Paper Menu >>

Journal Menu >>

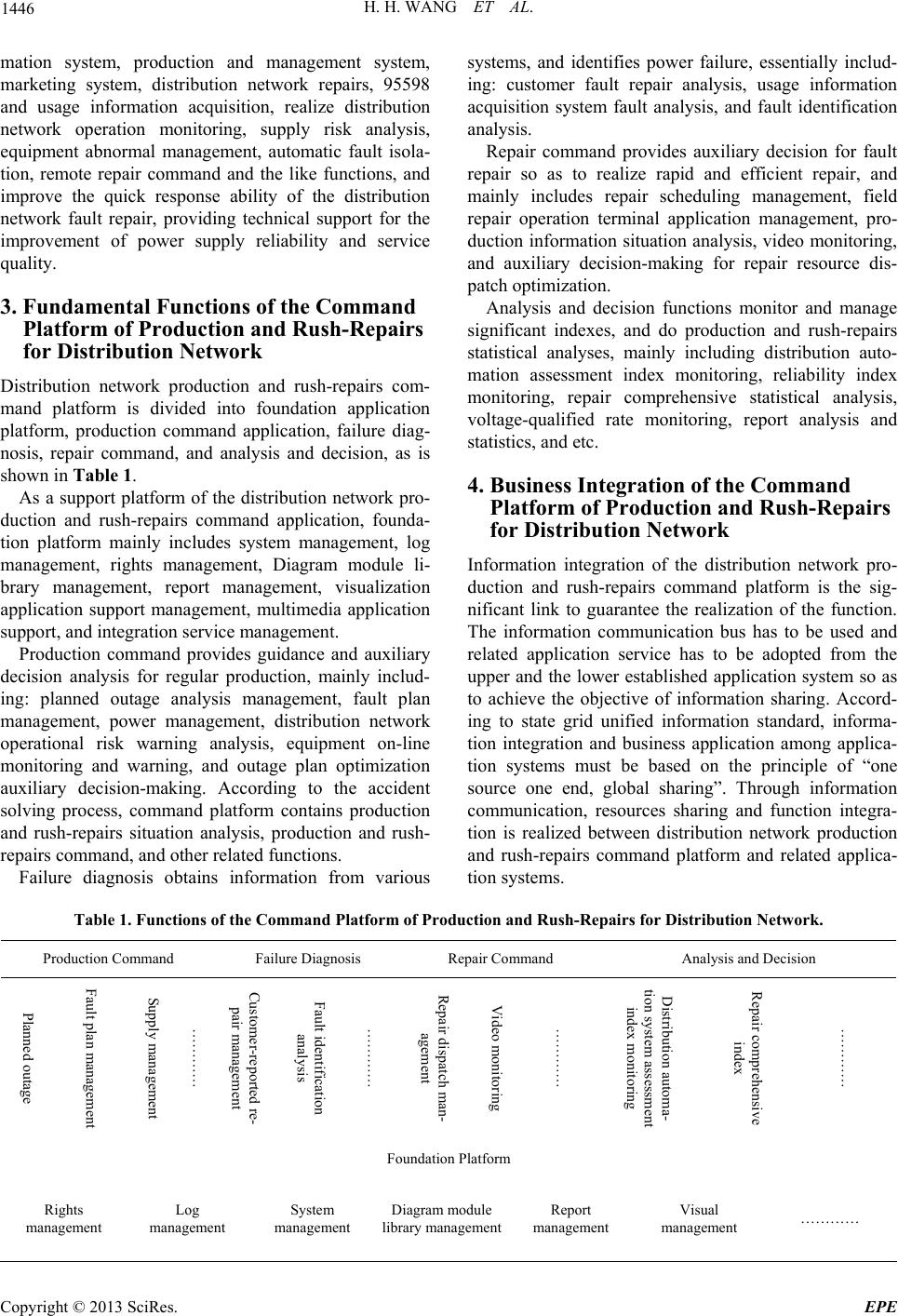

Energy and Power Engineering, 2013, 5, 1445-1448 doi:10.4236/epe.2013.54B274 Published Online July 2013 (http://www.scirp.org/journal/epe) Review on the Command Platform of Product i on an d Rush-Repairs for Distribution Network Honghao Wang, Jing Zhou, Wenbin Zhang, Xinhe Chen, Chao Zhang State Grid Electric Power Research Institute, Beijing, China Email: wanghonghao@sgeprissgcc.com.cn, zhoujing_0419@126.com Received September, 2012 ABSTRACT The command platform of production and rush-repairs for distribution Network is a supporting platform, based on in- formation technology, for the business applications of the command center. This article briefly described the basic func- tions and structural features of the platform, and discussed in detail the integration of business information, the contents and solutions needed to be focused on during inter-system data exchange, and the implementation techniques of the command platform. The benefits of the platform in the improvement of the distribution network production and rush-repairs are finally summed up. The entire above are provided as references. Keywords: Production and Rush-Repairs; Information Integration; Service-Oriented; Severity 1. Introduction The key business of the distribution network production is distribution network assets operation and maintenance which include equipment management, defect manage- ment, patrol inspection, fault repair, field operation, and instruments management, involving other related busi- ness such as outage management, power management, and etc. With continuous investment in information construc- tion of power grid company, support has been realized from information for most production and management business in recent years, e.g., PMS realized the equip- ment management, defect management, patrol manage- ment, and etc. In the fundamental platform construction, electric power companies have mostly constructed GIS system and dispatching automation system. Distribution network automation has been under construction during the past two years. However, information support is rela- tively weak for production and fault repair business. The following problems still exist in current power company: 1) Lacking of unified technique for production com- mand: production and management personnel cannot timely master and check production operation situation. Operation crew cannot effectively master and check equipment information, real time information, and opera- tion relate d in f ormation of distribution network. 2) Operation field is not connected to PMS, DMS, and the like system information: PMS realizes all-life cycle management and related patrol repair and other produc- tion business for distribution network equipment, but it cannot share information with field production operation. Even though mobile operation technology is adopted, mainly off-line, real-time interaction cannot be realized to support ope ration fiel d. 2. Propose of the Command Platform of Production and Rush-Repairs for Distribution Network In 2011, State Grid issued distribution 156 document[1], where standardized rush-repair for distribution network is put forward: aggressively develop distribution network production standardization management, distribution network state management, online operation, standard- ized rush-repair operation and the like system construc- tion; strengthen management of the entire process of the distribution network production; comprehensively im- prove the work quality of the distributio n network opera- tion, maintenance, repair and technical reform; fo rm sys- tematic and organizational guarantee for the improve- ment of the supply reliability and serv ice quality. With the progression of standardization, distribution network command organization has a larger and larger demand on information acquisition, integrated command, and unified resources dispatch. In 2012, state grid pro- duction technology department promulgated the con- struction of practical and efficient distribution production and rush-repairs command platform[2] so as to improve the function of the information communication bus, strengthen resources integration of the geographic infor- Copyright © 2013 SciRes. EPE  H. H. WANG ET AL. 1446 mation system, production and management system, marketing system, distribution network repairs, 95598 and usage information acquisition, realize distribution network operation monitoring, supply risk analysis, equipment abnormal management, automatic fault isola- tion, remote repair command and the like functions, and improve the quick response ability of the distribution network fault repair, providing technical support for the improvement of power supply reliability and service quality. 3. Fundamental Functions of the Command Platform of Production and Rush-Repairs for Distribution Network Distribution network production and rush-repairs com- mand platform is divided into foundation application platform, production command application, failure diag- nosis, repair command, and analysis and decision, as is shown in Table 1. As a support platform of the distribution network pro- duction and rush-repairs command application, founda- tion platform mainly includes system management, log management, rights management, Diagram module li- brary management, report management, visualization application support management, multimedia application support, and integration service management. Production command provides guidance and auxiliary decision analysis for regular production, mainly includ- ing: planned outage analysis management, fault plan management, power management, distribution network operational risk warning analysis, equipment on-line monitoring and warning, and outage plan optimization auxiliary decision-making. According to the accident solving process, command platform contains production and rush-repairs situation analysis, production and rush- repairs command, and other related functions. Failure diagnosis obtains information from various systems, and identifies power failure, essentially includ- ing: customer fault repair analysis, usage information acquisition system fault analysis, and fault identification analysis. Repair command provides auxiliary decision for fault repair so as to realize rapid and efficient repair, and mainly includes repair scheduling management, field repair operation terminal application management, pro- duction information situation analysis, video monitoring, and auxiliary decision-making for repair resource dis- patch optimization. Analysis and decision functions monitor and manage significant indexes, and do production and rush-repairs statistical analyses, mainly including distribution auto- mation assessment index monitoring, reliability index monitoring, repair comprehensive statistical analysis, voltage-qualified rate monitoring, report analysis and statistics, and etc. 4. Business Integration of the Command Platform of Production and Rush-Repairs for Distribution Network Information integration of the distribution network pro- duction and rush-repairs command platform is the sig- nificant link to guarantee the realization of the function. The information communication bus has to be used and related application service has to be adopted from the upper and the lower established application system so as to achieve the objective of information sharing. Accord- ing to state grid unified information standard, informa- tion integration and business application among applica- tion systems must be based on the principle of “one source one end, global sharing”. Through information communication, resources sharing and function integra- tion is realized between distribution network production and rush-repairs command platform and related applica- tion systems. Table 1. Functions of the Command Platform of Production and Rush-Repairs for Distribution Netw or k. Production Command Failure Diagnosis Repair Command Analysis and Decision Planned outage Fault plan management Supply management ………… Customer-reported re- pair management Fault identification analysis ………… Repair dispatch man- agement Video monitoring ………… Distribution automa- tion system assessment index monitoring Repair comprehensive index ………… Foundation Platform Rights management Log management System management Diagram module library managementReport management Visual management ………… Copyright © 2013 SciRes. EPE  H. H. WANG ET AL. 1447 Distribution network production and rush-repairs command platform realizes information communication with marketing systems, 95598, distribution automation, usage information acquisition, PMS, GIS and other re- lated systems through information communication bus which is in the accordance with distribution automation information communication standard. Production and rush-repairs command are core applications, and infor- mation integration application is realized. 1) Integration with GIS Distribution network production and rush-repairs command platform receives diagram and module data through the GIS system interface. Distribution network topology information and map information is visualized in the command platform. And network topolog y simula- tion analysis is realized by GIS topology information. Data interactive method is request response. 2) Integration with PMS Distribution network production and rush-repairs command platform receives outage plan, work ticket, scheduling command ticket, equipment defect, account information, and other information from PMS interface. Interactive method is request response. And the com- mand platform will feed the fault, fault treatment, and other related information back to the PMS system. Inter- active method is PMS push. In addition, the platform also has access to PMS interface for distribution network on-line monitoring information, such as distribution network equipment online temperature, sub-section post environment, and SF6 gas concentration. 3) Integration with distribution automation system Distribution automation system pushes switch position information, fault and its treatment information to distri- bution network production and rush-repair command platform through the information communication bus. The command platform obtains switch state section on demand. Data interactive method is active push by dis- tribution automation. 4) Integration with dispatching automation system Distribution network production and rush-repairs com- mand platform receives main network real-time informa- tion from dispatching automation system interface. Dis- patching automation system releases the following in- formation through the bus: switch deflection information (real-time), fault information (real-time), and real-time information section (fixed cycle, such as 30 minutes). Data interactive method is active push by dispatching automation system. 5) Integration with marketing system Marketing system (CIS) provides equipment account inquiry service, customer file inquiry service, important customer information, and etc. for distribution network production and rush-repair command platform. Interac- tive method is request response. 6) Integration with 95598 systems Distribution network production and rush-repair com- mand platform receives real-timely distribution system fault repair work order form 95598 system, and feeds repair process information back to the 95598 system. Interactive method is active push by 95598 system. 95598 systems also provides power failure inquiry ser- vice and release of power failure analysis results. 7) Integration with electric energy data acquisition sys- tem Electric energy data acquisition system actively finds out abnormal distribution network power supply, real- timely analyzes fault location together with PMS and GIS platforms, pushes fault location information to the command platform, assists repair commander determine whether it is distribution fault or not, precisely locates fault range, and provides service support for 95598 sys- tem. Interactive method is active push. 8) Integration with vehicle management system Vehicle management system sends vehicle location information to production and rush-repairs command platform. Interactive way is active push by vehicle man- agement system. 9) Integration with inventory management system Production and rush-repairs command platform re- ceives instrument inv entory information. Data interactive method is request response. 5. Implementation Techniques of the Com- mand Platform of Production and Rush-Repairs for Distribution Network Distribution network production and rush-repairs com- mand platform should be built in the city-level power supply company [3], coup led integrated with related sys- tems by data communication bus or data center. Ser- vice-oriented architecture (SOA) is adopted and service is released through the bus. Models and interactive stan- dards comply with the IEC61970/61968-CIM and SG- CIM standards and specifications. Resources of original information systems can be made full use of. Construc- tion costs can be reduced as well as construction period. And comprehensive benefit of information system appli- cation can be improved. 4.1. Service Oriented Architecture Service-oriented architecture (SOA) is an emerging technology solution to enterprise application integration. It retrieves discrete business functions of enterprise ap- plication, and organizes them into an interactive, stan- dard-based service. SOA offers a flexible and efficient system integration scheme by providing services to the enterprise. It combines and reuses modular and portable service in the composite application to meet business Copyright © 2013 SciRes. EPE  H. H. WANG ET AL. 1448 needs rapidly. Service, which refers to the function of defining interface specification (including format and transmission protocol) based on the open and neutral standard, is the most important part of the SOA system. Because interface specification has no relation to the specific hardware platform, operating system, and pro- gramming language, the caller and service provider can communicate in a unified and standard way. And service acts as a link connecting various business applications, technical standards, and implementation technologies. 4.2. Data Communication Bus Data communication bus responses for the data transmis- sion channel across isolation, interfaces with upper ap- plication system using standard web service interface, JMS message and etc., and supports transparent data transmission among upper application systems. From the viewpoint of the network, work completed in information interaction bus basically belongs to the transport layer, and transfers, but not analyzes the data of the upper ap- plication system. When application system transfers data through the bus, interface program should be developed and data should be encapsulated and analyzed in accor- dance with the interface format agreed to the bus. 4.3. Information Integration Technology Information integration is a management process, which is based on the trend of information development, and led by certain organization, to realize orderly, shared, and controllable information resources, and further informa- tion resource configuration optimization, to broaden the application fields of the information resources, and to maximize the information value. The purpose of the in- formation integration is to realize sending the right in- formation to the right user in the right time, in the right way, and in the distributed environment. Integration ar- chitecture is shown below. 4.4. Portal Technology Considering the function of the production and rush- repairs command platform as a production command center, its own content need to be displayed, besides, interface information of the other systems need to be in- tegrated in the future. Portal technology will be adopted. The interface demonstration is combined with GIS, charts, Gantt chart, instrument panel, and etc., through dynamic pages to meet the display demand of different roles (leaders, business specialties, and etc.). As a comprehensive platform across multiple profes- sional fields, distribution network production and rush- repairs command platform has to combine and integrate with multiple professional systems in various levels. It will be a challenge to make full use of the information resources of the professional systems, and at the same time consider personal view of different business domain users. Interface integration will be one of the important techniques to combine the system with different profess- sional applications. 5. Conclusions The covered area of the distribution network production is expanded in the context of the Three-Integrated and Five-Big, and professionalization rises up the operation requirement of maintenance and repair. Technical sup- port is lacked for the unified management of production operation. Existing information flow and interaction must be accelerated to improve the efficiency of production operation. Distribution network production and rush-repairs command platform helps command staff grasp produc- tion operation information, including th e involved people, tools, and etc. The field operation condition can be very intuitively monitored in the platform. And interaction is realized among the crew. Therefore, the platform will be one with artificial intelligence, scientific analysis, opera- tion simplification, and application practiced production and repair management platform. And it will further strengthen distribution network production and rush- repairs command, improve distribution network repair efficiency, and continuously rise up power supply reli- ability and service lev el. REFERENCES [1] “Functional Specifications of Production and Repair Command Platform for Distribution,” Distribution of State Grid Production and Technology Department, 2012, p. 82. [2] “About Promoting the Standardized Repair Work of Dis- tribution Network,” State Grid production and technology department, 2011, p. 156. [3] “Notice about Issuing the Program of Acceleration Dem- onstration Projects for Urban Distribution Grid,” State Grid Production and Technology Department, 2012, p. 148. Copyright © 2013 SciRes. EPE |