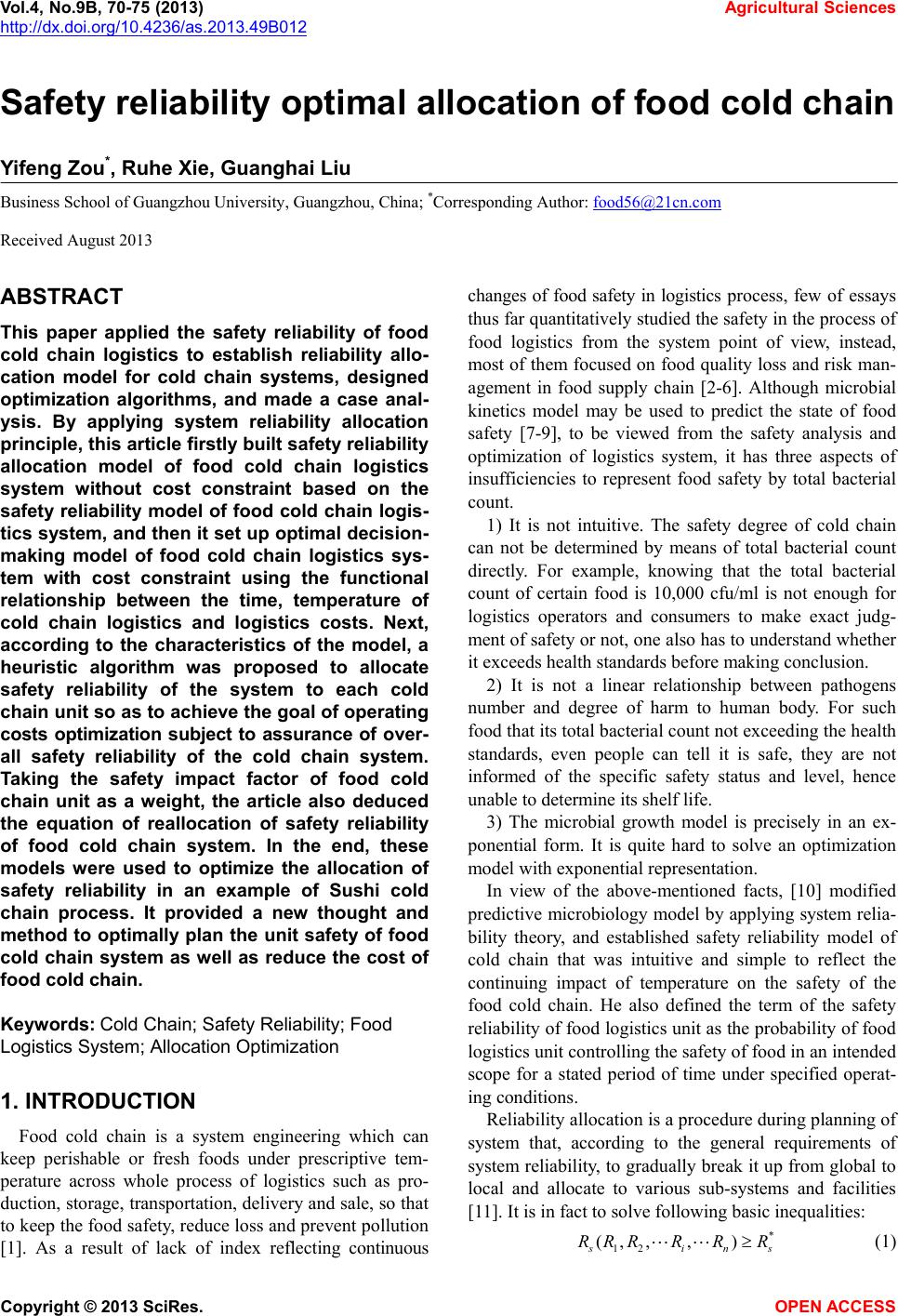

Vol.4, No.9B, 70-75 (2013) Agricultu ral Sciences http://dx.doi.org/10.4236/as.2013.49B012 Copyright © 2013 SciRes. OPEN A CCESS Safety reliability optimal allocation of food cold chain Yifeng Zou*, Ruhe Xie, Guanghai Liu Business School of Guangzhou University, Guangzhou, China; *Corresponding Author: food56@21cn.com Received August 2013 ABSTRACT This paper applied the safety reliability of food cold chain logistics to establish reliability allo- cation model for cold chain systems, designed optimization algorithms, and made a case anal- ysis. By applying system reliability allocation principle, this article firstly built saf ety reliabilit y allocation model of food cold chain logistics system without cost constraint based on the safety reliability model of food cold chain logis- tics system, and then it set up optimal decision- making model of food cold chain logistics sys- tem with cost constraint using the functional relationship between the time, temperature of cold chain logistics and logistics costs. Next, according to the characteristics of the model, a heuristic algorithm was proposed to allocate safety reliability of the system to each cold chain unit so as to achieve the goal of operating costs optimization subject to assurance of o ver- all safety reliability of the cold chain system. Taking the safety impact factor of food cold chain unit as a weight, the article also deduced the equation of reallocation of safety reliability of food cold chain system. In the end, these models were used to optimize the allocation of safety reliability in an example of Sushi cold chain process. It provided a new thought and method to optimally plan the unit safety of food cold chain system as well as reduce the cost of food cold chain. Keywords: Cold Ch ain; Safety Reliabilit y; Food Logistics System; Allocation Optimi zat ion 1. INTRODUCTION Food cold chain is a system engineering which can keep perishable or fresh foods under prescriptive tem- perature across whole process of logistics such as pro- duction, storage, transportation, deliver y and sale, so that to keep the food safety, reduce loss and prevent pollution [1]. As a result of lack of index reflecting continuous changes of food safety in logistics process, few of essays thus far quantitatively studied the safety in the process of food logistics from the system point of view, instead, most of them focused on food quality loss and risk man- agement in food supply chain [2-6]. Although microbial kinetics model may be used to predict the state of food safety [7-9], to be viewed from the safety analysis and optimization of logistics system, it has three aspects of insufficiencies to represent food safety by total bacterial count. 1) It is not intuitive. The safety degree of cold chain can not be determined by means of total bacterial count directly. For example, knowing that the total bacterial count of certain food is 10,000 cfu/ml is not enough for logistics operators and consumers to make exact judg- ment of safety or not, one also has to understand whether it exceeds health standards before making conclusion. 2) It is not a linear relationship between pathogens number and degree of harm to human body. For such food that its total bacterial co unt not ex ceed ing the health standards, even people can tell it is safe, they are not informed of the specific safety status and level, hence unable to determine its shelf life. 3) The microbial growth model is precisely in an ex- ponential form. It is quite hard to solve an optimization model with exponential representation. In view of the above-mentioned facts, [10] modified predictive microbiology model by applying system relia- bility theory, and established safety reliability model of cold chain that was intuitive and simple to reflect the continuing impact of temperature on the safety of the food cold chain. He also defined the term of the safety reliability of food logistics unit as the probability of food logistics unit controlling the safety of food in an intended scope for a stated period of time under specified operat- ing conditions. Reliability allocation is a procedure during planning of system that, according to the general requirements of system reliability, to gradually break it up from global to local and allocate to various sub-systems and facilities [11]. It is in fact to solve following basic inequalities: (1)  Y. F. Zou et al. / Agricultur al Sciences 4 (2013) 70-75 Copyright © 2013 SciRes. O PEN A CCESS (2) where: is system reliability output constraint, is synthesis constraint conditions to system planning, including expenses, weights, power loss, etc. For a cascade system, Eq.1 may be converted to * 12 () ()()()() i ns Rt RtRtRtRt⋅ ⋅⋅⋅≥ . (3) To achieve safety and high efficiency of food cold chain system, it shall take into account of two aspects of restraints when allocate safety reliability: First, the safety constraint, i.e. under the condition of given initial safety reliability, it must comply with the stipulated require- ments after food passes through the cold chain system; Second, the cost re straint. Food cold chain system is also an economic system that seeks for minimum logistics cost while satisfying safety demands. Therefore, safety reliability allocation of cold logistics system is how to allocate the total safety reliability to each unit so as to minimize total logistics cost. Yet there is no related re- search at present. This article applies the safety reliability of food cold chain logistics to establish reliability alloca- tion model for cold chain logistics systems, design opti- mization algorithms, and make a case analysis and dis- cussion. 2. ALLOCATION OF SAFETY RELIABI-LITY WITHOUT COST CONSTRAINT For a cold chain logistics system composed of m cold chain units, according to [10], its safety reliability Ri af- ter food continuously passes through the ith (i ≤ m)unit can be expressed as ( ) 2 01 01 i ijj i j RR dTtR = =− ∆≤≤ ∑ , (4) where: R0 is initial safety reliability of food cold chain system, (Tj is the temperature of cold chain unit j, Tmin is the temperature at which no growth of microbial), tj is logistics time of cold chain unit j, d is a parameter related to food variety). As , Ri is non-increasing function which means in food cold chain system, safety reliability grad- ually decreases from initial point to destination . Normal- ly lower temperature has higher demand for equipment conditions. Yet it is impossible for facilities to reach inf i- nite low temperature, there have to be certain low limits (for instance, some refrigerated trucks’ lowest tempera- ture can only reach down to 0˚C), which we indicate by . Moreover, it usually has re st ric ti ons on t he processing time of logistics unit. For example, the quickest for- warding time under existing conditions of food transpor- tation and distribution; the shortest time for producing and handling. Here let represent the time-limiting requirement. We now have safety reliability optimization allocation model of cold chain system as follows: (5) s.t. (6) (7) (8) Obviously when and , the lower limits of both the temperature and time of each cold chain unit are ap- plied to the above equations, is the smallest and the objective function reaches its maximum. Mean- time, the cold chain system has highest safety reliability. 3. ALLOCATION OF SAFETY RELIABILITY WITH COST CONSTRAINT 3.1. Model Establishing Suppose a cold chain system composed of m cold chain units, after food passed unit j(j=1, 2,… m), its lo- gistics cost is Cj, logistics service volume provided is Vj and safety reliability is Rj, then the function of cost of th e unit is . (9) Logistics service provided by food cold chain unit has typical scale effect (e.g. the higher inventory level in cold store, the lower unit operation cost is; the bigger delivery amount of refrigerated truck, the lower unit dis- tribution cost), that is to say, logistics cost and logistics service volume has the relation of and 2 2 0 j j C V ∂< ∂ . Given that cold chain system is a cascade system whose processing capacity is determined by the unit of least processing capacity, when system processing capac- ity is fixed, it can be represented by the processing time of the logistics system, i.e. for food logistics of certain quantity, processing time shortens as processing capacity increases. Therefore under the condition of fixed process- ing capacity of the system, the processing volume of food cold chain system is proportional to its processing time, while the above equation can be written as and 2 2 0 j j C t ∂< ∂ (10) To maintain low temperature in the process of food cold chain, it needs special refrigerate equipment and consumes energy. Moreover, along with the cold chain  Y. F. Zou et al. / Agricultur al Sciences 4 (2013) 70-75 Copyright © 2013 SciRes. OPEN A CCESS unit temperature drops, much more energy is consumed and equipment of higher technical conditions is required. Consequently, logistics cost increases quickly [12]. The- reupon, cold chain logistics cost and temperature has following relationship: and (11) At present food cold chain usually extends to selling section only. For the sake of consumption safety, it is necessary to reserve certain safety reliability at selling unit. Suppose the requisite final safety reliability of lo- gistics system is no less than RE, then we obtain from Eq.6 that . (12) In summary, for food cold chain system having con- straints of processing capability and safety reliability, its cost optimal decision-making model is as below: 11 Min(,)(, ) mm j jjjjj jj CCVRC Tt = = == ∆ ∑∑ (13) s.t. and 2 20 j j C t ∂< ∂ and . 3.2. Heuristic Algorit hm Considering that every cold chain unit has different cost function, plus the expression is complicated, it is rather difficult to solve the model directly. However, we can derive a quite straightforward heuristic algorithm from the special relationship of cold chain cost with temperature and time. Note from Eq.4 that the decrease of safety reliability is proportional to logistics time whereas it has a square relation with temperature in logistics unit. Hence it is more effective to regulate the temperature in logistics unit rather than logistic time for acquiring specific safety reliability. And the smaller temperature difference be- tween the various aspects of cold chains, it is more fa- vorable for food quality maintenance [13,14]. That is to say, under the premise of system’s overall safety reliabil- ity being no less than end-point safety reliability RE, starting from the logistics unit of lowest temperature, advance its temperature to the same value of the unit of most adjacent temperature; If there are a number of lo- gistics units of the same temperature, then give priority to the unit with longest logistics time; Thus keep adjust- ing until system’s overall safety reliability reaches the requirement RE. Following is the algorithm. Step 1: Arrange in ascending order to obtain a set S(s1, s2,……sm). Step 2: Let , (j=1, 2,… m). Step 3: If , then no solution and stop; Otherwise go to step 4. Step 4: Tak e the smallest element si from the remaind- er of set S, its corresponding logistics unit j, if there are more than one element of the lowest value, then take the one with greatest . Let , and temperatures of the rest units remain invariable. If , the optimal solution de- clared. If , then gradually narrow down till it satisfies , and we obtain the optimal solution. Step5: If , then remove si from the set S, rearrange set S per non-descending order of and return to Step 4. 4. REALLOCATION OF SAFETY RELIABILITY As aforementioned, there is no solution to the optimi- zation model if . Such situa- tion indicates that the existing food cold chain system can not meet the minimum safety reliability requirements and further modification of o rig inal planning is necessary to enhance its safety reliability, i.e. need to reallocate safety reliability to each logistics unit. The principle of reliability reallocation is that the unit of lower reliability is easier to improve, otherwise, more difficult. This is actually to reallocate reliability accord- ing to the weight of unit in the system. In food cold chain system, the cold chain unit of bigger has lower safety reliability whereas the one with smaller has bigger safety reliability. Therefore, reallocation of safety reliabilit y of food cold chain syste m can be carried on in accordance w ith of cold chain unit. Define of food cold chain unit j as its safety impact factor .  Y. F. Zou et al. / Agricultur al Sciences 4 (2013) 70-75 Copyright © 2013 SciRes. O PEN A CCESS (14) Assume food cold chain system has m units, then wj, the weight of unit j in the system is: (15) Safety reliability of system before optimization is: (16) Let ( >m R) the optimized safety reliability of cold chain system, the safety impact factor of each cold chain unit. Apply to Eq.4 to obtain . (17) Thus, according to the principle of reliability realloca- tion, the equation of optimized safety reliability of each cold chain unit can be written as follows: (18) 5. CASE ANALYSIS As made by hand, Sushi is apt to be infected by Sta- phylococcus aureus to cause food safety problem. Table 1 shows the data of temperature and time restrictions in the process of Sushi cold chain. Suppose the initial safety reliability is 1.0, expected safety reliability is 0.8 so as to ensure edibility after consumer purchased sushi for a period of time; moreover, d is 0.0003 and no-microbial- growth temperature is 5˚C [9]. According to Eq.4, we apply the lower limits of both the temperature and time of each cold chain unit to the equation, and obtain the end-point safety reliability 0.851 (refer to Table 1 for solving details) which is higher than the expectation of 0.8. From a cost perspective, the logis- tics system still needs to be optimized under the premise of ensuring safety. In the light of solution method, first is to optimize the unit of the lowest temperature. It is selling unit (11˚C) in this system. Use previous heuristic algorithm to advance the temperature of selling unit to the most adjacent value 13˚C of delivering unit, and solve again to acquire safety reliability of the system, which is by then still higher than the expectation of 0.8. Thus after several loops of solving steps, the algorithm finds optimal solution to the temperature and time of each cold chain unit (as shown in Table 2), i.e. under the premise of full assurance of food safety, it can save logistics cost as far as possible by an appropriate increase in the temperature of delivering unit and selling unit (2˚C and 2.5˚C respectively). If the end-point safety reliability requirement is raised to 0.9, when choosing the lower limits of both the tem- perature and time of each cold chain unit, the end-point safety reliability is 0.851 (see Table 1) which is lower than the expectation, the system cannot satisfy the re- quirement and must reallocate the safety reliability. The results of safety weight of each cold chain unit wj are shown in Table 3, wherein the delivering unit has the highest degree of weight that reaches 0.353, and then followed by the selling unit, 0.221, the loading unit is the least, only 0.044 . After reallocation, the system output of safety reliabi l- ity is 0.901 that satisfies the safety reliability requirement of no less than 0.9. By comparing and we can find that the safety reliability of delivering unit, the one with highest degree of weight needs to be improved Table 1. Data of Cold chain Units before Optimization. No. j Cold Chain Unit Temperature Tj (˚C) Time t j (h) d 1 Producing 15.0 0.8 80.0 80.0 0.024 0.976 2 Packing 17.0 0.5 72.0 152.0 0.046 0.954 3 Loading 22.0 0.1 28.9 180.9 0.054 0.946 4 Delivering 13.0 2.3 147.2 328.1 0.098 0.902 5 Unloading 21.0 0.2 51.2 379.3 0.114 0.886 6 Handling 20.0 0.2 45.0 424.3 0.127 0.873 7 Selling 11 .0 2.0 72.0 496.3 0.149 0.851 Table 2. Data of cold chain units after optimization. No. j Cold Chain Unit Temperature Tj (˚C) Time t j (h) 1 Producing 15.0 0.8 80.0 80.0 0.024 0.976 2 Packing 17.0 0.5 72.0 152.0 0.046 0.954 3 Loading 22.0 0.1 28.9 180.9 0.054 0.946 4 Delivering 15.0 2.3 230.0 410.9 0.123 0.877 5 Unloading 21.0 0.2 51.2 462.1 0.138 0.862 6 Handling 20.0 0.2 45.0 507.1 0.152 0.848 7 Selling 13.5 2.0 144.5 651.6 0.196 0.804  Y. F. Zou et al. / Agricultur al Sciences 4 (2013) 70-75 Copyright © 2013 SciRes. OPEN A CCESS the most by 0.048; while handling unit of the least weight needs to be improved the least by only 0.005. 6. CONCLUSION AND DISCUSSION Safety reliability provides a new quantitative method for the analysis and optimization of food cold chain sys- tem. For food cold chain system, once knowing ambient temperatures and logistics time, it is convenient to cal- culate the safety reliability of any cold chain unit and cold chain system, which effectively solves the problem of lack of quantitative tools in the study of cold chain system. However as a new indicator, the validity and scope of application is naturally an issue of concern. We re-calculated the shelf life in some liter ature according to the safety reliability model and then compared with the original data. The results indicated that the deviation fell in acceptable range (see Table 4). That proves that safety reliability model can be applied to reliability optimally allocate of food cold chain system under certain condi- tions. Certainly any model has its applicable conditions. Safety reliability model of food cold chain is built on the basis of kinetics model of microbial growth whose ap- plicable conditions also apply to safety reliability model. To be specific, there are following three aspects: 1) Sealed package. The sealed package is mainly to avoid secondary or multiple infections by microorgan- isms in food logistics process; it also prevents the physi- cal and chemical hazards. Without seal ed pack agin g, safety reliability model is unable to calculate and assess the final result because of uncertainty of the infected micro- be species and their initial values, plus possible conti- nuous new pathogenic invasion in logistics process. 2) Protein-rich food. Protein-r ich food (milk, meat and poultry, etc.) is suitable for microbial growth and micro- be hazard is the most important factor affecting its logis- tics safety, which can be expressed by safety reliability model. Yet for low-protein-content food such as fruits and vegetables, microbe hazards are not the main safety factors; moreover, if not to be eaten as it is (e.g. fruits, vegetables, etc.), instead, cleaned and even cooked for consumption, then the propagation of pathogenic bacteria may not cause actual harm to the human body. Thus the model has better effect for the safety assessment of fresh milk, chilled meat, frozen food and cooked food, etc. 3) Minimum logistics ambient temperature. When food logistics ambient temperature is below the minimum microbial growth temperature, the number of microbes will not increase, food safety remains unchanged. Mean- while in safety reliability model, indi- cates that safety reliability is reduced. Therefore safety reliability is only suitable for the situation when logistics ambient temperature is higher than the minimum micro- bial growth temperature. For the case of logistics am- bient temperature being lower than the minimum micro- bial growth temperature, as the microbes in a dormant state, pathogenic bacteria number in the logistics process will not increase, consequently at this moment there is no need to consider the safety changes in logistics proc ess. 7. ACKNOWLEDGEMENTS We thanks the National Nature Science Fund of China because our research was supp orted by NSFC “Safety Reliability of Fresh Agricul- tural Products Cold Chain Logistics and Its Dynamic Optimization” Table 3. Safety Reliability of Each Cold Chain Unit after Relocation. No. j Cold Chain Unit 1 Producing 80.0 0.123 59.9 0.982 2 Packing 72.0 0.110 54.0 0.965 3 Loading 28.9 0.044 21.7 0.959 4 Delivering 230.0 0.353 172.4 0.938 5 Unloading 51.2 0.078 38.5 0.926 6 Handling 45.0 0.069 33.7 0.916 7 Selling 144.5 0.221 36.1 0.901 Table 4. Comparison of shelf life results predicted by safety reliability model and original data in literature. Food Type T (˚C) Shelf Life (h) Reference Model Calculation (h) Deviation Sushi 17.4 4.7 [9] 4.26 9.3% Sushi 21.8 3.1 [9] 3.49 12.6% Chicken 8.0 168 [15] 187 11.3% Pork 4.0 11 6 [16] 124 6.9% Pork 10.0 60 [16] 55 9.2%  Y. F. Zou et al. / Agricultur al Sciences 4 (2013) 70-75 Copyright © 2013 SciRes. O PEN A CCESS (NO.71172077) and “The study on control mechanism and key para- meters optimization of perishable food multi-temperature refrigerated transport” (NO. 51008087). REFERENCES [1] Liu, B.L. (2004) Food preservation and cold chain. Chemical Industry Publishers of China, 163. [2] Adrie J. (2005) Food safety and transparency in food chains and networks. Food Control, 16, 481-486. http://dx.doi.org/10.1016/j.foodcont.2003.10.010 [3] Fearne, A., Hornibrook, S. and Dedman, S. (2001) The management of perceived risk in the food supply chain: a comparative study of retailer-led beef quality assurance schemes in Germany and Italy. The International Food and Agribusiness Management Review, 4, 19-36. http://dx.doi.org/10.1016/S1096-7508(01)00068-4 [4] Van der Gaag, M.A., Vos, F., Saatkamp, H.W., Van Boven, M., Van Beek, P. and Huirne, R.B.M. (2004) A state- transition simulation model for the spread of Salmonella in the pork supply chain. European Journal of Opera- tional Resear ch, 156, 782-798. http://dx.doi.org/10.1016/S0377-2217(03)00141-3 [5] Aruoma, O.I. (2006) The impact of food regulation on the food supply Chain. Toxicology, 221, 119-127. http://dx.doi.org/10.1016/j.tox.2005.12.024 [6] Tijskens, L.M.M. and Polderdijk, J.J. (1996) A generic model for keeping quality of vegetable produce during storage and distribution. Agricultural Systems, 51, 431- 452. http://dx.doi.org/10.1016/0308-521X(95)00058-D [7] Zwietering, M.H., De Wit, J.C. and Notermans, S. (1996) Application of predictive microbiology to estimate the number of bacillus cereus in pasteurized milk at the point of consumption. International Journal of Food Microbi- ology, 30, 55-70. [8] Zwietering, M.H. (2002) Quantification of microbial quality and safety in minimally processed foods. Interna- tional Dairy Journal, 12, 263-271. [9] Rho, M.-J. and Schaffner, D.W. (2007) Microbial risk assessment of staphylococcal food poisoning in Korean kimbab. Int ernational Journal of Food Microbiology, 116, 332-338. http://dx.doi.org/10.1016/j.ijfoodmicro.2007.02.006 [10] Zou, Y.F., Xie, R.H. and Lin C.P. (2010) Study on safety reliability of foods cold chain logistics. Proceedings of the 3rd International Conference on Logistics and Supply Chain Management, 2010, 425-443. [11] Zeng S.K., Zhao T.D., Zhang, J.G., Kang, R. and Shi, J.Y. (2001) Design and analysis textbook of system reliability. Beijing Aerospace University Publishers, Beijing, China, 52-66. [12] Liu, G.H. (2007) Study on analysis of energy consump- tion and optimization of refrigerated transportation equip- ment. Doctoral dissertation of Central South University, Changsha, China. [13] Chen, L., Shen, J. and Zou, T.H. (2002) The frequency analysis on the temperature fluctuation of the cold store. Journal of Refrigeration, 4, 13-17. [14] Flores, S., Cleland, A.C. and Cleland, D.J. (2001) Predic- tion of the dynamic thermal behavior of walls for refrige- rated rooms using lumped and distributed parameter models. International Journal of Refrigeration, 24, 272- 284. http://dx.doi.org/10.1016/S0140-7007(00)00018-9 [15] Betts, G. and Everis, L. (1996) Shelf-life determination and challenge. CCFRA Guideline No. 11, CCFRA, Chip- ping, Campden, UK, 1996. [16] Li, M.Y. (2006) Study on the analysis of microbial ecol- ogy in chilled pork and shelf life predictive mode. Dis- sertation of Nanjing Agricultural University, Nanjing, China, 91-104.

|