Open Journal of Civil Engineering

Vol. 3 No. 3 (2013) , Article ID: 36202 , 8 pages DOI:10.4236/ojce.2013.33018

Performance of Structures Exposed to Extreme High Temperature—An Overview

Department of Civil Engineering, American University of Sharjah, Sharjah, UAE

Email: syehia@aus.edu, ghakas90@gmail.com

Copyright © 2013 Sherif Yehia, Ghanim Kashwani. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received April 21, 2013; revised May 21, 2013; accepted May 28, 2013

Keywords: Construction Material; Fire Resistance; Impact of Fire on Structures; Structural Performance

ABSTRACT

Strength, durability and stability are the main criteria for material selection and design in the construction industry. Consequently, development and enhancement of construction materials is always an active and attractive field for engineers and researchers. Elevated temperature (fire) is a potential threat for any structural buildings that can cause a major damage. Response of construction materials exposed to elevated temperature or fire requires a full study and analysis with lessons learned from previous cases. In this paper, properties of the common construction materials such as concrete, steel and composite structures under high temperature events is presented and discussed. In addition, performance of advanced materials, such as Fiber Reinforced Polymer (FRP) and Concrete Filled Tubular (CFT) when exposed to high temperature was discussed. Recommendations from different design codes to increase fire resistance of structures are introduced. Finally, damage assessment of several bridges and buildings found in the literature exposed to fire events is summarized.

1. Introduction

Sustainability of structures is a main concern in the construction industry. Exposure to fire or elevated temperature is an extreme condition that leads to change in materials properties, consequently, change in overall behavior is expected. Many research efforts were devoted toward evaluation of materials’ performance when exposed to fire and high temperature events. These efforts provide understanding to the change of the materials properties and recommend guidelines to enhance preference in such events. Therefore, the objective of this paper is to highlight the differences in behavior of different construction materials when exposed to elevated temperature. In addition, design recommendations and codes requirements are emphasized to recognize these differences.

Structures exposed to high temperature events (fire) are usually investigated to evaluate their structure integrity and performance. Several active and passive fire protection approaches could be taken to minimize or control the impact of fire on structures and their components; however, the change of materials properties and the loss of structure stiffness require comprehensive evaluation of the structure’s performance to recommend the subsequent actions.

Three main categories: material properties, structural evaluation, and recommendations to increase fire resistance of structures and minimize the impact of high temperature events on structures are discussed in this paper.

2. Materials Properties

Material properties such as thermal expansion, density, and thermal conductivity need to be evaluated carefully to understand the change of the materials performance under extreme high temperature events. In addition, properties of materials’ constituents such as aggregates in case of concrete, affect the overall material behavior under high temperature events. The commonly used materials in the construction industry are discussed in the following subsections.

2.1. Concrete

Concrete during high temperature event has a complex behavior due to the differences in coefficient of thermal expansion of each constitution. Proportioning of concrete mixtures to achieve high strength and maintaining durability requirements during service live led to production of dense concrete mixtures with less water-cementitious material ratio (w/cm). Therefore, mechanical properties of HSC at elevated temperature are different from that of conventional concrete in two main areas: first, strength loss in the intermediate temperature range 100˚C to 400˚C and second the occurrence of explosive spalling of the HSC. Strength loss should be considered by incorporating the code and design specifications during the design stage. In addition, explosive spalling of the HSC and loss of the concrete cover during fire leads to direct exposure of the steel reinforcement to heat leading to loss of overall structural capacity [1,2]. Therefore, high strength concrete (HSC) and normal strength concrete (NSC) will have a significant difference in fire performance. Several factors that affect the fire resistance of concrete are concrete strength, moisture content, concrete density, and aggregate type [3,4].

Concrete Strength: Concrete with compressive strength higher than 55 MPa (8000 Psi) is more subjected to spalling than that of less compressive strength. Spalling of concrete usually happens during the initial stages of the fire due to the buildup of water pressure in the matrix or the effect of various thermal expansions in the matrix. HSC has very low permeability and water-cement ratio, consequently, moisture escapes with a slow rate and pore pressure will increase. This will lead to a major reduction in load bearing capacity and loss of concrete section during fire events is expected. Therefore, HSC could have a higher chance to spall more than NSC [3,4].

Moisture Content: Fire resistance of concrete is affected by the existence of free moisture or exposure to different levels of humidity (RH). Existence of free moisture depends on the nature of coarse aggregate and exposure to humidity. If the RH level exceeds 80%, major spalling may occur for the concrete element during fire. The ability of the free moisture to move from the side exposed to fire to the colder side reduces the internal pressure, hence, reduces the occurrence of spalling. In the case of HSC, the moisture movement is limited due to the high density, therefore, it is more susceptible to spalling [4,5].

Concrete Density: HSC has a dense paste, low watercement ratio, and other supplementary materials such as silica fume. In general, concrete with dense paste is prone to spalling when exposed to fire. During fire, the rate of transmission of the high temperature to the concrete core is high that leads to rapid loss of concrete surface layers (spalling) [3,4].

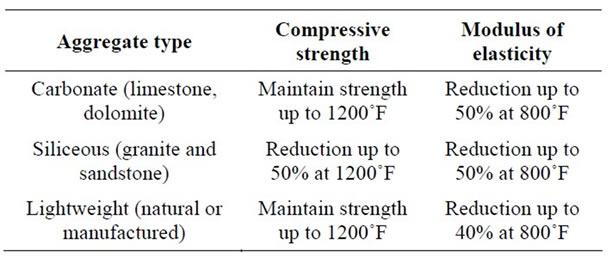

Type of Aggregate: 60% to 70% per volume of any concrete mixture is aggregate; therefore, change in the concrete proprieties is mainly affected by the type of coarse aggregates used in the mixture. Three types of aggregates are commonly used in the construction industry; carbonate, siliceous, and lightweight. Table 1 summarizes effect

Table 1. Effect of high temperature on concrete properties [6-8]. 1˚C = 33.8˚F.

of high temperature on compressive strength and modulus of elasticity of concrete based on aggregate type. In addition, specific heat and thermal conductivity are greatly affected by aggregate type. Thermal conductivity affects the rate of temperature increase in a case of a fire. Lightweight aggregate has lower thermal conductivity (0.577789317 Btu (IT) foot/hour/square foot/˚F at 0˚F) compared to other aggregate types. However, a reduction up to 50% of the thermal conductivity will happen at 650˚C for all aggregate types [6,7].

Fiber Reinforced Concrete

Steel fiber is usually added to concrete mixtures to improve plastic cracking characteristics, tensile and flexural strength, impact strength and control cracking. However, at elevated temperature steel fibers could reduce the fire resistance of the concrete structures. Polypropylene fiber or mix with steel fiber could be used to reduce the adverse effect of the steel fiber at elevated temperature [9,10].

2.2. Steel

Yield strength and modulus of elasticity of steel are reduced by about 12% to 14% when exposed to 482˚C temperatures, beyond this temperature a rapid decrease in both properties will happen. In addition, reduction in yield strength and modulus of elasticity at high temperature is also affected by the carbon percentage and stress level of the steel member [11].

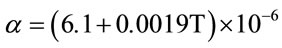

Other important property, coefficient of thermal expansion, also increases considerably as the steel temperature increases as expressed in Equation (1) [12]:

(1)

(1)

Where α is the coefficient of thermal expansion (in/in-˚F) and ∆T is the steel temperature rise above 100˚F.

2.2.1. Steel Reinforcement

Steel reinforcement if protected by the minimum cover specified by the code it is expected that the effect of high temperature on the reinforcement bars will be negligible. However, deformation due to thermal expansion and loss of bond between concrete and steel might cause the structure instability and affect the structural integrity [13-15].

2.2.2 High Strength Steel

Reduction in yield strength is related to the strain level; therefore, reduction in the yield strength of the high strength steel is smaller than that of the low strength steel. In addition, reduction in the modulus of elasticity is related to the carbon content of the high strength steel [10,16].

2.2.3. Cold Formed Steel

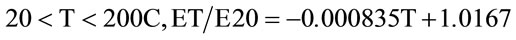

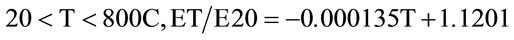

Cold formed steel structure when exposed to elevated temperature; the steel grade is the main parameter that controls the yield strength, while the steel thickness has a minor effect on the strength loss. In addition, there is no clear relationship between the elastic modulus and the steel grade or thickness, however, elastic modulus at elevated could be predicated by Equations (2) and (3) [17- 19]:

(2)

(2)

(3)

(3)

Where ET and E20 are the elastic modulus at elevated temperature and ambient temperature; respectively.

2.3. Composite Materials

To overcome some of the durability and steel corrosion problems, advances in the construction industry led to production of several new materials or introduction of new construction techniques, which are being used in many projects. Fiber Reinforced Polymer (FRP) is an example of the composite materials that showed good performance and provided the required mechanical properties. However, fire resistance and performance of composite materials when exposed to elevated temperature need to be evaluated.

Fiber Reinforced Polymer (FRP)

FRP bars are one of the top choices for high corrosion resistance in sever environmental conditions. However, FRP materials lose their strength and stiffness at early stage during fire. Wang et al. [20] conducted an experimental investigation to study the variations of strength and stiffness of carbon fiber reinforced polyester (CFRP) and glass fiber reinforced polyester (GFRP) compared to traditional steel bars. Their results showed that the critical temperature of FRP bars is about 343˚C; below this temperature the FRP bars can maintain about 90% of their original stuffiness. However, 35% to 45% reduction of the CFRP and GFRP original strength respectively happened at 343˚C. In addition, the stress-strain relationships of FRP bars remained almost linear at elevated temperatures until failure [20,21].

2.4. Composite Structures

2.4.1. Concrete Filled Tubular (CFT)

CFT consists of a concrete core confined by a steel tube. The confinement provided by the steel tube enhances the concrete properties and improves overall performance of the structural elements. In addition, high flexural load capacity, high seismic resistance and fast construction are some of the other advantages of using CFT in construction projects. However, performance of CFT when exposed to fire needs to be evaluated. Dimensions and slenderness of the tube, lower section factor (A/V ratio), direction of fire, and number of sides exposed to fire are some of the main factors that affect the fire resistance of a CFT section [22,23]. Numerical models and experimental studies showed that CFT columns have better performance than that of regular columns (steel or concrete) under elevated temperature due to its composite behavior [24,25]. This better performance could be explained by the dual action of the steel tube and the concrete core. When a CFT column is exposed to a fire, the load transfer will happen in two stages. In the first stage, the steel tube carries any additional stresses by the expansion of its cross section. However, when the temperature increases, the cross section starts to yield and a reduction in the compressive strength of the whole column occurs due to local buckling of the steel tube. This leads to the second stage, the load transfers from the steel tube to the concrete core and strength reduction continue with a slower rate because of the low thermal conductivity of the concrete until the column collapses either by buckling or compression failure [26].

2.4.2. Composite Concrete and Structure Steel

Composite concrete and structure steel sections usually consist of three main elements; reinforcement concrete (RC), steel, and studs (shear connectors) [27-29]. Fire resistance of a composite section is influenced by the behavior of all constituents:

Concrete Section: As discussed before spalling and exposure of steel reinforcement are major threat for concrete during fire. Buildup pressure and moisture movement are of a concern especially if steel plate is used at the bottom of the RC slab [28]. In addition, tension developed in the concrete slab and deformation of the supporting beams will lead to cracking and potential slippage near columns.

Structure Steel and Connections: Steel sections could be used as profile (sheet), beams, and columns. Local buckling of beam lower flange, shear in beam web, formation of plastic hinge, buckling of column flange in compression, fracture of the end-plate along the welds “connections”, elongation of holes in beam web, and excessive deformation are some of the possible damages of the steel cross sections during fire. These damages depend on direction of fire, location of the section, existence of restraining elements, and time of exposure [27, 28,30].

Shear Studs: Composite action between the RC and structural steel is usually achieved by shear studs. In addition, studs contribute to resistance of longitudinal shear (shank) and tensile loads normal to the interface (head). This can play a role in longitudinal slip. High strength and stiffness are required in the studs to ensure load transfer between the two sections. However, stiffness and capacity of the studs are reduced during high temperature events, which affect the overall performance of the composite section. In addition, number and arrangement of studs and existence of steel profile affect the slab-cracking pattern [29,31].

It is important to note that testing individual members provide information, which is used to improve codes and design requirements. However, interaction between members and connections that represents behavior of the structure as a whole cannot be clearly identified unless a full scale testing is conducted [29].

3. Structural Performance and Design Requirements

Performance (fire resistance) of any structure when exposed to fire depends on the material properties and insulation/barriers to withstand or to confine fire. However, fire resistance rating is an indicator about the expected fire resistance of a structure in half-hour or hourly increments [32].

Thermal expansion, structure end conditions (restrained or unrestrained), and loss of materials’ strength and stiffness affect the overall performance of a specific structure.

Concrete structures can have great performance during fire event if the concrete has lower thermal conductivity which leads to slower increase of the concrete temperature. Spalling of concrete during elevated temperature could affect the mechanical properties of concrete due to the increase of vapor pressure. This pressure leads to internal cracks and stress which exceeds the tensile strength of the concrete [6,32]. Hertz and Sørensen found that concrete does not spall if the moisture content was kept below 3% per weight, however, if the moisture content is greater than 3%, spalling/explosive spalling could be avoided by using cementations materials such as silica fume or fiber concrete [33].

For steel structures, strength, ductility, consistency of the steel material, shape of the structure and the applied load are important factors which should be observed for fire resistance calculation. The critical temperature depends on the load ratio and steel composition. The load ratio value is the ratio of the applied design load to that would generate a stress equal to yield stress at room temperature [12,34]. It is necessary to apply insulation material such as magnesia, vermiculite, sprayed mineral and ablative coatings to protect the steel structure from elevated temperature.

In composite structures, stresses and displacements caused by thermal expansion control the structural behavior in fire until just before failure reduction in materials’ strength and stiffness control the behavior again [35, 36].

3.1. Code and Specifications

Codes provide acceptable methods for determining the fire resistance of buildings, building assemblies, and structural elements for different construction materials (concrete, masonry, steel, wood, clay). The 2009 International Building Code (IBC 2009) [37] when calculating the fire resistance refers to the code requirements for fire resistance of concrete and masonry construction assemblies the (ACI 216.1-07/TMS-0216-07) [38] while for steel structures refers to the standard calculation methods for structural fire protection ASCE/SEI/SFPE 29-05- chapter 5 [39].

1) ACI 216.1-07/TMS-0216-07 The code provides four methods which could be considered when evaluating construction materials or assemblies; qualification by testing (according to ASTM E 119 [40]), calculated fire resistance (in accordance with ACI 216.1), approval through past experience (materials/assemblies which had history of acceptable performance), and alternative methods (encouraging new technology for predicting the life safety and property protection of structures) [38].

Minimum equivalent thickness (walls, floors, and roofs), minimum cover end condition (unrestrained or restrained), aggregate type, reinforcing steel type, nonprestressed or prestressed, structure type (floor, roof slabs, beams), number of layers, insulation materials used, and minimum column size are considered when determining the fire resistance rating for concrete structures.

2) ASCE/SEI/SFPE 29-05 The standard provides methods to calculate the fire resistance for structural members as an alternative to the ASTM E119 standard fire test [40]. Chapter 5 deals with structural steel construction which covers columns, beams, girders, and trusses. The fire resistance rating for steel column is based on the weight, heated perimeter, and type of protection material used. However, the standard provides procedures for beams and girders have different size from the approved fire resistance assemblies. The procedure considers the thickness of the protection material, weight of the beam or girder, in addition to the heated perimeter. In case of steel trusses, the thickness of the protection for each member should be determined following the same procedures for columns. However, for trusses support floors or roof, the beam/girder procedures should be followed [39].

3) Eurocode [41-45]

Similar to the ACI 261.1 and ASCE/SEI/SFPE 29-05 codes the Eurocode provide guidelines and recommendations to identify the differences from the regular normal temperature design. Eurocode 1 Part (1-2) (EN 1992- EN1996) is a general rules for fire resistance should be considered during design of any structure.

Eurocode 2 Part 1-2 (EN 1992-1-2) for concrete structures provides detailed calculations and models to account for the effect of high temperatures.

Eurocode 3 Part 1-2 (Eurocode 3-1-1, EN 1991-2-2) offers general structural fire design rules for steel structures which deal with the deformation criteria under fire conditions, material properties at elevated temperature, fire design for connections, classification of cross sections, and effect of non-uniform temperature distribution on the mechanical resistance of beams.

Composite steel and concrete structures when exposed to elevated temperature should be designed according to the Eurocode 4 (EN1994-1-2, EN 1991-2-2).

3.2. Analytical Models

Many analytical and experimental research efforts are conducted to help predicting the fire resistance of con-

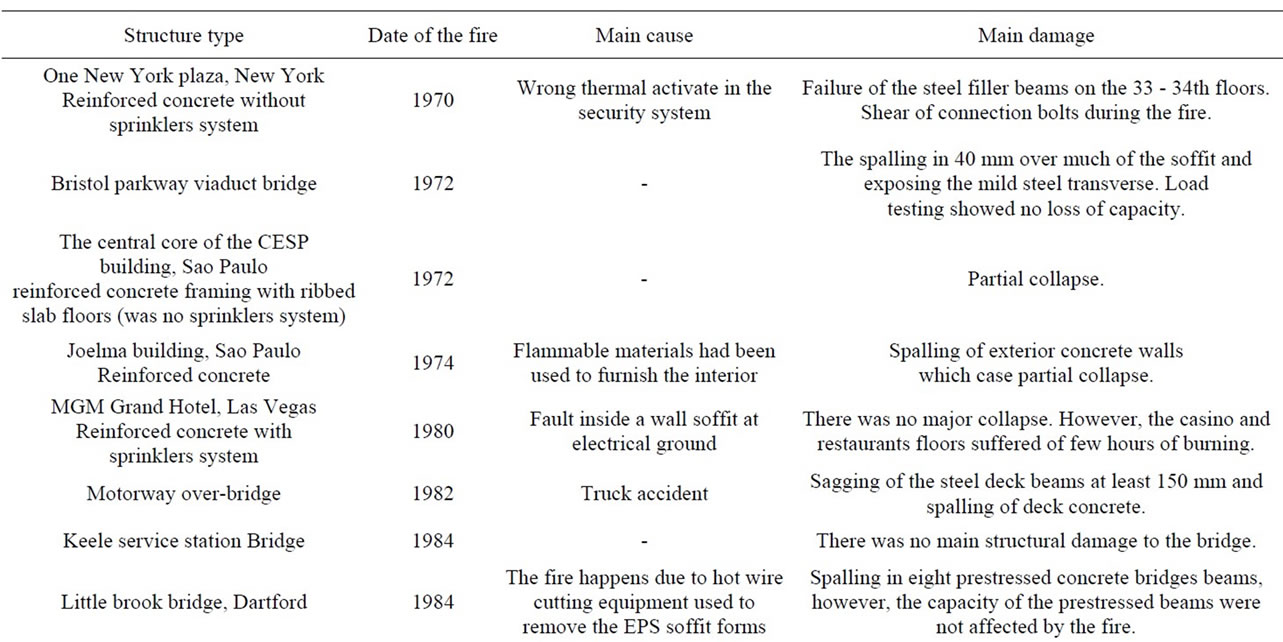

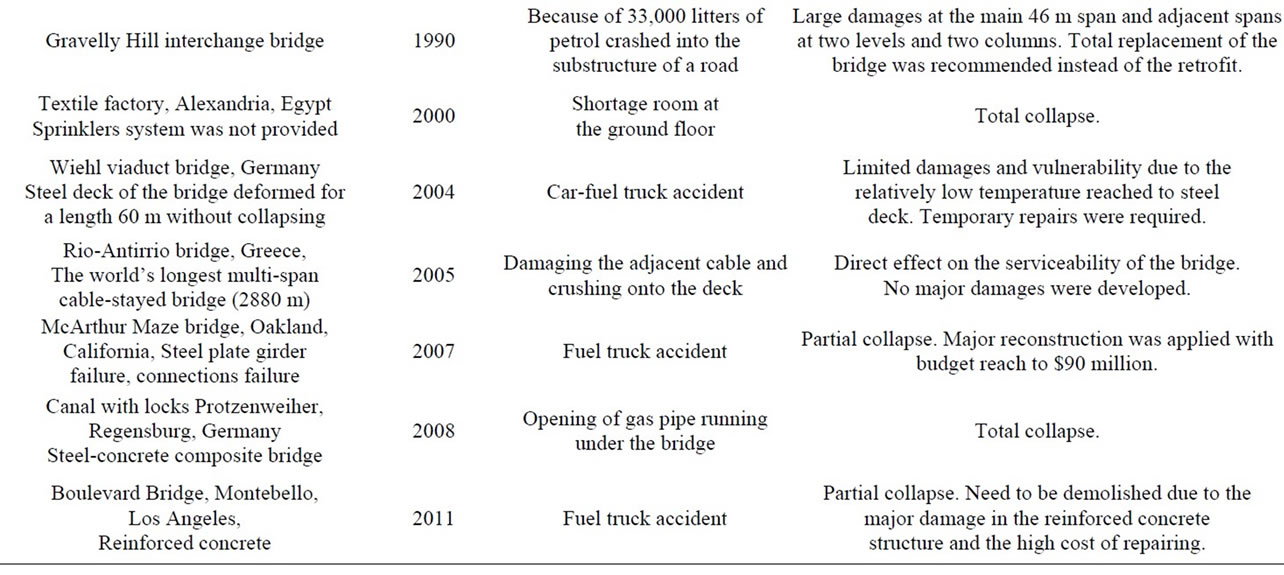

Table 2. Summary of some structures (bridges and multi-story buildings) exposed to fire events [52-55].

struction materials or assemblies. The main objective of these analytical investigations is to provide understanding of the construction materials/assemblies behavior when exposed to elevated temperature specially, the experimental research requires special testing environment [46-51].

4. Lessons Learned from Previous Events

Table 2 summarizes some of the accidental fire cases for bridges and multi-story buildings found in the literature. Every fire case is different (cause of fire, exposure time to the elevated temperature), however; several cases survived the fire because of the adequate cover which was provided during design stages [52,53].

5. Conclusion

This study presents an overview of the research efforts that were devoted to investigate behavior of the commonly used construction materials under elevated temperature events. Several experimental investigations, numerical models and design requirements were included in the survey. In addition, behavior of composite structures was discussed. Temperature level, exposure time, protection, and methods used to control a fire have great impact on the performance of structures during and after fire. Fire resistance of structural members should be considered during the design stage to meet certain behavior and performance if exposed to accidental fire. Many research efforts in addition to the codes and specifications provide guidelines to account for the change in the material properties when exposed to elevated temperature. Most of the research motivations come from lessons learned from previous events.

REFERENCES

- C. Castillo and A. J. Durrani, “Effect of Transient High Temperature on High-Strength Concrete,” ACI Materials Journal, Vol. 87, No 1, 1990, pp. 47-53.

- L. T. Phan, “Pore Pressure in High Strength Concrete at High Temperature,” Proceedings of the 3rd International Conference on Construction Materials: Performance, Innovations and Structural Implications, Vancouver, 2005.

- “Fire Safety of Concrete Buildings,” Cement Concrete & Aggregates Australia, 2010.

- V. Kodur, “Fire Performance of High-Strength Concrete Structural Members,” Institute for Research in Construction, Ottawa, 1999.

- D. R. Flynn, “Response of High Performance Concrete to Fire Conditions: Review of Thermal Property Data and Measurement,” Techniques Report NIST GCR 99-767.

- E. Ashley, “Fire Resistance of Concrete Structure,” National Ready Mixed Concrete Association, 2007, pp. 67- 70. http://www.nrmca.org/research/FireResistance_CIF_Winter_07.pdf

- J. A. Purkiss, “Fire Safety Engineering Design of Structures,” Butterworth-Heinemann, Jordon Hill, Oxford, 1996.

- D. N. Bilow and M. R. Kamara, “Fire and Concrete Structures,” Structures 2008: Crossing Borders, ASCE 2008.

- J. P. Rodrigues, L. Laím and A. M. Correia, “Behavior of Fiber Reinforced Concrete Columns in Fire,” Composite Structures, Vol. 92, No. 5, 2010, pp. 1263-1268. doi:10.1016/j.compstruct.2009.10.029

- T. Kasper, C. Edvardsen, G. Wittneben and D. Neumann, “Lining Design for the District Heating Tunnel in Copenhagen with Steel Fiber Reinforced Concrete Segments,” Tunneling and Underground Space Technology, Vol. 23, No. 5, 2008, pp. 574-587. doi:10.1016/j.tust.2007.11.001

- S. Somayaji, “Civil Engineering Materials,” 2nd Edition, Prentice Hall, 2001.

- R. G. Zalosh, “Industrial Fire Protection Engineering,” Wiley, Hoboken, 2003.

- R. H. Haddad, R. J. Al-Saleh and N. M. Al-Akhras, “Effect of Elevated Temperature on Bond between Steel Reinforcement and Fiber Reinforced Concrete,” Fire Safety Journal, Vol. 43, No. 5, 2008. pp. 334-343. doi:10.1016/j.firesaf.2007.11.002

- Eurocode 2, “Design of Concrete Structures: Part 1.2: General Rules—Structural Fire Design,” European Committee for Standardization, Brussels, BS EN 1992-1-2, 2004.

- A. Y. Elghazouli, B. A. Izzuddin and K. A. Cashell, “Experimental Evaluation of the Mechanical Properties of Steel Reinforcement at Elevated Temperature,” Fire Safety Journal, Vol. 44, No. 6, 2009, pp. 909-919. doi:10.1016/j.firesaf.2009.05.004

- J. P. Rodrigues, L. Laím and A. M. Correia, “Behavior of Fiber Reinforced Concrete Columns in Fire,” Composite Structures, Vol. 92, No. 5, 2010. pp. 1263-1268. doi:10.1016/j.compstruct.2009.10.029

- N. D. Kankanamge and M. Mahendran, “Mechanical Properties of Cold-Formed Steels at Elevated Temperatures,” Thin-Walled Structures, Vol. 49, No. 1, 2011. pp. 26-44. doi:10.1016/j.tws.2010.08.004

- J. H. Lee, M. Mahendran and P. Makelainen, “Prediction of Mechanical Properties of Light Gauge Steels at Elevated Temperatures,” Journal of Constructional Steel Research, Vol. 59, No. 12, 2003, pp. 1517-1532. doi:10.1016/S0143-974X(03)00087-7

- J. Chen and B. Young, “Experimental Investigation of Cold-Formed Steel Material at Elevated Temperature,” Thin-Walled Structures, Vol. 45, No. 1, 2007, pp. 96-110. doi:10.1016/j.tws.2006.11.003

- Y. C. Wang, P. M. H. Wong and V. Kodur, “An Experimental Study of the Mechanical Properties of Fiber Reinforced Polymer (FRP) and Steel Reinforcing Bars at Elevated Temperatures,” Composite Structures, Vol. 80, No. 1, 2007, pp. 131-140. doi:10.1016/j.compstruct.2006.04.069

- A. Abbasi and P. Hogg, “Temperature and Environmental Effects on Glass Fiber Rebar: Modulus, Strength and Interfacial Bond Strength with Concrete,” Composites: Part B, Vol. 36, No. 5, 2005, pp. 394-404. doi:10.1016/j.compositesb.2005.01.006

- A. Espinos, L. Gardner, M. L. Romero and A. Hospitaler, “Fire Behavior of Concrete Filled Elliptical Steel Columns,” Thin-Walled Structures, Vol. 49, No. 2, 2011, pp. 239-255. doi:10.1016/j.tws.2010.10.008

- M. Yu, X. Zha, J. Ye and Y. Li, “Fire Responses and Resistance of Concrete-Filled Steel Tubular Frame Structures,” International Journal of Structural Stability and Dynamics, Vol. 10, No. 2, 2009, pp. 253-271.

- V. Moliner, A. Espinos, M. Romero and A. Hospitaler, “Fire Behavior of Eccentrically Loaded Slender High Strength Concrete-Filled Tubular Columns,” Journal of Constructional Steel Research, Vol. 83, 2013, pp. 137- 146. doi:10.1016/j.jcsr.2013.01.011

- Q.-H. Tan, L.-H. Han and H.-X. Yu, “Fire Performance of Concrete Filled Steel Tubular (CFST) Column to RC Beam Joints,” Fire Safety Journal, Vol. 51, 2012, pp. 68- 84. doi:10.1016/j.firesaf.2012.03.002

- A. Espinos, M. L. Romero and A. Hospitaler, “Advanced Model for Predicting the Fire Response of Concrete Filled Tubular Columns,” Journal of Constructional Steel Research, Vol. 66, No. 8-9, 2010, pp. 1030-1046. doi:10.1016/j.jcsr.2010.03.002

- Z. Ma and P. Mäkeläinen, “Behaviour of Composite Slim Floor Structures in Fire,” Journal of Structural Engineering, Vol. 126, No. 7, 2000, pp. 830-837. doi:10.1061/(ASCE)0733-9445(2000)126:7(830)

- Z. Huang, I. W. Burgess and R. J. Plank, “The Influence of Shear Connectors on the Behavior of Composite SteelFramed Buildings in Fire,” Journal of Constructional Steel Research, Vol. 51, No. 3, 1999, pp. 219-237. doi:10.1016/S0143-974X(99)00028-0

- F. Wald, L. Simões da Silva, D. Moorec, T. Lennon, M. Chladna, A. Santiago, M. Benes and L. Borges, “Experimental Behavior of a Steel Structure under Natural Fire,” Fire Safety Journal, Vol. 41, 2006, pp. 509-522. doi:10.1016/j.firesaf.2006.05.006

- T. Hozjan, M. Saje, I. Planinc, S. Srpčič and S. Bratina, “Behavior of a Composite Concrete Trapezoidal Steel Plate Slab in Fire,” Open Journal of Civil Engineering, 2010.

- L. C. Leston-Jones, “The Influence of Semi-Rigid Connections on the Performance of Steel Framed Structures in Fire,” Ph.D. Dissertation, University of Sheffield, 1997.

- ACI 216.1-07/TMS-0216-07, “Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies,” American Concrete Institute, 2007.

- K. D. Hertz and L. S. Sørensen, “Test Method for Spalling of Fire Exposed Concrete,” Fire Safety Journal, Vol. 40, No. 5, 2003, pp. 466-476. doi:10.1016/j.firesaf.2005.04.001

- K. Yang, H. Lee and O. Chan, “Experimental Study of Fire-Resistant Steel H-Columns at Elevated Temperature,” Journal of Constructional Steel Research, Vol. 62, No. 6, 2006, pp. 544-553. doi:10.1016/j.jcsr.2005.09.008

- A. S. Usmani, J. M. Rotter, S. Lamont, A. M. Sanad and M. Gillie, “Fundamental Principles of Structural Behavior under Thermal Effects,” Fire Safety Journal, Vol. 36, No. 8, 2001, pp. 721-744. doi:10.1016/S0379-7112(01)00037-6

- A. M. Sanad, J. M. Rotter, A. S. Usmani and M. A. Connor, “Composite Beams in Large Buildings under Fire— Numerical Modeling and Structural Behavior,” Fire Safety Journal, Vol. 35, No. 3, 2000, pp. 165-188. doi:10.1016/S0379-7112(00)00034-5

- International Code Council, “2009 International Building Code (IBC 2009),” Country Club Hills, 2009.

- ACI/TMS Standard, “Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies (ACI 216.1-07/TMS-0216-07),” American Concrete Institute, Farmington Hills, 2007.

- American Society of Civil Engineers, “Standard Calculation Methods for Structural Fire Protection (ASCE/SEI/ SFPE 29-05),” Reston, 2007.

- ASTM E119-10b, “Standard Test Methods for Fire Tests of Building Construction and Materials,” ASTM International, West Conshohocken, 2003. www.astm.org

- L. R. Taerwe, “Fire Design of Concrete Structures According to the Eurocodes: A Review,” ACI SP-255-4, 2008.

- L. Twilt, “The New Eurocode on Fire Design of Steel Structures,” The International Seminar on Steel Structures in Fire, Shanghai, 1-3 November 2001.

- Eurocode-Resouces.com, 2011. www.eurocode-resources.com

- ENV 1993-1-2, “Eurocode 3: Design of Steel Structures,” Part 1-2: General Rules, Structural Fire Design, CEN, 2006.

- EN1994-1-2, “Eurocode 4: Design of Composite Steel and Concrete Structures,” 2005.

- C. Gutiérrez-Montesa, E. Sanmiguel-Rojasa, A. S. Kaiserb and A. Viedmab, “Numerical Model and Validation Experiments of Atrium Enclosure Fire in a New Fire Test Facility,” Building and Environment, Vol. 43, No. 11, 2008, pp. 1912-1928. doi:10.1016/j.buildenv.2007.11.010

- V. K. R. Kodur and M. Dwaikat, “A Numerical Model for Predicting the Fire Resistance of Reinforced Concrete Beams,” Cement and Concrete Research, Vol. 30, No. 5, 2008, pp. 431-443. doi:10.1016/j.cemconcomp.2007.08.012

- M. B. Dwaikat and V. K. R. Kodur, “A Numerical Approach for Modeling the Fire Induced Restraint Effects in Reinforced Concrete Beams,” Fire Safety Journal, Vol. 43, No. 11, 2008, pp. 291-307. doi:10.1016/j.firesaf.2007.08.003

- V. K. R. Kodur and N. K. Raut, “Fire Resistance of Reinforced Concrete Columns—State-of-the-Art and Research Needs,” ACI SP-255-4, 2008.

- H. M. Ali, P. E. Senseny and R. L. Alpert, “Lateral Displacement and Collapse of Single-Story Steel Frames in Uncontrolled Fire,” Engineering Structures, Vol. 26, No. 5, 2004, pp. 593-607. doi:10.1016/j.engstruct.2003.12.007

- A. Y. Elghazouli and B. A. Izzuddin, “Analytical Assessment of the Structural Performance of Composite Floors Subject to Compartment Fires,” Fire Safety Journal, Vol. 36, No. 8, 2001, pp. 769-793. doi:10.1016/S0379-7112(01)00039-X

- G. P. Mallett, “State-of-the-Art Review-Repair of Concrete Bridges,” Thomas Telford, London, 1994.

- J. J. Beitiel and N. R. Iwankiw, “Historical Survey of Multi-Story Building Collapses Due to Fire,” FPE 3rd Quarter, 2005.

- L. Giuliani, C. Crosti and F. Gentili, “Vulnerability of Bridges to Fire,” Proceedings of the 6th International Conference on Bridge Maintenance, Safety and Management, Stresa, 8-12 July 2012.

- J. Scheer, “Failed Bridges Case Studies and Consequences,” Ernts & Sohn, Berlin, 2010.