A. M. YENENEH ET AL.

10

loidon

3.3. Effect of Pretreatment on Biogas

Th e ma4 21.85 and pre-

ve-ultrasonic pretreatment improve

al charge may have also contributed to the reducti

in dewaterability. Ultrasonication is known to have ef-

fects of changing the surface charge.

Composition and CH4/CO2 Ratio

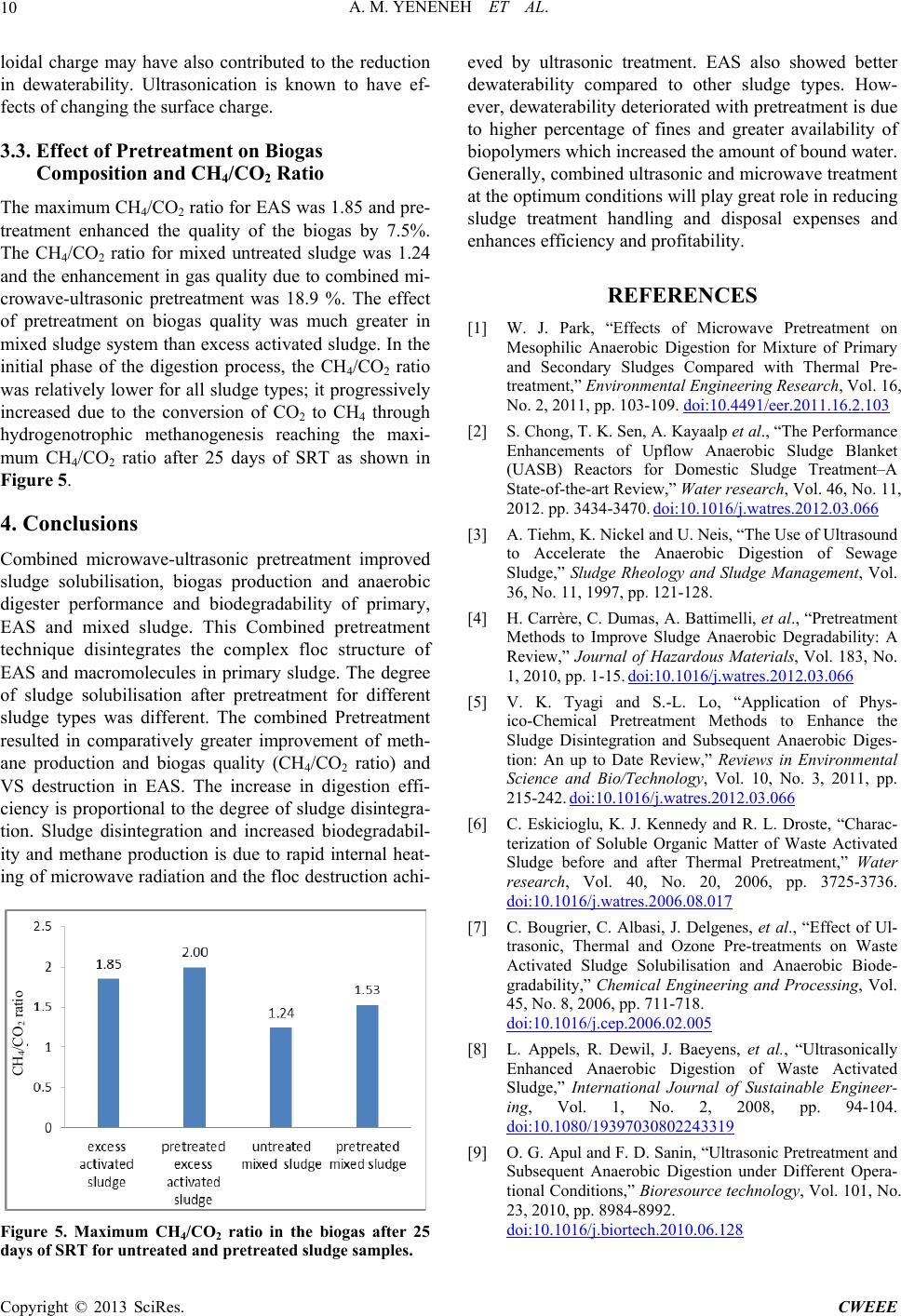

xi mum C H/CO ratio for EAS was

treatment enhanced the quality of the biogas by 7.5%.

The CH4/CO2 ratio for mixed untreated sludge was 1.24

and the enhancement in gas quality due to combined mi-

crowave-ultrasonic pretreatment was 18.9 %. The effect

of pretreatment on biogas quality was much greater in

mixed sludge system than excess activated sludge. In the

initial phase of the digestion process, the CH4/CO2 ratio

was relatively lower for all sludge types; it progressively

increased due to the conversion of CO2 to CH4 through

hydrogenotrophic methanogenesis reaching the maxi-

mum CH4/CO2 ratio after 25 days of SRT as shown in

Figure 5.

4. Conclusions

Combined microwad

sludge solubilisation, biogas production and anaerobic

digester performance and biodegradability of primary,

EAS and mixed sludge. This Combined pretreatment

technique disintegrates the complex floc structure of

EAS and macromolecules in primary sludge. The degree

of sludge solubilisation after pretreatment for different

sludge types was different. The combined Pretreatment

resulted in comparatively greater improvement of meth-

ane production and biogas quality (CH4/CO2 ratio) and

VS destruction in EAS. The increase in digestion effi-

ciency is proportional to the degree of sludge disintegra-

tion. Sludge disintegration and increased biodegradabil-

ity and methane production is due to rapid internal heat-

ing of microwave radiation and the floc destruction achi-

CH

4

/CO

2

ratio

eved by ultrasonic treatment. EAS also showed better

dewaterability compared to other sludge types. How-

ever, dewaterability deteriorated with pretreatment is due

to higher percentage of fines and greater availability of

biopolymers which increased the amount of bound water.

Generally, combined ultrasonic and microwave treatment

at the optimum cond itions will play great role in reducing

sludge treatment handling and disposal expenses and

enhances efficiency and profitability.

REFERENCES

Figure 5. Maximum CH4/CO2 ratio in the biogas after 25

days of SRT for untreated and pretr e ated sludge samples.

[1] W. J. Park, Pretreatment on

Mesophilic Aixture of Primary

“Effects of Microwave

naerobic Digestion for M

and Secondary Sludges Compared with Thermal Pre-

treatment,” Environmental Engineering Research, Vol. 16,

No. 2, 2011, pp. 103-109. doi:10.4491/eer.2011.16.2.103

[2] S. Chong, T. K. Sen, A. Kayaalp et al., “The Performance

Enhancements of Upflow Anaerobic Sludge Blanket

(UASB) Reactors for Domestic Sludge Treatment–A

State-of-the-art Review,” Water research, Vol. 46, No. 11,

2012. pp. 3434-3470. doi:10.1016/j.watres.2012.03.066

[3] A. Tiehm, K. Nickel and U. Neis, “The Use of Ultrasound

to Accelerate the Anaerobic Digestion of Sewage

aerobic Degradability: A

Sludge,” Sludge Rheology and Sludge Management, Vol.

36, No. 11, 1997, pp. 121-128.

[4] H. Carrère, C. Dumas, A. Battimelli, et al., “Pretreatment

Methods to Improve Sludge An

Review,” Journal of Hazardous Materials, Vol. 183, No.

1, 2010, pp. 1-15. doi:10.1016/j.watres.2012.03.066

[5] V. K. Tyagi and S.-L. Lo, “Application of Phys-

ico-Chemical Pretreatment Methods to Enhance the

Sludge Disintegration and Subsequent Anaerobic Diges-

tion: An up to Date Review,” Reviews in Environmental

Science and Bio/Technology, Vol. 10, No. 3, 2011, pp.

215-242. doi:10.1016/j.watres.2012.03.066

[6] C. Eskicioglu, K. J. Kennedy and R. L. Droste, “Charac-

terization of Soluble Organic Matter of Waste Activated

Sludge before and after Thermal Pretreatment,” Water

research, Vol. 40, No. 20, 2006, pp. 3725-3736.

doi:10.1016/j.watres.2006.08.017

[7] C. Bougrier, C. Albasi, J. Delgenes, et al., “Effect of Ul-

trasonic, Thermal and Ozone Pre-treatments on Waste

Activated Sludge Solubilisation and Anaerobic Biode-

gradability,” Chemical Engineering and Processing, Vol.

45, No. 8, 2006, pp. 711-718.

doi:10.1016/j.cep.2006.02.005

[8] L. Appels, R. Dewil, J. Baeye

Enhanced Anaerobic Digestio

ns, et al., “Ultrasonically

n of Waste Activated

Sludge,” International Journal of Sustainable Engineer-

ing, Vol. 1, No. 2, 2008, pp. 94-104.

doi:10.1080/19397030802243319

[9] O. G. Apul and F. D. Sanin, “Ultrasonic Pretreatment and

Subsequent Anaerobic Digestion under Different Opera-

tional Conditions,” Bioresource technology, Vol. 101, No.

23, 2010, pp. 8984-8992.

doi:10.1016/j.biortech.2010.06.128

Copyright © 2013 SciRes. CWEEE