American Journal of Industrial and Business Management, 2013, 3, 725-739 Published Online December 2013 (http://www.scirp.org/journal/ajibm) http://dx.doi.org/10.4236/ajibm.2013.38083 Open Access AJIBM 725 Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China Runhua Tan National Technological Innovation Methods and Tools Engineering Research Center, Hebei University of Technology, Tianjin, China. Email: rhtan@hebut.edu.cn Received November 6th, 2013; revised December 4th, 2013; accepted December 10th, 2013 Copyright © 2013 Runhua Tan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. In accordance of the Creative Commons Attribution License all Copy rights © 2013 are reserved for SCIRP and the owner of the intellectual property Runhua Tan. All Copyright © 2013 are guarded by law and by SCIRP as a guardian. ABSTRACT To transfer knowledg e to compan ies by training engineers is directly related to iden tifying opportunities of innovation. This paper introduces the knowledge system of four levels and an interactive training model for innovative engineers. Training outputs of two classes as cases are analyzed in order to find some factors to affect the training activities. Seven stimuli to identify opportunities of innovation , which are implied in the knowledge system and the training process, are concluded from many face-to-face discussions with the engineers joining our classes. The application of the stimuli is also described, which should be app lied in the future training process to improve the possibility to id en tify opportun ities of innovation for innovative engineers. Keywords: Training Innovative Engineers; Knowledge System; Interactive Training Model; Seven Stimuli 1. Introduction Innovation, the implementation of new ideas is viewed by researchers as the key to both su stain ing a competitive advantage [1] and the lifeblood or the best hope for their future growth for companies [2]. In China, the innovation capability to both leading domestic companies [3] and other companies [4] is also a key factor for their survival in facing the competition in the market. But most inno va- tions result from a conscious, purposeful search for op- portunities—within the co mpany and the industry as well as in the larger social and intellectual environment [5]. Understanding the opportunities and their identification represents one of the core intellectual questions for crea- tivity and innovation management [6-8]. Training or external learning for companies is directly related to identifying opportunities of innovation. Boze- man [9] shows that training as a kind of external learning is becoming more widely recognized for improvement of human resources of companies. Bauernschuster et al. [10] argue that if innovation is the weapon, education or, es- pecially, training is the ammunition that renders it use- ful and effective. Bao et al. [11] find that external learn- ing increases the opportunities of innovation for Chinese companies, which includes technical and administrative learning, learning technical knowledge or learning ad- ministrative knowledge. In 2008, China government made a training plan to transfer the knowledge of creativity and innov ation to the companies nationwide in order to increase their innova- tion capabilities. Our center was selected as one of the major institutions for the training pro gram. We h ave car- ried out several classes to train the engineers from com- panies in the past years. The training activities are going on now. One of objectives of the training program is to train many engineers for various industries and make them become innovative. But there is no definition for an in- novative engineer in Ch ina. In the literatu re [12], invent- tors are classified into five categories related to the in- novation process, namely entrepreneurs with technology, industry-specific inventors, professional inventors, grantsmen, and inveterate inventors. We define that an  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 726 innovative engin eer is an industry-specific inventor, who has specific technical improvements for product designs or processes in their workplaces. The improvements in- clude ideations and inventions. The engineers to join the calsses should generate new ideas and push the ideas into inventions. The companies may form development teams to transform the inventions into innovations. As a result, the training becomes an activity to increase innovation capability of the companies. In the past five years, we have carried out 20 classes. More than 150 companies from manufacturing, energy, materials, food and other industries in different regions of China joined the program. More than 500 engineers did follow the process and have been certificated to in- novative engineers. Most of them have applied patents and some have developed new products which are being sold in markets now. A number of innovations of differ- ent types are emerging as a result of our training program. Many discussions face to face with the engineers in our classes show that to identify opportunities for inno- vation is the most important step to follow the training classes for engineers. But we should analyze what stimu- lates them to identify an opportunity. This paper first presents the practice of our training process for classes. Then we make analysis for two training cases and try to locate some factors to affect training. Third, we present the seven stimuli for engineers to identify opportunities of innovation, which are the main findings from our training practices. Last, a new model of the stimuli ap- plication is outlined. 2. Literature Review 2.1. How to Identify Opportunities for Innovation There are many studies related to the opportunity identi- fication for innovation. Drucker [6] gives out seven key areas looking for innovation opportunities, and he argues that most innovative business ideas come from methodic analysis of these seven areas. Detienne and Chandle [8] indicate four ways in which opportunities are identified: active search, passive search, fortuitous discovery, and creation of opportunities. Koen et al. [13] show that for- mal or informal processes may be utilized for opportu- nity identification . Toubia [14] recommends four sources of opportunities: observational research, blue ocean strategy [15], disruptive technology [16] and lead users. The view of David [17] is that various tools and methods help to identify existing opportunities: lateral thinking; metaphoric thinking; positive thinking; association trig- ger; capturing and interpreting dreams. Robert [18] finds that pattern recognition is used for opportunity identify- cation. Gregoire [19] explores that variations in the su- perficial and structural similarities characterized new technology-market combinations systematically influ- ence the formation of opportunities. The studies show that there is some ways or processes for identifying op- portunities of innovation, but the research in this area is going on. 2.2. Training and Identifying Opportunities The research studies in the literatures [20,21] establish a positive linkage between training and innovation in companies. Vichet [22] reveals that majority of the training participants perceive that training contributed moderately, highly, or very highly to the company’s in- novation. Frazis et al. [23] analyze the data obtained from US companies and find that companies with more innovative workplace practices have a tendency to offer more training. Steven [24] finds that team training accel- erates the pace of change in GE. Christian and Uschi [25] examine some companies in German speaking countries and find that high quality, curriculum-based training at the workplace is positively associated with general inno- vation, product innovation, process innovation, and pat- ent applications, which makes the companies more inno- vative. Izyani [26] investigates some knowledge-based companies in Malaysia and shows that training activities positively influence innovation of them. Shohreh et al. [27] confirm that there is a statistically significant rela- tionship between participation in training courses and numbers of innovations in food firms in rural Iran. Anja and Igor [28] show that in-house learning is not sufficient for generating innovation and that companies need to supplement internal knowledg e with knowledge acquired outside the companies. Yannis et al. [29] support that both internal capabilities and openness towards knowl- edge sharing among companies are important for up- grading innovative performance. All the studies show that training is positively relative to the innovations in companies by new or external knowledge which implies opportunities for innovations. To identify the opportunities is a start-up of innovations. 2.3. The Knowledge to Be Transferred by Training Many companies have organized the training programs to uplift creative capabilities of their engineers [30]. In these programs creativity techniques are the knowledge to be transferred to the companies. There existed many creativity techniques [31,32], which are divided into two types, intuitive and logical [33]. TRIZ, theory of invent- tive problem solving, is one of them, which is developed by Altshuller [34] in former USSR. Several countries, including China, have established National TRIZ Asso- Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 727 ciation, the main motivation in which is transfer TRIZ to companies. TRIZ possesses considerable advantages over other techniques in identifying problems and offer- ing direct solutions to them with confidence [35]. TRIZ has been transferred to many companies in the world through training classes in the past years. Kamal et al. [36] study the impact of TRIZ training on creativity and innovation of engineers in companies, and indicate that participation in TRIZ training led to short-term im- provements in both the creative problem solving skills and motivation to innov ate, and these are associated with longer term improvements in their idea suggestion in the workplace. Nakagawa [37] shows the experiences train- ing engineers successfully to solve real unsolved prob- lems using TRIZ in Japan. In the practice, he integrates the TRIZ into Unified Structured Inventive Thinking (USIT) [38] in order to make the TRIZ simpler. Jun and Shin [39] state that TRIZ is used as an innovation tool more aggressively in SAMSUNG than any other com- pany in the world and the training has been carried out in this company for years. Through a survey, Imoh et al. [40] conclude that the application of TRIZ leads to more effective inventive teamwork, faster ideation, foreseeing how technical systems and technologies develop, but there are some challenges associated with TRIZ, and understanding TRIZ an “inordinate time requirement”. Integrating TRIZ with other techniques, methods, and processes shows a trend for the easy application in the literatures. Axiomatic design (AD) is applied as a com- plementarily of TRIZ to find contradictions [41,42]. Stratton and Mann [43] show that TOC may be used to- gether with TRIZ to find and solve contradictions. Cas- cini et al. [44] integrate TRIZ and optimization tools to form a systematic design. Tan et al. [45] apply TRIZ to the Pahl and Beitz’s model [46] to form a new concept process model. Sun and Tan [47] connect the TRIZ with disruptive innovation process [16] to forecast. The inte- gration may make up for some deficiencies of TRIZ, such as finding a problem. Training as an external learning process has a positive linkage with the innovation in companies. But the litera- tures show that its process should be carefully designed for engineers of companies to overcome the difficulties in the study. The following factor s must be considered in our training program in order to gain better results. 1) Select appropriate engineers from the companies to join the classes. 2) Design a knowledge system to be transferred to the companies, in which TRIZ is the core. 3) Design a training process to help the engineers to overcome the difficulties in the study. 4) Try to find stimuli for opportunity identification of innovation in order to improve the quality for training program nationwide. 3. Practice to Train Engineers into Innovative Ones in China The objects for engineers to join our training classes are as follows: 1) Learn the new knowledge related to creativity, in- vention and innovations. 2) Identify new or unsolved problems in their work- places. 3) Generate new ideas from solving the problems in order to improve designs, processes, or develop new products that are new in the companies or in the markets. 4) Transform the new ideas into inventions whose vi- abilities are proofed. 5) Push the team members to put the inventions into innovations in their co mpanies. As Figure 1 shows the activities during, before and after a training class. The engineers to join a class from different companies or one company should be selected at first place. Then there will be the training activities: lecturing, identifying problems, discussing, generating ideas and making inventions. The last step is the activity after training in which the inventions may be transformed into innovations. 3.1. Selection of the Engineers to Join the Classes The engineers to join the classes should identify new problems or unsolved problems in their workplaces, where the engineers work. There are diverse workplaces for engineers who work at different stages of the innova- tion in a company. Figure 2 shows an entire innovation process in a manufacturing company typically in China. The process is divided into three stages: fuzzy front end (FFE), new product development (NPD), and commercialization [48]. The fuzzy front end is considered as the first stage of the innovation process and cov ers the sub-processes include- ing from the opportunity identification, opportunity analysis, idea generation, idea selection, and concept definition [48]. The outputs of FFE are the ideas evalu- ated and as the input of NPD. In the NPD stage, the ideas from FFE are transformed into products. There are two sub-processes in NPD, design and manufacturing. In the design process there are four sub-processes, namely de- sign specification, conceptual design, embodiment design, and detailed design [46]. In the manufacturing process, the first is to design the process and then actual manu- facturing. The commercialization is the last stage, in which the products are put into markets. The environ- ments for fuzzy front end, new product development, ommercialization and the sub-processes are the work- c Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China Open Access AJIBM 728 Team members in company I New knowledge Knowledge New or unsolved New ideas Inventions Innovations Training activities Activities after training Engineers in a class Engineers selected Activities before training Figure 1. Activities during, before and after training. Opportunity Identification Opportunity Analysis Idea Generati o n Idea Selection Design Specification Manufacturing Commercialization Conceptual design Embodiment design Detailed design Concept Definition Process Design Fuzzy Front end New Product Development Commercialization Workplace for design engineers Workplace for entrepreneurs / chief engineer/ R&D engineers Workplace for Process engineers Figure 2. An innovation process and workplaces for engineers in a manufacturing company. 3.2. The Knowledge System for Traini ng places, where the engineers are supposed to find new or unsolved problems. Training is a process to transfer external knowledge into companies. The knowledge to be transferred with the knowledge existed in companies will inspire the engi- neers to generate new ideas in workplaces [56]. A key attribute of a new idea is novelty, which is the first statement of something not previously known or demon- strated. That a selected idea is embodied in a tangible yet provisional form–a proof of its viability is an invention worth a key attribute of feasibility [57]. That inventions will be further refined and reach some final form with commercial intent, such as a functional device or service, are innovations with the key attribute of utility, in addi- tion to the novelty and feasibility. Transferring external knowledge into companies, as a result of training, is an object of our training classes. Figure 2 also shows that the engineers at different stages have corresponding responsibilities. The job for design engineers is to make design specification, con- ceptual design, embodiment design and detailed design. The process engineer will design the process for manu- facturing, control the quality, test for the products, etc. Chief engineer/R & D engineers may generate new ideas in fuzzy front end and solve difficult problems in design, manufacturing or marketing. The entrepreneurs may pay more attention to all the activities happen in the innova- tion process. Ideation [49,50] in fuzzy front end, con- ceptual design [51,52] and embodiment design [2,53], process design [54,55] in NPD are key activities in the innovation process. The engineers related to these active- ties which are the core for innovation processes should be selected to join our classes. In practice, there are in- deed some entrepreneurs working in middle or small companies joining our classes. So we should also con- sider their needs for the classes. Figure 3 shows the knowledge system for training, which will be transferred to the companies. This system is divided into two parts, the knowledge of four levels and application cases. The four levels are basic concepts, basic methods, systematic methods and computer-aided innovation (CAI). The first level knowledge is about the definitions, such as creation, invention and innovation, well structured and ill structured problems [58,59], rou- ine and inventive problems [60], process of innovation The companies to join the classes should also be se- lected. They must have strong demands for innovation and will assist the engineers to join the classes for the whole training process. t  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 729 Systematic methods: Method for incremental innovation, method for radical innovation, Method for disruptive innovation etc. Basic concepts: Definition of creation, invention and innovation, Process of innovation, Problems and solutions, Routine and inventive roblems, etc.. Basic methods: Methods in TRIZ (contr adiction solving, standard solution, effect, technical evolution, etc.), Creativit y enhanced techn iques, Funct ion analys is and conceptual design, etc. Compute r-aided innovation (CAI): Coputer aided innovation process and methods, Introduction of CAI tools in the world, InventionTool etc. Fuzzy front end: Opportunity identification, Ideation. Process design: Development for new processes, Improvement for existing rocesses. Embodiment design: Development for new structures, Improvement for existing structures. Conceptual design: Development for new working principles, Improvement for existing working pri nc i ple. Knowledge levels Application Cases Figure 3. Knowledge system for transfer in the training process. [61,62], etc. The second level is the basic methods, such as the methods in TRIZ [63,64]: contradiction solving, standard solution, effect, technical evolution, and some other creativity techniques. Th e third level is the system- atic methods, such as a method for incremental innova- tion, radical innovation [65], disruptive innovation [47,66,67], patent round innovation [68], analogy-based design [69], etc. The fourth level is about the com- puter-aided innovation, including CAI tools and applica- tion process [45,70,71]. In the training process we pre- sent many cases which show the applications of the knowledge step by step in different level as the applica- tion cases. It is a significant training activity that the en- gineers imitate the processes in those cases. 3.3. A Training Process Model New or external knowledge should be transferred into a company which is integrated with th e knowled ge existed in the company in order to support th e process of innov a- tion. The knowledge system in Figure 3 is new to Chi- nese companies and should be transferred into them. These knowledge must also be integrated with the knowledge existed in these Chinese companies. The training process should be designed to satisfy the need for knowledge transfer and integration. TRIZ is the core in the knowledge system in Figure 3. The training processes for TRIZ in companies have been studied for years. Rantanen and Domb [72] have devel- oped a flowchart or a model for TRIZ training in a com- pany. Jun and Shin [39] have also developed a flow chart for training TRIZ in Samsung. These flowcharts show that the TRIZ experts outside the organization should carry out a TRIZ pilot project to show that it is powerful for innovation in a company. This process is no t suitable for the situations faced in China. We have no time to carry out a pilot project for every company to test TRIZ because the local governments push many companies to join a training class at the same time. Before the begin- ning of the training, most of the companies do not know what TRIZ is. A new model for this situation is needed in China. We put forward an interactive model for training in- novative engineers, as in Figure 4. There are four main parts, an innovation process, a training process, an inter- face between the two parts, and the companies to join the program. The innovation process includes fuzzy front end, new product development and commercialization. The training process are seven steps which are selecting companies, selecting engineers, training stage-1, finding problems, training stage-2, finding solutions and sum- ming up. in the middle of the two parts is an interface, which includes oppo rtunities and so lutions fo r innovatio n, also the contained problems. The companies selected to join the class may be one or more. A class lasts 6 to 15 months accordingly. Step 1: Selecting companies The companies to join th e class are selected. Some in- stitution of a local government, or an organizer, is re- ponsible for the organization and selection of the com- s Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 730 Company-1 Selecting Engineers Governments, Training institutions, Mass-companies Commercialization ew product development Fuzzy front end Company-2 Company-n Sunning - Up Training Sta e-1 Finding Problems Training Stage-2 Finding Solutions Opportunities Problems Solutions Mass-companies Interface Figure 4. An interactive training model for innovative engineers in China. panies to join the class for a region. For example, the Productivity Promotion Center of Guangdong (PPCG), which is an institution supported by Guangdong Science and Technology Department in Guangdong province, was responsible for the selection of the 19 companies from the province to join the first training class held from August of 2010 to March of 2011 . Step 2: Selecting engineers The companies selected make recommendation for a list of engineers to join the class and the organizer of a class is responsible for the final selectio n of the engineers. We make suggestions that the engineers with bachelor degrees should have almost ten years work experiences and with master or doctor degree may be unrestricted. Step 3: Training stage-1 Our teacher team gives lessons to the engineers. In this stage, the major knowledge is the lev el one and two, that are basic concepts, basic methods. The most methods in TRIZ, such as contradiction solving, standard solution, effects and technological evolution etc will be taught. Many cases applying these methods are also demon- strated. The knowledg e transferred in this stage will pro- vide a background to identify opportunities, problems and solving them for engineers. Step 4: Finding a probl em Every engineer join ing the class must fin d an inv entiv e problem from the innovation process or the workplace of the companies for innovative activities. The problems are implied in opportunities found. An engineer needs to understand the theories or methods in depth and to con- nect them to the situations of workplaces and identify an opportunity and a problem implied. Step 5: Training stage-2 Again, our teacher team gives lessons to the engineers for the level three and four knowledge, which are sys- tematic methods and CAI. The major methods in this stage are extended methods of TRIZ. Such as anticipa- tory failure determination (AFD) [73] is a methods to be trained, which is an app lication of I-TRIZ to risk an alysis and prediction developed by Ideation International Inc in USA. Some cases applying these methods are also dem- onstrated. The knowledge transferred in this stage will provide a background to solving problems for engineers. Step 6: Solving problem In this phase, every engineer must develop at least one accessible technical solution for the problem in a few months, at the same time they should work. At the be- ginning, the solutions are ideas. After that ideas should be transformed into inventions, which may be a new de- sign prototype, new process in the form of a patent ap- plication, or a new concept accepted by the company. Step 7: Summing up Summing Up is the last phase, in which the final oral examination is made and engineers will present their results with slides. Members of a committee specific in charge of the examination make discussions with them. An evaluation is made and a certificate is presented to some qualified engineers who are innovative. Finding a problem or an obstacle in the innovation process in step 4 is a key activity to follow the training process for an engineer. If he or she does find a problem the knowledge system studied in step 3 and 5 are very useful for them to so lving it and to get the solutions. Th e solutions are returned to th e innovation process, in which the obstacle is eliminated. If an engineer cannot find a problem he or she will be sifted out in the middle of the training proces s. In the past five years, we have carried out 20 classes for more than 150 companies nationwide. More than 500 engineers did follow our training process shown in Fig- ure 4 and have been certificated as innovative engineers. Most of the engineers who finished the processes did have applied patents and some of them have been devel- oped to new products which are being sold in markets now. Several innovations in companies are introduced as a result of our training program. Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 731 4. Analysis of the Training Outcomes Every engineer who finishes the training process does have one or more inventions. Some of the inventions have been developed to innovations in companies. The first step in the process for an engineer is to identify an opportunity for innovation. More than half of the engi- neers joining the classes do pass successfully the step. The major factors for them to identify opportunities should be studied for the future training activities. 4.1. Case 1: GD-1 GD-1 was the first training class organized by Guang- dong Science and Tech nology Depa rtment in Guan gdong province from August of 2010 to March of 2011, which is the organization of local government for the develop- ment of sciences and technologies. Our center carried out the training process. 75 engineers were selected from 19 companies in Guangdong province, including BYD, BROAD-OCEAN and GAC et al. 52 passed the final examination. 30 of them were certificated as Innovative Engineers Level 2, while the others were Level 1. 23 engineers did not fol- low the training process and dropped out in the middle. All the 52 engineers found out 52 inventive problems from the innovation processes of 17 different companies and solved them at last. As a result, 52 inventions were formed, in which 36 had patent applications, which were 22 patents for inventions and 14 patents for utility mod- els. They have been sent to SIPO (State Intellectual Property Office of the PRC) and all application numbers have been got the end of the class. Problems in different stages and the methods to solve them for this class are shown in Figure 5. Figure 5(a) is the relationship between the numbers of the problems and innovation stages or sub-processes. The most problems, which are 18, are found from manufac- turing. The least problems, which are 4, are in fuzzy front end. The problems from design process are total 30, in which the problems to the conceptual design, embodi- ment design and detailed design are 10, 15, and 5 respec- tively. Figure 5(b) shows the relationship between the numbers of the problems and the methods to solve them. The method for solving contradictions is mostly used by 42 engineers. Standard solutions and trimming are used 3 times respectively. Four methods, ideal final result, re- sources, AFD (anticipate possible failures) and technol- ogy evolution (evolution lines), are applied once. Most companies to join the class are belonging to manufacturing industry. The problems found by engi- neers are mainly in manufacturing, embodiment design and conceptual design. The major methods to solve these problems are contradiction solving, trimming and stan- dard solution of TRIZ. Figure 5 shows that to find con- tradictions in manufacturing processes, embodiment de- sign or conceptual design process, is certainly an oppor- tunity of innovation for engineers. 4.2. Case 2: LF-1 LF-1 was the first training class organized from July of 2012 to January of 2013 by Hebei Science and Technol- ogy Department in Langfang, a city between Beijing and Tianjin. Our center carried out the training pr oce ss. 41 engineers were selected from 17 companies in Langfang to join the class. 22 passed the final examina- tion and certificated as Innovative Engineers. 19 engi- neers did not follow the training process and dropped out in the middle. All the 22 engineers found 22 inventive problems from the innovation processes of different companies and solved them at last. Figure 6 shows the results. 10 problems are found from conceptual design process in Figure 6(a), while the only 1 occurs in detailed design process. The problem numbers from design processes are 17. This also illus- trates that there are the most opportunities for innov ation from designs processes. Figure 6(b) presents that the methods for solving contradictions are also mostly used by 10 engineers. S-field analyses and standard solutions are used 6 times. Ideal final result and trimming are ap- plied twice. The companies in this class are from different field, such as geology. Most problems are found in conceptual and embodiment design. The contradiction solving and standard solutions are still the major methods to solve problems. To find problems in design stages is also an opportunity of innovatio n for engineers. 4.3. Major Factors for Successful Training The training activities for trainers mainly include giving lectures, discussions of all possible opportunities and problems, making suggestions and debating, etc. Discus- sions can be carried out in classrooms, in workplaces, by e-mail, on telephones, and by text massages etc. From several years training activities we summarize that 4 fac- tors are major for successful training, which are the ex- periences in workplace for engineers, the knowledge system to be transferred, the pressure and responsibility for engineers, the stimuli for identifying opportunities of innovation. Factor 1: The experiences in workplace for engi- neers Figures 5(a) and 6(a) show that the inventive prob- lems are directly related innovation stages or sub-proc- esses. The experience in workplaces is the first factor for ngineers to identify an opportunity and find the prob- e Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China Open Access AJIBM 732 (a)Number and stage relation 0 5 10 15 20 Fuzzy front end Conceptul design Embodiment design Detailed design Manufacturing Stages Numbers (b) Method and number relation 0 5 10 15 20 25 30 35 40 45 S-field Ideal final result Resources Contradiction Triming AFD function design Technology evolution Methods Numbers Figure 5. Relations between problems and stages or methods from GD-1. (a) Number and stage relation 0 2 4 6 8 10 12 Fuzzy front end Conceptul design Embodiment design Detailed design Manufacturing Stages Numbers (b) Method and number relation 0 2 4 6 8 10 12 S-field Ideal final result Resources Contradiction Triming AFD function design Technology evolution Methods Numbers Figure 6. Case2: analysis of inventions from LF-1. Factor 4: Stimuli for identifying opportunities of innovation lems. Several years work in one or similar workplaces make the engineers to understand the situation in depth. They know that there are certainly some problems be- cause of chaotic situation . They estimate that something should be changed. How to define a problem from a chaotic situation of a workplace is the most important step to follow our classes. Why do the engineers not define a problem for a long time in the workplaces? For many discussions with engineers face to face we find that the stimuli for opportunity identification are an important factor. The stimuli are contained in the knowledge system that is transferred to the engineers in our training. Such as, Fig- ures 5(b) and 6(b) show that engineers frequently apply the method of contradiction solving. They try to find a contradiction which is an inventive problem in workplace. So to find a contradiction is a stimulus for identifying opportunity of innovation. We need to identify other stimuli for the future application in the training classes. Factor 2: the knowledge system to be transferred to the engineers Why have some changes not happened for a long time? One reason is that the engineers lack the suitable knowl- edge to push the change to happen. So the knowledge system to be transferred to the engineers by training should be carefully design ed in th e creativity and innova- tion domain. We select TRIZ as the core knowledge and others as periphery one. The core and periphery knowl- edge need to be integrated and developed carefully in order to be accepted easily by the engineers. Factor 3: the pressure and responsibility for engi- neers 5. Seven Stimuli for Identifying Opportunities The engineers to join our classes are selected as excel- lent ones from companies. They all have pressure and responsibility to follow the train ing pro cess. The pressure makes the engineers in tension states. They must concen- trate all the vigor on study and research activities during the training process. The responsibility makes the engi- neers consider seriously what kind of problems should be found and solved for innovation of the companies. The engineers selected to join our classes do have in- depth experience and long-term focus in product or process designs in different workplaces, which are the playground for creativity and innovation in the domain. But stimuli are also needed for them to identify opportu- nities for innovation. The knowledge system shown in  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 733 Figure 3 and the training process in Figure 4 imply some stimuli. We find that there are seven sti muli, which excite the engineers to identify opportunities of innova- tion in our classes. Stimuli 1: Be close to an Ideal System Any system, whether it is a technology, product or process, is in evolution to the direction of ideality. One way to define ideality is the ideal system, which occupies no space, has no weight, requires no labor or mainte- nance, etc. The ideal system delivers benefit without harm and solves its own problems. The current state of any system is not an ideal system, but it is final state for the system evolution. So an innovative engineer’s job is to push a system to b e close to the ideal system at least a little step. The step will result in an innovative solution for a product or a process. Making an imaginary ideal system and considering how to be close to the system for an innovative eng ineer is opportunities for innovation. Case 1: A new switching power supply Golden Field Industrial, Located in Dongguan, Guangzhou, China, is a company producing computer gadgets and accessories - PC case, switching power supply, multimedia speakers, mouse and keyboard, etc. Four engineers in this company joined the first training class conducted in Guangzhou from August, 2010 to March, 2011. One of the engineers has gotten a patent for a new switching power supply which reduces the power loss to zero in the standby mode for computer gadgets. The new supply will help computers to save energy which is meaningful for industries, offices, families. The opportunity for this new technology is stimulated by Stimuli 1. In the standby mode for a computer the power loss is from 0.4 W to 6 W. This is a huge energy loss for the whole China or the world. The opportunity for a producer of computer peripherals is to develop an energy saving supply, which is a small step to the d irection of an ideal system. Being stimulated the engineer does develop a new supply to reduce the loss to zero. Stimuli 2: Use unexpected resources A resource is anything in and around a system that is not being used to its maximum potential. Substances, fields, functions, information, time and space are all pos- sible resources. Some resources are explicit but others are tacit. One of the key concepts in TRIZ is that the strongest solutions transform the unwanted or even harmful elements in a system into useful resources. The suitable application of any resource might lead to dis- covery of an opportunity for innov ation. Engineers working in a company for several years may be familiar with the surroundings and all the resources but they are not used to applying some resources in in- novation process especially tacit once. When they stud- ied the different viewpoints for resources and some ap- plication cases, some resources are unexpected treasure and may stimulate some opportunities for them. Case 2: Fresh keeping wolfberries Qinghaiqing, a company located in Qinghai province, China, produces wolfberry and buckthorn based products. Three engineers in this company joined the first training class conducted in Xining, Qinghai, from January, 2011 to May, 2012. One of the engineers has gotten a patent for a fresh keeping technology for wolfberries and also a new product for the company. The people outside Qing- hai, such as Shanghai or Beijing, can taste the fresh wolfberry produced in Qinghai in the near future. The wolfberries are traditionally dried, packed and trans- ported to different places to be sold. Fresh wolfberries are not only tasted good but also full of nutrition. The new product has made the company to have competitive ability in this market. The opportunity for this new tech- nology is stimulated by Stimuli 2. There is a kind of resources called evolutionary re- sources, including the knowledge developed in the given area, or other areas, sociology, marketing and psychol- ogy etc. According to the concept of the evolutionary resources, the storing technologies in low temperature, the storing film, and the storing technologies using con- trolled air in other areas may be resources for storing the fresh wolfberries. But resources need integrating into new system for the specific application. This is stimula- tion for the engineer to identify an opportunity for de- velopment of a new technology and new product for fresh keeping wolfberries. Stimuli 3: Find a contradiction In TRIZ, contradiction is one of the core concepts, which is used to formulate problems and guide towards innovative ideas. A contradiction arises when two mutu- ally conflicting demands are put on in the same syste m or a situation. This happens quite often in product design and manufacturing processes. To evolve a system or technology further contradictions should be resolved. TRIZ offers 40 inventive principles, a matrix and 39 pa- rameters to solve contradictions. Using these principles engineers may come up breakthrough solutions but not compromises, or trade-offs. The solutions always result in an incremental innovation . The engineers in china have studied the concept of universality of contradiction in their educations from middle schools to universities. But Chinese way of deal- ing with contradictions is seeking a “middle way” that is retaining basic elements of opposing perspectives. In our class we pay more attention to find and solve contradict- tions in the specific process for innovation. Solving a contradiction means to elimin ate it but not to find a mid- dle way. Most of the engineers could use this stimulus Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 734 more easily for opportunity identification. Case 3: A new processing method for chestnuts Liyuan, a company located in Tangshan, Hebei prov- ince, China, produces chestnuts, cereals and other agri- cultural by-products, by industrial deep processing methods. One engineer in this company joined the training class conducted in Baoding, Hebei province, from May, 2011 to January, 2012. The engineer has gotten a patent for a new processing method of chestnuts which have a con- stant mouth feel. The opportunity for this new technol- ogy is stimulated by Stimuli 3. Some consumers complain that the sweetness level of the chestnuts produced in this company is lower and the hardness level is higher. In the past several years the company has not made improvements for the product to meet the needs. The engineer made an analysis and found that there were two contradictions for the quality prob- lems of the product. The matrix and inventive principles were applied to solve the contradictions. At last a new processing method was formed and the experiment for the improved chestnuts showed that the processing was right. An improved product has been put into the market. The Stimuli 3 inspired the engineer to make this innova- tion happe n. Stimuli 4: Trim some elements A product consists of several elements and links among them. An element is defined as a physically dis- tinct portion of the product that could not be divided fur- ther for analysis. A link is kind of relationship between two elements, which is an action. Two elements and a link between them make up a function under TRIZ con- cept. All the functions for the product form the function model which is a function net. There are four kinds of actions which are useful, harmful, excessive and inade- quate. If one of harmful, excessive or inadequate actions is identified the link and the two elements are a problem- atic function. There may be one or more problematic functions in the function model for an existing product. One or some problematic functions should be eliminated for the improvement of the product performance. Trimming in TRIZ is a kind of operation to cut off some elements relating to the problematic functions by some rules. Basic principle of trimming is simplification for an existing product which reduces the cost, size, weight, or simplifies the operations that make the prod- ucts easy to be used. As a result, trimming is an opportu- nity of innovation for innovative engineers. Case 4: A new structured motor Broad-Ocean, a company of Guangzhou, China, is a producer of micro-motors. Two engineers in this company joined the first training class conducted in Guangzhou from August, 2010 to March, 2011. One of the engineers has gotten a patent for a new structural design for the one-way asynchronous motor produced in this company. The efficiency assembling process for one motor is improved and the cost is reduced by the new design. The opportunity for this engineer is stimulated by Stimuli 4. In the traditional design the rotating magnetic field in one-way asynchronous motor is produced by a capacity connected outside the shell of the motor. The module of the capacity is located to the shell by screws that lead to some harmful results. That the module may fall off in the operation is a clear weakness. According to the basic idea of the Stimuli 4, the capacity should be trimmed off. This is an opportunity for the engineer. The engineer did take advantage of the opportunity to develop a new structure that the capacity is not outside the shell. New products using the structure have been put out. Stimuli 5: Anticipate possible failures To anticipate possible failures for products or proc- esses are certainly a kind of opportunities for innovation. Anticipatory failure determination (AFD) may be applied for this purpose, which is an application of TRIZ to risk analysis and prediction. There are two templates, AFD-1 and AFD-2, for applications. AFD-1, failure analysis, applies to find the cause of a failure that has already oc- curred but is not yet understood. AFD-2, failure predict- tion, is to identify possible failures that have not yet oc- curred for a new system design or for any system in which negative effects or drawbacks have not yet mani- fested themselves. The basic concepts and methods of TRIZ, such as resources and contradictions solving, may be used in the process of AFD. The application of AFD for both existing and being designed products is an op- portunity of innovation for the engineers in the classes. Case 5: New currency recognition modules GRGBanking, a company located in Guangzhou, is a provider of currency recognition and cash processing solutions in the market. Automatic Teller Machine (ATM) is a major kind of product in this company. More than 20 engineers in this company jo ined our two training classes from August, 2010 to December, 2012. One of the engi- neers has gotten several patents for different currency recognition objects in ATM. The new ATMs using the patents have been operated in several cities. The oppor- tunity for this engineer is stimu lated by Stimuli 5. One challenge for the company is to recognize the counterfeit cash in or out ATM in high precision. Preci- sions for recognition used to be a problem in this com- pany. The engineer applied the AFD-1 and AFD-2 to identify the root causes of old designs and put forward new principles and formed new modules for ATM. The AFD stimulated the engineer to find problems and solu- tions. Stimuli 6: Add another purpose function Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 735 A function for a product is what does. There are two kinds of functions, purpose and operation. The purpose function is a description of a users’ intention or the pur- pose of a design, and the operation function is a descrip- tion of the intended operation of the design. Users can understand the usefulness of the purpose function for an existing product. That is the reason why users buy this product. Maybe some users hope to buy products with more purpose functions. Multi-function is an evolution trend for some products. So to add another purpose func- tion is an opportunity for innovative engineers. Case 6: New structured headstock and tailstock of EMU Tangshan Railway Vehicle (TRC) located in Tangshan, Hebei province, China, produces electric multiple units (EMU), passenger coaches, etc. We organized a class for this company from May, 2012 to December, 2012. At first 60 engineers in different workplaces were joined the class and 28 engineers followed the whole training proc- ess. One engineer has gotten a few patents for the new structured headstocks and tailstocks of EMU. The op- portunity for the new technologies is stimulated by Stim- uli 6. The headstock and the tailstock in an EMU are of the same structure. The headstock in one runn ing direction is the tailstock for the reveres running. The air dynamics for the headstock and the tailstock are different because of the state change for running condition. The air resis- tances are not in optimal condition for the same struc- tures for both sides. Adding a function to reduce resis- tance for headstock an d tailstock is an opportunity fo r th e new design of EMU. Stimuli 6 makes the engineer to design new dynamic structures for headstock and tail- stock to adapted different conditions. The new technolo- gies reduce energy loss when the EMU is running. The inventions of the engineer are quite important for the company, also for the industry. Stimuli 7: Change behaviors A behavior for a product is how does. Behaviors can be regarded as actions or physical state transitions among the elements of a product; or it can be regarded as the physical interactions including the input actions and output actions to or from elements. These actions can be both the intended and unintended, such as side-effects. If one or some physical state transitions are substituted by new ones the performance of the product may be better. This will result in a kind of invention and innovation. So to change some behaviors for selected products is an op- portunity for innovative engineers. Case 7: A new testing instrument for solar cell modules Qinghai Tianpu Solar Energy Company, located in Qinghai province, China, is a producer of photovoltaic products for west China. Three engineers in this company joined the first training class conducted in Xining, Qianhai, from January, 2011 to May, 2012. One of the engineers has developed a new product, a testing instrument for solar cell modules for the company. The opportunity for this new product is the application of changing behaviors. The voltage, current, and peak power for a solar cell module should be tested by instruments for evaluating the performance. The instruments existing in the market now are used in house of module producers. But the modules are operated in open countries, which are out- side the workshops of the producers. The existing in- struments are not suitable to some customers’ new needs for operations in some locations. Changing the behaviors of the existing instruments is an opportunity for devel- opment of a new one which can serve better in different locations. The LabVIEW and Matlab are used and the reliability is increased in the new design. The new prod- uct has been developed and tested successfully in this company. 6. Possibility in Applying the Stimuli The stimuli are concluded from the knowledge system in Figure 3 with the help of training practices. One stimu- lus may or may not be used in a stage of innovation. Ta- ble 1 shows the possibility of the application for every stimulus in different stages or sub-processes of innova- tion. There are three types of possibilities, high, middle or low. High or low possibility means that the result to find an opportunity could happen or almost could not happen. Middle possibility is between high and low. The table also shows the following features: 1) Every stimulus may be used to identify opportuni- ties in fuzzy front end. 2) Every stimulus may be used to identify opportuni- ties in conceptual d esign. 3) To find a contradiction is an important activity in opportunity identification for fuzzy front end and new product development. There is no any symbol in the right commercializatio n column of the table. In practice we find that a few entre- preneurs, chief engineers or R&D engineers do find op- portunities in commercialization stage. But we have not concluded one or two stimuli for them to use. This will be a research topic in the future. Figure 7 is a process model for applying the 7 stimuli. First, the engineer selects one or more stimuli and then applies them to a stage, such as fuzzy front end. If an opportunity is identified the engineers find the implied problems. There are two possible paths to manage the problems which are called self-circled or passing on. In he first path, the engineers solve the problems in their t Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China Open Access AJIBM 736 Table 1. Possibility between stimuli and opportunities for innovation. New Product Development Possibility Phases Stimuli Fuzzy Front End Conceptual designEmbodiment designDetailed designManufacturing Commercialization Be close to an Ideal System Use unexpected resources Find a contradiction Trim some components Anticipate possible failures Add another purpose f un c ti o n Change behaviors High Middle Low. Self-circled Fuzzy front Conceptual Embodiment DetailedCommercialization Stimuli 1 2 3 4 5 6 7 Problem transferred Figure 7. A process applying the stimuli. workplace. In the second the problems are passed on other engineers who are working in relevant workplaces. The second path shows that some problems in one stage or a sub-process should be solved in another stage or sub-process. 7 stimuli are not many enough to make a difficult process of being chosen one by one for engi- neers. Now we have added the 7 stimuli as new knowledge in the training stage-1 and stage-2 of Figure 4. We hope that they will assist the engineers to join the classes to identify opportunities a little easier. 7. Discussions An interactive model is developed in this study for train - ing innovative engineers for a variety of companies in China. The specific feature for this model is that the en- gineers must find and solve inventive problems in their workplaces during the training process. The solutions from the problems are new ideas which are improved to form some inventions. Experiences show that engineers and their companies make high evaluation about the training proces s. To organize the companies and engineers to join the classes are the job of local governments but the lectur ing and other activities are the job of our center. The advan- tages of two sides are brought into play. This is feasible model for transferring creativity and innovation knowl- edge to companies in Chin a. The knowledge system transferred in the training process is specially organized at four levels, which are basic concepts, basic methods, systematic methods and computer-aided innovation. TRIZ is selected as the core knowledge and the others dealing with creativity and innovation are supplementary in this system. TRIZ is strong in solving difficulties or inventive problems but other techniques are needed to find problems and inte- grated into an innovation processes. The integration of two kinds of knowledge forms a whole knowledge sys- tem from finding to solving a problem for an innovation process. The knowledge system is different from only TRIZ and is a key factor for successful training. From many discussions face to face with the engineers in the training process, 7 stimuli are found, which excite them to identify opportunities for innovation in our classes. The knowledge system of four levels is p regnant with all the stimuli. The stimuli are directly related with fuzzy front end, new product design and manufacturing. That the engineers apply them one by one to workplaces may help them to id entify opportun ities and the prob lems contained. The knowledge system is an open system, to which new relevant knowledge could be enriched. The classes  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 737 are organized in more and more provinces in China and the experiences are accumulated. Some new stimuli may be concluded and should be added to the stimulus set of this study. It needs our attention whether the stimuli may excite the engineers to identify opportunities in the stage of commercialization. The stimuli are suitable for adding to the interactive training process for engineers. But for a long term con- sideration they should be applied in the process of crea- tivity and innovation management for companies. We are trying to make experiences in one or two companies now in this direction and hope to have some results in the fu- ture. 8. Conclusions The practices show that improving the innovation capa- bility is possible through training engineers in China. More than half of the engineers having joined our classes do pass the training process though some engineers drop out in the middle. TRIZ, which is the core technique in knowledge sys- tem with four levels, is particularly useful for the engi- neers to make inventions. Because learning TRIZ is not easy, the training process should be developed carefully. The interactive training model for training innovative engineers in this study is a possible selection. The knowledge to be transferred and the process used imply some stimuli to identify opportunities of innova- tion, in which problems are contained. Seven stimuli are concluded by many face to face discussions with the en- gineers to join our training classes. A possible process to apply them is also described. There will also be some researches for future work, such as adding new knowledge to the system, finding new stimuli and applying them into commercializatio n in companies for a long term management. 9. Acknowledgements The research is supported in part by the Chinese Natural Science Foundation (Grant No. 51275153) and by the National Innovation Project (Grant No. 2011M010200). No part of this paper represents the views and opinions of any of the sponsors mention e d above. REFERENCES [1] T. D. Kuczmarski, “What Is Innovation? And Why Aren’t Companies Doing More of It?” Journal of Consumer Marketing, Vol. 20, No. 6, 2003, pp. 536-541. http://dx.doi.org/10.1108/07363760310499110 [2] B. M. Sihem and C. D. Florence, “Enhancing Discon- tinuous Innovation through Knowledge Combination: The Case of an Exploratory Unit within an Established Auto- motive Firm,” Creativity and innovation Management, Vol. 17, No. 2, 2008, pp. 127-135. http://dx.doi.org/10.1111/j.1467-8691.2008.00473.x [3] P. L. Fan, “Catching up through Developing Innovation Capability: Evidence from China’s Telecom-Equipment Industry,” Technovation, Vol. 26, No. 3, 2006, pp. 359- 368. http://dx.doi.org/10.1016/j.technovation.2004.10.004 [4] K. Z. Zhou, “Innovation, Imitation, and New Product Per- formance: The Case of China,” Industrial Marketing Management, Vol. 35, No. 3, 2006, pp. 394-402. http://dx.doi.org/10.1016/j.indmarman.2005.10.006 [5] D. Pitta and E. Pitta, “Transforming the Nature and Scope of New Product Development,” Journal of Product & Brand Management, Vol. 21, No. 1, 2012, pp. 35-46. http://dx.doi.org/10.1108/10610421211203097 [6] P. F. Drucker, “The Discipline of Innovation,” Harvard Business Review, Vol. 76, No. 6, 1998, pp. 149-157. [7] S. Kaish and B. Gilad, “Characteristics of Opportunities Search of Entrepreneurs v. Executives: Sources, Interest, and General Alertness,” Journal of Business Venturing, Vol. 6, No. 1, 1991, pp. 45-61. http://dx.doi.org/10.1016/0883-9026(91)90005-X [8] D. R. Detienne and G. N. Chandler, “Opportunity Identi- fication and Its Role in the Entrepreneurial Classroom: A Pedagogical Approach and Empirical Test,” Academy of Management Learning and Education, Vol. 3, No. 3, 2004, pp. 242-257. http://dx.doi.org/10.5465/AMLE.2004.14242103 [9] B. Bozeman, “Technology Transfer and Public Policy: A Review of Research and Theory,” Research Policy, Vol. 29, No. 4-5, 2000, pp. 627-655. http://dx.doi.org/10.1016/S0048-7333(99)00093-1 [10] S. Bauernschuster, O. Falck and S. Heblich, “The Impact of Continuous Training on a Firm’s Innovations,” CESifo Working Paper Series, Munich, 2008, Paper No. 2258. [11] Y. C. Bao, X. B. Chen and K. Z. Zhou, “External Learn- ing, Market Dynamics, and Radical Innovation: Evidence from China’s High-Tech Firms,” Journal of Business Re- search, Vol. 65, No. 8, 2012, pp. 1226-1233. http://dx.doi.org/10.1016/j.jbusres.2011.06.036 [12] C. L. Howard, S. L. David, and A. B. Marilyn, “Human Factors and the Innovation Process,” Technovation, Vol. 16, No. 4, 1996, pp. 173-186. http://dx.doi.org/10.1016/0166-4972(95)00046-1 [13] P. Koen, G. Ajamian, R. Burkart, A. Clamen, J. Davidson, R. D. Amore, C. Elkins, K. Herald, M. Incorvia, A. John- son, R. Karol, R. Seibert, A. Slavejkov and K. Wagner, “Provding Clarity and a Common Language to the ‘Fuzzy Front End’,” Research-Technology Management, Vol. 44, No. 2, 2001, pp. 46-55. [14] O. Toubia, “New Product Development,” In: H. Bidgoli, Ed., Handbook of Technology Management, Wiley, Ho- boken, 2010, pp. 953-1092. [15] W. C. Kim and M. Renée, “Blue Ocean Strategy,” Har- vard Business School Press, Boston, 2005. [16] C. M. Christensen, “The Innovator’s Dilemma: When Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China 738 New Technologies Cause Great Firms to Fail,” Harvard Business School Press, Boston, 1997. [17] T. David, “Applying Creative Thinking Techniques to Everyday Problems,” Journal of Consumer Marketing, Vol. 9, No. 4, 1992, pp. 23-28. http://dx.doi.org/10.1108/07363769210037051 [18] A. B. Robert, “Opportunity Recognition as Pattern Rec- ognition: How Entrepreneurs ‘Connect the Dots’ to Iden- tify New Business Opportunities,” Academy of Manage- ment Perspectives, Vol. 20, No. 1, 2006, pp. 104-119. http://dx.doi.org/10.5465/AMP.2006.19873412 [19] D. A. Gregoire, “Technology Market Combinations and the Identification of Entrepreneurial of the Opportunity Individual Nexus,” Academy of Management Journal, Vol. 55, No. 4, 2012, pp. 753-785. http://dx.doi.org/10.5465/amj.2011.0126 [20] R. Blundell, L. Dearden, C. Meghir and B. Sianes, “Hu- man Capital Invest ment: The Retu rns from Educatio n and Training to the Individual, the Firm and the Economy,” Fiscal Studies, Vol. 20, No. 1, 1999, pp. 1-23. http://dx.doi.org/10.1111/j.1475-5890.1999.tb00001.x [21] M. E. Porter and S. Stern, “National Innovative Capac- ity,” In M. E. Porter, et al., Eds., The Global Competi- tiveness Report, 2001-2002, Oxford University Press, New York, 2002, pp. 102-118. [22] S. Vichet, “Strategic Integration of Training and Innova- tion: Significantly Connected,” Journal of Global Infor- mation Technology, Vol. 7, No. 1-2, 2009, pp. 7-20. [23] H. Frazis, M. Gittleman and M. Joyce, “Determinants of Training: An Analysis Using Both Employer and Em- ployee Characteristics,” United States Department of Commerce, Bureau of Labor Statistics, Washington DC, 1998. [24] P. Steven, “How GE Teaches Teams to Lead Change,” Harvard Business Review, Vol. 87, No. 1, 2009, pp. 99- 106. [25] R. Christian and B. G. Uschi, “High Quality Workplace Training and Innovation in Highly Developed Countries,” Economics of Education Working Paper Series, Univer- sity of Zurich, Institute for Strategy and Business Eco- nomics, Zurich, Paper No. 0074, 2012. [26] Z. Izyani, “Training and Innovation among Knowl- edge-Based Companies in Malaysia,” Journal of Eco- nomic Cooperation and Development, Vol. 33, No. 2, 2012, pp. 53-74. [27] S. S. F. Shohreh, H. Jamal and S. M. Mirdamadi, “The Role of Training in Facilitating Innovation in Small Food Industries in Rural Iran,” African Journal of Agricultural Research, Vol. 5, No. 17, 2010, pp. 2332-2340. [28] C. S. Anja and P. Igor, “How Internal and External Sources of Knowledge Contribute to Firms’ Innovation Performance,” Managing Global Transitions, Vol. 6, No. 3, 2008, pp. 277-299. [29] C. Yannis, K. Ioanna and T. Aggelos, “Internal Capabili- ties and External Knowledge Sources: Complements or Substitutes for Innovative Performance?” Technovation, Vol. 24, No. 1, 2004, pp. 29-39. http://dx.doi.org/10.1016/S0166-4972(02)00051-2 [30] G. J. Puccio, R. L. Firestien, C. Coyle and C. Masucci, “A Review of the Effectiveness of CPS Training: A Fo- cus on Workplace Issues,” Creativity and Innovation Management, Vol. 15, No. 1, 2006, pp. 19-33. http://dx.doi.org/10.1111/j.1467-8691.2006.00366.x [31] A. B. VanGundy, “Techniques of Structured Problem Solving,” Van Nostrand Reinhold, New York, 1988. [32] S. David, S. Philip and D. Neil, “The Innovator’s Tool- kit,” John Wiley & Sons, Hoboken, 2009. [33] J. J. Shah, “Experimental Investigation of Progressive Idea Generation Techniques in Engineering Design,” ASME DETC Design Theory and Methodology Confer- ence, Atlanta, 1998. [34] G. Altshuller, “Creativity as an Exact Science,” Gordon & Breach, Luxembourg, 1984. [35] G. Karen, “TRIZ for Engineers: Enabling Inventive Problem Solving,” John Wiley&Sons, Ltd., Chichester, 2011. [36] B. Kamal, L. Desmond and M. Wissam, “Evaluating the Impact of TRIZ Creativity Training: An Organizational Field Study,” R&D Management, Vol. 42, No. 4, 2012, pp. 315-326. [37] T. Nakagawa, “Education and Training of Creative Prob- lem Solving Thinking with TRIZ/USIT,” Procedia Engi- neering, Vol. 9, 2011, pp. 582-595. http://dx.doi.org/10.1016/j.proeng.2011.03.144 [38] E. N. Sickafus, “Unified Structured Inventive Thinking: How to Invent,” Ntelleck, Grosse Ile, 1997. [39] Q. Jun and D. L. Shin, “TRIZ Propagation Strategies in SAMSUNG Electronics Co.,” 2013. http://www.triz.co.kr/data/qcjun.pdf [40] M. I. Imoh, P. David and P. Robert, “A Review of TRIZ, and Its Benefits and Challenges in Practice,” Technovation, Vol. 33, No. 2-3, 2011, pp. 30-37. [41] J. R. Duflou and W. Dewulf, “On the Complementarity of TRIZ and Axiomatic Design: From Decoupling Objective to Contradiction Identification,” Prodedia Engineering, Vol. 9, 2011, pp. 633-639. [42] M. Ogot, “Conceptual Design Using Axiomatic Design in a TRIZ Framework,” Prodedia Engineering, Vol. 9, 2011, pp. 736-744. [43] R. Stratton and D. Mann, “Systematic Innovation and the Underlying Principles behind TRIZ and TOC,” Journal of Materials Processing Tech nology , Vol. 139, No. 1-3, 2003, pp. 120-126. http://dx.doi.org/10.1016/S0924-0136(03)00192-4 [44] G. Cascini, P. Rissone, F. Rotini and D. Russo, “System- atic Design through the Integration of TRIZ and Optimi- zation Tools,” Prodedia Engineering, Vol. 9, 2011, pp. 674-679. http://dx.doi.org/10.1016/j.proeng.2011.03.154 [45] R. H. Tan, J. H. Ma, F. Liu and Z. H. Wei, “UXDs- Driven Conceptual Design Process Model for Contradic- tion Solving Using CAIs,” Computers in Industry, Vol. 60, No. 8, 2009, pp. 584-591. http://dx.doi.org/10.1016/j.compind.2009.05.019 Open Access AJIBM  Seven Stimuli to Identify Opportunities of Innovation: A Practice of Training Innovative Engineers and Some Findings in China Open Access AJIBM 739 [46] G. Pahl and W. Beitz, “Engineering Design—A System- atic Approach,” 2nd Edition, Springer, London, 1996. [47] J. G. Sun and R. H. Tan, “Method for Forecasting DI Based on TRIZ Technology System Evolution Theory,” International Journal of Innovation and Technology Man- agement, Vol. 9, No. 2, 2012, pp. 1250010-1-1250010-20. [48] P. A. Koen, G. M. Ajamian, S. Boyce, A. Clamen, E. Fisher, S. Fountoulakis, A. Johnson, P. Puri and R. Seibert, “Fuzzy Front End: Effective Methods, Tools and Techniques,” In: P. Belliveau, A. Griffen and S. Sorer- meyer, Eds., PDMA Toolbook for New Product Devel- opment, John Wiley and Sons, New York, 2002, pp. 2-35. [49] H. Wilderich, “The Integration of Ideation and Project Portfolio Management—A Key Factor for Sustainable Success,” International Journal of Project Management, Vol. 30, No. 5, 2012, pp. 582-595. http://dx.doi.org/10.1016/j.ijproman.2012.01.014 [50] R. H. Tan, L. H. Ma, B. J. Yang and J. G. Sun, “System- atic Method to Generate New Ideas in Fuzzy Front End Using TRIZ,” Chinese Journal of Mechnical Engineering, Vol. 21, No. 2, 2008, pp. 114-119. http://dx.doi.org/10.3901/CJME.2008.02.114 [51] W. Q. Li, Y. Li, J. Wang and X. Y. Liu, “The Process Model to Aid Innovation of Products Conceptual Design,” Expert Systems with Applications, Vol. 37, No. 5, 2010, pp. 3574-3587. http://dx.doi.org/10.1016/j.eswa.2009.10.034 [52] K. O. Sarah, Y. T. Irem, K. Wood and C. Seepersad, “A Comparison of Creativity and Innovation Metrics and Sample Validation through In-Class Design Projects,” Re- search in Engineering Design, Vol. 24, No. 1, 2013, pp. 65-92. http://dx.doi.org/10.1007/s00163-012-0138-9 [53] H. Yousef and S. Tamer, “Engineering Design Process,” 2nd Edition, Cengage Learning, Stamford, 2011. [54] I. P. Daniel, L. Tritos, S. Amrik and B. I. Sakun, “Manu- facturing Strategies and Innovation Performance in Newly Industrialised Countries,” Industrial Management & Data Systems, Vol. 107, No. 1, 2007, pp. 52-68. http://dx.doi.org/10.1108/02635570710719052 [55] Y. Yamamoto and M. Bellgran, “Four Types of Manu- facturing Process Innovation and Their Managerial Con- cerns,” Procedia CIRP, Vol. 7, 2013, pp. 479-484. http://dx.doi.org/10.1016/j.procir.2013.06.019 [56] J. P. Lane and J. L. Flagg, “Translating Three States of Knowledge-Discovery, Invention, and Innovation,” Imple- mentation Science, Vol. 5, No. 9, 2010, p. 9. [57] O. Gassmann and E. Enkel, “Towards a Theory of Open Innovation: Three Core Process Archetypes,” R&D man- agement Conference, Lisabon, 21-24 June 2004, pp.1-18. [58] S. J. Ellspermann, G. Evans and M. Basadur, “The Impact of Training on the Formulation of Ill-Structured Prob- lems,” Omega, Vol. 35, No. 2, 2007, pp. 221-236. http://dx.doi.org/10.1016/j.omega.2005.05.005 [59] J. F. Voss, “Toulmin’s Model and the Solving of Ill- Structured Problems,” In: D. Hitchcock and B. Verheij, Eds., Arguing on the Toulmin Model: New Essays in Ar- gument Analysis and Evaluation, Springer Netherlands, Berlin, 2006, pp. 303-311. http://dx.doi.org/10.1007/978-1-4020-4938-5_20 [60] S. D. Savransky, “Attributes of the Inventive Problems,” AAAI Spring Symposium on Search Techniques for Prob- lem Solving under Uncertainty and Incomplete Informa- tion, Stanford, 22-24 March 1999, pp. 113-118. [61] H. Michael, “Firm-Level Innovation Models: Perspec- tives on Research in Developed and Developing Coun- tries,” Technology Analysis & Strategic Management, Vol. 17, No. 2, 2005, pp. 121-146. http://dx.doi.org/10.1080/09537320500088666 [62] R. H. Tan, “Eliminating Technical Obstacles in Innova- tion Pipelines Using CAIs,” Computers in Industry, Vol. 62, No. 4, 2011, pp. 414-422. http://dx.doi.org/10.1016/j.compind.2010.12.004 [63] R. H. Tan, “TRIZ and Applications,” High Educat ion Press, Beijing, 2010. [64] S. D. Savransky, “Engineering of Creativity,” CRC Press, New York, 2000. http://dx.doi.org/10.1201/9781420038958 [65] G. Z. Cao, R. H. Tan and J. G. Sun, “Process and Reali- zation of Functional Design Based on Extended-Effect Model,” Chinese Journal of Mechanical En gineering, Vol. 45, No. 7, 2009, pp. 157-167. http://dx.doi.org/10.3901/JME.2009.07.157 [66] J. G. Sun, R. H. Tan and P. Jiang, “Model for Roadmap- ping Disruptive Innovation Based on Technology Evolu- tion Theory,” Chinese Journal of Mechanical Engineer- ing, Vol. 48, No. 11, 2012, pp. 11-20. http://dx.doi.org/10.3901/JME.2012.11.011 [67] C. M. Christensen and M. Overdorf, “Meeting the Chal- lenge of Disruptive Change,” Harvard Business Review, Vol. 78, No. 2, 2000, pp. 67-77. [68] P. Jiang, P. Y. Luo, J. G. Sun and R. H. Tan, “Method about patent design around based on function trimming,” Chinese Journal of Mechanical Engineering, Vol. 48, No. 11, 2012, pp. 46-54. http://dx.doi.org/10.3901/JME.2012.11.046 [69] R. H. Tan, “Process of Two Stages Analogy-Based De- sign Employing TRIZ,” International Journal of Product Development, Vol. 4, No. 1-2, 2007, pp. 109-121. http://dx.doi.org/10.1504/IJPD.2007.011537 [70] J. H. Zhang, R. H. Tan, P. Zhang and G. Z. Cao, “Process Model of New Ideas Generation for Product Conceptual Design Driven by CAI,” Computer Integerated Manau- facturing Systems, Vol. 19, No. 2, 2013, pp. 284-292. [71] D. Cavallucci and N. Leon, “Computer-Supported Inno- vation Pipelines: Current Research and Trends,” Compt- ers in Industry, Vol. 62, No. 4, 2011, pp. 375-376. http://dx.doi.org/10.1016/j.compind.2010.12.011 [72] K. Rantanen and El. Domb, “Simplified TRIZ,” 2nd Edi- tion, Auerbach Publications, New York, 2008. [73] S. Kaplan, S. Visnepolschi, B. Zlotin and A. Zusman, “New Tools for Failure and Risk Analysis: Anticipatory Failure Determination,” Ideation International Inc, Detroit, 1999.

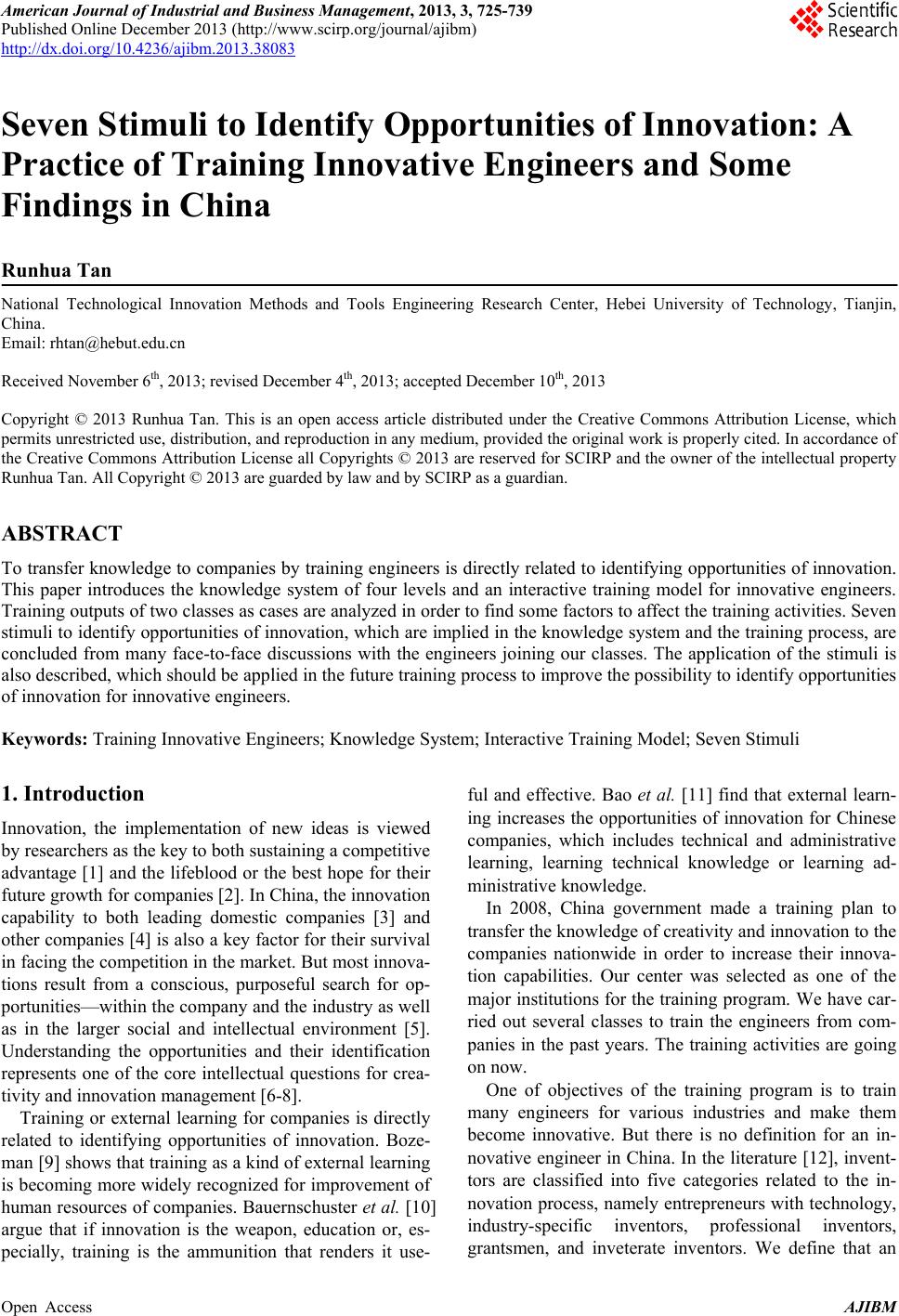

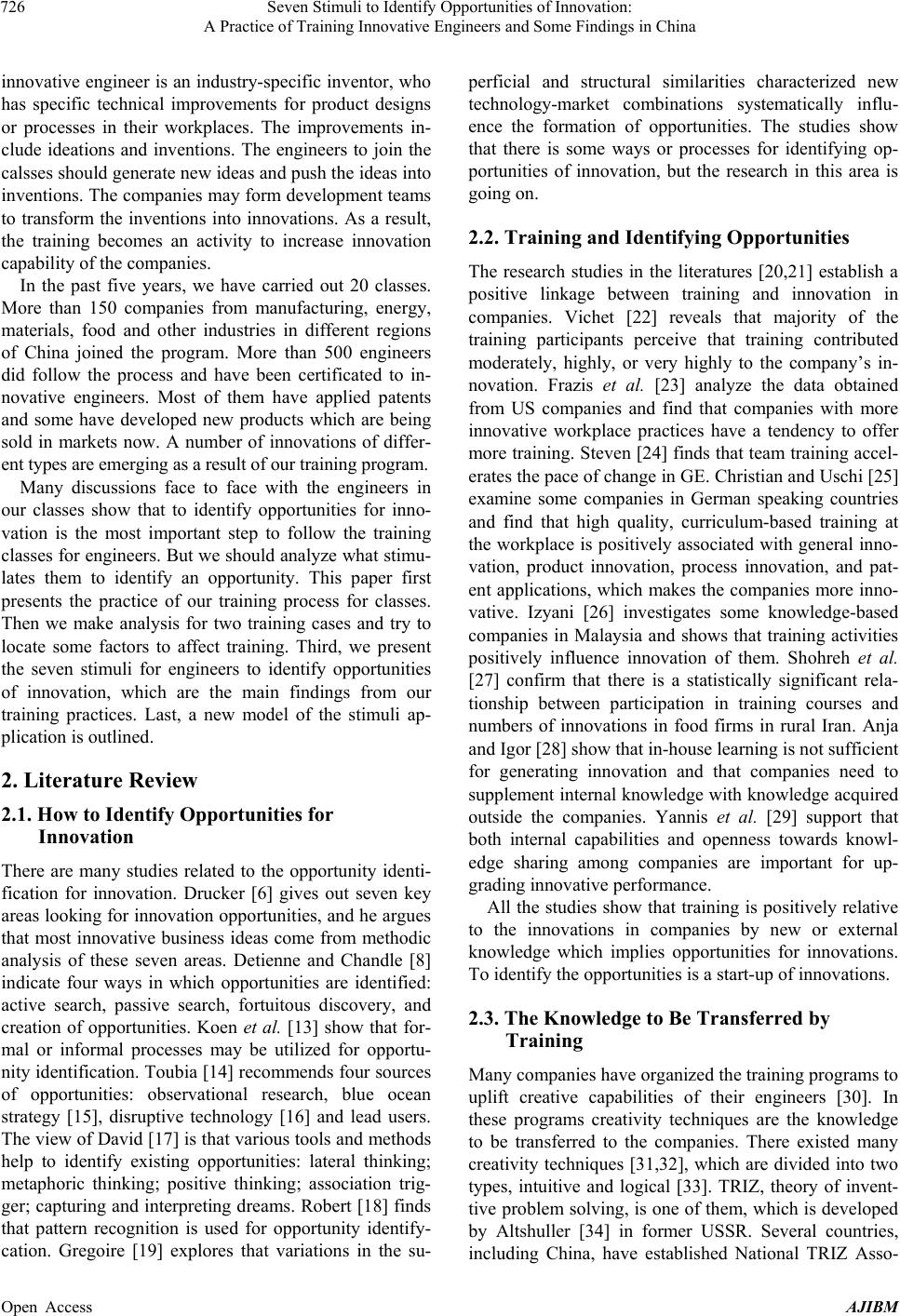

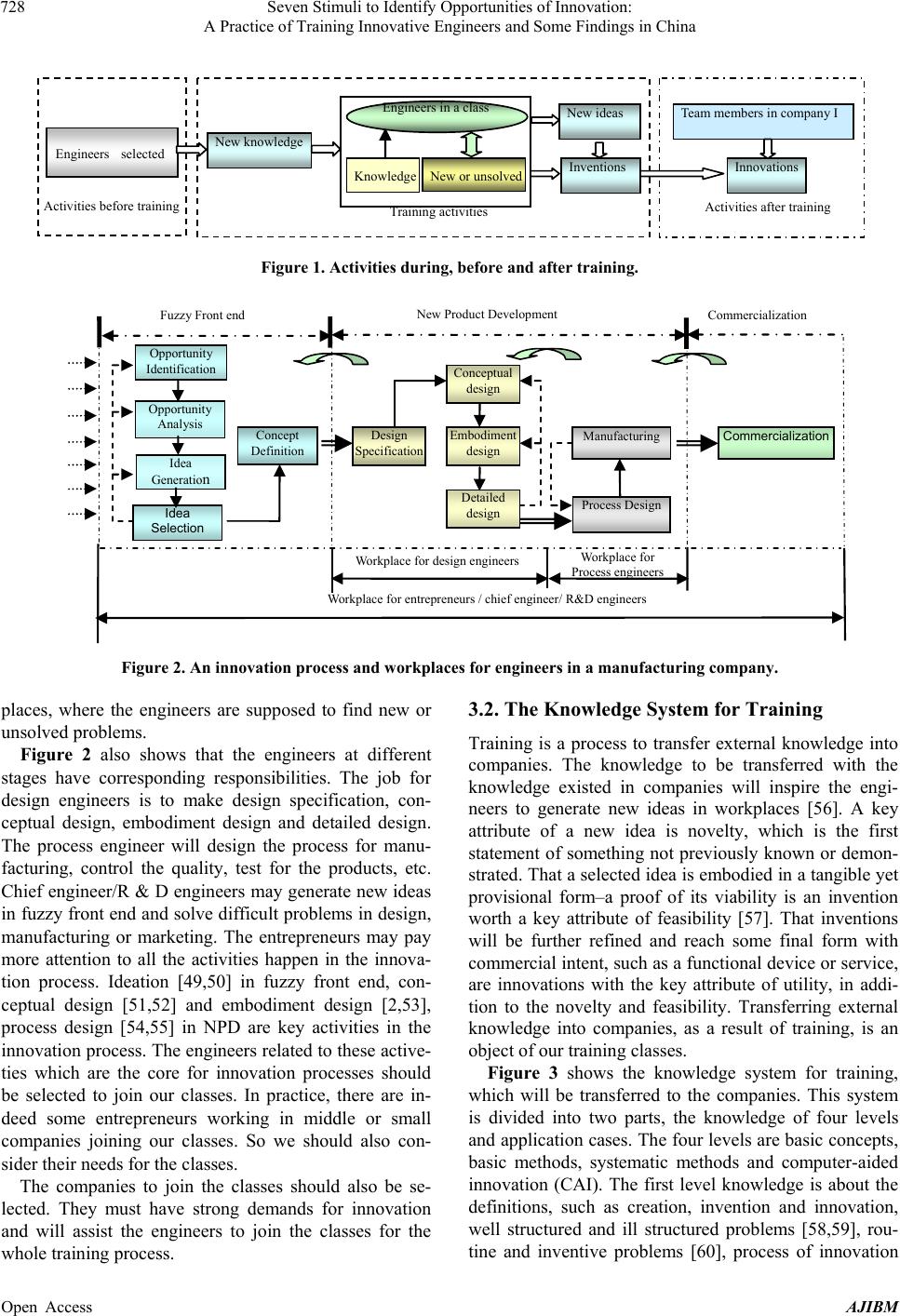

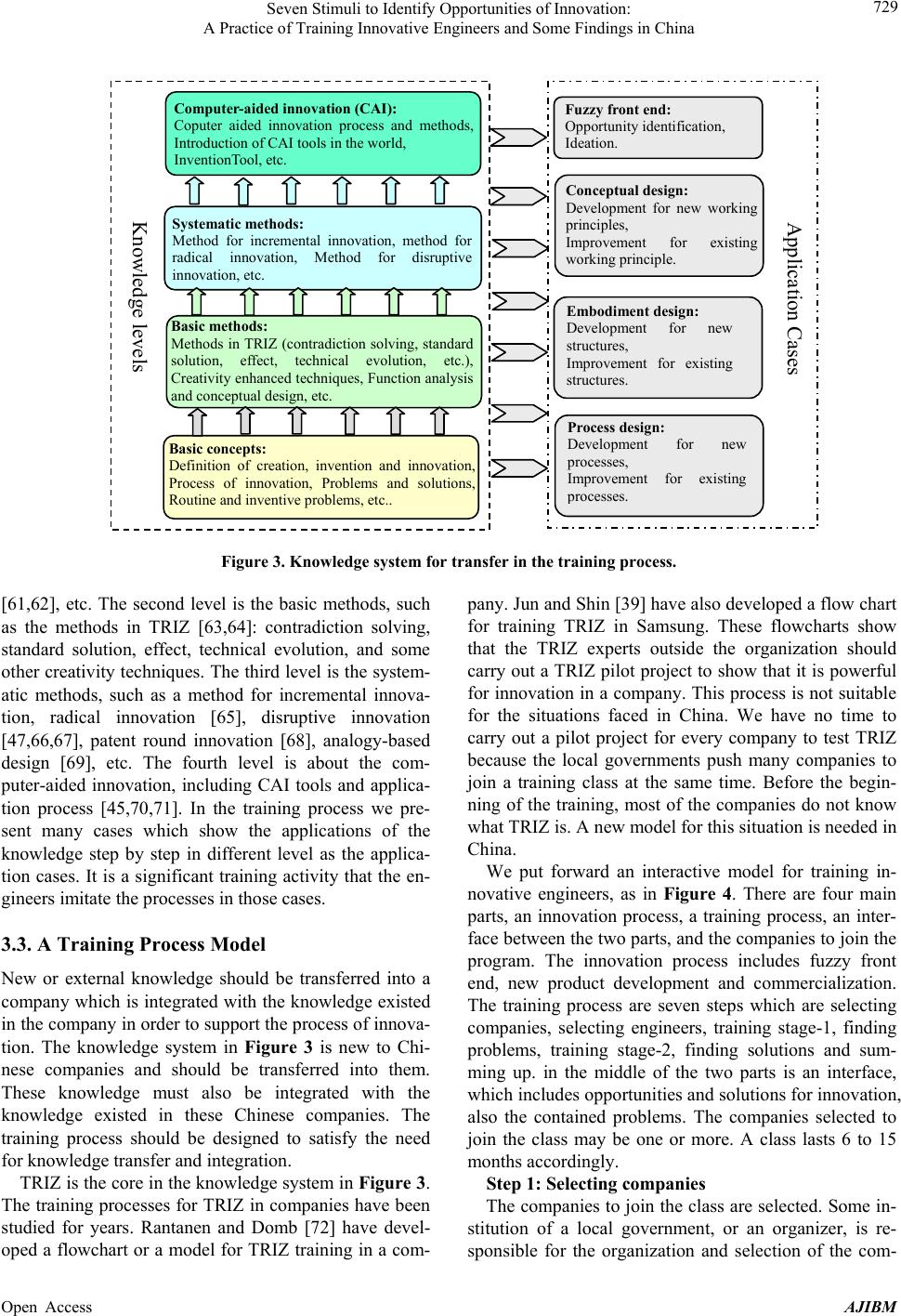

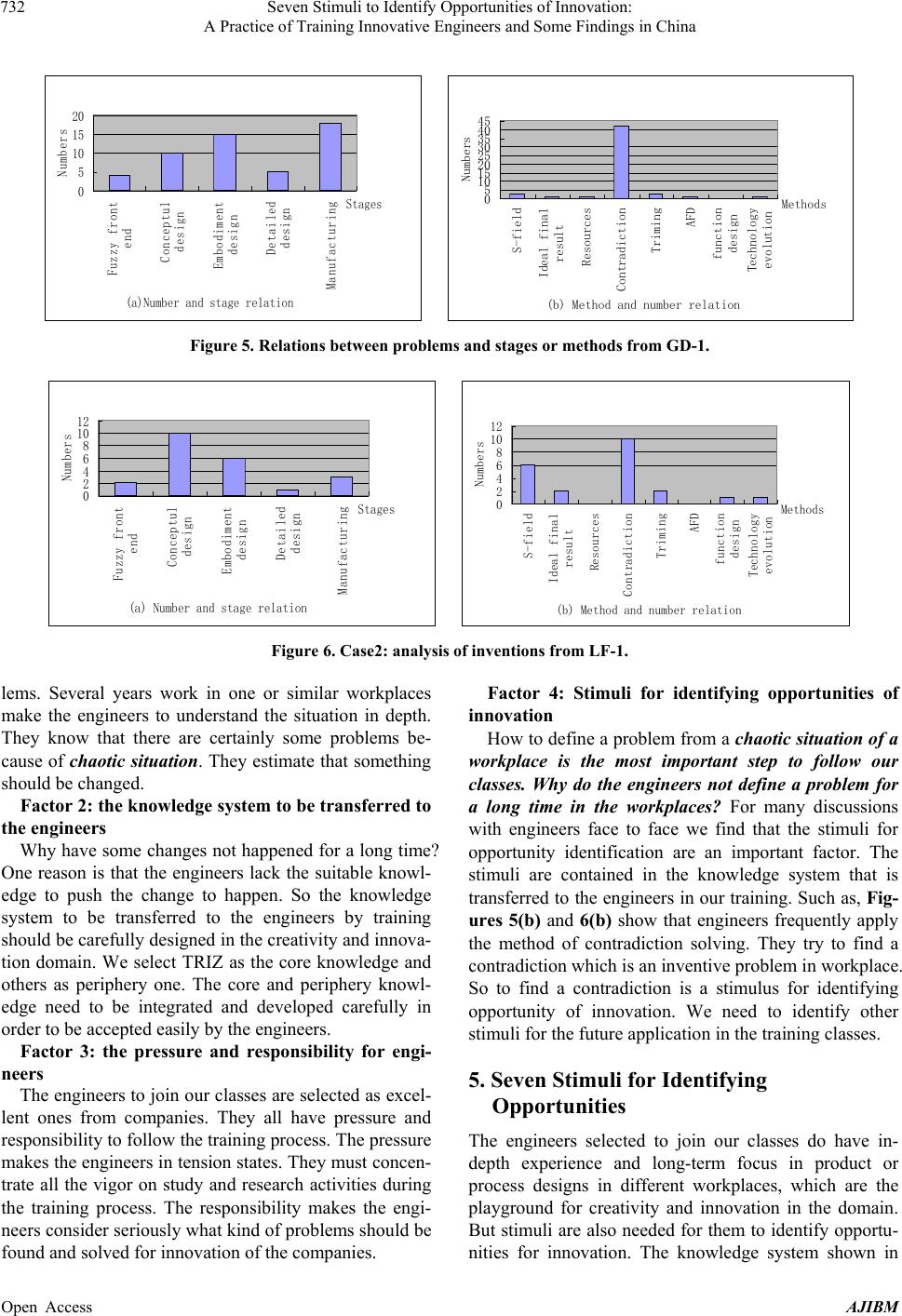

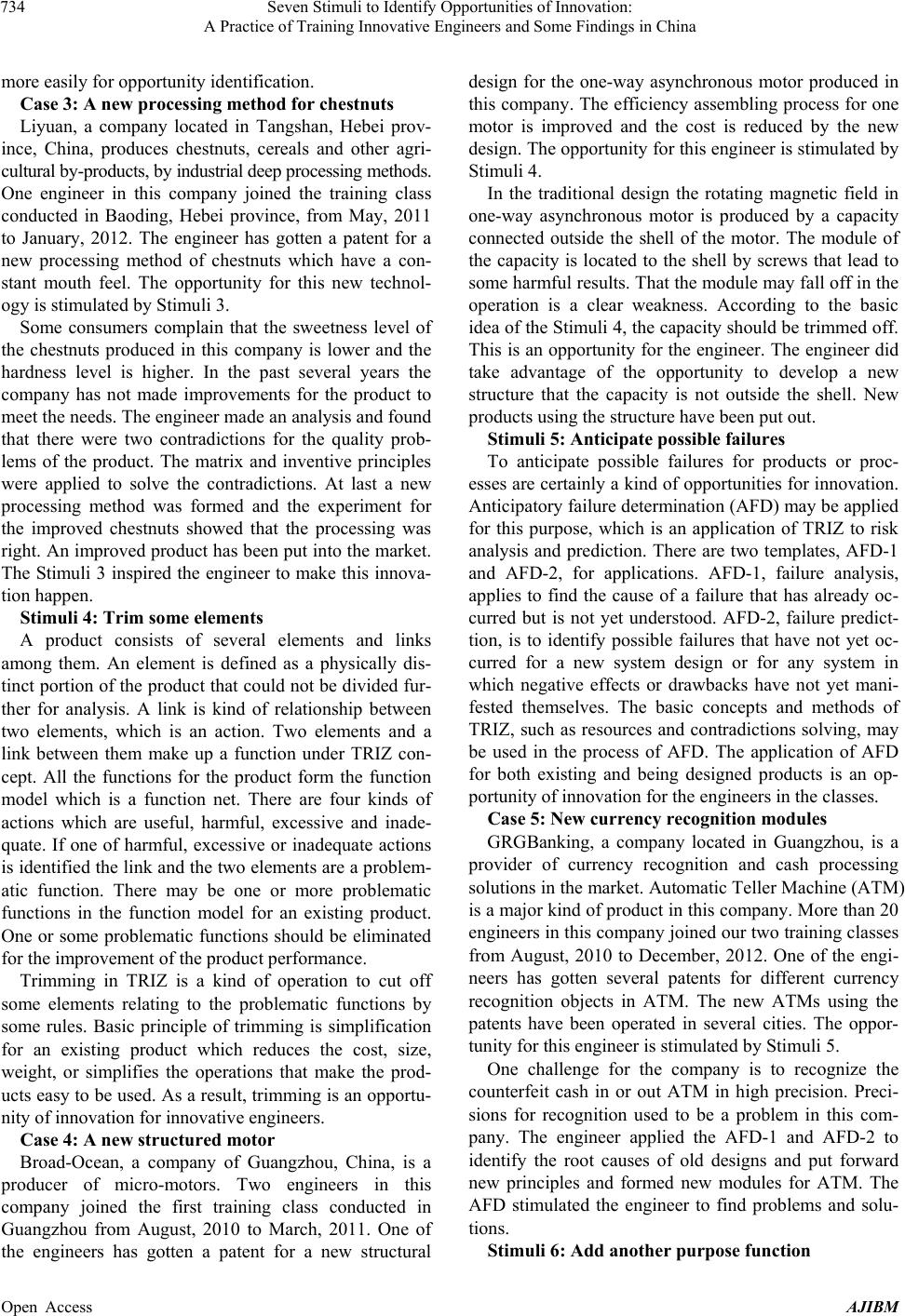

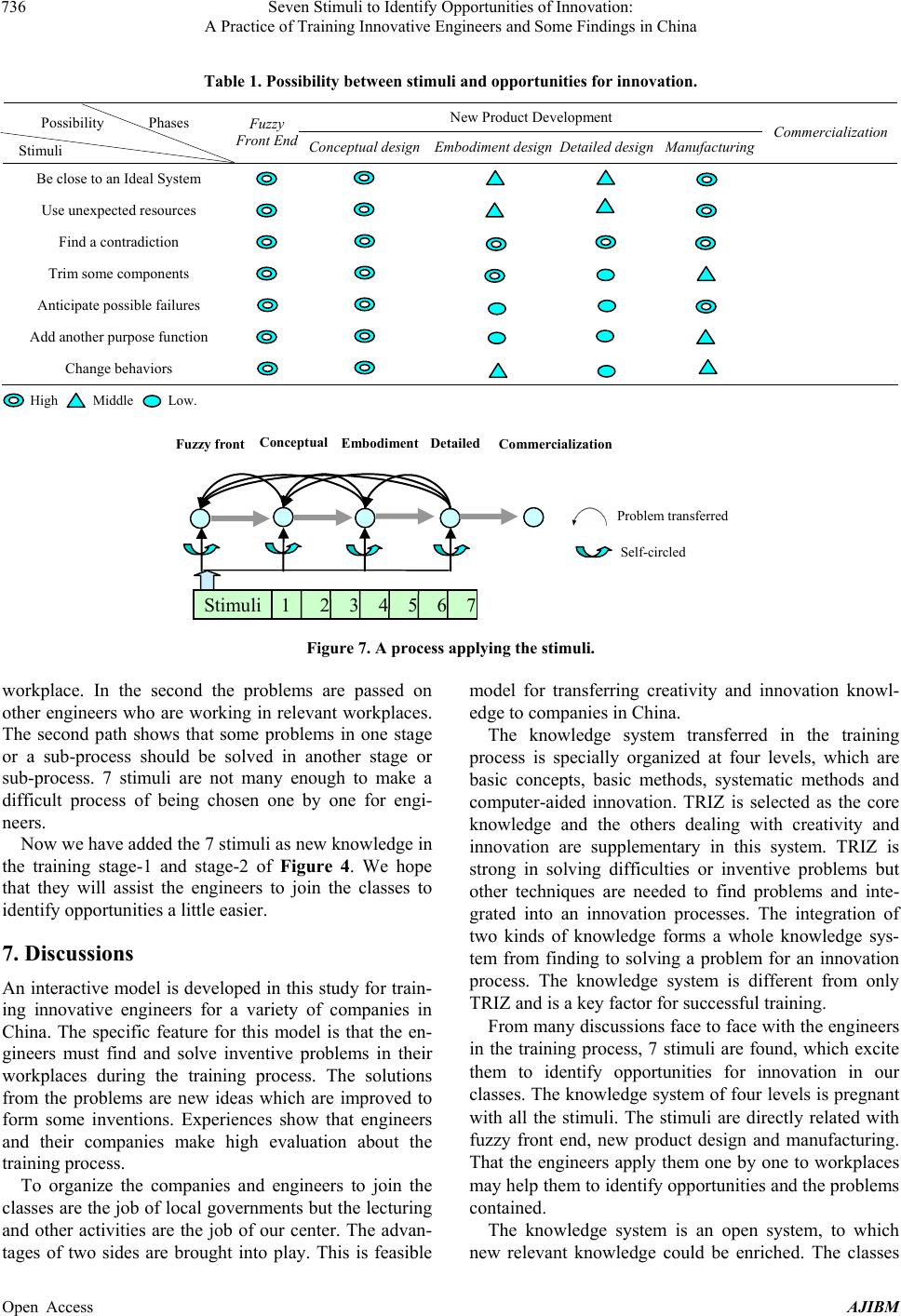

|