А. ERMILOV, E. NURULLAEV

480

rfo m

EEE f

and the experimental data for filled elastomers based on

these rubbers. It is evident that the result of the experi-

mental verification of the theoretical approach is in

agreement with the data of Fedors [6] and Chong et al. [5]

both in terms of the dynamic viscosity coefficient (Fig-

ure 1) and the relative initial viscoelastic modulus of

different polymer compositions (Figure 2).

4. Engineering Applications

The formula of reinforcement of rubbers and 3D cross-

linked elastomers (1) allows, alongside with the calcula-

tion methods proposed by Ermilov and Fedoseev [9], to

determine the value of the maximum filling of the poly-

mer binder with separate filler fractions or polydisperse

fractions based on them and to minimize the number of

the experiments. Indeed, the transformation of the Equa-

tion (1) in relation to m

results in the following for-

mula:

1.25 1

,

fo

m

fo

(7)

which allows to estimate the value of m

by aviscomet-

ric method. This provides a more accurate estimation of

the maximum filling compared to determination of the

packing density of the particles in bulk since it “auto-

matically” takes into account the intermolecular interac-

tion at the filler-binder interface. Therefore, the most

appropriate binder is low-molecular-weight polybutadi-

ene SKD-KTR grade rubber with terminal carboxyl

groups of medium polarity in terms of the immobilizing

effect of the dispersed filler on the molecular mobility of

the binder. The coefficients of dynamic viscosity of the

binders and filled compositions based on them were de-

termined using Heppler consistometer at one of the mod-

erate values of

and 3 - 5 parallel measurements. The

levels of the gradients of shear rate and experimental

temperatures were selected in compliance with practical

needs and interests of the particular branches of science

and industry.

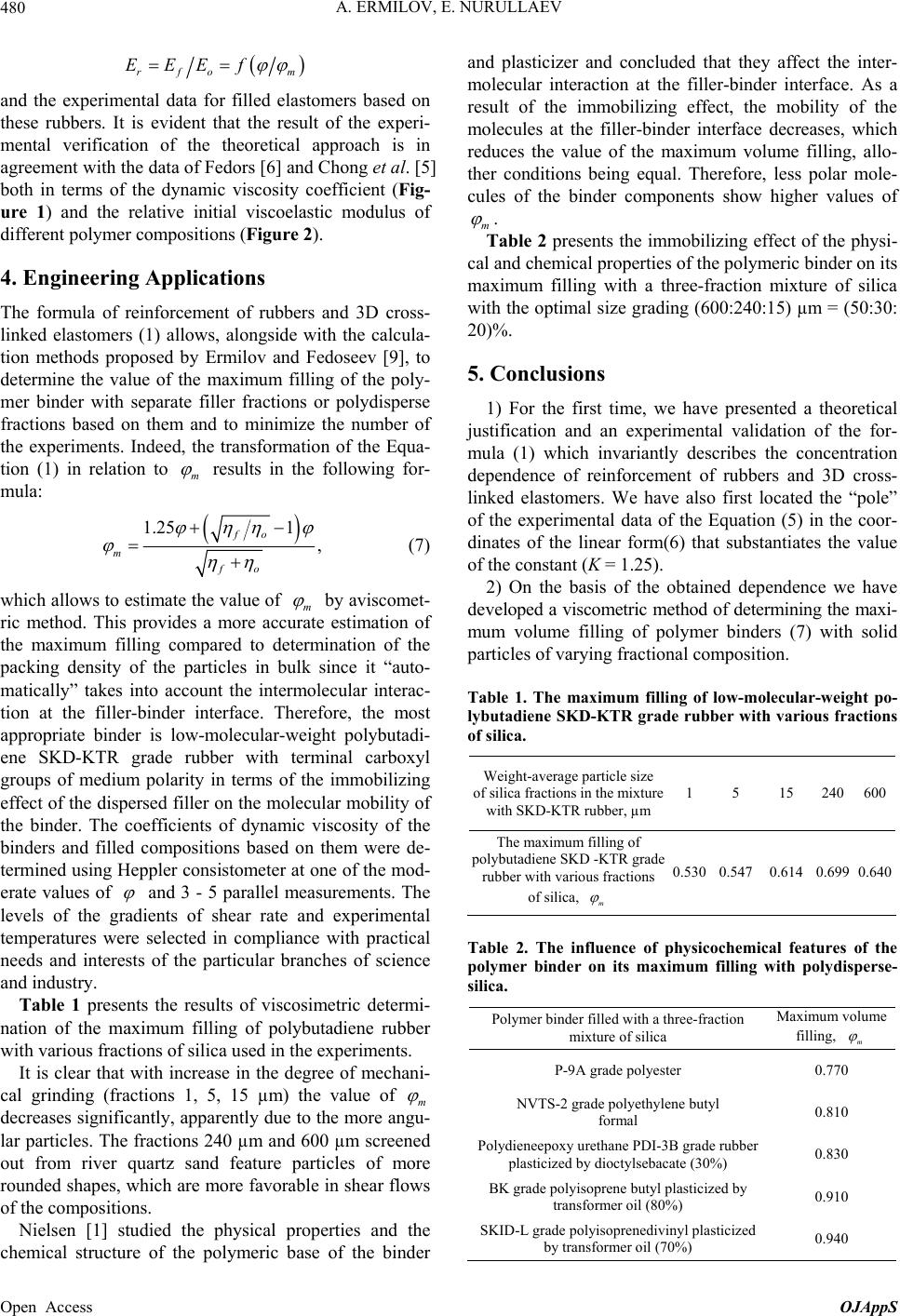

Table 1 presents the results of viscosimetric determi-

nation of the maximum filling of polybutadiene rubber

with various fractions of silica used in the experiments.

It is clear that with increase in the degree of mechani-

cal grinding (fractions 1, 5, 15 µm) the value of m

decreases significantly, apparently due to the more angu-

lar particles. The fractions 240 µm and 600 µm screened

out from river quartz sand feature particles of more

rounded shapes, which are more favorable in shear flows

of the compositions.

Nielsen [1] studied the physical properties and the

chemical structure of the polymeric base of the binder

and plasticizer and concluded that they affect the inter-

molecular interaction at the filler-binder interface. As a

result of the immobilizing effect, the mobility of the

molecules at the filler-binder interface decreases, which

reduces the value of the maximum volume filling, allo-

ther conditions being equal. Therefore, less polar mole-

cules of the binder components show higher values of

m

.

Table 2 presents the immobilizing effect of the physi-

cal and chemical properties of the polymeric binder on its

maximum filling with a three-fraction mixture of silica

with the optimal size grading (600:240:15) µm = (50:30:

20)%.

5. Conclusions

1) For the first time, we have presented a theoretical

justification and an experimental validation of the for-

mula (1) which invariantly describes the concentration

dependence of reinforcement of rubbers and 3D cross-

linked elastomers. We have also first located the “pole”

of the experimental data of the Equation (5) in the coor-

dinates of the linear form(6) that substantiates the value

of the constant (K = 1.25).

2) On the basis of the obtained dependence we have

developed a viscometric method of determining the maxi-

mum volume filling of polymer binders (7) with solid

particles of varying fractional composition.

Table 1. The maximum filling of low-molecular-weight po-

lybutadiene SKD-KTR grade rubber with various fractions

of silica.

Weight-average particle size

of silica fractions in the mixture

with SKD-KTR rubber, µm

1 5 15 240600

The maximum filling of

polybutadiene SKD -KTR grade

rubber with various fractions

of silica, m

0.530 0.547 0.614 0.6990.640

Table 2. The influence of physicochemical features of the

polymer binder on its maximum filling with polydisperse-

silica.

Polymer binder filled with a three-fraction

mixture of silica

Maximum volume

filling, m

P-9А grade polyester 0.770

NVTS-2 grade polyethylene butyl

formal 0.810

Polydieneepoxy urethane PDI-3B grade rubber

plasticized by dioctylsebacate (30%) 0.830

BK grade polyisoprene butyl plasticized by

transformer oil (80%) 0.910

SKID-L grade polyisoprenedivinyl plasticized

by transformer oil (70%) 0.940

Open Access OJAppS