Energy and Power Engineering, 2013, 5, 1089-1092

doi:10.4236/epe.2013.54B207 Published Online July 2013 (http://www.scirp.org/journal/epe)

3D Finite Element Analysis of the Stray Loss in Power

Transformer Structure Parts*

Yan Li, Longnv Li, Yongteng Jing, Bo Zhang

Research Institute of Special Electrical Machines, Shenyang University of Technology, Shenyang, China

Email: lilongnv620@163.com

Received March, 2013

ABSTRACT

In order to analyze the leakage magnetic field and stray loss in power transformer, leakage magnetic field and stray loss

in structure parts of a power transformer are calculated by three-dimensional (3-D) non-linear time harmonic finite ele-

ment method (FEM). The results show th at stray loss and loss density in structure parts are large an d which may lead to

local overheating and affect performance of the transformer. The magnetic shields are used to reduce the stray loss and

loss density of power transformer. Effects of these shields on stray loss and loss density of structure parts are discussed.

The results show that stray loss and local overheating can be reduced and eliminated effectively by adding magnetic

shields. It provides some references for the analysis of stray loss and optimization design in transformer.

Keywords: Finite Element Method; Stray Loss; Leakage Magnetic Field; Local Overheating; Magnetic Sh ields

1. Introduction

Power transformer is the core of energy conversion and

transmission in power network, which is also the most

important and expensive equipment. So it will have an

essential impact of power network whether the trans-

former is safe, reliable and economic operation or not [1].

With the increase of capacity of the transformer, the

magnetic leakage field is increasing which may enlarge

the stray loss in the structure parts of power transformer.

In the large power transformer, leakage magnetic field

generated by the winding current will produce losses in

the metal structure parts, and these losses is part of the

transformer load losses, it often tend to local overheating

because of its unevenly distribution. So it is quite neces-

sary to study the magnetic leakage and stray loss deeply

and accurately [2,3].

In this paper, a practical power transformer model of

type SZ10-5000 0kVA/110k V was app lied to research the

stray loss problem in large power transformer by using

3-D nonlinear time harmonic analysis. Detailed calcula-

tion and analysis was proceeded in order to determine the

concentration of stray loss in transformer structure parts,

and magnetic shields were used to reduce stray loss and

prevent local overheating.

2. 3D Calculation Model and Calculation

Method

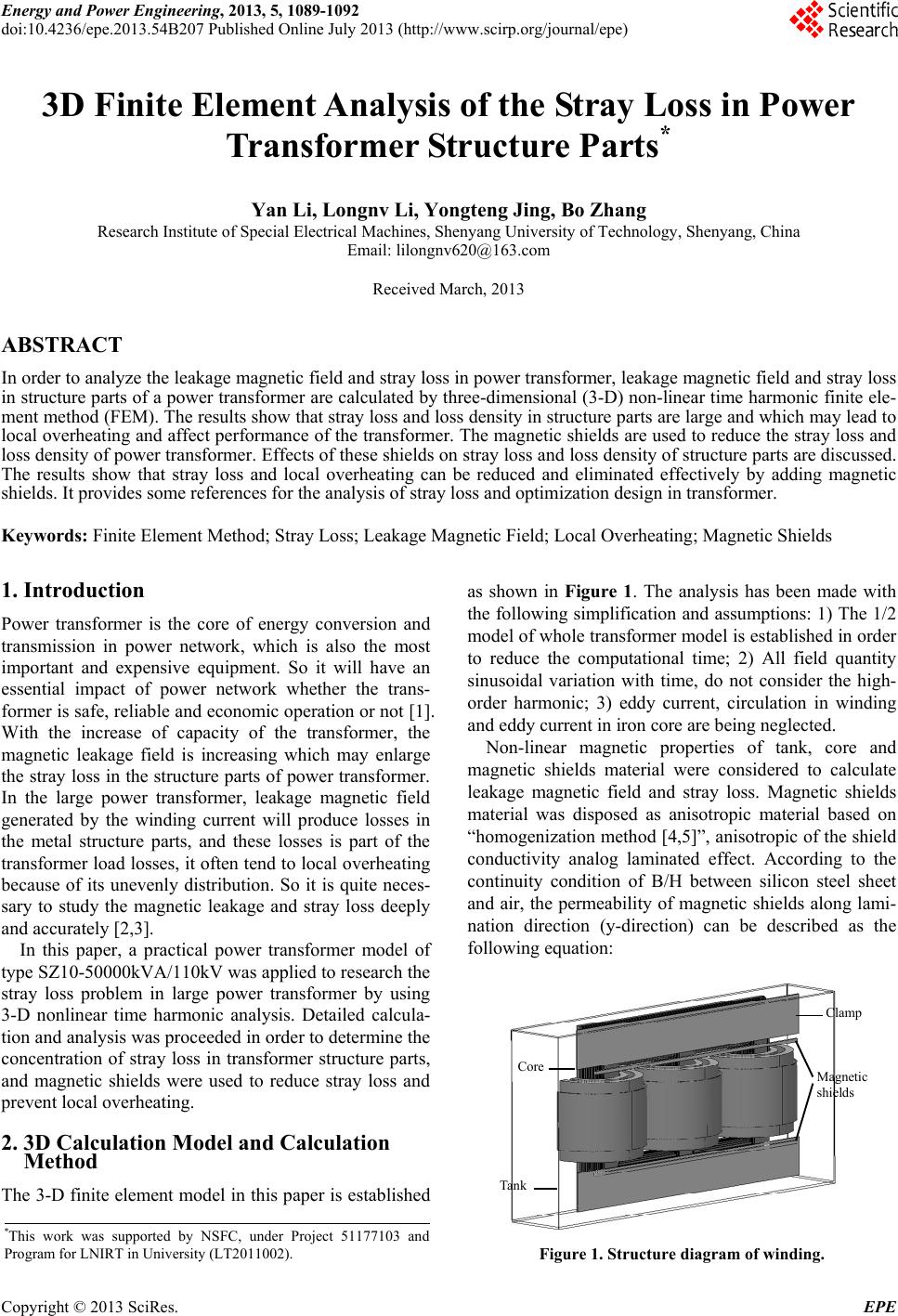

The 3-D finite element model in this paper is established

as shown in Figure 1. The analysis has been made with

the following simplification and assumptions: 1) The 1/2

model of whole transformer model is established in order

to reduce the computational time; 2) All field quantity

sinusoidal variation with time, do not consider the high-

order harmonic; 3) eddy current, circulation in winding

and eddy current in iron core are being neglected.

Non-linear magnetic properties of tank, core and

magnetic shields material were considered to calculate

leakage magnetic field and stray loss. Magnetic shields

material was disposed as anisotropic material based on

“homogenization method [4,5]”, anisotropic of the shield

conductivity analog laminated effect. According to the

continuity condition of B/H between silicon steel sheet

and air, the permeability of magnetic shields along lami-

nation direction (y-direction) can be described as the

following equation:

Core

Tank

Clamp

Magnetic

shields

*This work was supported by NSFC, under Project 51177103 and

Program for LNIRT in University (LT2011002). Figure 1. Structure diagram of winding.

Copyright © 2013 SciRes. EPE