Estimation of the Temperature in the Weld Penetration Channel in Electron Beam Welding

Copyright © 2013 SciRes. JPEE

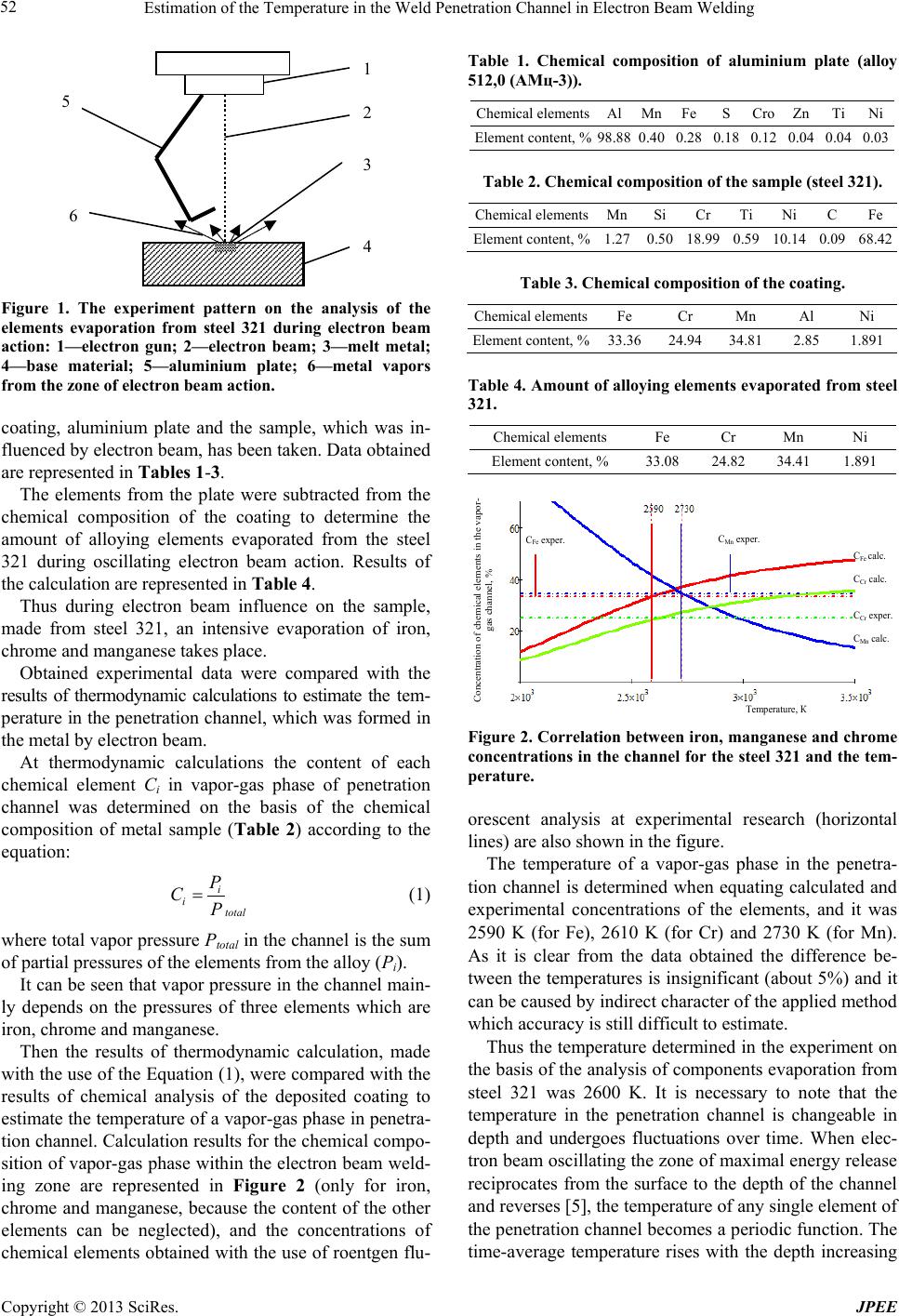

Figure 1. The experiment pattern on the analysis of the

elements evaporation from steel 321 during electron beam

action: 1—electron gun; 2—electron beam; 3—melt metal;

4—base material; 5—aluminium plate; 6—metal vapors

from the zone of electron beam action.

coating, aluminium plate and the sample, which was in-

fluenced by electron beam, has been taken. Data obtained

are represented in Tables 1-3.

The elements from the plate were subtracted from the

chemical composition of the coating to determine the

amount of alloying elements evaporated from the steel

321 during oscillating electron beam action. Results of

the calculation are represented in Table 4.

Thus during electron beam influence on the sample,

made from steel 321, an intensive evaporation of iron,

chrome and manganese takes place.

Obtained experimental data were compared with the

results of thermodynamic calculations to estimate the tem-

perature in the penetration channel, which was formed in

the metal by electron beam.

At thermodynamic calculations the content of each

chemical element Сi in vapor-gas phase of penetration

channel was determined on the basis of the chemical

composition of metal sample (Table 2) according to the

equation:

(1)

where total vapor pressure Ptotal in the channel is the sum

of partial pressures of the elements from the alloy (Рi).

It can be seen that vapor pressure in the channel main-

ly depends on the pressures of three elements which are

iron, chrome and manganese.

Then the results of thermodynamic calculation, made

with the use of the Equation (1), were compared with the

results of chemical analysis of the deposited coating to

estimate the temperature of a vapor-gas phase in penetra-

tion channel. Calculation results for the chemical comp o-

sition of vapor-gas phase within the electron beam weld-

ing zone are represented in Figure 2 (only for iron,

chrome and manganese, because the content of the other

elements can be neglected), and the concentrations of

chemical elements obtained with the use of roentgen flu-

Table 1. Chemical composition of aluminium plate (alloy

512,0 (AМц-3)).

Chemical elements Al Mn Fe S Crо Zn Ti Ni

Element content, % 98.88

0.40 0.28 0.18 0.12 0.04 0.04 0.03

Table 2. Chemical composition of the sample (steel 321).

Chemical elements Mn Si Cr Ti Ni C Fe

Element content, % 1.27 0.50 18.99 0.59 10.14 0.09 68.42

Table 3. Chemical composition of the coating.

Chemical elements Fe Cr Mn Al Ni

Element content, % 33.36 24.94 34.81 2.85 1.891

Table 4. Amount of alloying elements evaporated from steel

321.

Chemical elements Fe Cr Mn Ni

Element content, % 33.08 24.82 34.41 1.891

Figure 2. Correlation between iron, manganese and chrome

concentrations in the channel for the steel 321 and the tem-

perature.

orescent analysis at experimental research (horizontal

lines) are also shown in the figure.

The temperature of a vapor-gas phase in the penetra-

tion channel is determined when equating calculated and

experimental concentrations of the elements, and it was

2590 K (for Fe), 2610 K (for Cr) and 2730 K (for Mn).

As it is clear from the data obtained the difference be-

tween the temperatures is insignificant (about 5 %) and it

can be caused by indirect character of the applied method

which accuracy is still difficult to estimate.

Thus the temperature determined in the experiment on

the basis of the analysis of components evaporation from

steel 321 was 2600 K. It is necessary to note that the

temperature in the penetration channel is changeable in

depth and undergoes fluctuations over time. When elec-

tron beam oscillating the zone of maximal energy release

reciprocates from the surface to the depth of the channel

and reverses [5], the temperature of any single element of

the penetration channel becomes a periodic function. The

time -average temperature rises with the depth increasing

Concentration of chemical elemen ts in the vapor-

gas channel , %

С

Fe

calc.

C

Cr

calc.

С

Cr

exper.

C

Mn

calc.