Double-Pulse Remote Laser-Induced Breakdown Spectroscopy Analysis of Magnesium Alloys

Open Access JCC

10% and the calibration curves that allow quantitative

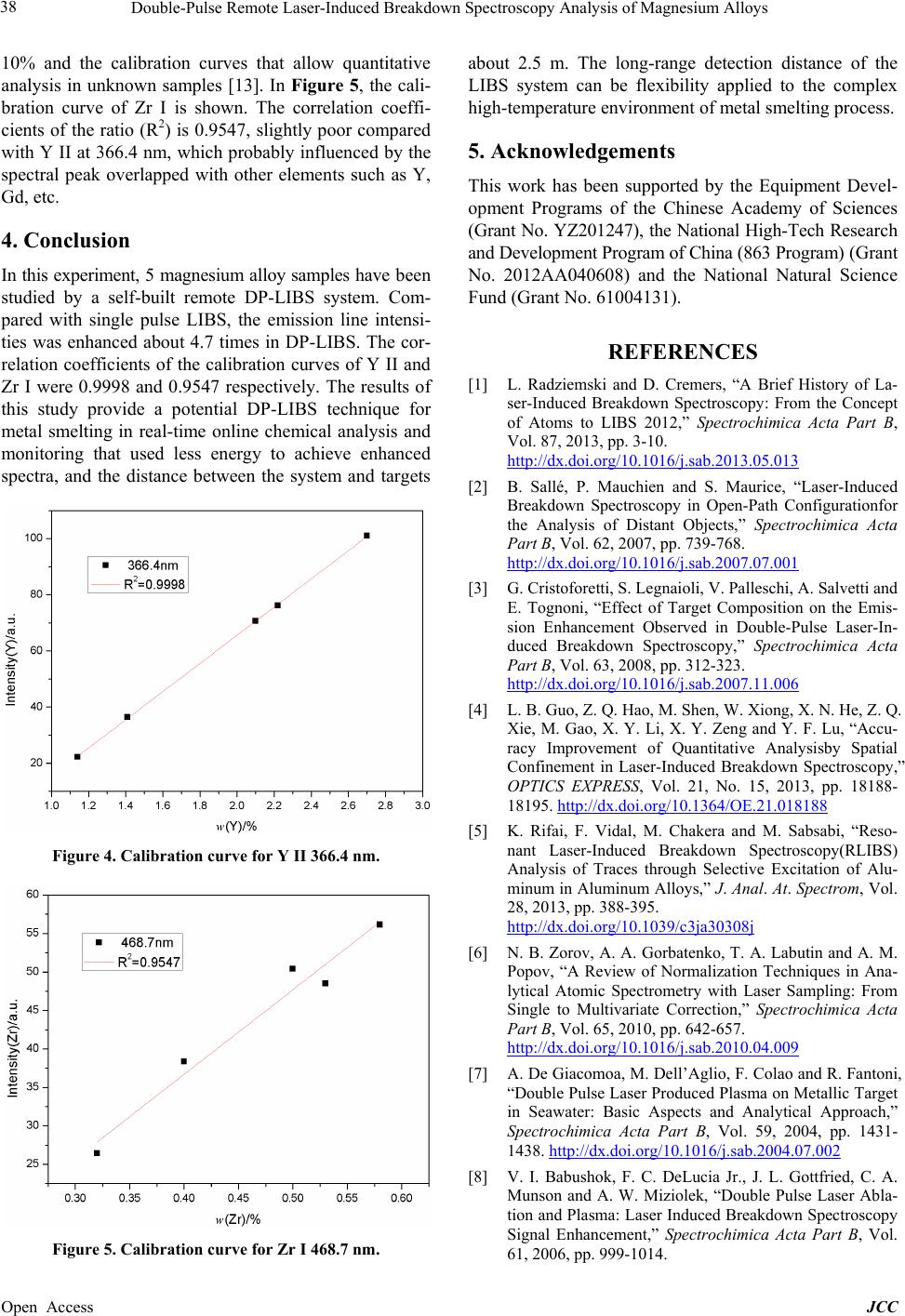

analysis in unknown samples [13]. In Figure 5, the cali-

bration curve of Zr I is shown. The correlation coeffi-

cients of the ratio (R2) is 0.9547, slightly poor compared

with Y II at 366 .4 nm, which probably influenced by the

spectral peak overlapped with other elements such as Y,

Gd, etc.

4. Conclusion

In this experiment, 5 magnesium alloy samples have been

studied by a self-built remote DP-LIBS system. Com-

pared with single pulse LIBS, the emission line intensi-

ties was enhanced about 4.7 times in DP-LIBS. The cor-

relation coefficients of the calibration curves of Y II and

Zr I were 0.9998 and 0.9547 respectively. The results of

this study provide a potential DP-LIBS technique for

metal smelting in real-time online chemical analysis and

monitoring that used less energy to achieve enhanced

spectra, and the distance between the system and targets

Figure 4. Calibration curve for Y II 366.4 nm.

Figure 5. Calibration curve for Zr I 468.7 nm.

about 2.5 m. The long-range detection distance of the

LIBS system can be flexibility applied to the complex

high-temperature environment of metal smelting process.

5. Acknowledgements

This work has been supported by the Equipment Devel-

opment Programs of the Chinese Academy of Sciences

(Grant No. YZ201247), the National High-Tech Research

and Development Program of China (863 Program) (Grant

No. 2012AA040608) and the National Natural Science

Fund (Grant No. 61004131).

REFERENCES

[1] L. Radziemski and D. Cremers, “A Brief History of La-

ser-Induced Breakdown Spectroscopy: From the Concept

of Atoms to LIBS 2012,” Spectrochimica Acta Part B,

Vol. 87, 2013, pp. 3-10.

http://dx.doi.org/10.1016/j.sab.2013.05.013

[2] B. Sallé, P. Mauchien and S. Maurice, “Laser-Induced

Breakdown Spectroscopy in Open-Path Configurationfor

the Analysis of Distant Objects,” Spectrochimica Acta

Part B, Vol. 62, 2007, pp. 739-768.

http://dx.doi.org/10.1016/j.sab.2007.07.001

[3] G. Cristoforetti, S. Legnaioli, V. Palleschi, A. Salvetti and

E. Tognoni, “Effect of Target Composition on the Emis-

sion Enhancement Observed in Double-Pulse Laser-In-

duced Breakdown Spectroscopy,” Spectrochimica Acta

Part B, Vol. 63, 2008, pp. 312-323.

http://dx.doi.org/10.1016/j.sab.2007.11.006

[4] L. B. Guo, Z. Q. Hao, M. Shen, W. Xiong, X. N. He, Z. Q.

Xie, M. Gao, X. Y. Li, X. Y. Zeng and Y. F. Lu, “Accu-

racy Improvement of Quantitative Analysisby Spatial

Confinement in Laser-Induced Breakdown Spectroscopy,”

OPTICS EXPRESS, Vol. 21, No. 15, 2013, pp. 18188-

18195. http://dx.doi.org/10.1364/OE.21.018188

[5] K. Rifai, F. Vidal, M. Chakera and M. Sabsabi, “Reso-

nant Laser-Induced Breakdown Spectroscopy(RLIBS)

Analysis of Traces through Selective Excitation of Alu-

minum in Aluminum Alloys,” J. Anal. At. Spectrom, Vol.

28, 2013, pp. 388-395.

http://dx.doi.org/10.1039/c3ja30308j

[6] N. B. Zorov, A. A. Gorbatenko, T. A. Labutin and A. M.

Popov, “A Review of Normalization Techniques in Ana-

lytical Atomic Spectrometry with Laser Sampling: From

Single to Multivariate Correction,” Spectrochimica Acta

Part B, Vol. 65, 2010, pp. 642-657.

http://dx.doi.org/10.1016/j.sab.2010.04.009

[7] A. De Giacomoa, M. Dell’Aglio, F. Colao and R. Fantoni,

“Double Pulse Laser Produced Plasma on Metallic Target

in Seawater: Basic Aspects and Analytical Approach,”

Spectrochimica Acta Part B, Vol. 59, 2004, pp. 1431-

1438. http://dx.doi.org/10.1016/j.sab.2004.07.002

[8] V. I. Babushok, F. C. DeLucia Jr., J. L. Gottfried, C. A.

Munson and A. W. Miziolek, “Double Pulse Laser Abla-

tion and Plasma: Laser Induced Breakdown Spectroscopy

Signal Enhancement,” Spectrochimica Acta Part B, Vol.

61, 2006, pp. 999-1014.