S. V. GLADYSHEV ET AL.

Copyright © 2013 SciRes. MSCE

NaOH 20.0; Na2CO3 25.0; Na2SiO3 10.0. The treatment

was made for 10 ÷ 30 min at 70˚C ÷ 90˚C until complete

watering. The degreasing solution was washed out with

hot water. To exclude oxidizing of the electrode it was

put in 5% sol ution of hy drochl oric acid.

Metal electrodes were cover ed with gallium via multi-

ple submerging in liquid gallium with 20% hydrochloric

acid solution over it at 70˚C - 80˚C [13]. The duration of

gallium covering was 1 ÷ 2 min. Surplus of liquid gal-

lium was removed from the electrode surface with a filter

moistened with 5% hydrochloric acid solution.

Phase composition of solid-liquid interface was stud-

ied with X-ray diffractometer D8ADVANCE “Bruker”

using filtered Со-Кα radiation.

Stationary potential was recorded with PGSTAT12

potentiostate. All potential values were measured refer-

ring to standard hydrogen electrode. Concentration of

gallium in the solution was determined using chemical

methods.

To determine stability of the gallium cover electrodes

were put in the 100 ml Pyrex glass cell filled with alka-

line solution at 50˚C. Composition of the solution was

similar to that for commercial electrolytic cells, i.e.

Na2Ototal = 160 g/dm3. Each result was reproduced five

times.

3. Results and Discussion

Pretreatment of the electrode surface is very important to

get stable and uniform gallium cover.

Different inorganic acids, HCI, HNO3, H2SO4 and

H3PO4, with concentrations from 0.1% to 20%, were

used for the pretreatment but gallium covering is possible

only when hydrochl oric acid soluti o n wa s u s e d.

Leaching of metal electrodes (Steel 3) with HNO3,

H2SO4 and H3PO4, solutions cause vigorous hydrogen

bubble-formation on steel surface. The bubble-formation

is increased greatly when gallium is put in contact with

the surface.

Intensive gas formation on the surface of the electrode

excludes the possibility of damping the surface with gal-

lium. Besides, flow characteristics of gallium in solutions

of the acids are reduced.

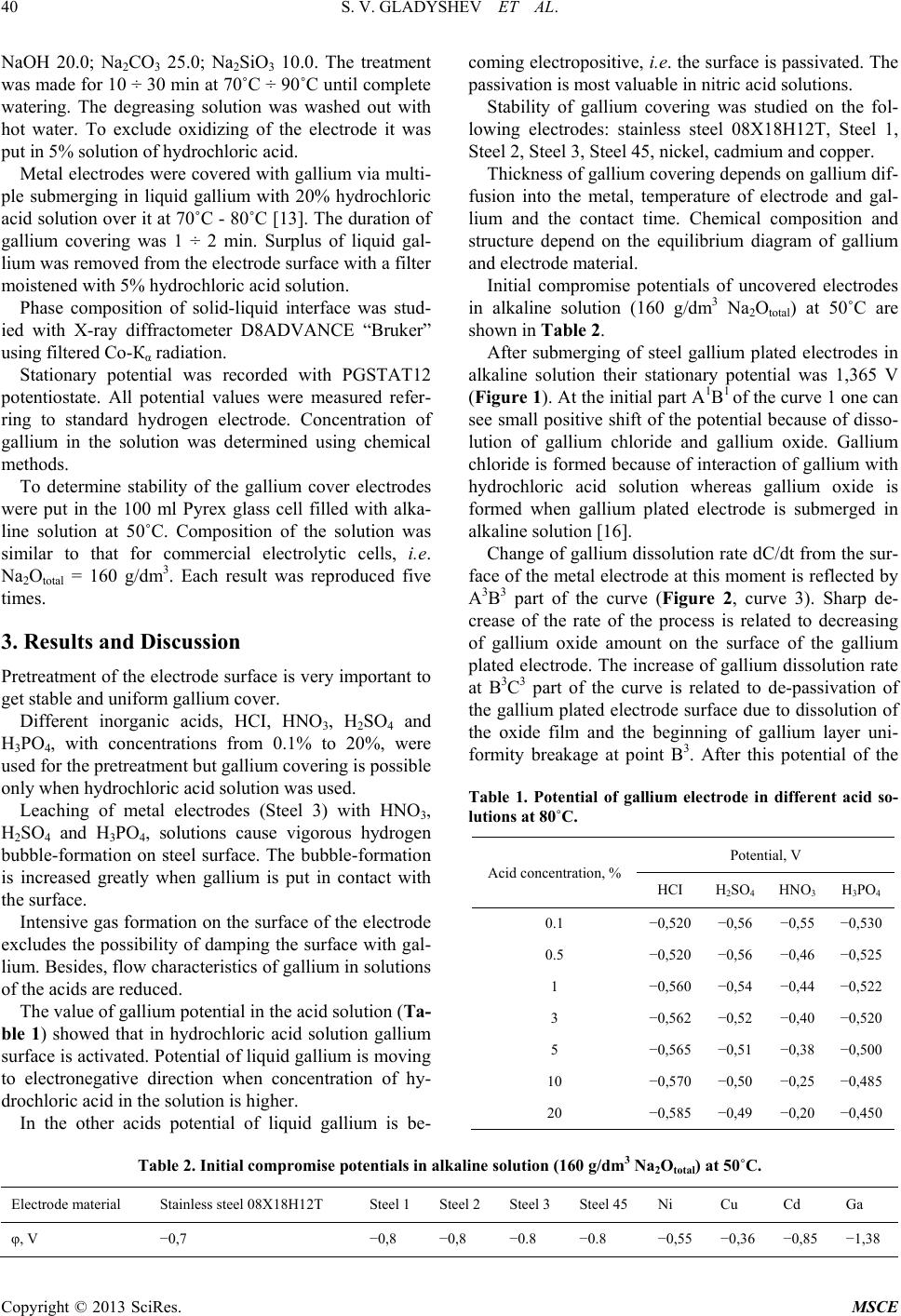

The value of gallium potential in the acid solution (Ta-

ble 1) showed that in hydrochloric acid solution gallium

surface is activated. Potential of liqu id gallium is moving

to electronegative direction when concentration of hy-

drochloric acid in the solution is higher.

In the other acids potential of liquid gallium is be-

coming electropositive, i.e . the surface is passivated. The

passivation is most valuable in nitric acid solutions.

Stability of gallium covering was studied on the fol-

lowing electrodes: stainless steel 08Х18Н12Т, Steel 1,

Steel 2, Steel 3, Steel 45, nickel, cadmium and copper.

Thickness of gallium covering depends on gallium dif-

fusion into the metal, temperature of electrode and gal-

lium and the contact time. Chemical composition and

structure depend on the equilibrium diagram of gallium

and electrode material.

Initial compromise potentials of uncovered electrodes

in alkaline solution (160 g/dm3 Na2Ototal) at 50˚C are

shown in Table 2.

After submerging of steel gallium plated electrodes in

alkaline solution their stationary potential was 1,365 V

(Figu re 1). At the initial part А1В1 of the curve 1 one can

see small positive shift of the potential because of disso-

lution of gallium chloride and gallium oxide. Gallium

chloride is formed because of interaction of gallium with

hydrochloric acid solution whereas gallium oxide is

formed when gallium plated electrode is submerged in

alkaline solution [16].

Change of gallium diss olution rate dC/dt from the sur-

face of the metal electrode at this moment is reflected by

А3В3 part of the curve (Figure 2, curve 3). Sharp de-

crease of the rate of the process is related to decreasing

of gallium oxide amount on the surface of the gallium

plated electrode. The increase of gallium dissolution rate

at В3С3 part of the curve is related to de-passivation of

the gallium plated electrode surface due to disso lution of

the oxide film and the beginning of gallium layer uni-

formity breakage at point В3. After this potential of the

Table 1. Potential of gallium electrode in different acid so-

lutions at 80˚C.

Acid concentration, % Potential, V

HCI H2SO4 HNO3 H3PO4

0.1 −0,520 −0,56 −0,55 −0,530

0.5 −0,520 −0,56 −0,46 −0,525

1 −0,560 −0,54 −0,44 −0,522

3 −0,562 −0,52 −0,40 −0,520

5 −0,565 −0,51 −0,38 −0,500

10 −0,570 −0,50 −0,25 −0,485

20 −0,585 −0,49 −0,20 −0,450

Table 2. Initial compromise potentials in alkaline solution (160 g/dm3 Na2Ototal) at 50˚C.

Electrode material Stainless steel 08Х18Н12Т Steel 1 Steel 2 Steel 3 Steel 45 Ni Cu Cd Ga

φ, V −0,7 −0,8 −0,8 −0.8 −0.8 −0,55 −0,36 −0,85 −1,38