Silver-Doped Layers of Implants Prepared by Pulsed Laser Deposition

Open Access JCC

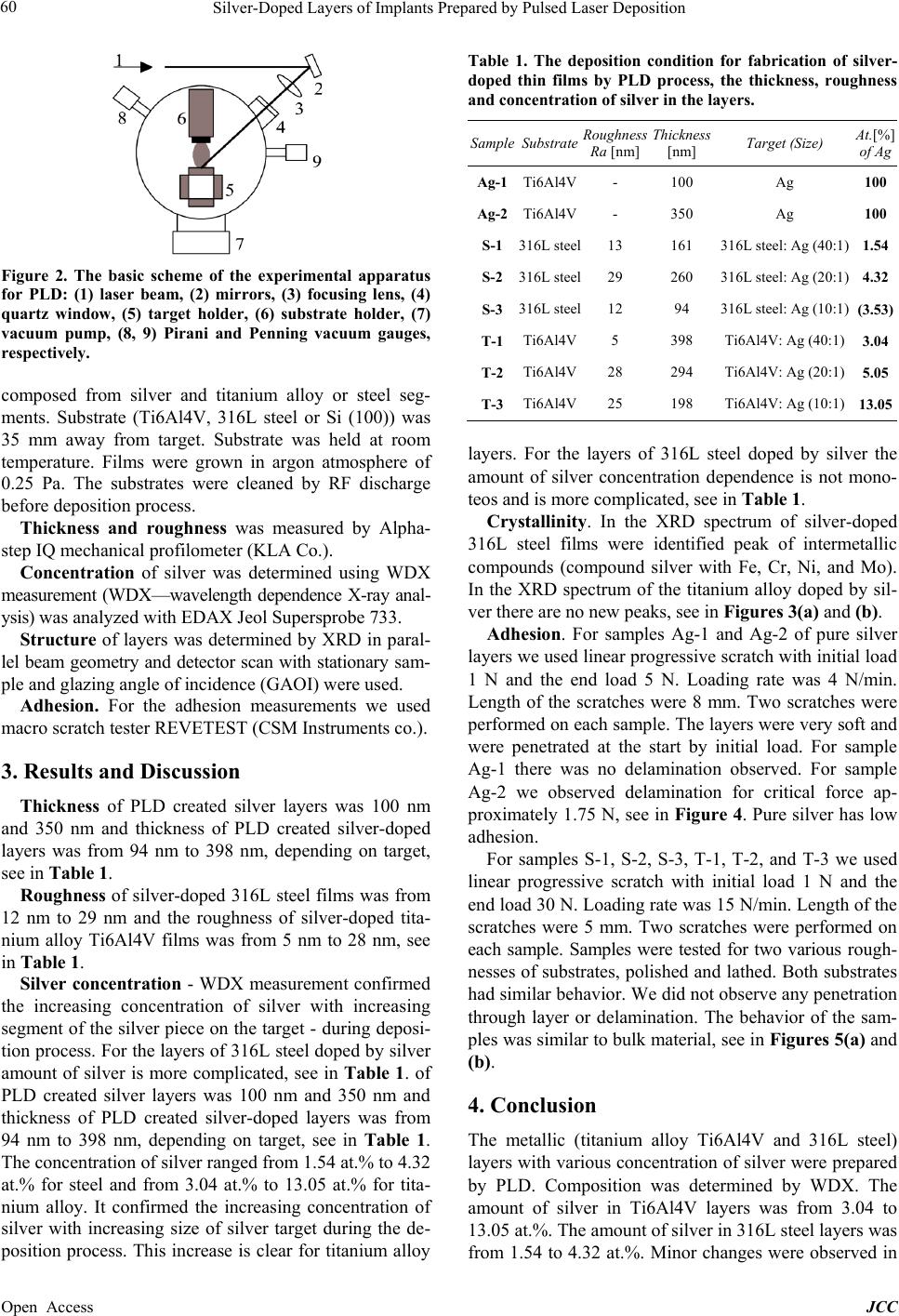

Figure 2. The basic scheme of the experimental apparatus

for PLD: (1) laser beam, (2) mirrors, (3) focusing lens, (4)

quartz window, (5) target holder, (6) substrate holder, (7)

vacuum pump, (8, 9) Pirani and Penning vacuum gauges,

respectively.

composed from silver and titanium alloy or steel seg-

ments. Substrate (Ti6Al4V, 316L steel or Si (100)) was

35 mm away from target. Substrate was held at room

temperature. Films were grown in argon atmosphere of

0.25 Pa. The substrates were cleaned by RF discharge

before deposition process.

Thickness and roughness was measured by Alpha-

step IQ mechanical profilometer (KLA Co.).

Concentration of silver was determined using WDX

measurement (WDX—wavelength dependence X-ray anal-

ysis) was analyzed with EDAX Jeol Supersprobe 733.

Structure of layers was determined by XRD in paral-

lel beam geometry and detector scan with stationar y sam-

ple and glazing angle of incidence (GAOI) were used.

Adhesion. For the adhesion measurements we used

macro scratch tester REVETEST (CSM Instruments co.).

3. Results and Discussion

Thickness of PLD created silver layers was 100 nm

and 350 nm and thickness of PLD created silver-doped

layers was from 94 nm to 398 nm, depending on target,

see in Table 1.

Roughness of silver-doped 316L steel films was from

12 nm to 29 nm and the roughness of silver-doped tita-

nium alloy Ti6Al4V films was from 5 nm to 28 nm, see

in Table 1.

Silver concentration - WDX measurement confirmed

the increasing concentration of silver with increasing

segment of the silver piece on the target - during deposi-

tion process. For the layers of 316L steel doped by silver

amount of silver is more complicated, see in Table 1 . of

PLD created silver layers was 100 nm and 350 nm and

thickness of PLD created silver-doped layers was from

94 nm to 398 nm, depending on target, see in Table 1.

The concentration of silv er rang ed from 1.54 at. % to 4.32

at.% for steel and from 3.04 at.% to 13.05 at.% for tita-

nium alloy. It confirmed the increasing concentration of

silver with increasing size of silver target during the de-

position process. This increase is clear for titanium alloy

Table 1. The deposition condition for fabrication of silver-

doped thin films by PLD process, the thickness, roughness

and concentration of silver in the layers.

Sample Substrate

Target (Size)

Ag-1 Ti6Al4V - 100 Ag 100

Ag-2 Ti6Al4V - 350 Ag 100

S-1 316L steel

13 161 316L steel: Ag (40:1) 1.54

S-2 316L steel

29 260 316L steel: Ag (20:1) 4.32

S-3 316L steel

12 94 316L steel: Ag (10:1) (3.53)

T-1 Ti6Al4V 5 398 Ti6Al4V: Ag (40:1) 3.04

T-2 Ti6Al4V 28 294 Ti6Al4V: Ag (20:1) 5.05

T-3 Ti6Al4V 25 198 Ti6Al4V: Ag (10:1) 13.05

layers. For the layers of 316L steel doped by silver the

amount of silver concentration dependence is not mono-

teos and is more complicated, see in Table 1.

Crystallinity. In the XRD spectrum of silver-doped

316L steel films were identified peak of intermetallic

compounds (compound silver with Fe, Cr, Ni, and Mo).

In the XRD spectrum of the titanium alloy doped by sil-

ver there are no new peaks, see in Figures 3(a) and (b).

Adhesion. For samples Ag-1 and Ag-2 of pure silver

layers we used linear progressiv e scratch with initial load

1 N and the end load 5 N. Loading rate was 4 N/min.

Length of the scratches were 8 mm. Two scratches were

performed on each sample. The layers were very soft and

were penetrated at the start by initial load. For sample

Ag-1 there was no delamination observed. For sample

Ag-2 we observed delamination for critical force ap-

proximately 1.75 N, see in Fig ure 4. Pure silver has low

adhesion.

For samples S-1, S-2, S-3, T-1, T-2, and T-3 we used

linear progressive scratch with initial load 1 N and the

end load 30 N. Loading rate was 15 N/min. Length of the

scratches were 5 mm. Two scratches were performed on

each sample. Samples were tested for two various rough-

nesses of substrates, polished and lathed. Both substrates

had similar behavior. We did not observe any penetration

through layer or delamination. The behavior of the sam-

ples was similar to bulk material, see in Figures 5(a) and

(b).

4. Conclusion

The metallic (titanium alloy Ti6Al4V and 316L steel)

layers with various concentration of silver were prepared

by PLD. Composition was determined by WDX. The

amount of silver in Ti6Al4V layers was from 3.04 to

13.05 at.%. The amount of silver in 316L steel layers was

from 1.54 to 4.32 at.%. Minor changes were observed in