs, connectors and all the scrap containing the precious metals are processed in smelters. Smelters turn fractions into metals of high purity in an environment friendly and economic way. It is successfully used to extract metals in a few countries. Modern integrated smelters recover a large wide range of metals from complex precious metals bearing materia ls as gold, silv er and platinu m group met- als (palladium, platinum, rhodium, iridium, ruthenium), and also base metals as copper, lead, nickel, etc., and can make use of organics such as plastics in place of coke as a reducing agent and fuel as an energy source. Kim et al. [6] have proposed a novel process to simultaneously ex- tract precious metals such as gold, palladium and plati- num from spent printed circuit boards and honeycomb type autocatalysts by smelting without addition of any collector metals. 3. Sources of Waste PCBs Discarded e-waste account for the generation of huge quantity of waste PCBs. Waste PCBs are generated from overstock, obsolete and end-of-life computers, medical appliances, fax and copying machines, household ap- pliances such as televisions, refrigerators, washing ma- chines, ovens, electronic toys, mobile phones, video cas- sette players and recorders, MP3 players, air conditioners, etc. According to study carried by GTZ (German Technic- al Collaboration agency) MAIT (Manufacturers’ Associ- ation for Information Technology) in 2007, the total quantities of generated and recycled E-waste were 380,000 tons and 19,000 tons respectively. Above this about 50,000 tons got imported illegally into the country. About 14 million mobile handsets had been replaced in 2007. But there is lack of authentic and comprehensive data on E-Waste which is further exaggerating the prob- OPEN ACCESS JEP Review: Current Status of Recycling of Waste Printed Circuit Boards in India lems associated with E -waste mana ge ment in t he co unt ry. Although various State Pollution Control Boards have initiated the exercise to collect data on E-Waste genera- tion, such exercises are not practiced with utmost sincer- ity. [7]. The exponential increase of this waste every year might soon turn the nation into the world’s largest e-waste graveyard. 70% of e-waste is generated in ten states. Maharashtra ranks the first followed by Tamil Nadu, Andhra Pradesh, Uttar Pradesh, West Bengal, Delhi, Karnataka, Gujarat, Madhya Pradesh and Punjab. Maharashtra produces 20,270.6 tons per year due to presence of large number of InfoTech Parks and elec- tronic products manufacturing companies situated in these areas. Sixty five cities in India generate more than 60% of e-waste. Among the cities, Mumbai ranks first followed by Delhi, Bangalore, Chennai, and Hyderabad. Mumbai alone generates approximately 19,000 tons of e-waste excluding those from import. Bangalore gene- rates 8000 tons of e-waste annually [8]. Toxics Link sur- vey revealed that huge quantity of computer scrap also comes into India from the USA, Singapore, Malaysia and West A si a. 4. Legislation With ma ny countr ie s havi ng i ntr od uc ed legisla tion to b an the import of e-waste, India has emerged as the prime destination for dumping of e-waste. In China the State Environment Protection Administration (SEPA) is in charge of the general solid waste management and the import of all kinds of waste. Import of abandoned com- puters, monitors, CRTs, copiers, microwave ovens, air conditioners, video cameras, electric cooking devices, rice cookers, telephones, video games (except for processing for re-export), televisions, picture tubes and refrigerators has been restricted [9]. European Union (EU) has already released two directives in 2003. One was the “Directive on Restriction of the use of Certain Hazardous Substances in Electrical and Electronic Equipment” (RoHS ), which directs all its member states to e nsure that from 1 July 2006 all new electrical and electronic equip ment put on the market does not contain lead, mer- cury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) or polybrominated diphenyl ethers (PBDEs). The second “EU Directive on Waste Electric and Electronic Equipment (WEEE)” includes producers, distributors, consumers and all parties involved in the treatment of WEEE. Producers are requested to finance the collection, treatment, recovery for environmentally sound disposal of WEEE [10,11]. According to the “California Electronics Waste Recy- cling Act” 2003, the State of California directs each manufacturer that sells electronic devices to either collect an equivalent of 90% of the number of devices they sell or they must pay the alternative fee for recycling the de- vices they sell [12]. In US, different stake holders, like the original equipment manufacturers (OEMs), govern- ment agencies, environmental organizations and others are coming together with joint nationwide plan for man- aging electronic waste. In Japan the manufacturers and importers are forced to take back their products at desig- nated collection sites and to recycle them according to the regulations set by the government. Retailers take back used home appliances that they sell and transfer them to the corresponding manufacturers and importers. The two major laws covering broad range of e-waste items are “The Law for Recycling of Specified Kinds of Home Appliances” (LRHA) and “The law for Promotion of the Effective Utilization of Resources” (LPUR). In Malaysia, the guidelines for the classification of used electronic and Electronic Equipments entered into force in January 2008, which prohibits the import of WEEE. Though India is one of the most affected countries by e-waste problem, yet there had not been any effective e-waste policy till the year 2012. This may be because it was not considered as a potential threat which needed to be handled effectively. Earlier the Ministry of Environ- ment and Forests (MoEF), Government of India, had issued notifications related to hazardous wastes which were implemented through the State Pollution Control Boards, Central Pollution Control Board and control committees i n States and Union Territories. But none of the environmental legislations mentioned above had direct and specific reference of handling of electronic waste as hazardous in nature. Accord ing to the Hazardous Wastes Rules (1989), e-waste was not treated as hazardous unless proved to have higher concentration of certain substances. With the collaborative efforts by Greenpeace, MAIT, GTZ and Toxics link along with support from major electronic companies in India, the Ministry of Environment and Forests notified the E-waste (Management and Handling) Rule on May 30, 2011. The rule is implemented throughout the country from May 1, 2012. Every producer, consumer involved in the manufacture, sale, purchase and processing of electrical and electronic equipment or components, col- lection centers, dismantlers and recyclers of e-waste come under this law. The rule gives guidelines for man- agement, handling and disposal of e-waste and places responsibility on the producers for the entire lifecycle of a product from design to disposal i.e. it is based on Ex- tended Producer Responsibility (EPR). Disposal of e-waste in municipal landfills will be prohibited by the new regulations. Manufacturers will be made financially and legally responsible for the safe disposal of their products. Producers will have to provide all information regard- ing disposal of the equipment after use to prevent e-waste from being dropped in domestic waste and about the ha- OPEN ACCESS JEP Review: Current Status of Recycling of Waste Printed Circuit Boards in India zardous components present. All commercial consumers and Government departments will be responsible for re- cycling of e-waste. The new Legislation includes me- chanisms for better designs for recycling, reuse and re- duction in the use of toxic material and encourage intro- duction of green electronic products in the market. It is mandatory to register all handling and recycling of ha- zardous wastes with Central Pollution Control Board (CPCB). But there are certain loopholes in the existing legisla- tion. There is no directive on ban of import of second hand electronic goods brought to the country for charity and reuse purpose which finally finds its destination in informal recycling. Also, India being a signatory to the Basel Convention, a UN treaty on the control of trans- boundary movement of Hazardous Wastes and Disposal, it cannot export hazardous waste listed in Annex VIII of the convention to countries that have ratified the agree- ment. However the Convention does not restrict the im- port of such wastes from countries that have not ratified the B ase l agr e e men t . Thus t he r e i s no p r o visio n to e ns ur e the ban of imports of electronic waste. Greater scrutiny and vigilance by the custom authorities on the cross- border movements can prevent the dumping of obsolete electrical and electronic products from developed coun- tries. 5. Review of Informal Recycling Printed circuit boards in e-waste contain both valuable materials such as gold, palladium, silver and base metals such as copper, nickel, iron, and aluminum. Recovery of precious metals is the main driving force for the recy- cling of PCBs. Lack of access to appropriate technolo- gies and methodologies and the infrastructure capable of handling the increasing volumes of the scrap lead to in- formal recycling. Informal sector consists of small workshops which cannot handle large quantity of e-waste at a time. There are scrap dealers or Kawarees who col- lect domestic e-waste as well as from offices and educa- tional institutes and corporates. The scrap dealers pay consumers a price for their waste appliances and they in turn sell them to dismantlers and recyclers in the infor- mal sector. It is t he livelihood for the uno rga nized r ecyc- lers and the y risk t heir l ives a nd en viron ment d ue to la ck of awareness. Over 25,000 people handle 50,000 tons of e-waste in various scrap yards in Delhi every year (Tox- ics Link). There are similar scrap yards at Meerut, Fero- zabad, Chennai, Bangalore and Mumbai. The informal recycling system includes small to me- dium scale units and are involved in dismantling, sorting and also harmful processes such as burning and leaching in order to extract metals from the e-waste particularly the PCBs. The accrued electronic and electric waste is first dismantled and sorted to fractions as printed circuit boards, cathode ray tubes, cables, plastics, metals, con- densers and others. The methods of salvaging material from circuit boards drawn from monitors, CPU disc, floppy drives, printers, etc. are highly destructive as they involve heating and open burning for extraction of metals. Toxic chemicals are used to recover valuable metals such as gold, silver and copper from the PCBs. Working in poorly ventilated areas without proper personal protec- tive equipment leads to exposure to dangerous and slow- poisoning chemicals. Even after such harmful methods are used, only a very few of the metals are recovered and the recovery percentage is very low. According to a comprehensive report by Maharashtra Pollution Control Board, 2007, there is no organized mechanism for collection, transportation and disposal of WEEE. The dismantling of the e-waste is done by the crudest methods by use of hammer, chisel, screw driver and bare hands to separate copper containing parts, steel, plastic and other metals. Recyclers are mainly interested in recycling PCBs as they contain the precious metals. Precious metals are present as thin layer on surface of copper , nickel and iron in pins, condensers, etc. on PCBs. Preheating process is applied to remove the resalable compo ne nt s like IC s, c o nde n s er s, be a ri ngs (p ul le ys) fr o m floppy drive and hard drive. Pre-heating means simply putting the mother board on a stove. Then resalable chips, condensers, bearings, etc. are plucked out manually fro m the pre-heated PCBs from TV, PC, cell phone, etc. The gold-plated pins are manually removed. The core of each mother boar d has a flat lamin ated gold plate which is cut down and sold to goldsmiths for gold recovery. The pre- heated circuit boards are taken by other dealers for re- covery of solder (consisting of lead and mercury). The method of solder recovery is very rudimentary [13]. 6. Impact of Informal Recycling The Basel Convention, a UN Treaty, defines Printed Circuit Boards as hazardous. In the absence of suitable techniques and protective measures, PCBs recycling by crude methods result in toxic emissions to the air, water and soil and pose a serious health and environmental hazard. Improper recycling can cause irreversible dam- age to the human body and environment. Women and children are often directly exposed to lead and other ha- zardous materials in this process. The acid treatment and burning cause occupational hazards to the workers and contaminate the environment through efflue nts and to xin laden smoke. Highly toxic fumes as dioxins and furans are produced when plastics casings are burnt to retrieve metals and these are released into the air. Waste acid water is discharged into neighboring grounds. Working in poorly ventilated enclosed areas without masks and technical expertise results in exposure to dangerous and slow poiso ning che micals. T h us with al most a ll rec ycling OPEN ACCESS JEP Review: Current Status of Recycling of Waste Printed Circuit Boards in India being done in illegal scrap yards, there are no controls on the processes and discharge of effluents. Even after such harmful methods are used only a few of the materials are recovered. 7. Management Strategies for Formal Recycling of PCBs Proper management for recycling of waste PCBs will dep end no t o nly on the e ffec ti vene ss of lo cal gover nme nt but also on the attitude of consumers and manufacturers. Collaborative campaigns are required for educating the consumers. Encouragement of donation of e-wastes to underdeveloped areas and second-hand markets can help reduce the quant ity of waste PCBs produced. An efficient collection and recycling infrastructure is required. For financing, either the consumers can pay via fee at pur- chase or shared by producers (for transport and recycling) and municipalities (for collection). In Switzerland, Ad- vance Recycling Fee (ARF) is charged on all new ap- pliances. The ARF is used to pay for the collection, transport and recycling of the disposed appliances. The effective collectio n o f e-waste in Switzerland is pri maril y due to efficient management of the waste by two Pro- ducer Responsibilty Organisations (PROs)-SWICO (The Swiss Association for Information, Communication and Organisational Technology) and S.EN.S. (Stiflung Ent- sorgung Schweiz) [14]. Integration of the existing informal recyclers into the formal sector can be done by giving them incentives. Proper knowledge transfer and skill upgrading through seminars and training are required. Since the informal sectors have their own limitations to implement all processes, there is a need for responsibility being given to formal sector which would be responsible to pay the informal sector an attractive price for the scrap material. For environmentally sound management of waste PCBs proper collection, transportation, storage, recovery and disposal facility at regional and national levels certified by the regulatory authorities are required. E-waste col- lection, exchange and recycling centers should be en- couraged in partnership with government, NGOs and manufacturers. Proper recycling of materials present in PCBs requires sophisticated technology and specific skill s and trai nin g for the o pe ratio n. T hus invo l vement o f both formal and informal players is required. The infor- mal sector should concentrate more on collection, disas- sembly and segregation and be discouraged from treating PCBs. The formal sector should purchase the PCBs from the informal sector and concentrate only on the core ac- tivity of PC B recycling. Rochat et al. 2008 [1 5], ha ve d iscus sed the wor king o f “baseline scenario” and “alternate business models” for different qualities of PCBs. Presently, the collection and segregation of e-waste is done by middleman, scrap dealers and rag pickers (kabadiwallas). In the baseline scenario, the PCBs are collected and dismantled in order to segregate the gold-conta ining p arts a s pins, c onnecto rs, chips from which gold is extracted by wet chemical processes. The rest is thrown away, or sold to vendors for the extraction of copper. In the alternate business model, the recyclers collect and segregate the boards in order to accumulate them until they obtain the minimal required amount to be shipped to an integrated smelter abroad. By replacing the traditional wet chemical leaching process for the recovery of gold with the export towards inte- grated smelters and refineries, safer practice and higher revenue per unit of e-waste collected are generated. A refining charge is agreed beforehand in a refining con- tract. An accurate determination of the exact composition and the precious metal content of the received materials is crucial to enable a correct settlement with the custom- ers but also to steer the optimum processing of the ma- terial throu gh the plant [16]. In another model S. Chaterjee and Krishna Kumar, 2004 [2] have proposed for equal participation of the formal and non-formal sector to make e-waste manage- ment business a profitable one. The no n-for m al operators will concentrate on collection, disassembly, segregation of e-waste, whereas formal sector will concentrate on the processing of the PCBs to extract precious metals. The 95% - 97% of the e-waste by weight contains metal, glass and plastics which can be easily disassembled and segregated manually without damaging the environment; whereas 3% - 5% by weight which actually contains PCBs need environmentally friendly recycling tech- niques and the formal recyclers will concentrate on that. Segregated items like PCBs and connectors will be con- verted into powder by a professional agency for which they will charge fee a nd then sell the PCB po wder to the established recyclers at the right market price based on the as sessment of assay. 7.1. Initiat ives by the Prod ucers Industry has shown considerable initiative for handling e-waste responsibly. Dell has instituted recycling pro- grams by offering a take-back program for free. Hewlett Packard (HP) complies with RoHS norms and has started recycling program by offering a take-back program for consumers. It has started a reuse approach where the products recycled can be used again. HCL has all its prod ucts RoHS complia nt and star ted a take-back facility to all its consumers (both corporations and individuals). Lenovo also offers a take-back facility to all its consum- ers. Products are picked from consumer premises by a third party enlisted by Lenovo and the service is free of cost to its customers. Wipro has become 100% RoHS compliant and started a take-back policy for all its end- of-life (EOL) products. OPEN ACCESS JEP  Review: Current Status of Recycling of Waste Printed Circuit Boards in India 7.2. Initiatives by Private Parties The re are a fe w firms t hat have taken up t he task of e ffi- cient disposal of PCBs from e-waste. Formalizing the informal sector (particularly the processes with the high- est environment and health impacts) with improved technology and skills along with improved working and living environment of the people working in the informal sector has been the main objective of the newly formed “Clean E-Waste Channels” in India (e-waste guide, 2008). “Clean E-Waste Channel” is based on a voluntary agreement amongst producers formed by the Electronics City Industries Association (ELCIA), Bangalore, to or- ganize the take back of e-waste through authorized re- cyclers. A “Clean E-Waste Channel” is supposed to pro- vide convenient collection points for consumers, provide transportation of e-waste to a trader/recycler, involve trained informal sector for certain tasks and ensure that the e-waste is processed by licensed recyclers only. For this the consumers should also be made aware and should give their obsolete electronic waste to authorized recyc- lers only. The producers should agree on individual or collective take- back system at authorized collection points. The recyclers should have proper and sustainable recycling facility of e-waste along with license from the State Pollution Control Board and also contractual agreements with the producers about receiving e-waste. The producers of electronic goods are supposed to form a “Producer Responsibility Organization” (PRO) which will manage the take-back and ensure that the e-waste particularly the PCBs will be processed in an environ- menta ll y fri e nd l y manne r. With the growing recognition of business prospects and opportunities many companies have cropped up in India and are doing business in this field recently. Few leading brands active in India have been trying to provide takeback and recycling services in India. There have been a few private parties which are coming forward in this direction to invest in PCBs recycling. Electronic waste recyclers and processors have to be registered with Central Pollution Control Board. 23 recycling units ha ve been registered as of 2010. Table 2 gives the list regis- tered e-waste recycling units in India. Table 2. List of regi s t ered e-waste recycling units in India. SN. Company Location Recycling capacity (MTA) 1. M/S Ramky E-Waste Recycling Facility ( Ramky Enviro Engineers Ltd) Mahe shwar am, A ndhra Pra desh 10,000 2. M/S Earth sense Recycle Pvt. Ltd. Rang areddy Andhr a P ra desh 1800 3. M/S Ash Recyclers Unit II BangaloreKarnataka 120 4. M/S New Port Computer Services ( India) Private Ltd. Bangalo re, Karn a tak a 500 5. M/S EWA RDD & Co. Ban galo re, Karn a tak a 600 6. M/S E -R3 Solutions Pvt. Ltd. Bangalore, Karnataka 120,00 0 Units 7. M/S A sh Recy clers , U nit I Bangalore, Karnataka 120 8. M/S E-Parisara Pvt. Ltd. Bangalore, Karnataka 1800 9. M/S Surface Chem Finishers Bangalore, Karnataka 600 Kg/Annum 10. M/S Jhagadia Copper Lt d. Bharuch, Gujarat 12,000 11. M/S Eco Re cycl ing T hane, Maharashtra 7200 12. M/S Earth Sense Recycle Pvt. Ltd. Thane, Maharashtra 360 13. M/S Hi- Tech Recycling India (P) Ltd Pune, Mah ar as h tra 500 14. M/S Green scape ecomanagem ent Pv t. Ltd Alwar, Rajasthan 450 15. M/S Trishyiraya Recycling I ndia Pv t . Lt d Chen nai, Tamil N adu 740 16. TES AMM Private Ltd. K anchip ur am, Tamil Nadu 30,000 17. M/S Global E-waste M anagement and Servic es (GEMS) Kanchip ur am, Tamil Na du 387 18. M/S Victory Recovery and Recycle Technologies India Pvt. Ltd. Thiriv al l uv ar, Tam il Nad u 6000 19. M/S Ultrust Solutions (India) Pvt. Ltd. Thiruval luvar, Tamil Na du 1500 20. M/S INAA Enterprises Chennai,Tamil Nadu 300 21. M/S TIC Group India Pvt. Ltd. Noida,Uttar Pradesh 1000 22. M/S Attero Recycling Pvt. Ltd. Roorke, Uttara khand 12,000 23. M/S Earth Sense Recycle Pvt. Lt d. Gurgaon, Haryana 1200 OPEN ACCESS JEP  Review: Current Status of Recycling of Waste Printed Circuit Boards in India 7.3. Initiat ives by Govern ment Government of India has initiated various activities for dealing with issues of hazardous waste management. The State Governments are in the process of identifying ha- zard ous wast e disp osal sit es. WEEE Task Force has been constituted comprising the Ministry of Environment and Forests, Central Pollutio n Contro l Board, Ministr y of IT, Manufacturers Association for Information Technology (MAIT), The National Association of Software and Ser- vices Companies (NASSCOM) and some industry asso- ciations and various NGOs such as Sahaas and Toxic Link. The Task Force has set up guidelines for formula- tion of Regulatio n Polic y for e-waste on issues such as: 1) Policy and Legislation; 2) Baseline Studies; 3) Restruc- turing and Recycling; 4) System of Extended Producer Responsibility; 5) Awareness-building. Based on these guidelines the legislation regarding e-waste has been passed which has come into effect from May, 2012. 8. Actual Problems to the Formal Recycling of PCBs in India The new legislation regarding e-waste with effect from May, 2012 does not have any provision for ban on import of second hand electronic equipment for charity and reuse purpose. Absence of this strong clause will not be able to curb the i mport of large q uantities of e-waste the- reby producing huge amount of waste PCBs which end up in informal re cycli ng yard. In developing and industrializing countries waste is viewed as a resource and income-generat ing op por tunity. There is a general reluctance to pay for waste recycling and disposal services, particularly when consumers can make some money by selling their old and broken ap- pliances [17]. Also due to lack of awareness of hazards of the e-waste, consumers sell their electronic waste to informal recyclers for quick money as it is easier and faster. Informal collectors take at a lower price. Thus a regular supply of PCBs is an issue which the registered recycling units face. The formal recyclers should have a stead y supp ly of PCB s fro m e-waste for their sustenance. Currently the authorized e-waste recycling facilities in India capture only 3% of the total e-waste generated and rest make way in i nforma l recycling. As mentioned by Rochat et al. [15] in the “alternate business model” after dismantling, the PCBs are re- moved and exported collectively for smelting abroad to recover precious and base metals. However, the cost linked to the transportation to the integrated smelters is the main limiting factor. Hence new alternative treatment processes to recover the precious metals which will be viable and attrac tive for the investors i n this fie ld need to be developed for recycling of metals in PCBs indige- nous ly in India for gre ater returns. Huge investments are made by the producers on pro- duction and delivery of goods as compared to their refur- bishments and recycling. Few leading companies are offering take-back services for cleaner recycling. Ac- cording to the report “An Assessment of E-waste take- backs in India”, 2008 which reviews the company poli- cies and practices on take-back in India nine of twenty bra nds surve yed had no take-back and recycling services in India despite many of these same global brands pro- vide voluntary take-back service in countries like US. Only one global brand, Toshiba and two Indian brands, HCL and Wipro are offering voluntary take-back servic- es to their customers in India. HP offers take-back ser- vice only for its corporate customers but small business and individual customers are missing in this service. Study shows that information related to take-back ser- vices is not easily accessilble. Some of the brands, nota- bly LG Electro nics and Dell have not po sted information on take back in India on their respective Indian websites. One has to visit their global portals to get this informa- tion (www.designouttoxics.org) [18]. Ta b l e 3 g ives a list of compani es and thei r take back programme s in India But there are few favorable factors for PCBs recycling in India. The tradition to reuse the electronic products in India has an advantage of slightly reducing the quantity of waste PCBs. Due to low manpower cost, managing the recycling of PCBs with appropriate technology will be more cost effective. 9. Conclusions It is clear that many initiatives have been started to deal with t he pr o b le m of re c ycl i ng of PCBs. Measures such as specific product take-back obligations, greater attentions to the new product de s ign, b an or restriction on the use of certain substances will help reduce the problem to a great extent. In order to develop newer ways to deal with the problem of recycling in an eco-friendly way and to make it continuous and sustainable at the same time, more re- search work needs to be undertaken. There should be regulations and standards besides incentives on invest- ment. Effective implementation of the new e-waste law will help to tackle the problem. Environmentally, sound recycling of printed circuit boards from e-waste requires development of proper e-waste collection, transportation, storage, treatment, recovery and disposal facilities at the regional and na- tional level. Producers are to be made more responsible. Though the original equipment manufacturers may have their own limitations, it should be imperative on their part to take the r espo nsibilit y for rec ycling the r isk y parts particularly. Ackno wledg ements We wo uld li ke to thank Dr . K. K. Tiwari (Consultant and OPEN ACCESS JEP  Review: Current Status of Recycling of Waste Printed Circuit Boards in India Table 3. How companies line up on take -back in India (www .des ig nout tox i cs. org ). Take back service available in India Take back service not available in India Acer Apple Dell * Microsoft HCL Panasonic Hewlett Packard (HP)** PC S Tec hno logy Le novo Philips LG Electronics^ Sharp Motorola Son y Nokia Sony Ericsson Wi pro Toshiba Zeni th Samsung *Informat i on regard ing take back in India is only availa b le on global websi te; ^Take back service is only available for mobile phone; **Ta ke-back service is only available for corporate customers. Visiting Professor at JUET) for all his guidance in writ- ing this re vi ew paper. REFERENCES [1] I. O. Ogunniyi, M. K. G. Vermaak and D. R. Groot, “Chemical Composition and Liberation Characterization of Printed Circuit Board Communition Fines for Benefic- iation Investigations,” Waste Management, Vol. 29, No. 7, 2009, pp. 2140-2146. http://dx.doi.org/10.1016/j.wasman.2009.03.004 [2] S. Chatterjee and K. Kumar , “Review Effective Electron- ic Waste Management and Recycling Process Involving Formal and Non-Formal Sectors,” International Journal of Physica l Sciences, Vol . 4, No. 13, 2009, pp. 893-905 [3] J. Li, P. Shrivastava, Z. Gao and H. C. Zhang, “Printed Circuit Board Recycling: A State-of-The Art Survey,” IEEE Transactions on Electronics Packaging Manufac- turing, Vol. 27, No. 1, 2004, pp. 33-42. [4] Y. J. Park and D. J. Fra y, “Separation of Zinc and Nickel Ions in a S trong Acid through Liqu id -Liquid Extraction,” Journal of Hazardous Materials, Vol. 163, No. 1, 2009, pp. 259-265. http://dx.doi.org/10.1016/j.jhazmat.2008.06.085 [5] Y. J. Park and D. J. Fray, “Recovery of High Purity Pre- cious Metals fro m Printed Circuit Boards,” Journal of Hazardou s Materials, Vol. 164, No. 2-3, 2008, pp. 1152- 1158. [6] B. Kim, J. Lee, S. Seo, Y. Park and H. Sohn, “A Process for Extract in g Precio us M etals fro m Spent Printed Circuit Boards and Automobile Catalysts,” JOM, Vol. 56, No. 12, 2004, pp. 55-58. http://dx.doi.org/10.1007/s11837-004-0237-9 [7] A. Borthakur and K. Sinha, “Generation of Electronic Waste in India: Current Scenario, Dilemmas and Stake- holders,” African Journal of Environmental Science and Technology, Vol. 7, No. 9, 2013 , pp. 899-910. [8] ENVIS Newsletter, October 2008, Envis Centre, Envi- ronment Department, Government of Maharashtra, Mumbai. [9] Y. Jing, “The Legislation Framework of E-Waste Man- agement in China,” 7th UK CARE Annual General Meet- ing, UK Chinese Association of Resources and Environ- ment, Greenwich, 15 September 2007. [10] European Parliament and Council of the European Union, “Directive 2002/95/EC of the European Parliament and of the Council of 27 January 2003 on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS),” Official Journal of the European Communities, 20 03, pp. 19-23. [11] European Parliament and Council of the European Union, “Directive 2002/95/EC of the European Parliament and of the Council of 27 January 2003 on Waste Electrical and Electronic Equipment (WEEE),” Official Journal of the European Communities, Vol. 13, No. 2, 2003, pp. 24-38. [12] H. Y. Kang and J. M. Schoenung, “Electronic Waste Re- cycling: A Review of US Infrastructure and Technology Options,” Resources, Conservation and Recycling, Vol. 45, No. 4, 2005, pp. 368-400. http://dx.doi.org/10.1016/j.resconrec.2005.06.001 [13] Maharashtra Pollution Control Board, “Report on As- sessment of Electronic Wastes in Mumbai-Pune Area,” 2007. http://mpcb.mah.nic.in [14] D. Sinha-Khetriwal, P. Kraeuchi and M. Schwaninger, “A comparison of electronic waste recycling in Switzerland and in India,” Environmental Impact Assessment Review, Vol. 25, No. 5, 2005, pp. 492-504. http://dx.doi.org/10.1016/j.eiar.2005.04.006 [15] D. Rochat, W. Rodrigue s and A. Gantenbein, “India: In- cluding the Existing Informal Sector in a Clean e-Waste Channel,” Proceedings of the 19th Waste Management Conference of the IWMSA (WasteCon 2008), 6-10 Octo- ber 2008, Durban, pp. 477-483. [16] C. Hagelüken, “Recycling of Electronic Scrap at Umi- core’s Integrated Metals Smelter and Refinery,” Pro- ceedings of EMC 2005, Vol. 59, No. 3, pp. 152-161. [17] O. Osibanjo and I.C. Nnorom, “The Challenge of Elec- tronic (e-Waste) Management in Developing Countries,” Waste Management & Research, Vol. 25, No. 6, 2007, pp. 489-501. http://dx.doi.org/10.1177/0734242X07082028 [18] “An Assessment of E-Waste Ta ke-Back in India,” 2008. www.designouttoxics.org OPEN ACCESS JEP

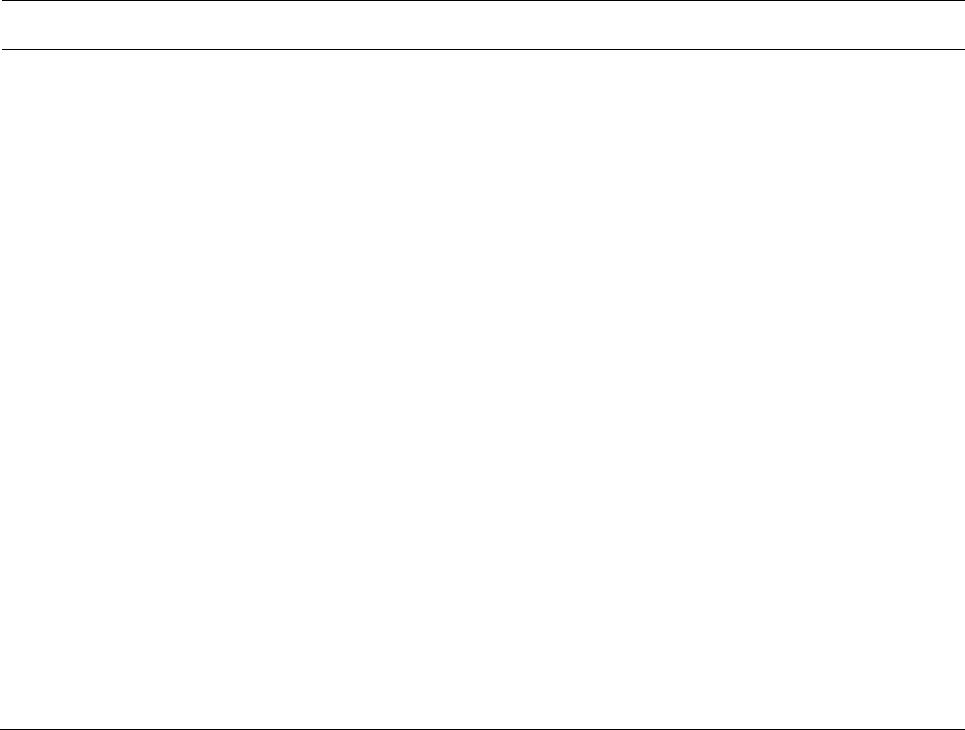

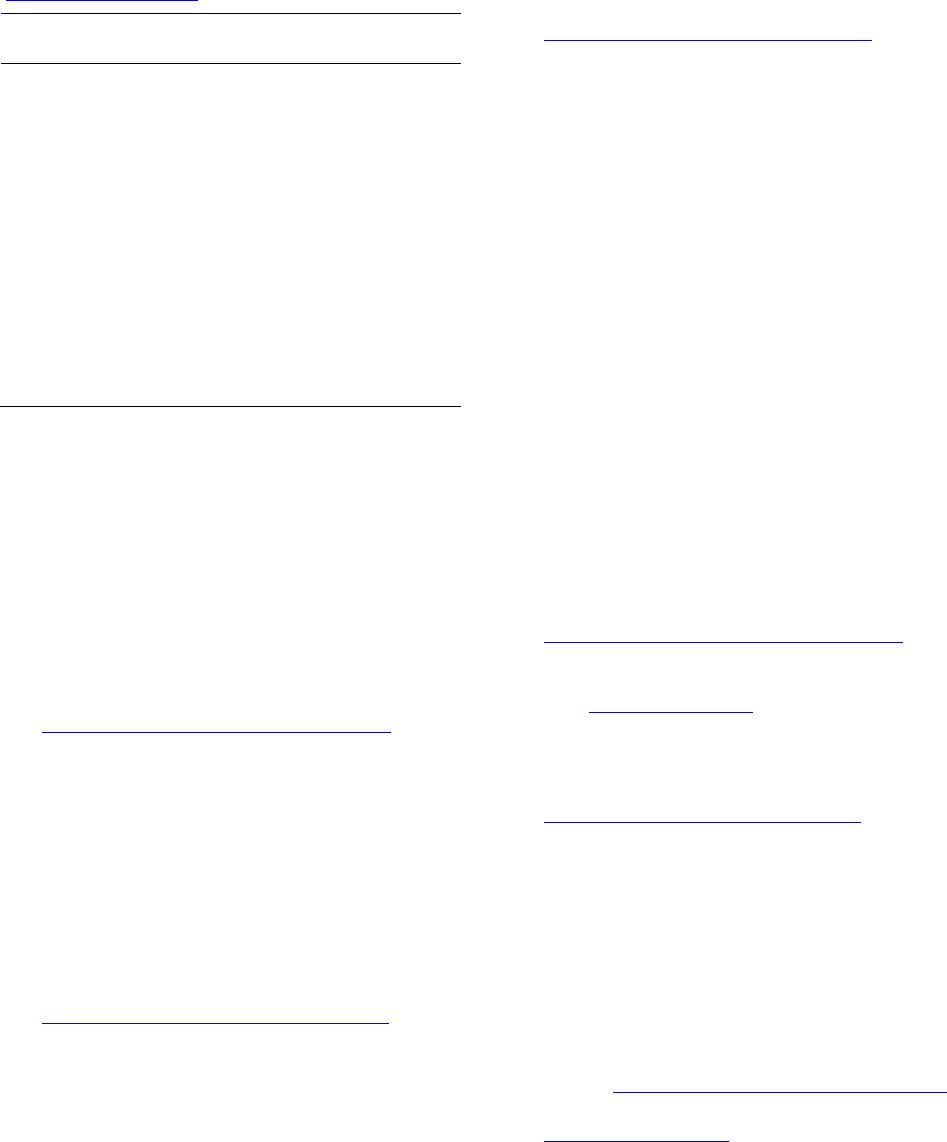

|